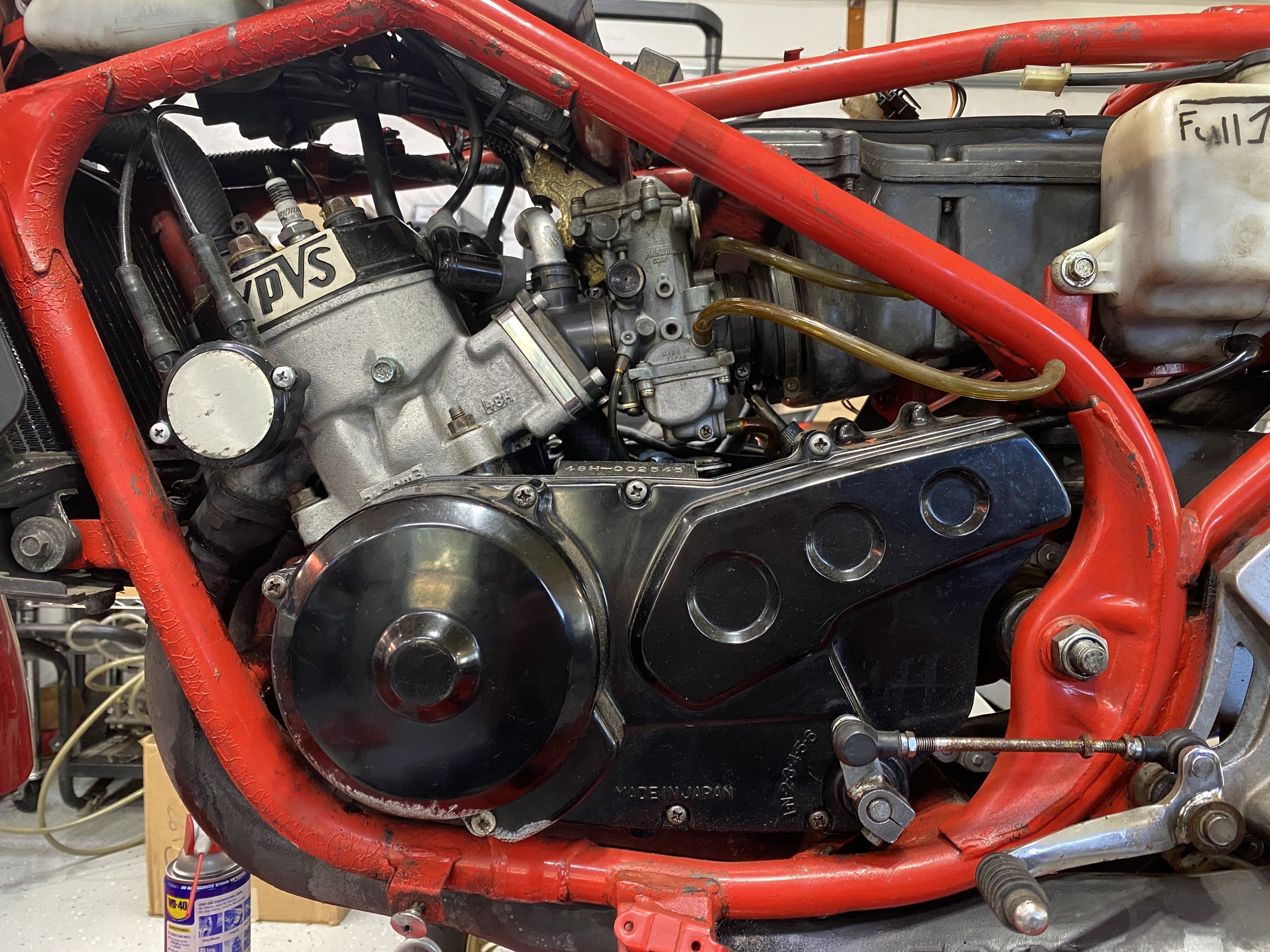

1984 Yamaha RZ350L YPVS (48H)

Reckless impulse, and my 61st birthday, made me buy this red & white model on E-bay in August 2021 out of frustration of never finding a yellow & black version at a decent price. The bike was in Connecticut, a state which I happened to be passing through in October with a semi truck. The Previous Owner, whom we will call Bruce (for that is his name), kindly kept the bike until then and even drove an hour to Westport to meet us with it and we threw it on the truck in between soundcheck and the show.

Original E-Bay ad: “1984 Yamaha RZ350 2 Stroke Motorcycle. Running & Currently Registered, fires right up whenever I get a chance to use it. Sounds & shifts as it should. - The motorcycle has 23,000 miles on it - I bought this bike a few years ago planning on doing a cosmetic restoration. I'm no mechanic but the bike does not need anything major. - The past owner had recently gone through the motor and it runs strong, has Factory Pipe Products aftermarket exhaust (Expansion Chambers) and is re-jetted for the exhaust system. - The past owner also put on the current gas tank (dented a shown in pictures) because the original tank had rusted/leaked as so many RZ gas tanks did. - I have some spare parts that I have collect that will go with the bike including a set of rear turn signals (current right rear is taped). - Comes with a Yamaha Service Manual- Feel free to contact me if you have any questions regarding the condition or shipping/pick up. - I can help with local delivery or the buyer is responsible for shipping- Bike is sold with a current registration and a bill of sale (Connecticut does not title motorcycles that are 37 years old) The motorcycle is a matching numbers bike. I have added pictures of the motor numbers and frame numbers.”

Some original Pictures from the ad below…..Also: the sharp eyes and ears of Rare Sports Bikes for Sale picked up on it (and two others!) and wrote about them here….

RZ. Race Zeveloped?

No question- the pipes look good.

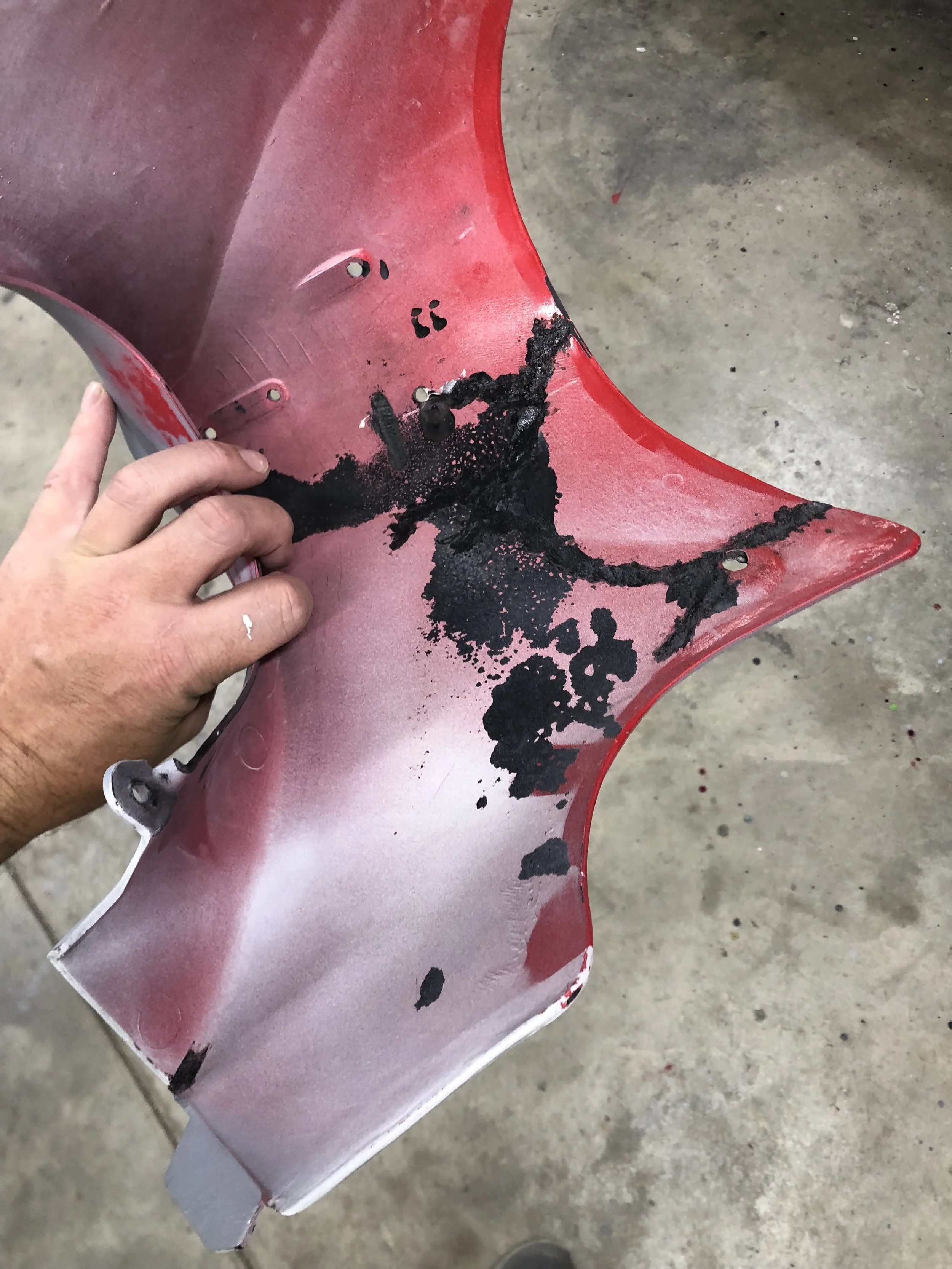

I am not entirely sure what would cause this kind of damage.....

.....first thoughts are the 'bars...but both sides in the same wreck?

Well, the fix is holding for the moment....I don't relish the the thought of installing a new cover...however it is an excuse for buying a a new tool. I read somewhere that a Dewalt electric staple gun loaded with 6mm (1/4 inch) staples are just the ticket...

Heh....well...maybe for the first 1/4 mile....

Bike tied down in our truck/production office in New Jersey. When the headline act takes up all the available rooms backstage- we set up office in our trailer.

It's not too bad when 1) the truck is parked in the dock and 2) its not the usual 100º weather.....

Cozy

I'll see you in Nashville buddy.

Bike makes it home to Nashville…

Riding it back from our storage depot to the workshop was a handful. The bike seemed to have a mind of it’s own when it came to going the direction I wanted it to. You never want your bike to have a second opinion when it comes to needing a swift change of trajectory in traffic. I put it down to overtight or dry steering bearings. A tapered set has already been ordered from All Balls. The Factory Pipes sound good and appear to work in sync with the carbs. Could it be that I’ve bought a 2-stroke bike that’s been meticulously jetted to run perfectly with aftermarket pipes?

That’ll be a first.

I know I shoulda shot it landscape. Next time.

Brief History : Bruce had the same plans I have- restore it and ride it- but after real life intervened he realized it wasn’t going to happen. He put it on e-bay and I fell for it. It’s a little annoying that 8 years ago you could get a great finished restoration for what I paid for it…but life’s getting too short and I need grab what I want now. (I also spent too much on my RZ500, and it hurt for a few days, but everytime I get on it….I only think about the fast approaching powerband…never the bank account. I think that will happen with this bike.) The other thing to know is that during his brief ownership Bruce literally did nothing to the bike, so I will not be holding him responsible for any of the misdemeanors that will no doubt be discovered…:)

2nd generation of the nose fairing is the best.

Non factory petcock. "Make sure it's switched off or it will leak fuel" advice from Bruce suggests the carbs need a rebuild or at the very least have the float height checked.

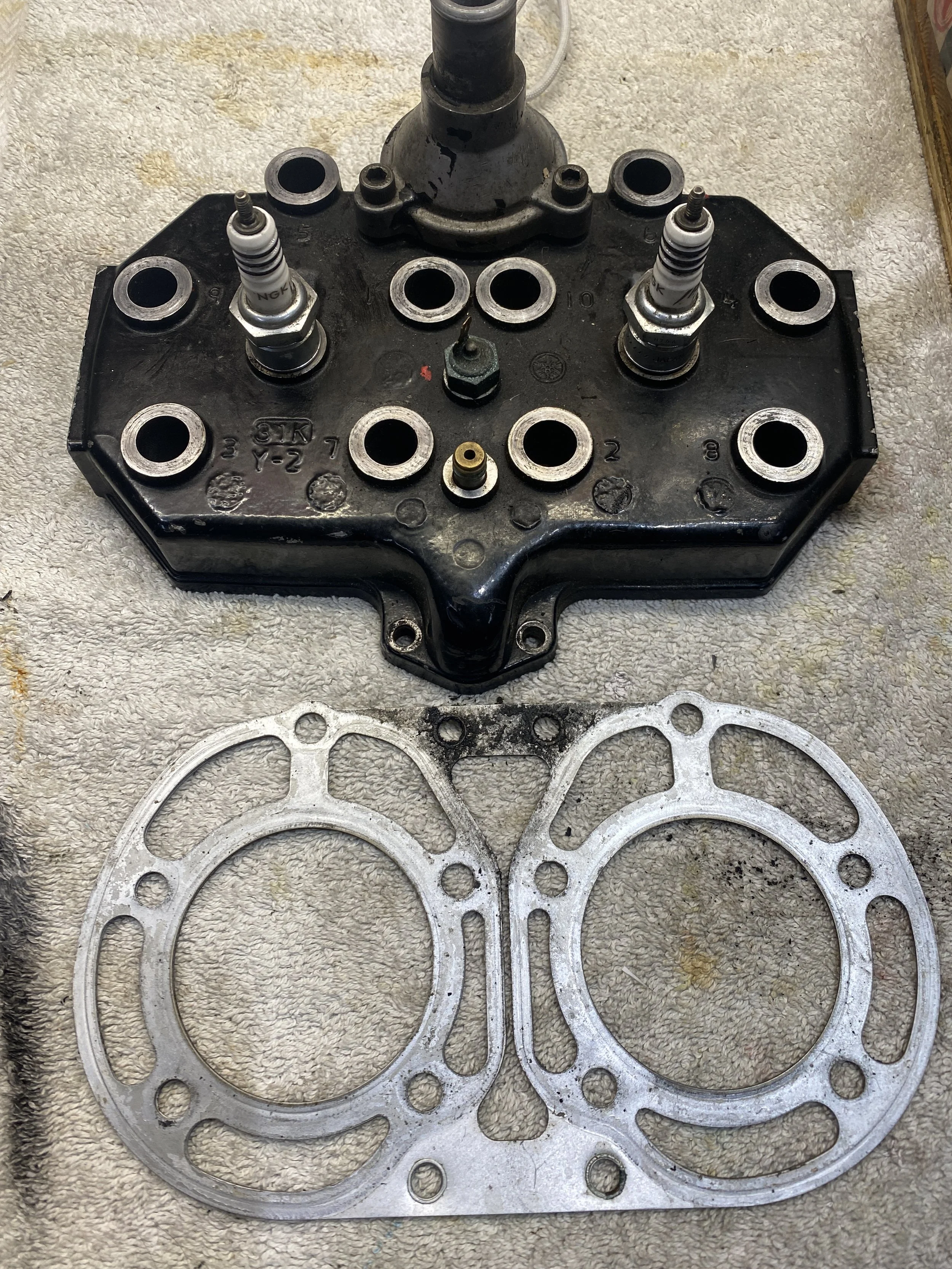

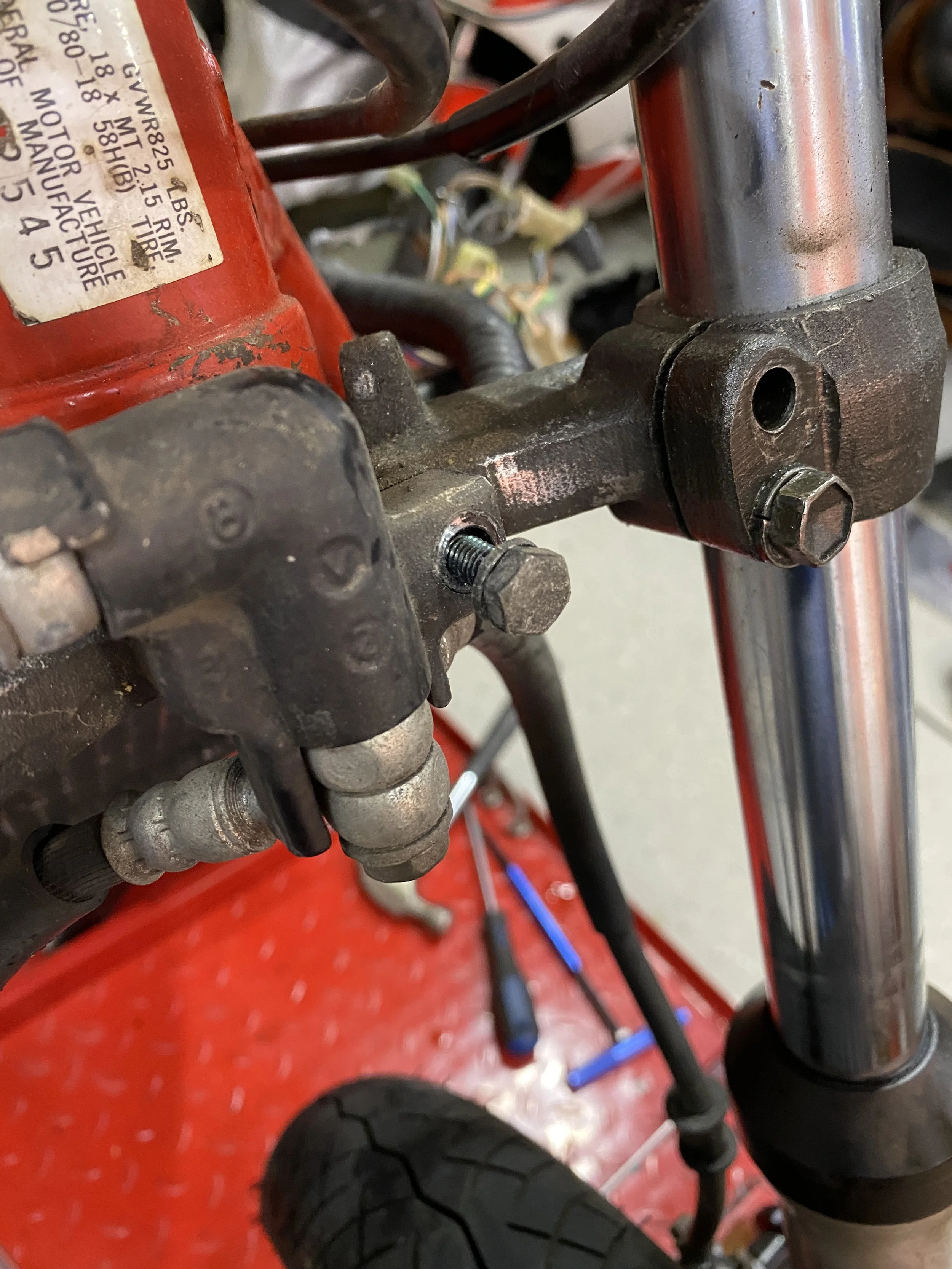

Evidence that this bike was once equipped with a leaking fuel tank. The escaping liquid left it's mark on the frame and headbolts.

Informed RZ heads (In particular Blake Loehr from Houston,TX) say that the main reason barrels are left bare ( at least by engine builders) is that the engines run cooler due to the paint retaining heat. On some bikes you can see 20 to 30 degree temp changes.

Busted mounting. This side panel was held on by a zip-tie.

Very interesting handlebar risers.

Battle scars and mismatched paint. Signs of living on the edge...finding it....and then getting back on the horse before the paint dries. The 80's.

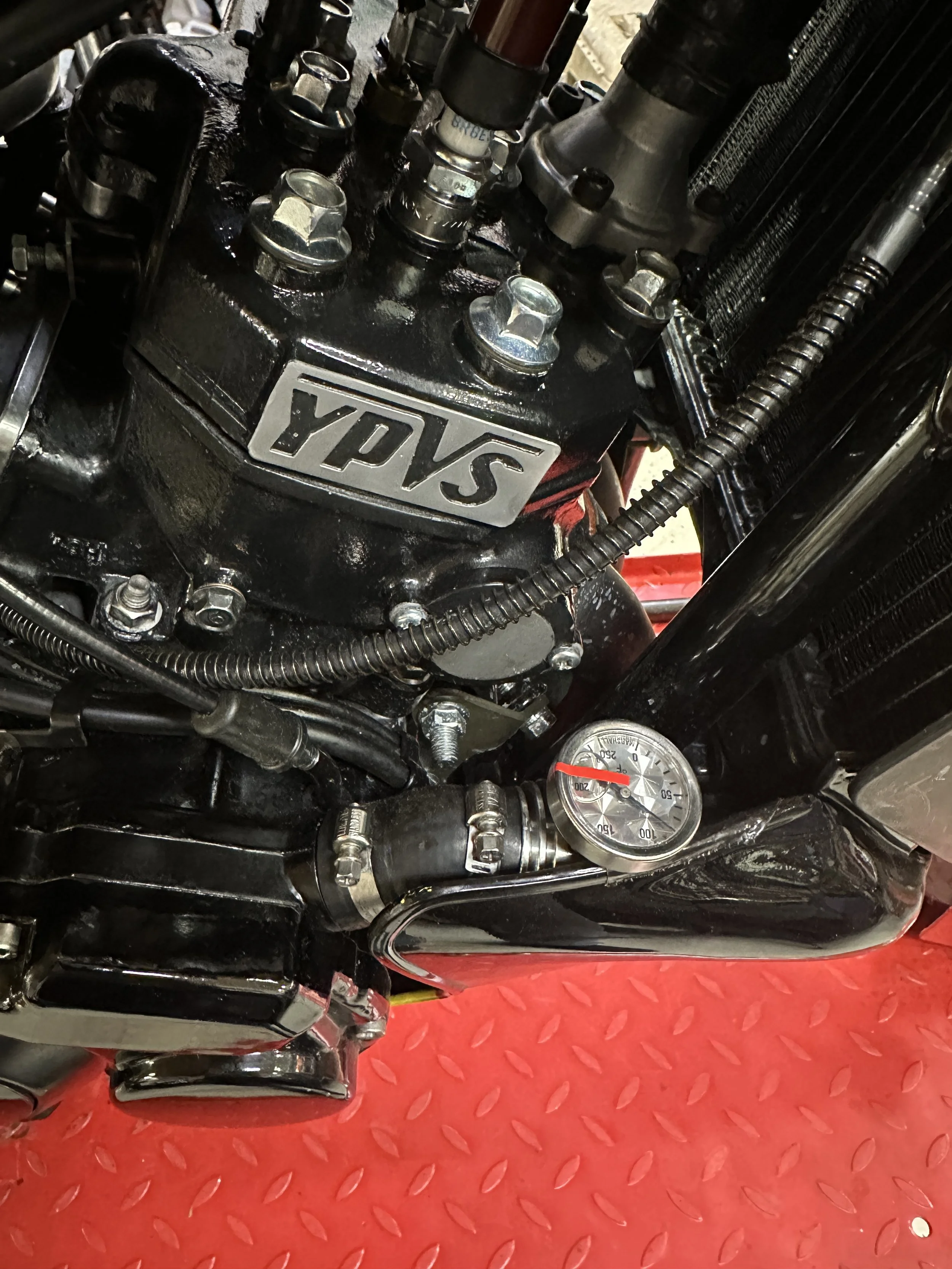

Analog oil tank gauge.

Original pegs came with the bike, but one is rusted and twisted....so there are these. They actually feel really good!

Didn't see this great white sized bite out of the bellypan this before....

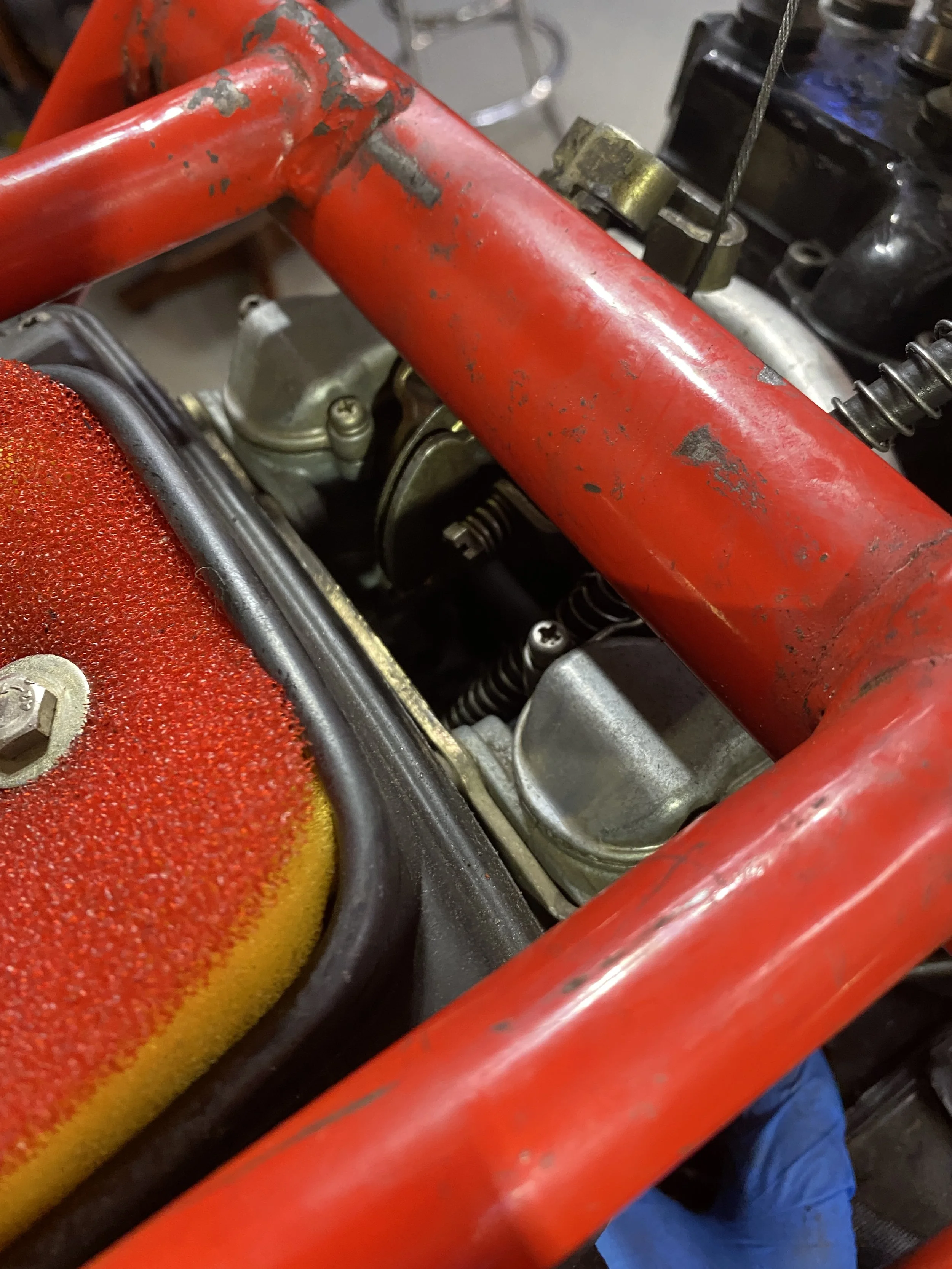

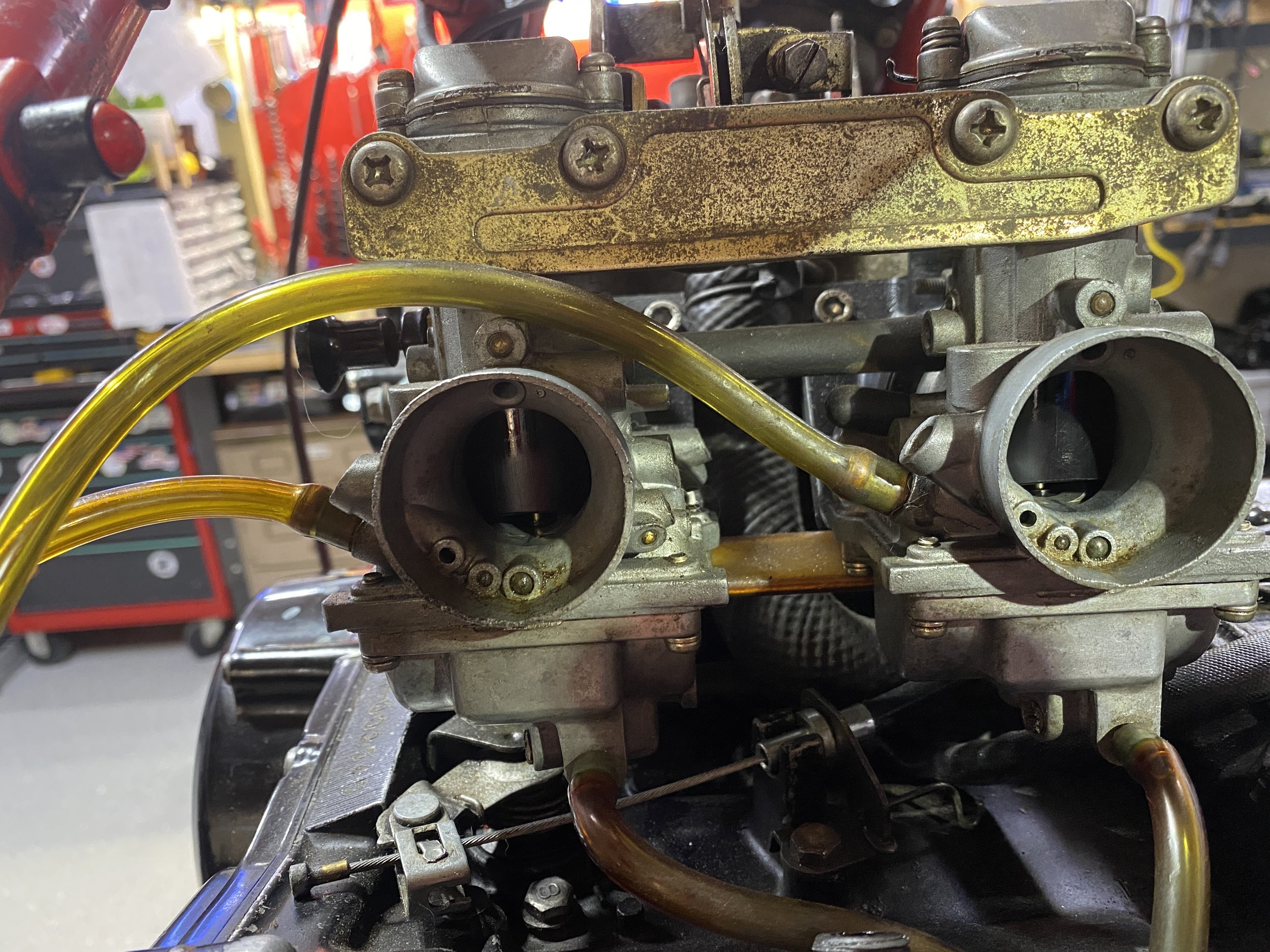

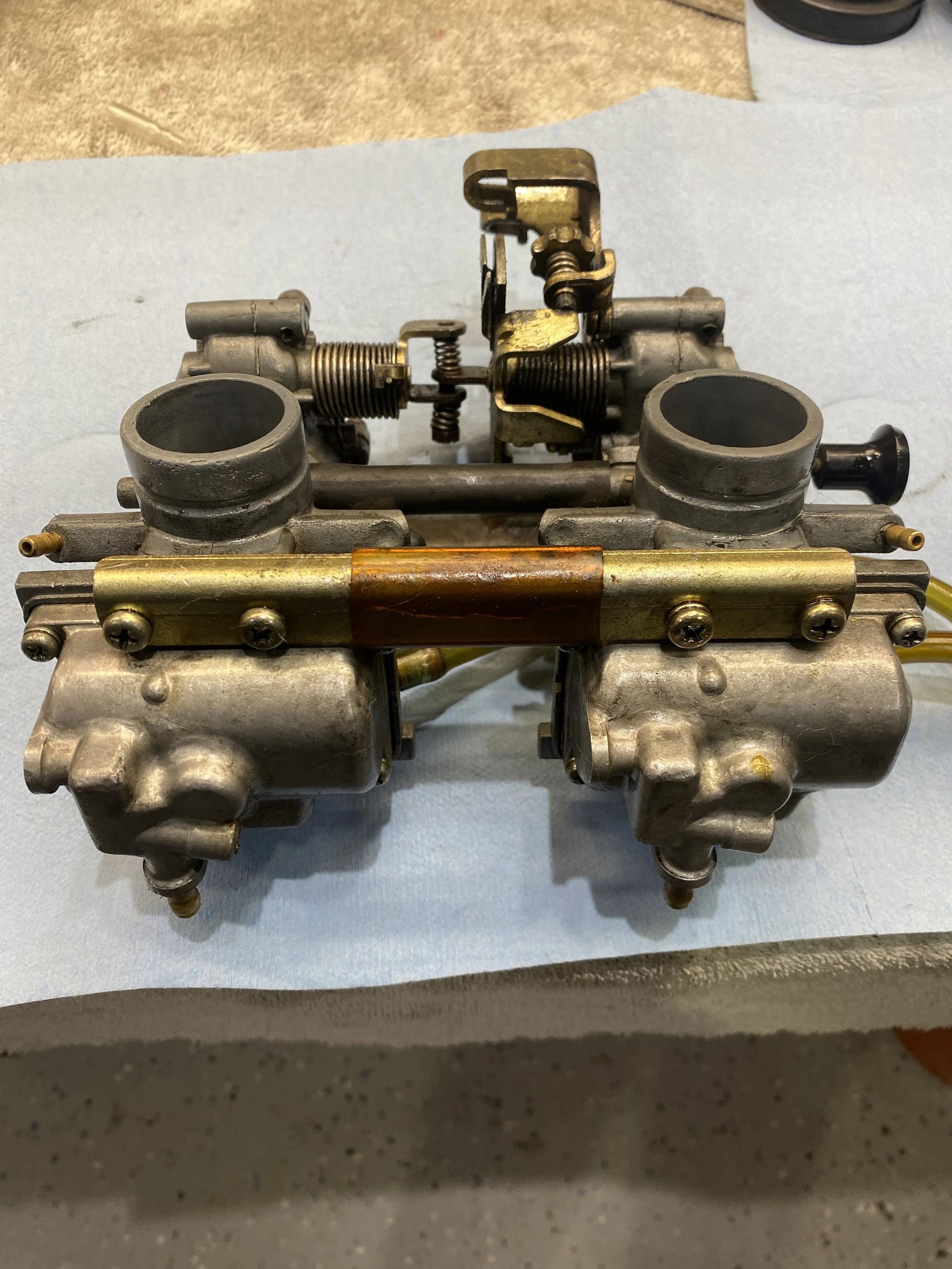

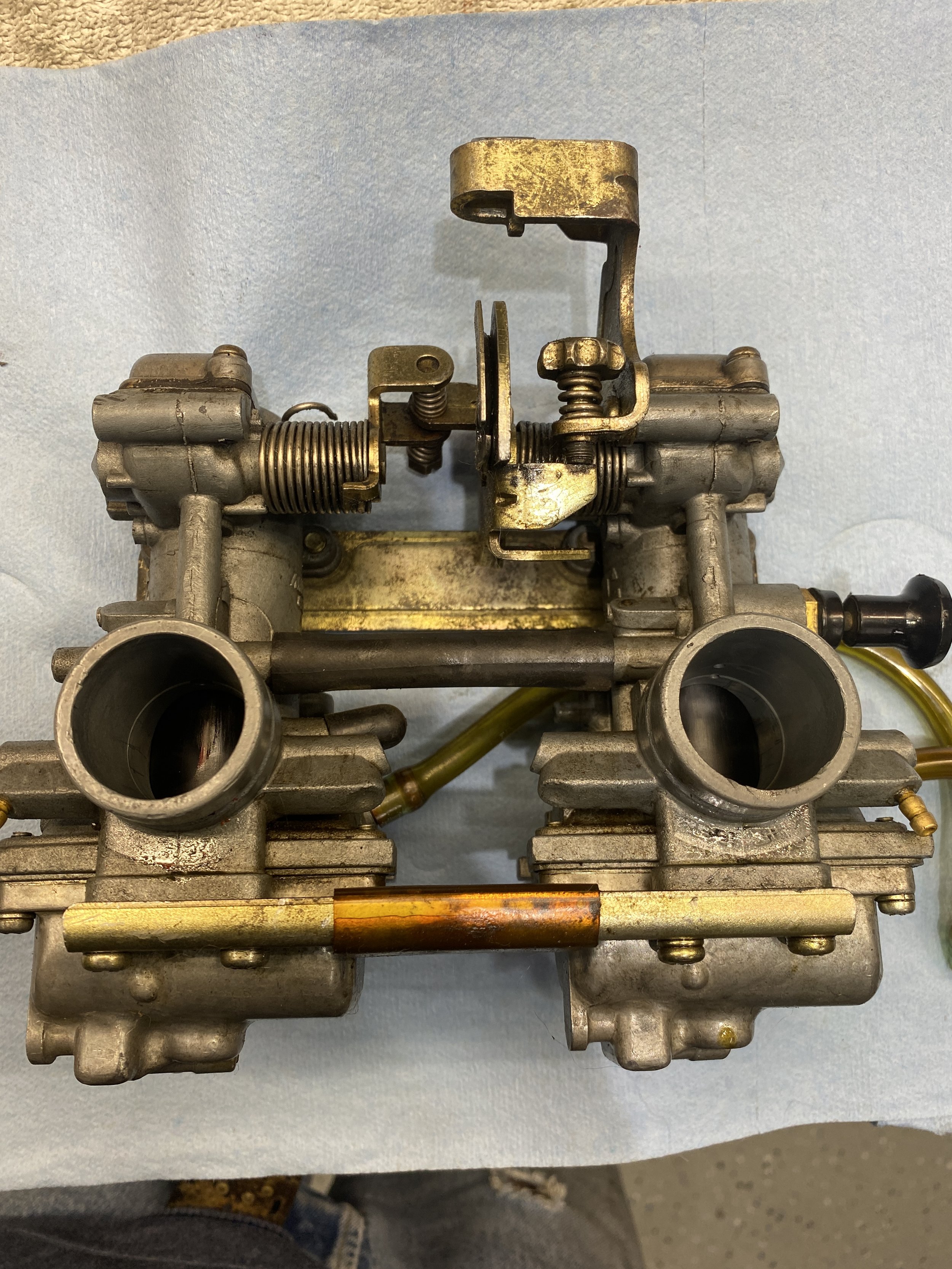

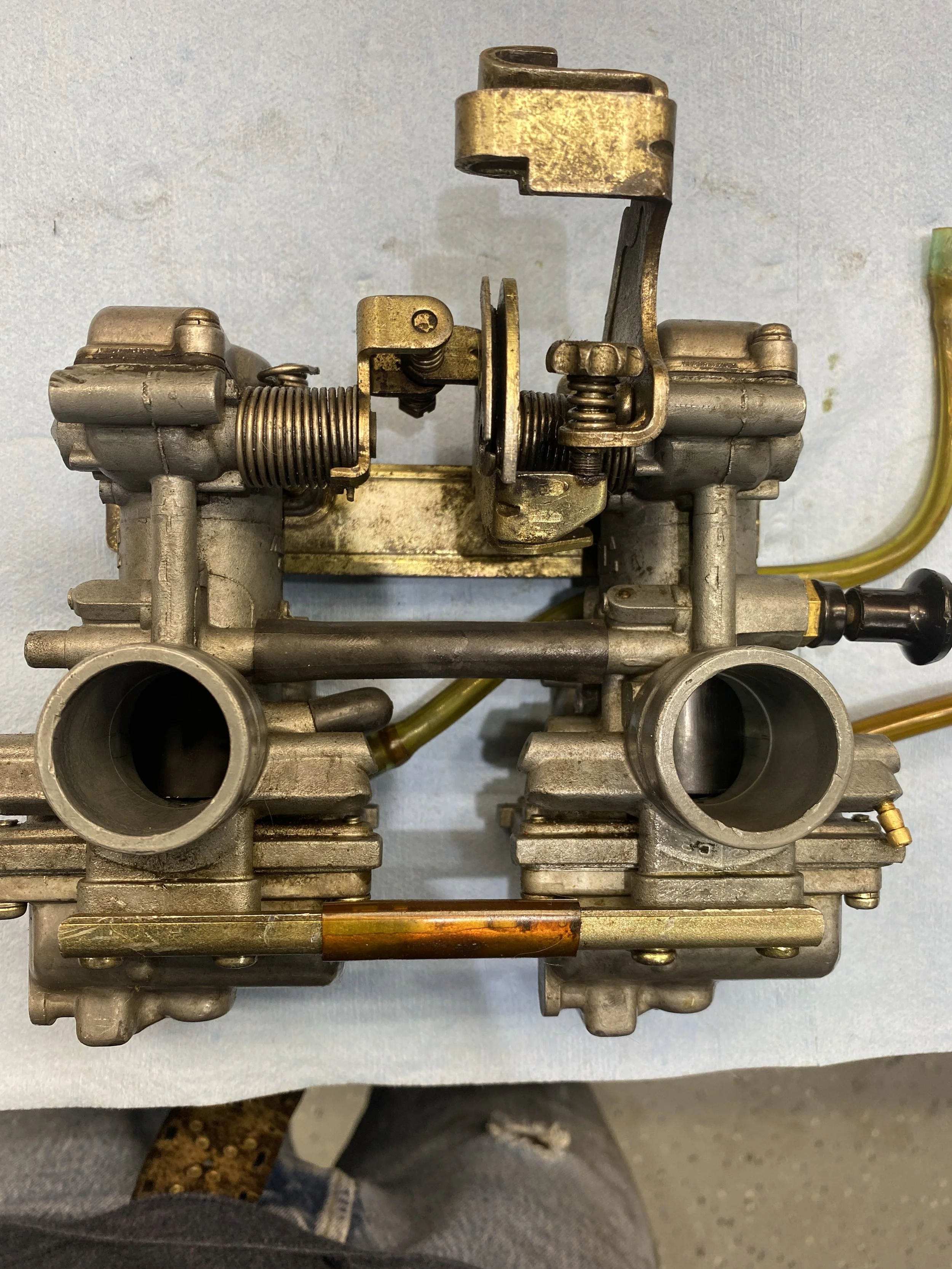

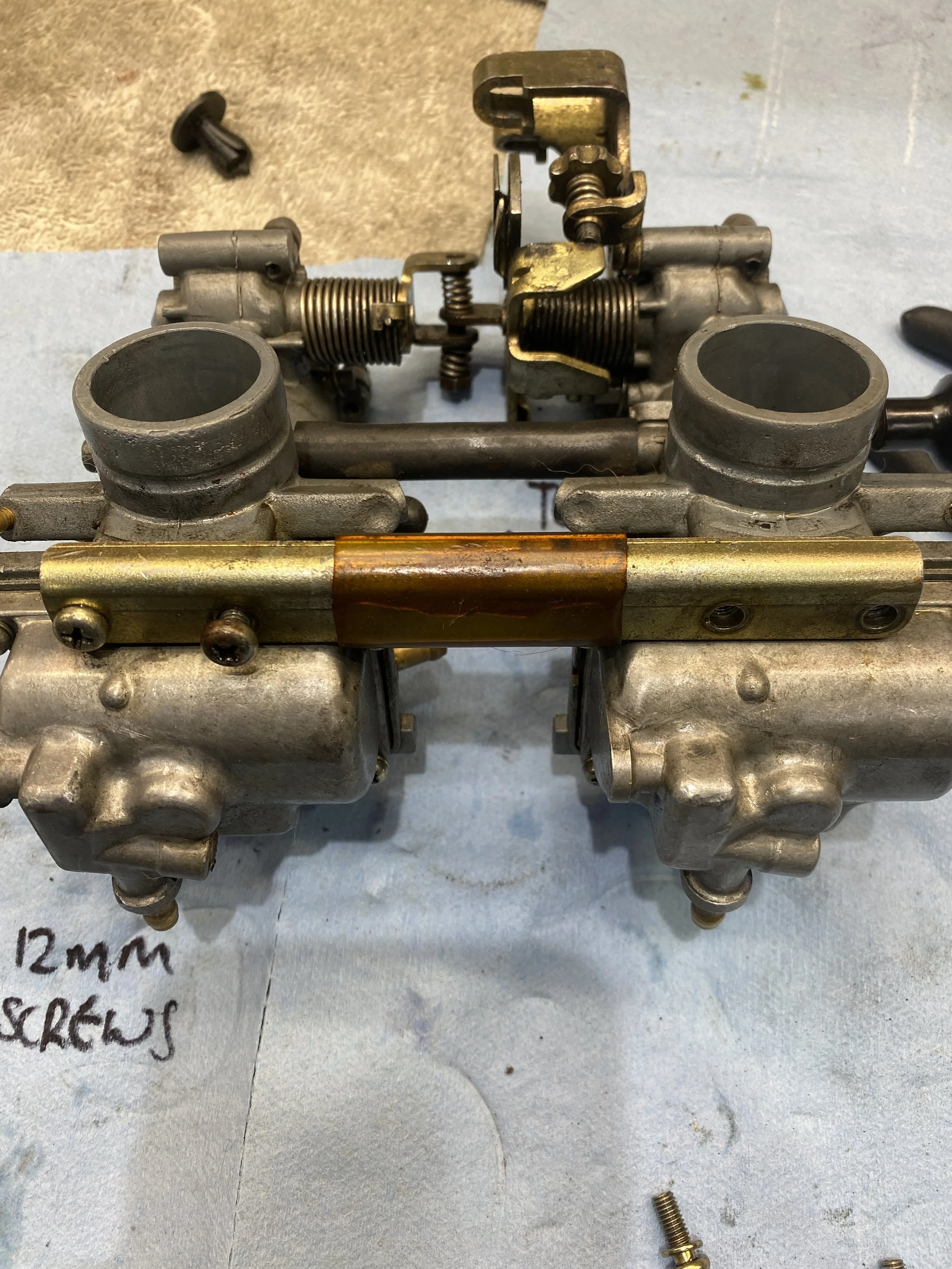

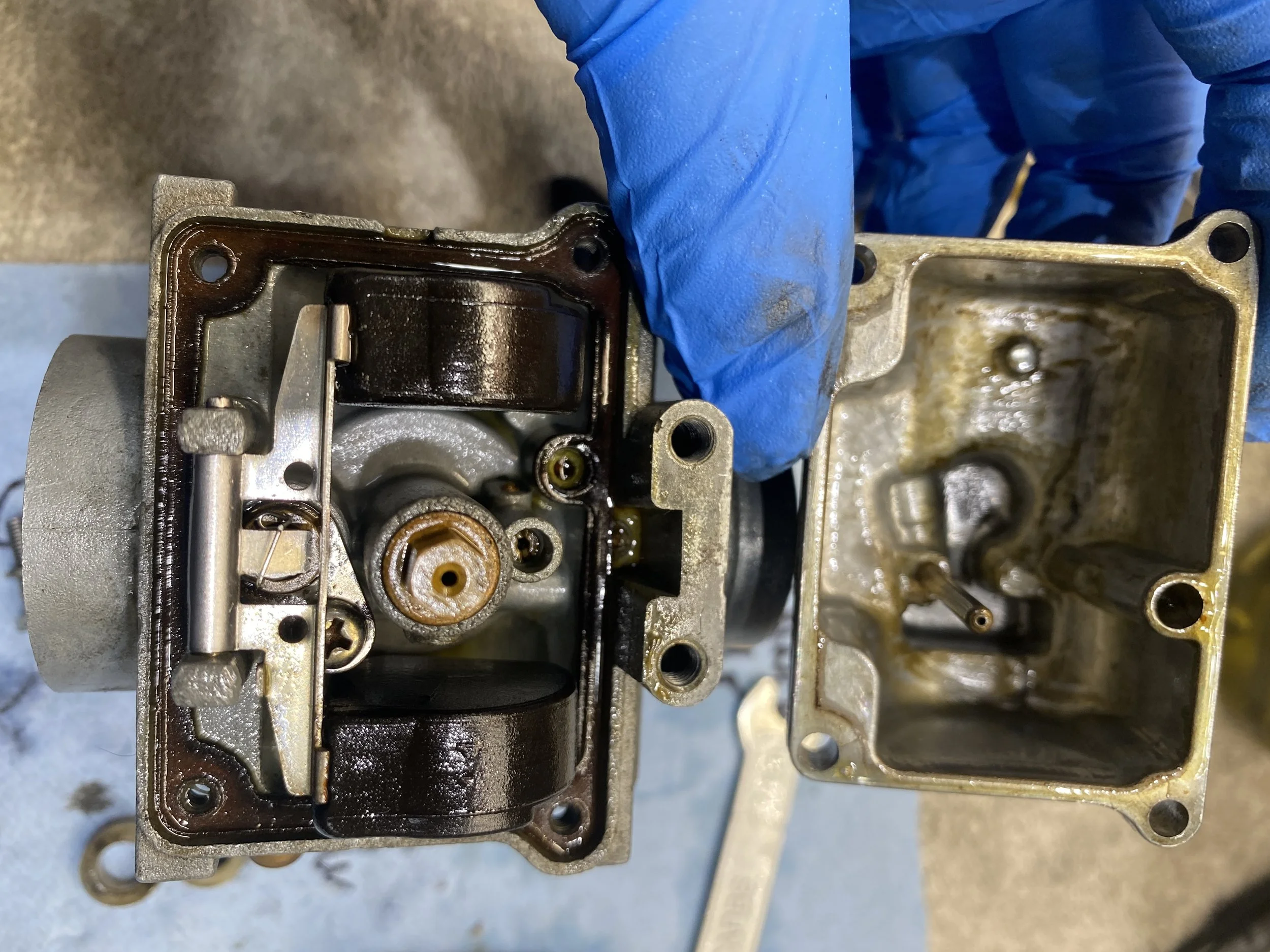

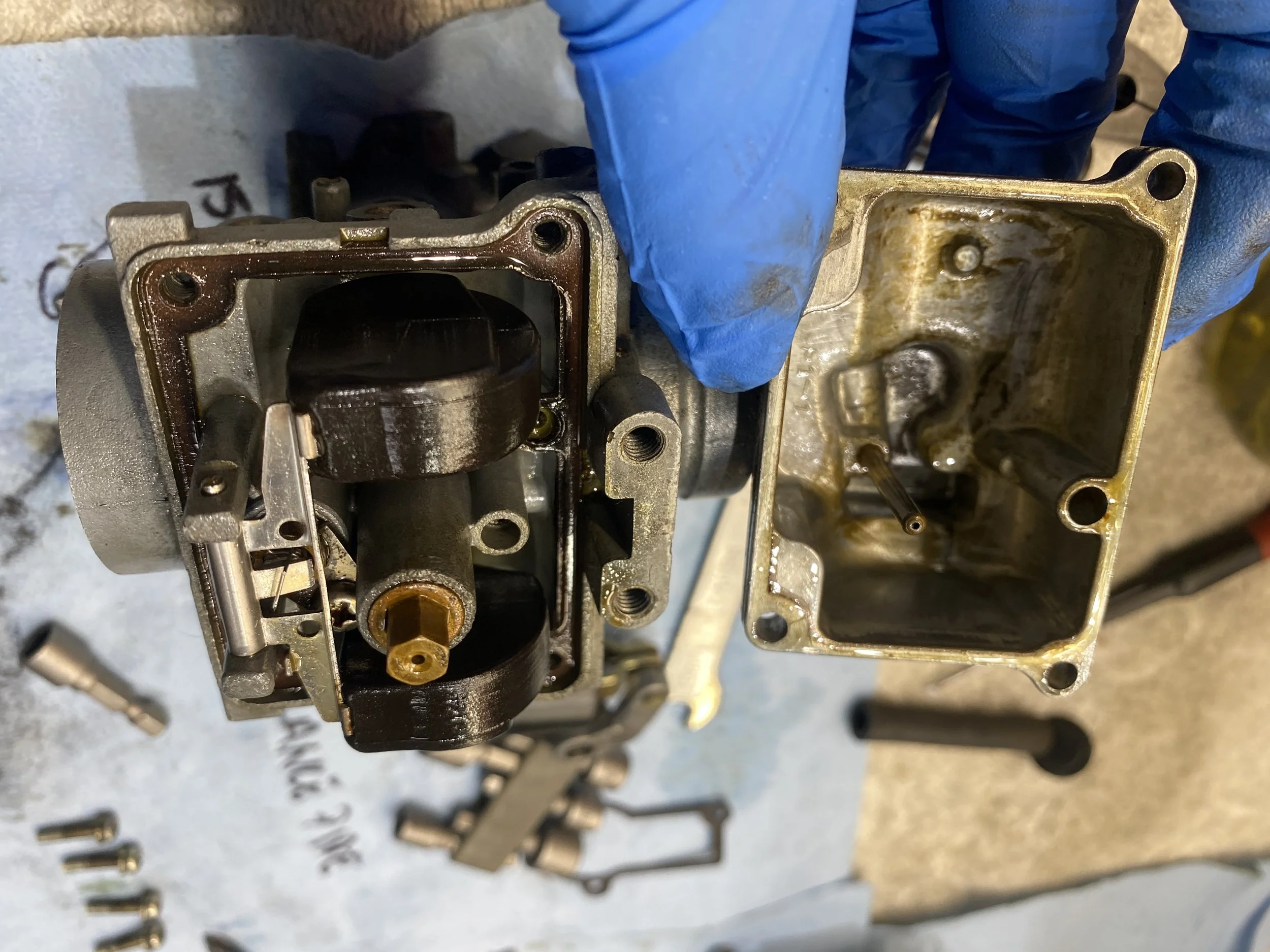

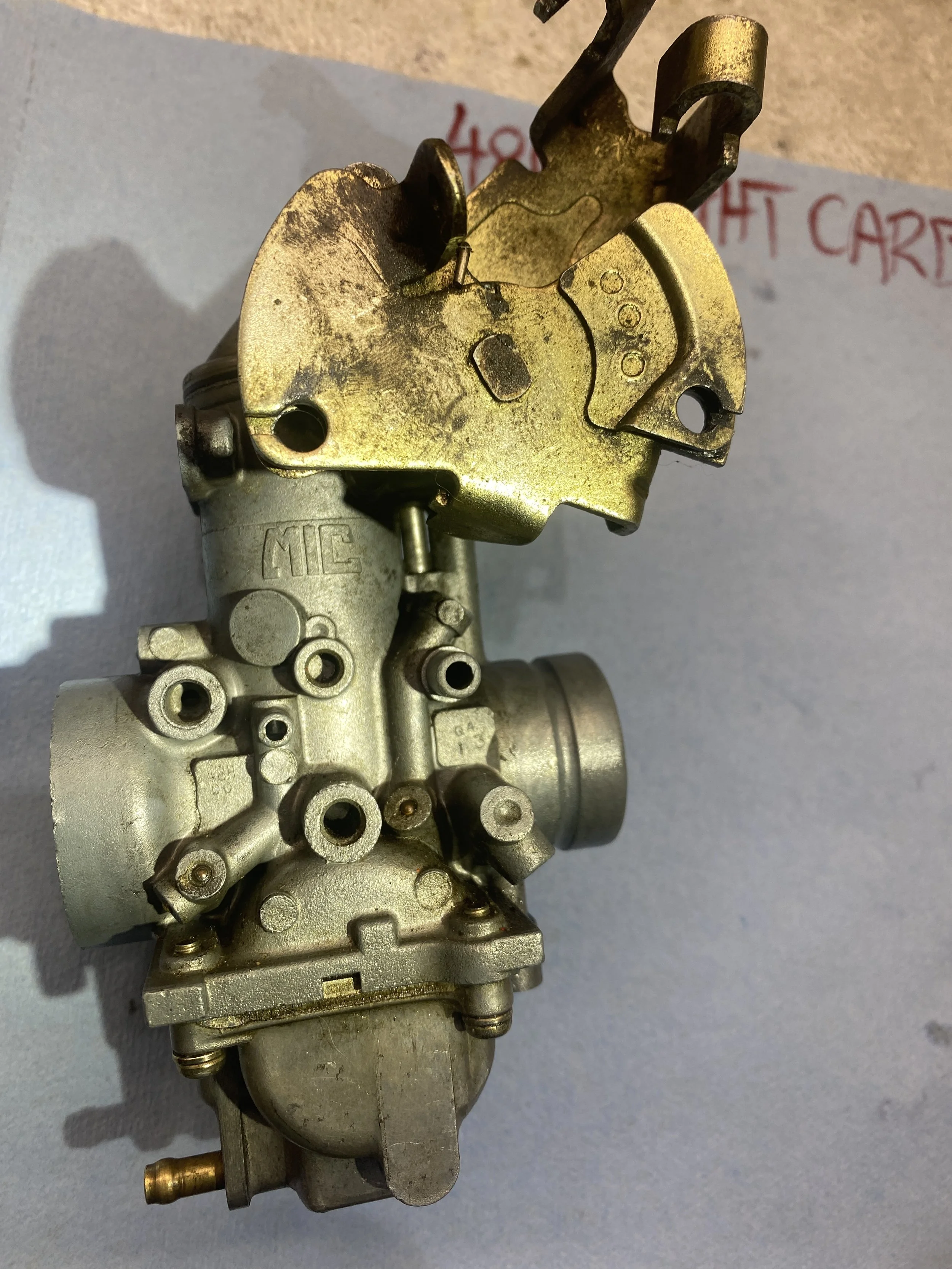

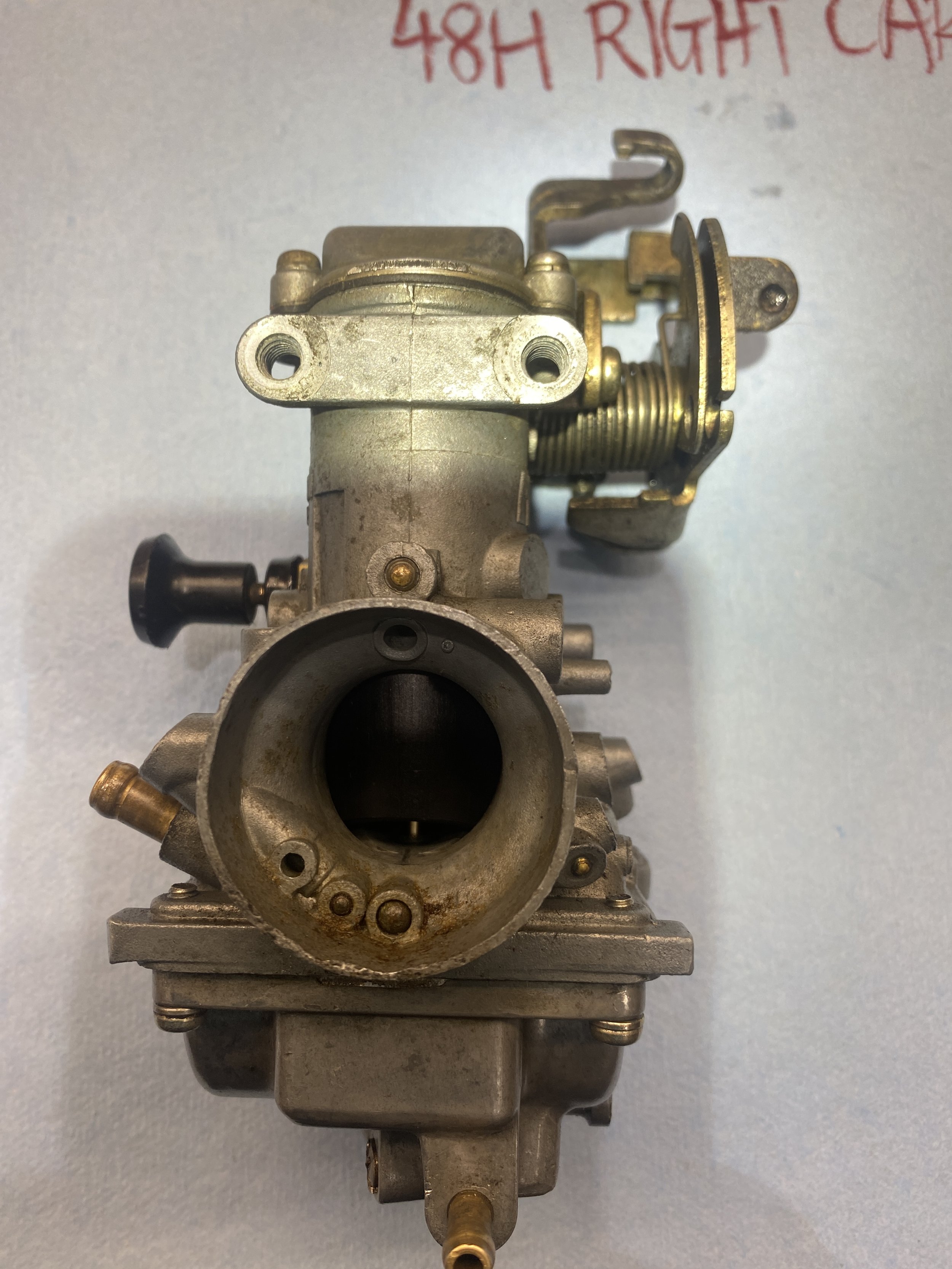

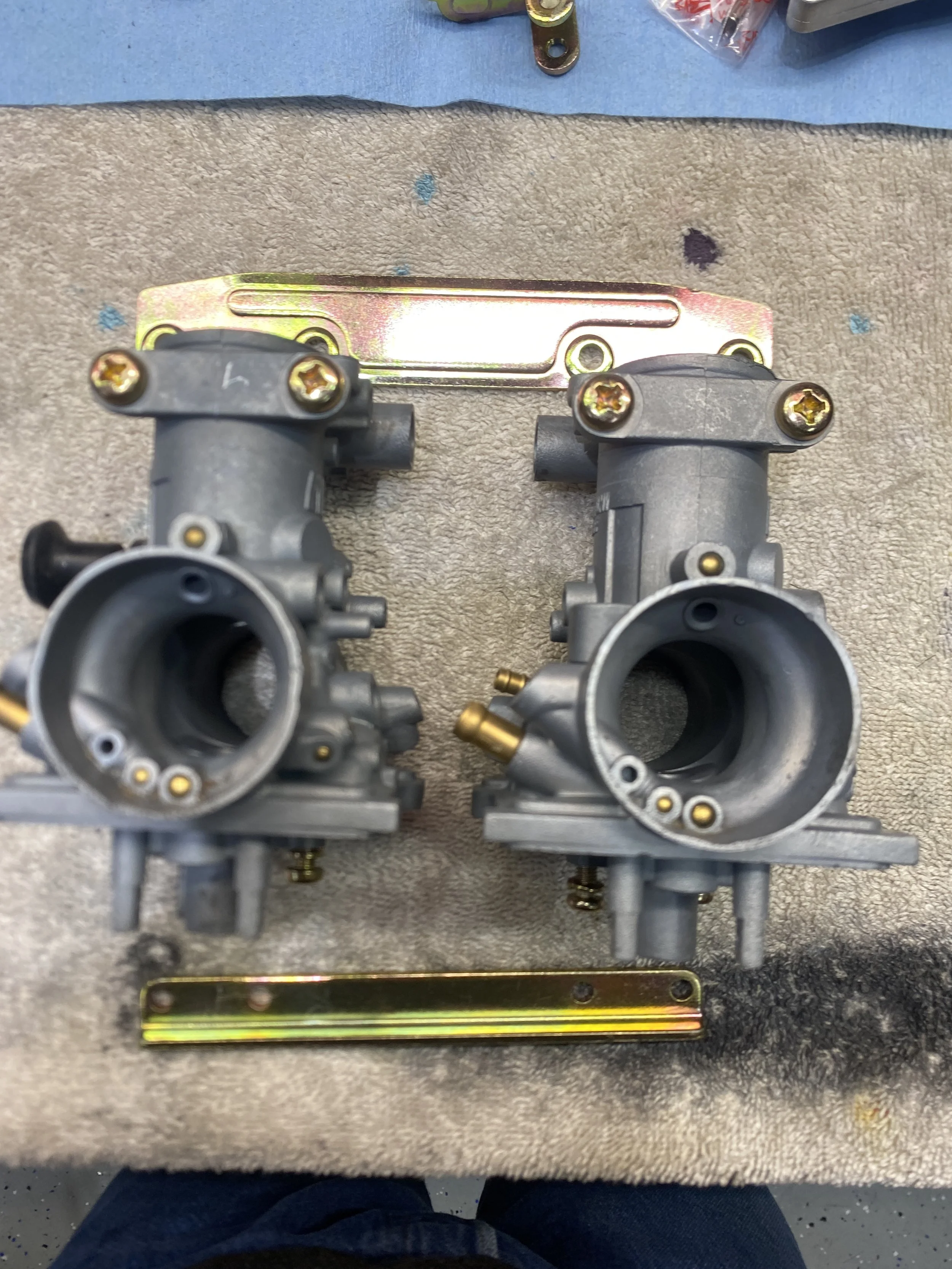

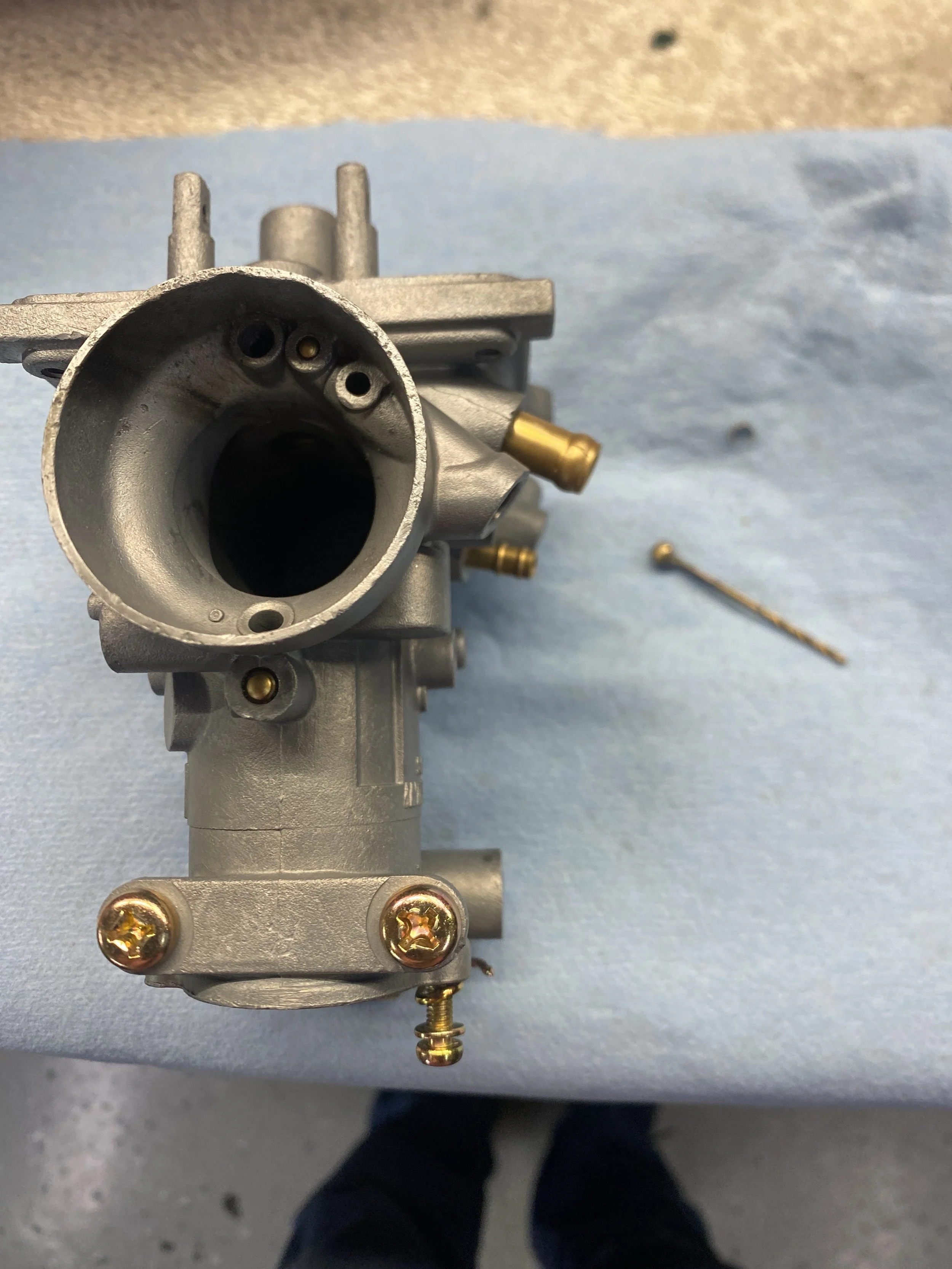

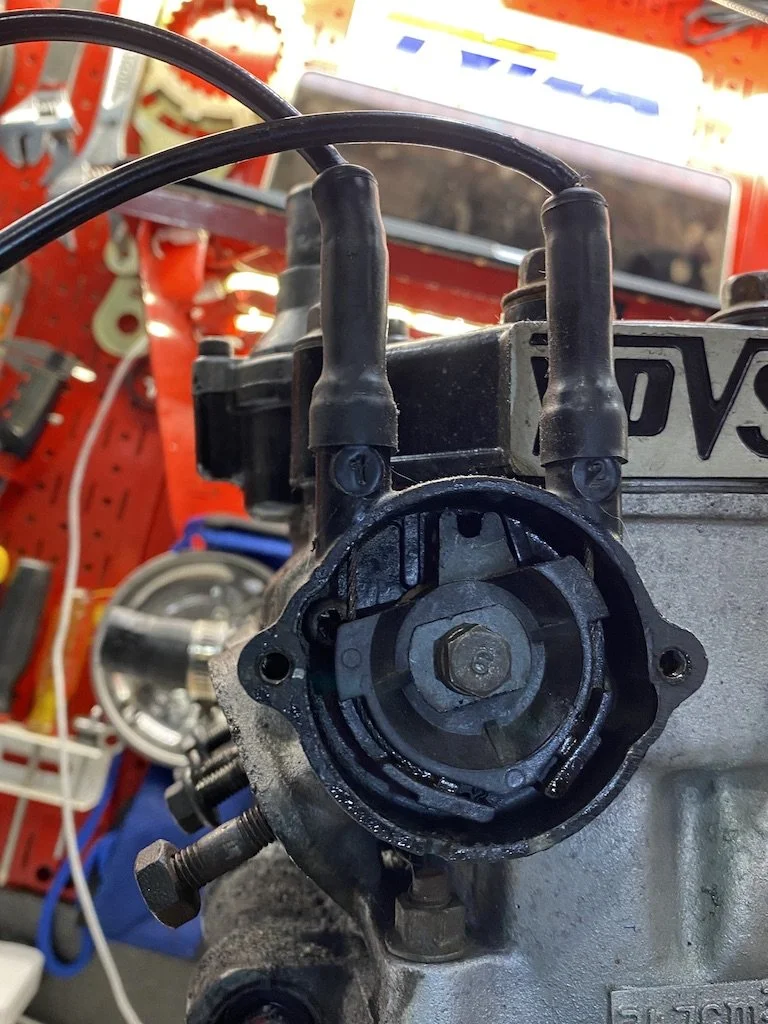

Original carbs. Good.

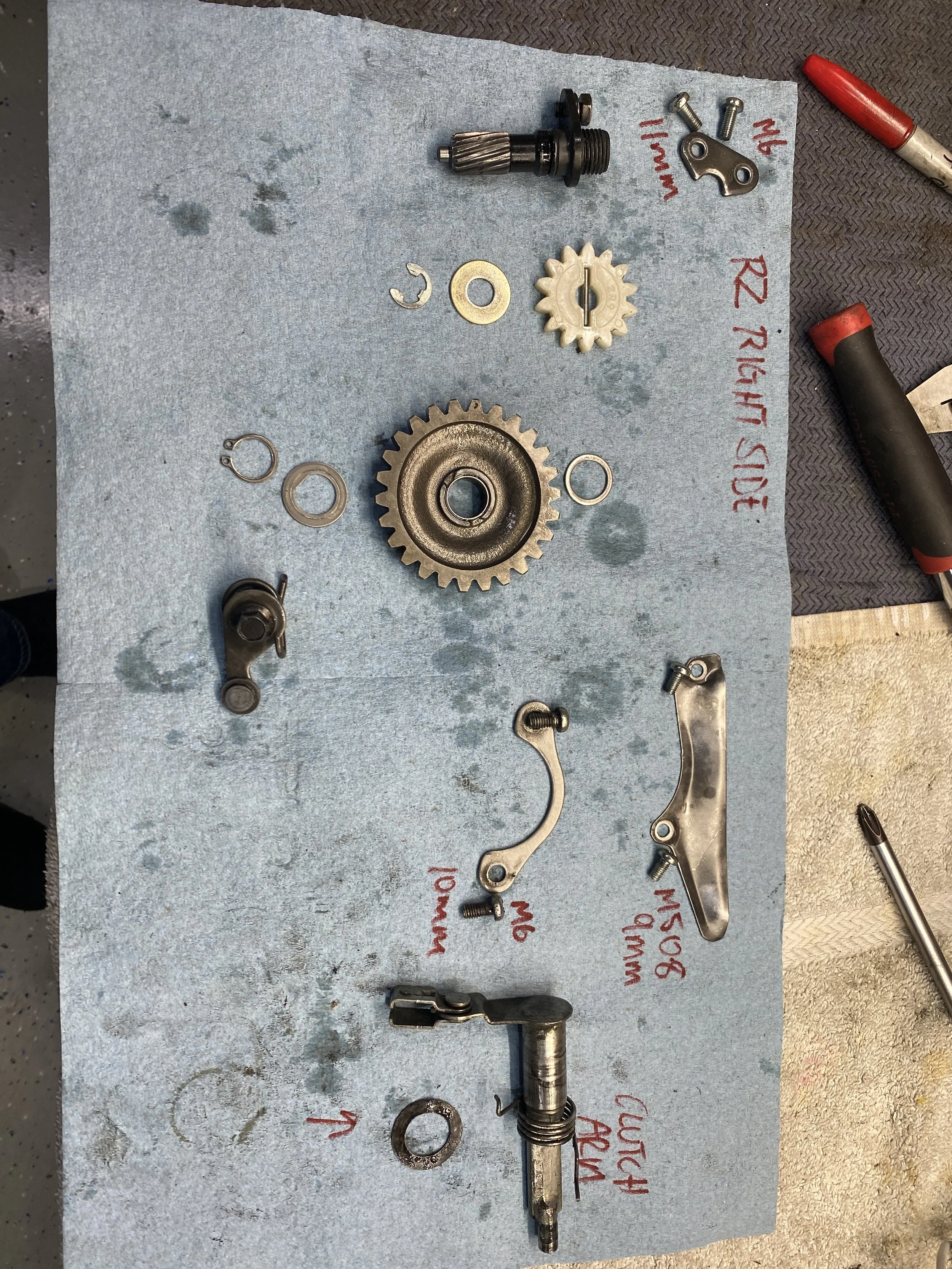

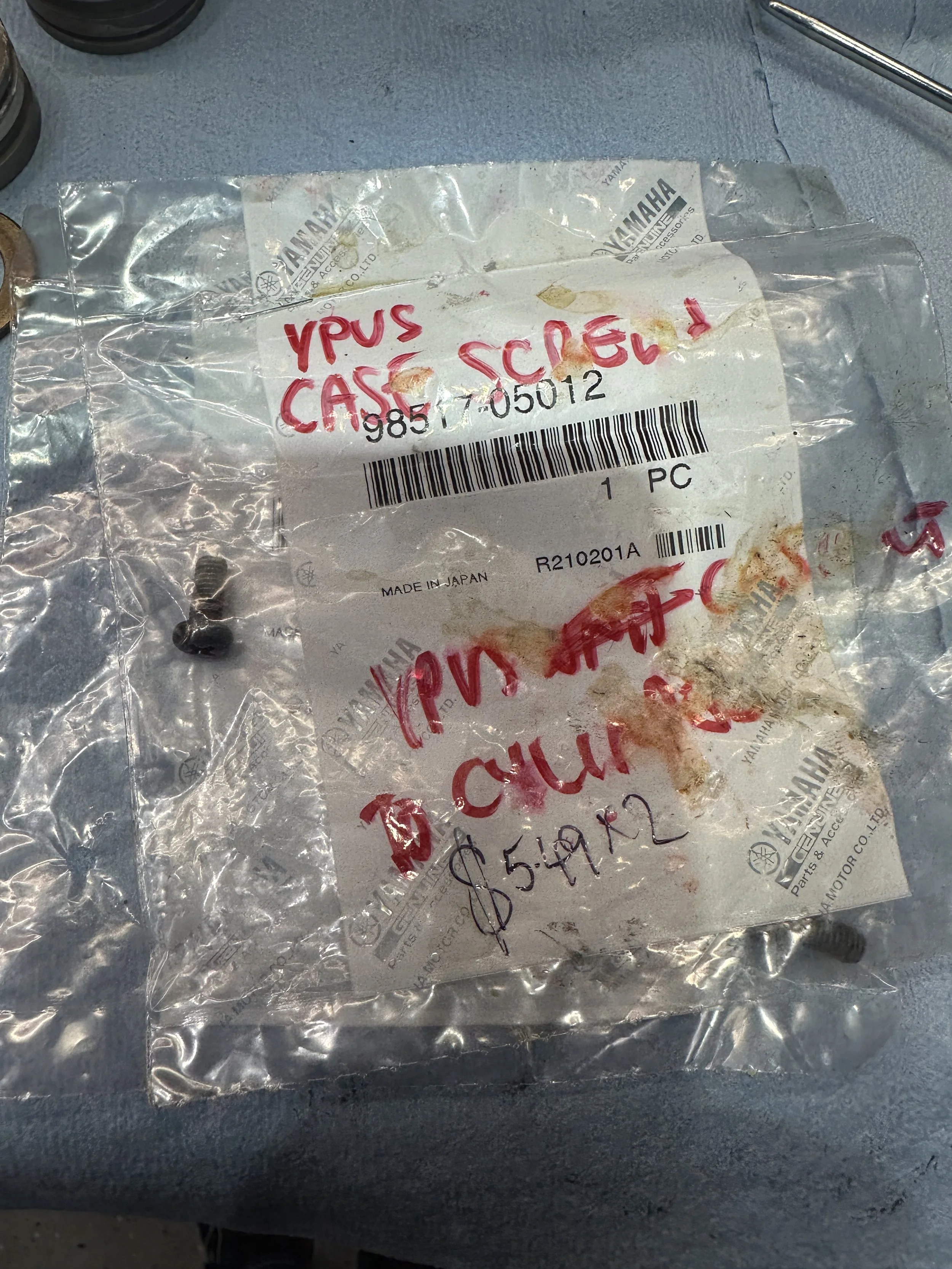

Here are all the bits that came with the bike that are clues to what may have been done to it….

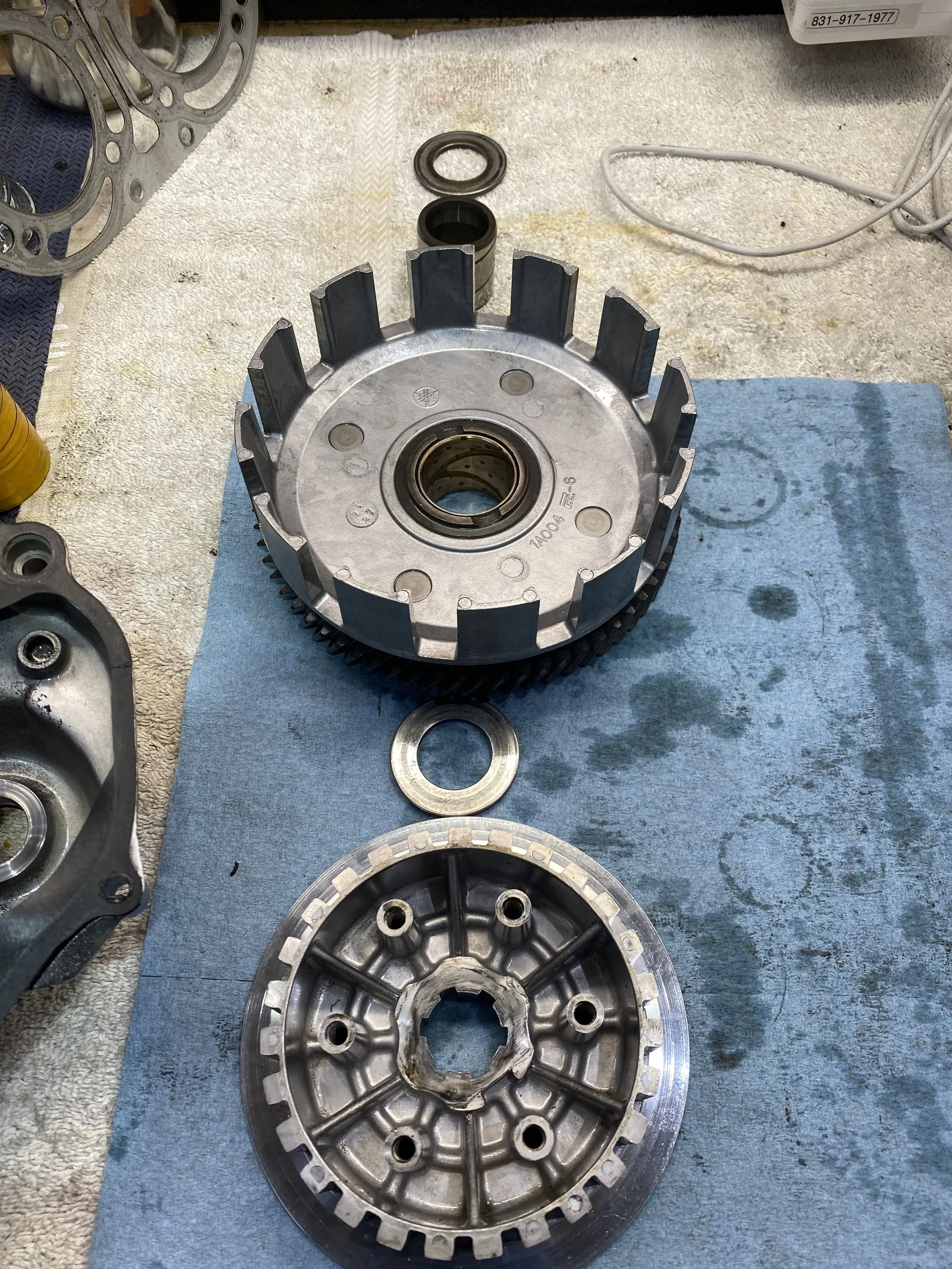

Clutch basket. What can go wrong with this? Fingers are flat and ungrooved...ah...looks like there was some welding done, but why there?

Apart from the glued crack on the bottom right...this looks pretty good and will replace the current very cracked version....need to get hold of an Unleaded Fuel Only sticker. ....

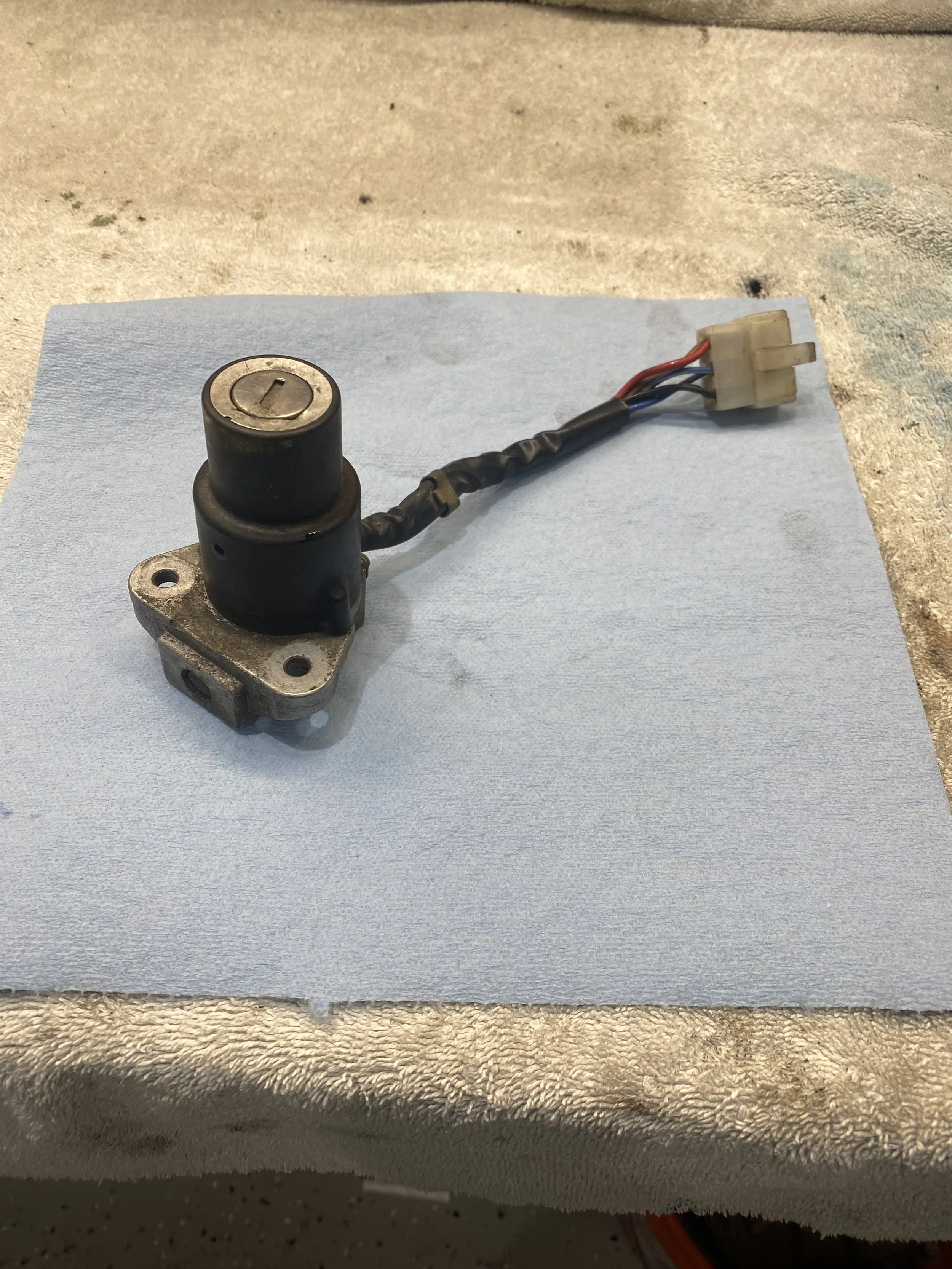

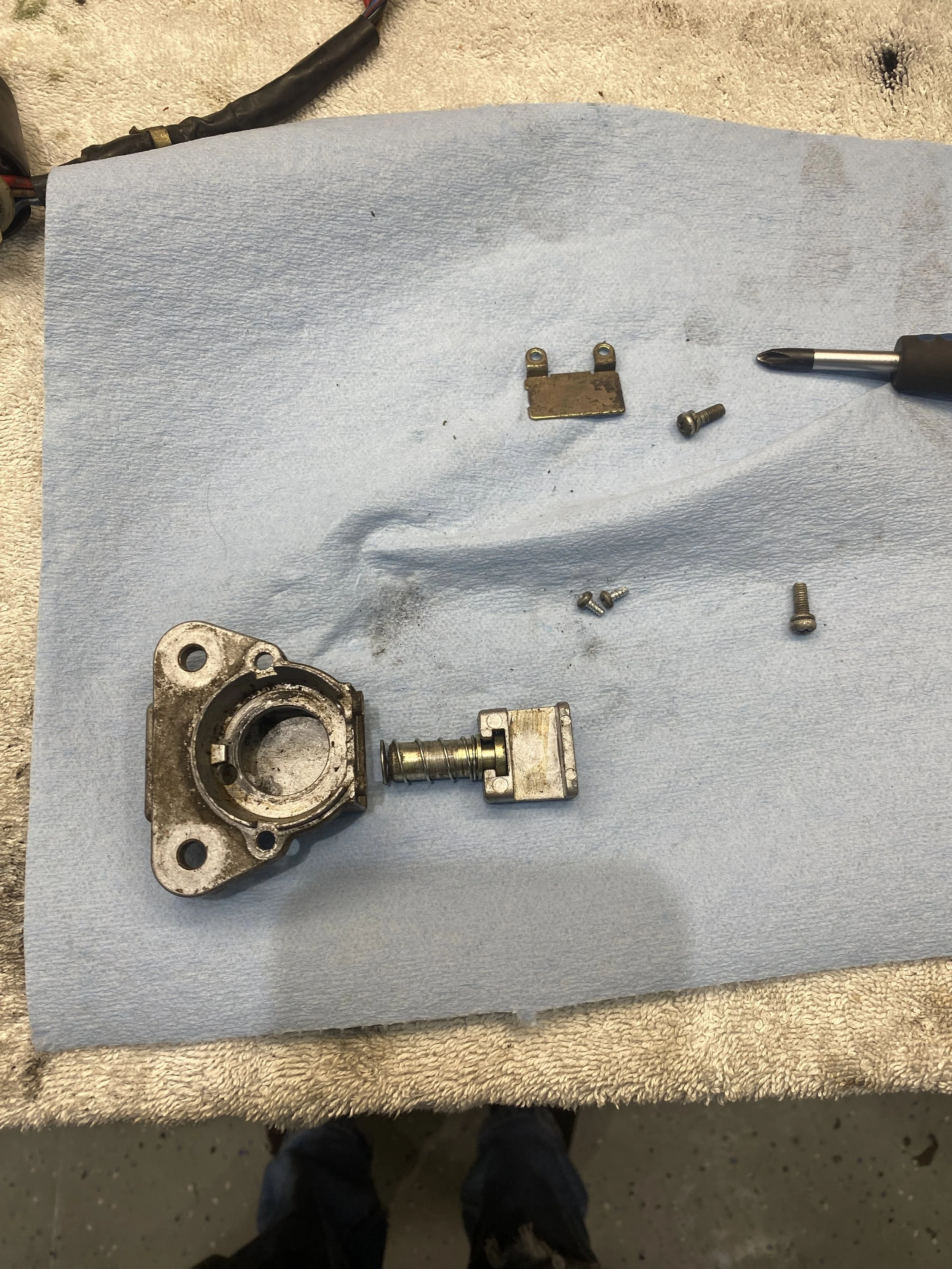

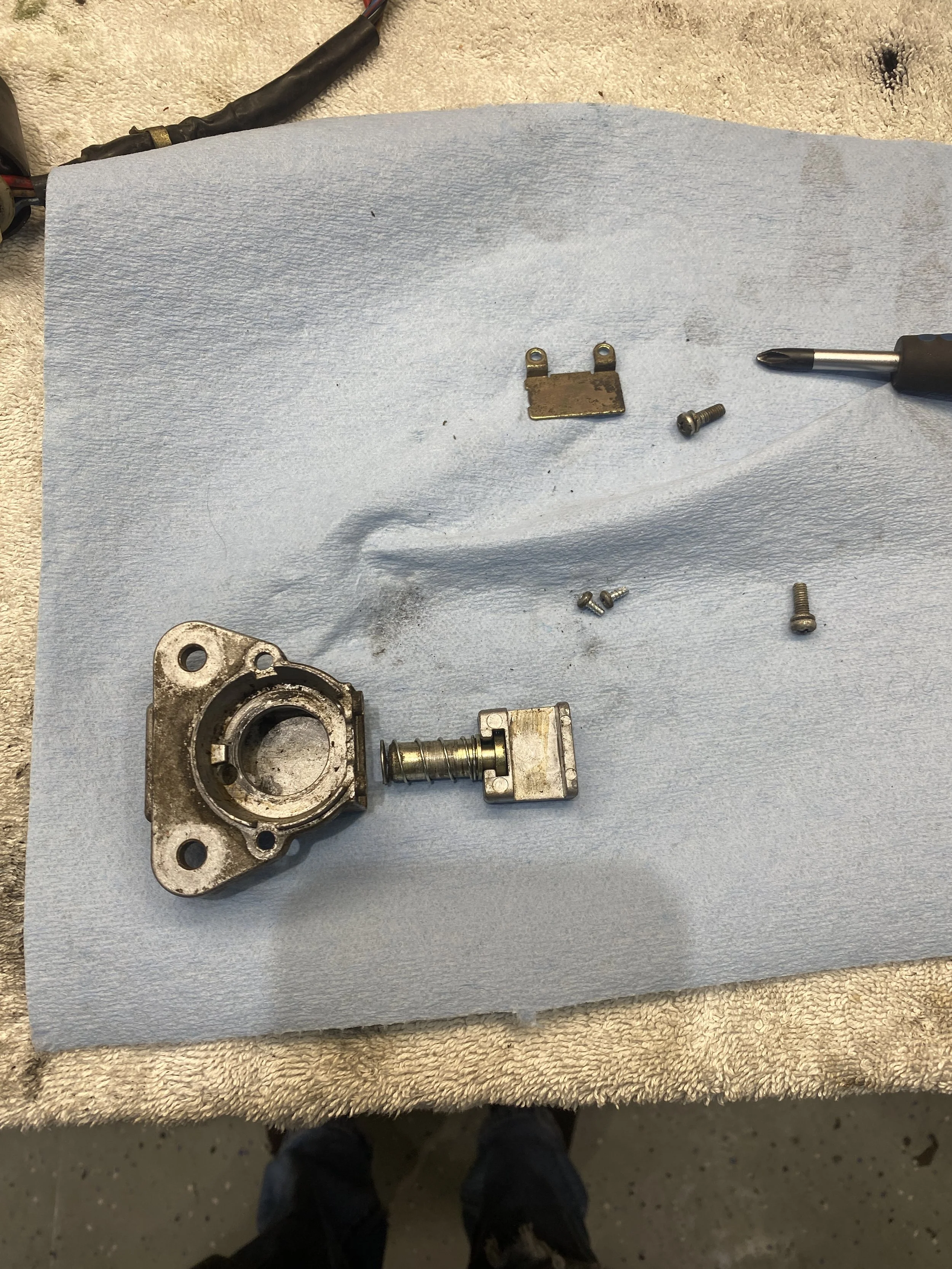

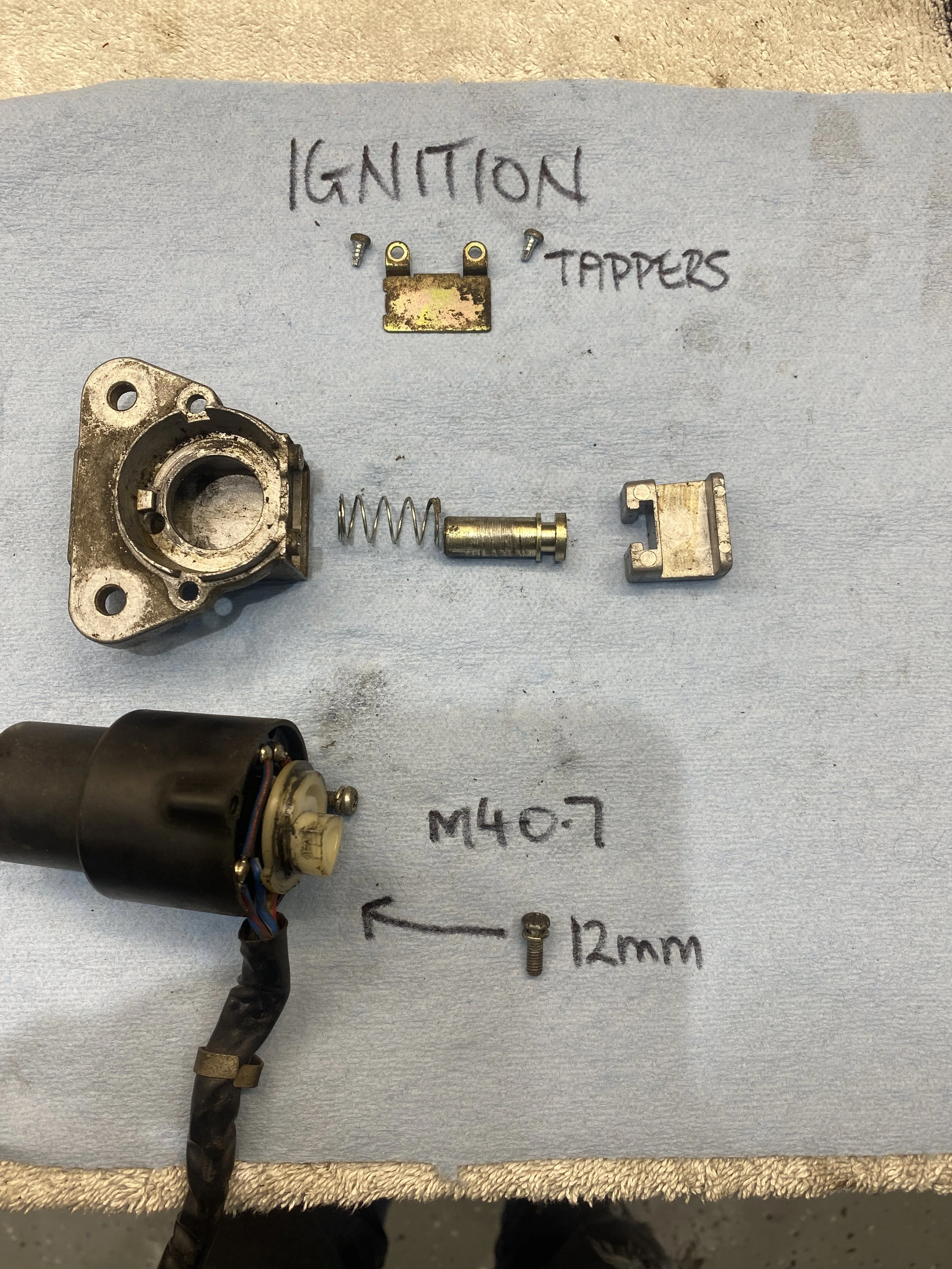

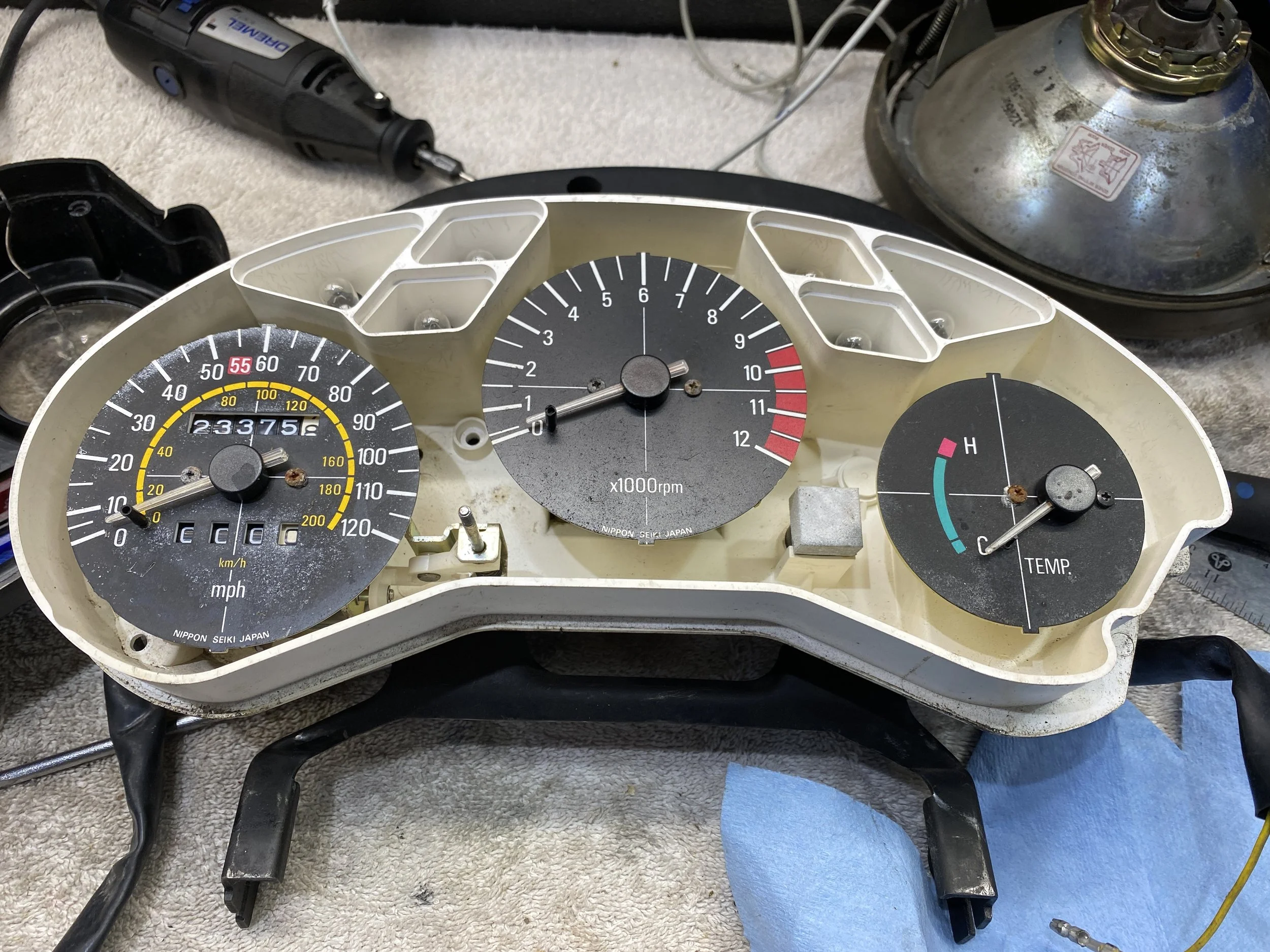

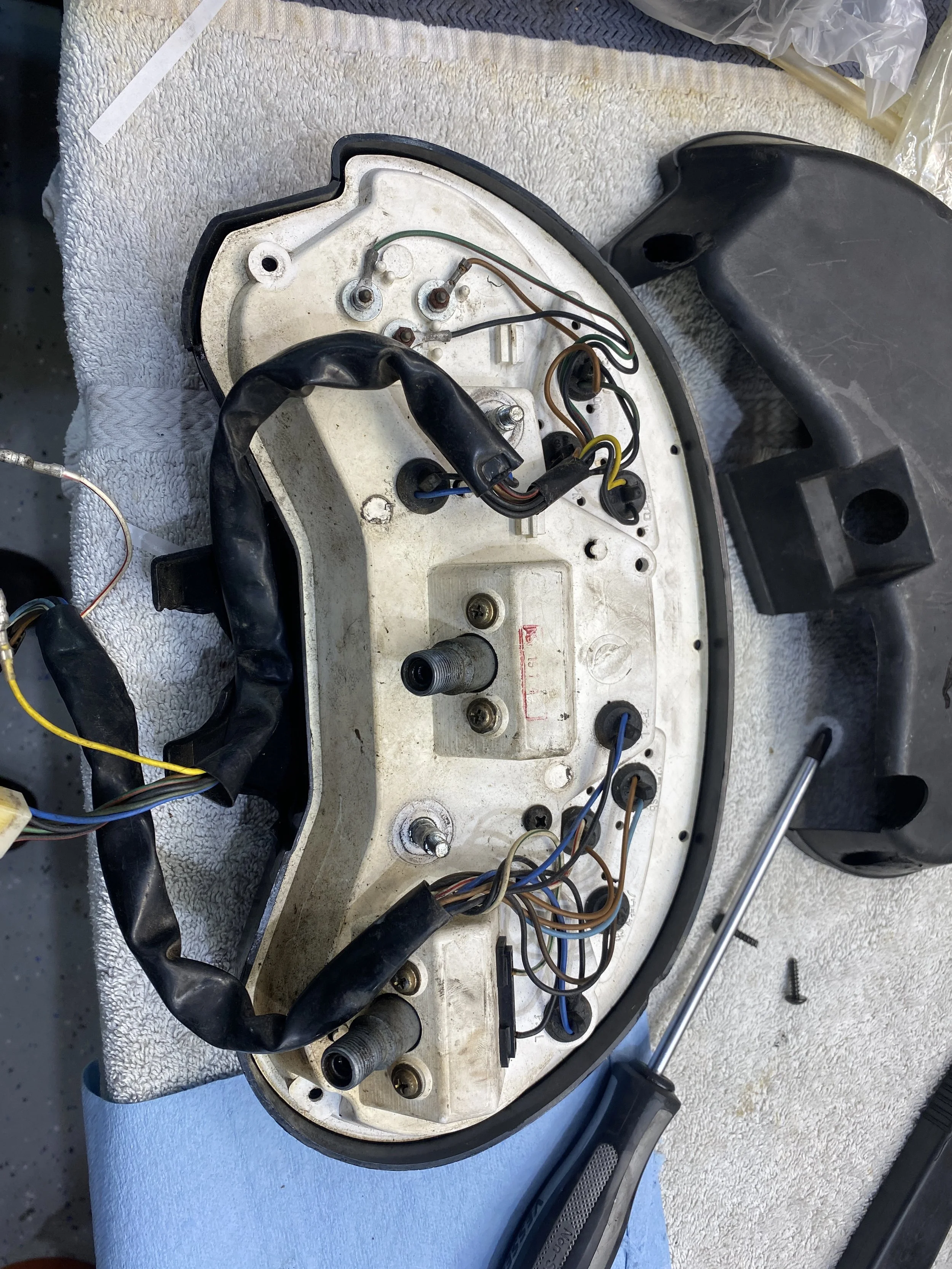

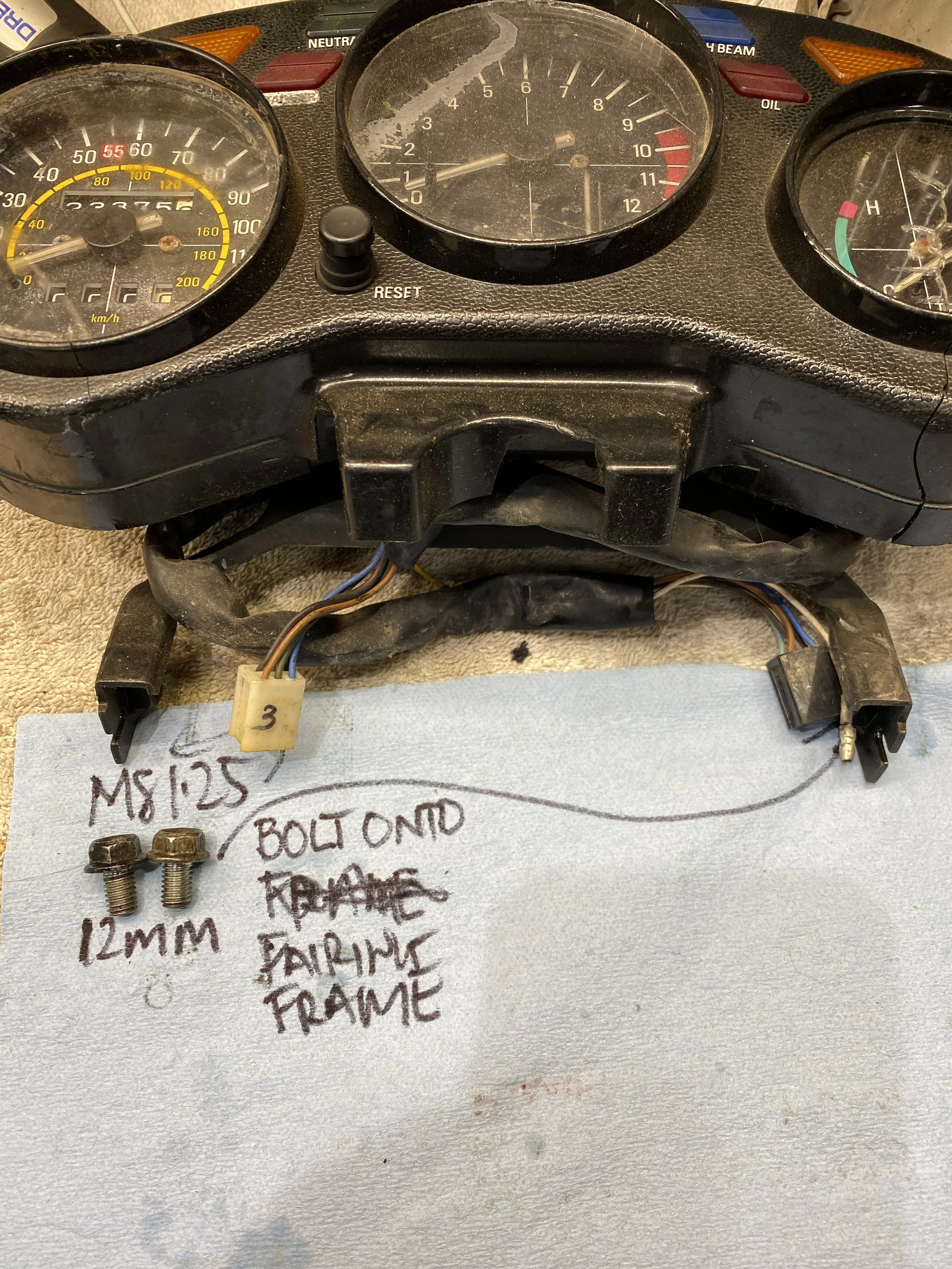

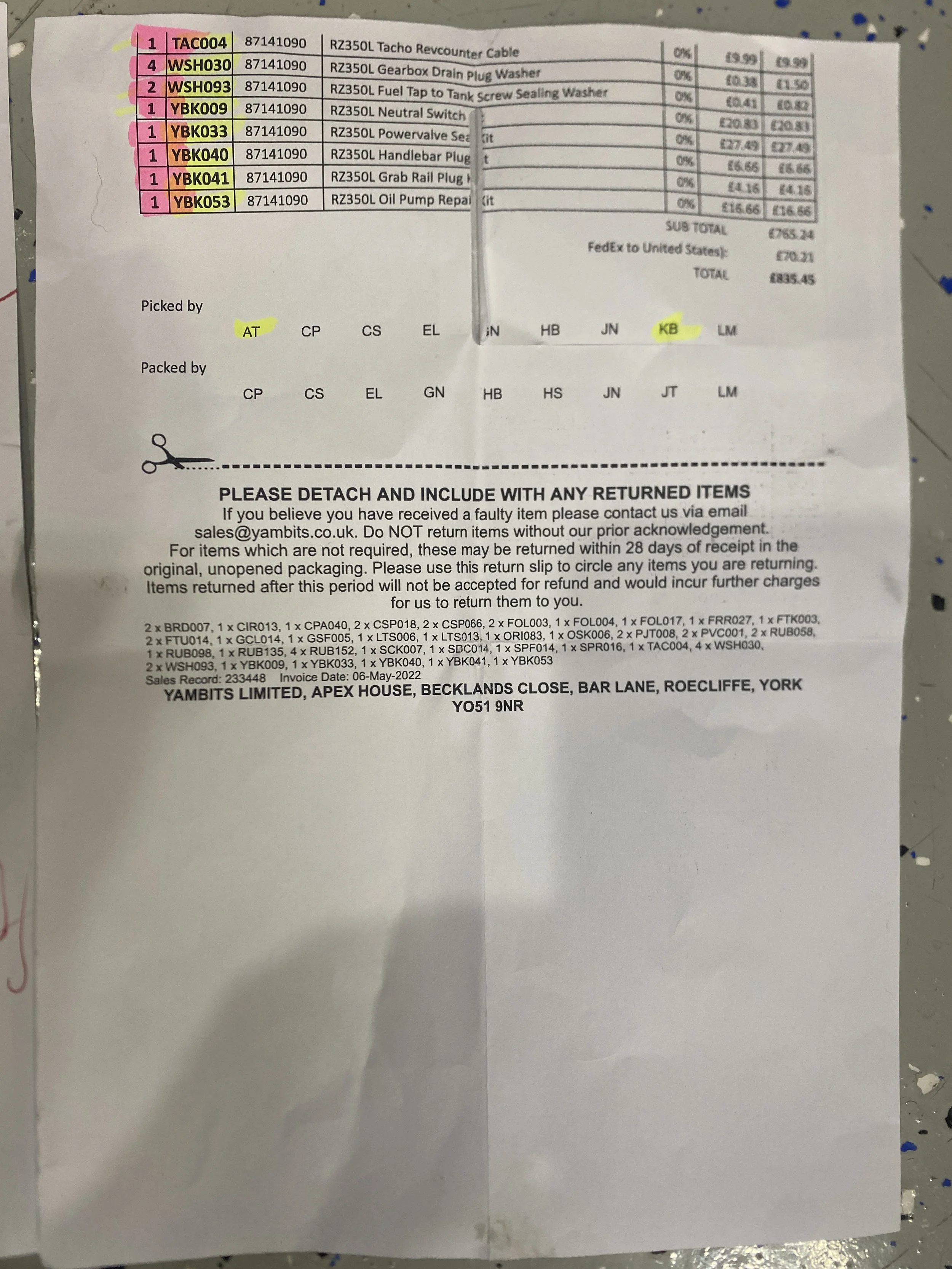

...which sits above the ignition switch. Clocks will likely need their mechanicals refurbed/lubricated and some bright new faces from https://www.diablocycle.com/

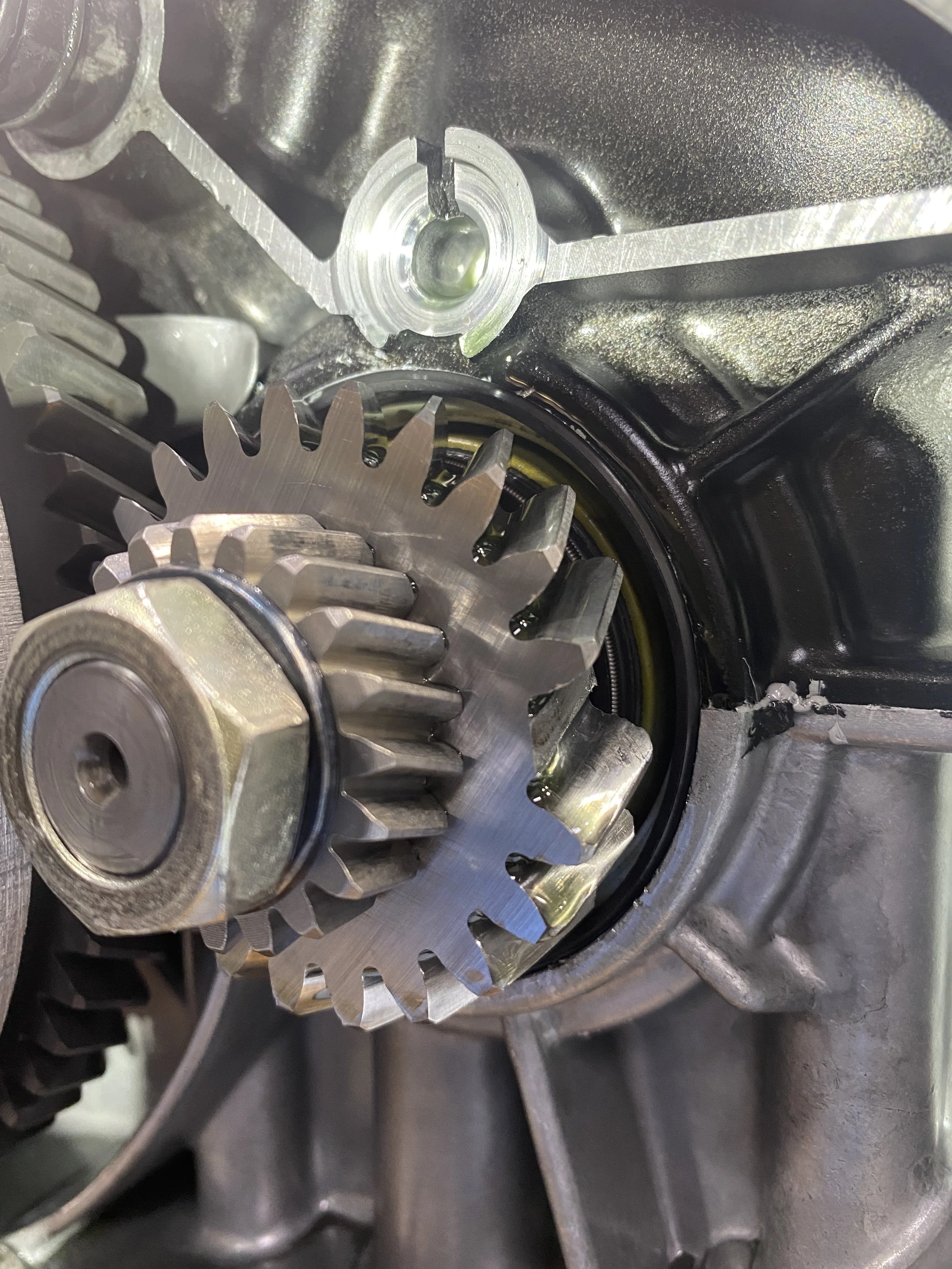

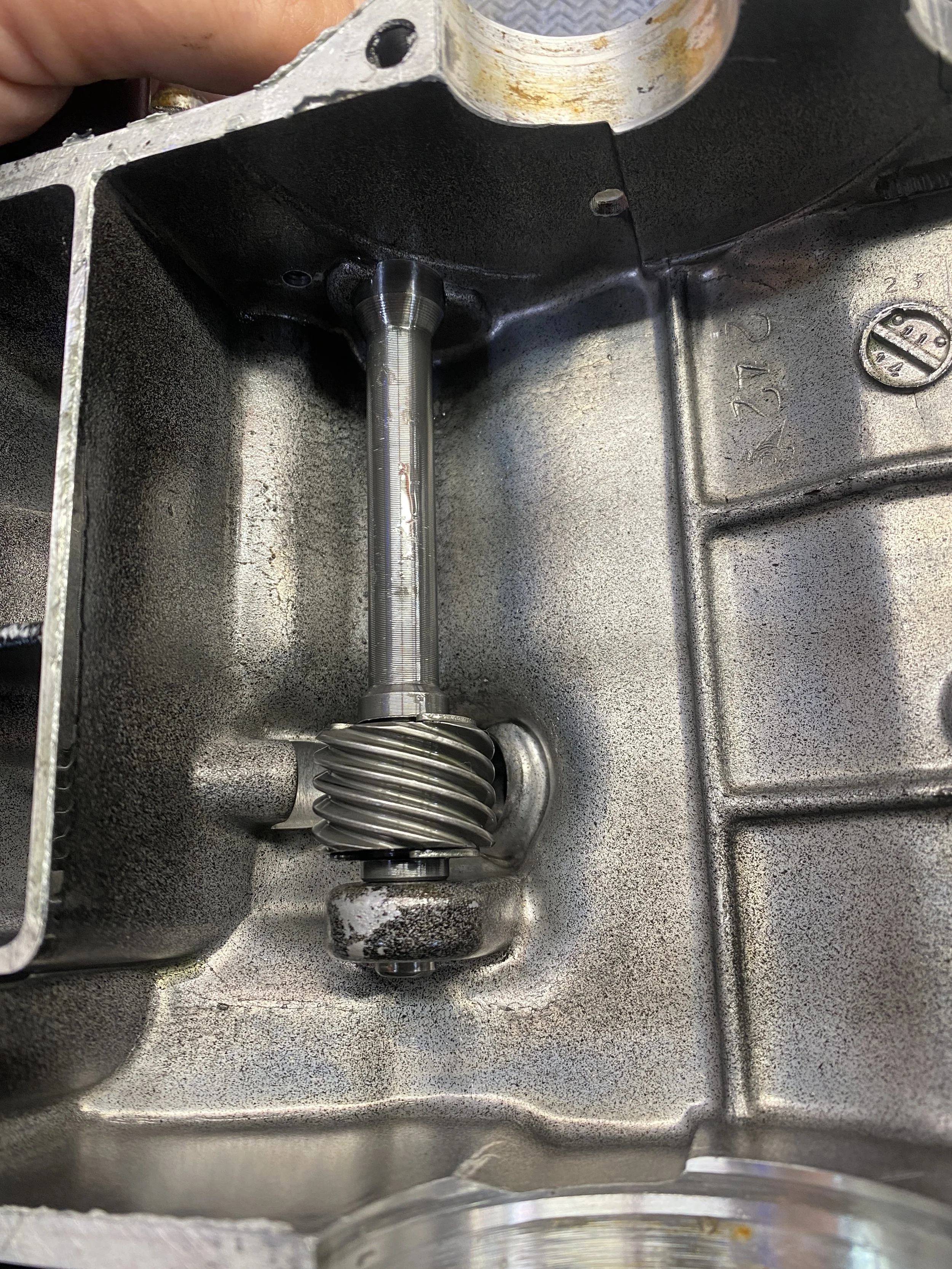

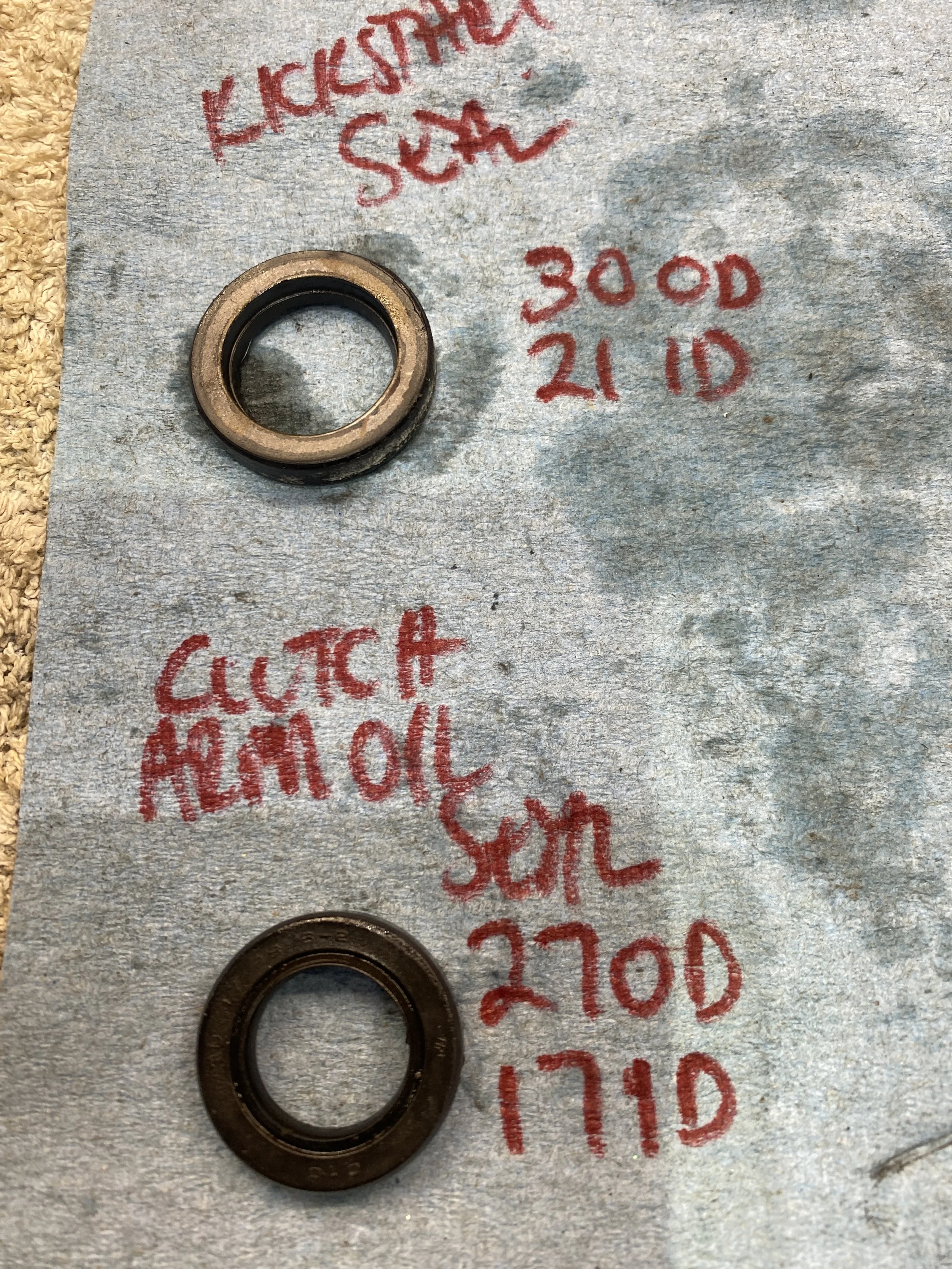

These are interesting. Look to me like old crankseals...this could mean that the engine was split but I can't remember if you can replace the seals without going that far....either way it's a good sign.

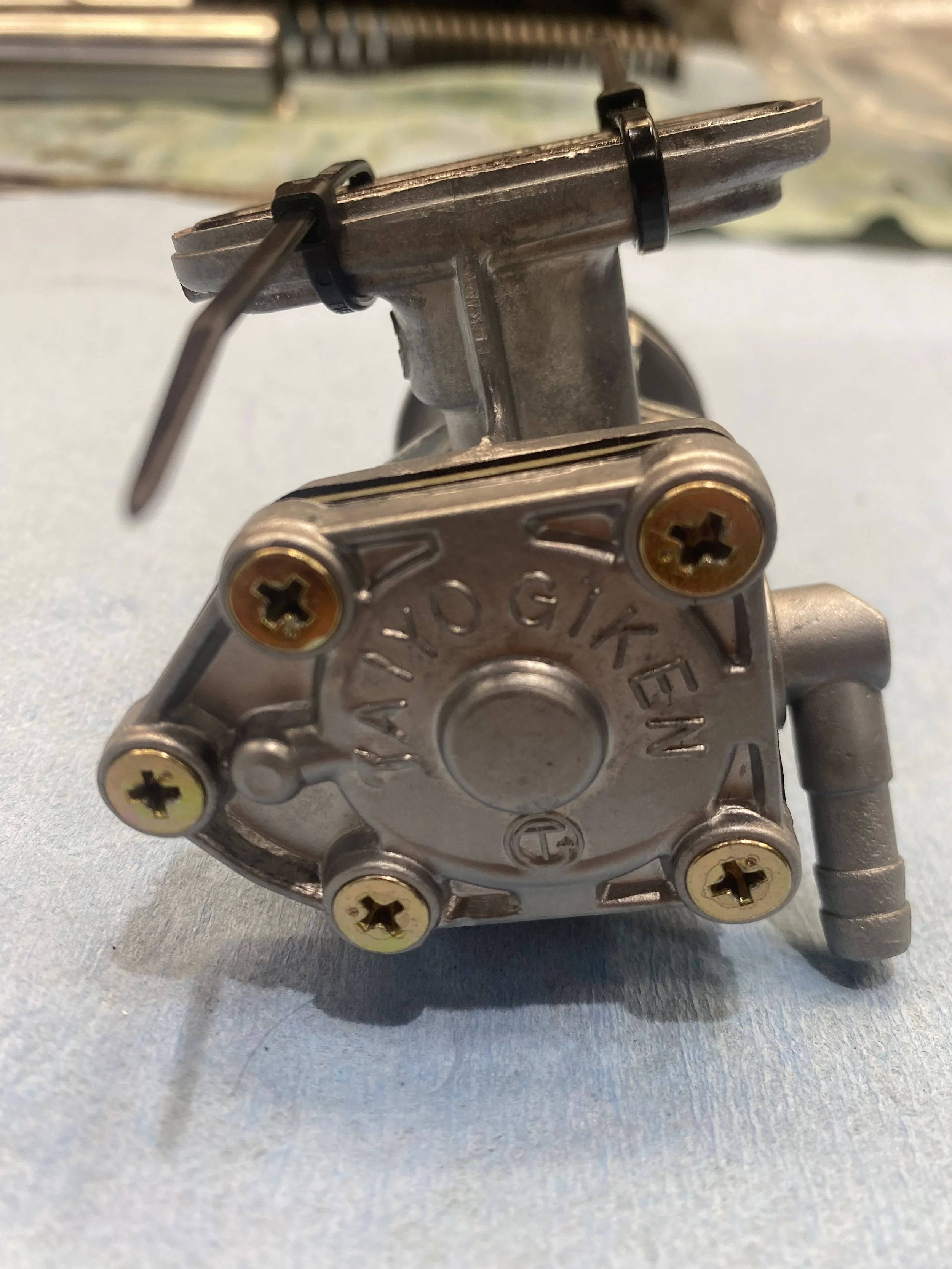

Good to have the original petcock complete with knob. I'm sure a rebuild kit from Norbo will have it working ok. At least it's not a vacuum tap, or is it?

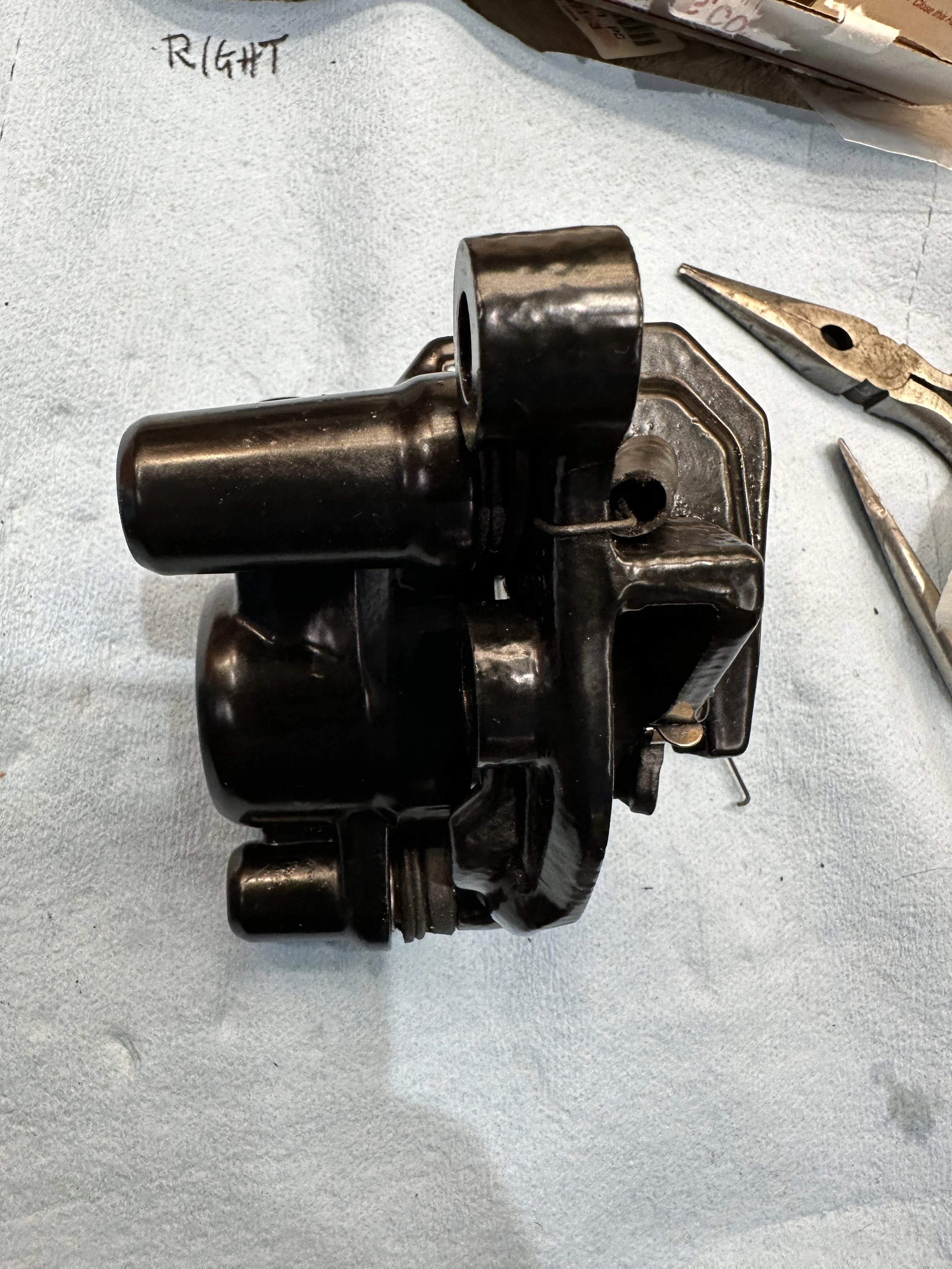

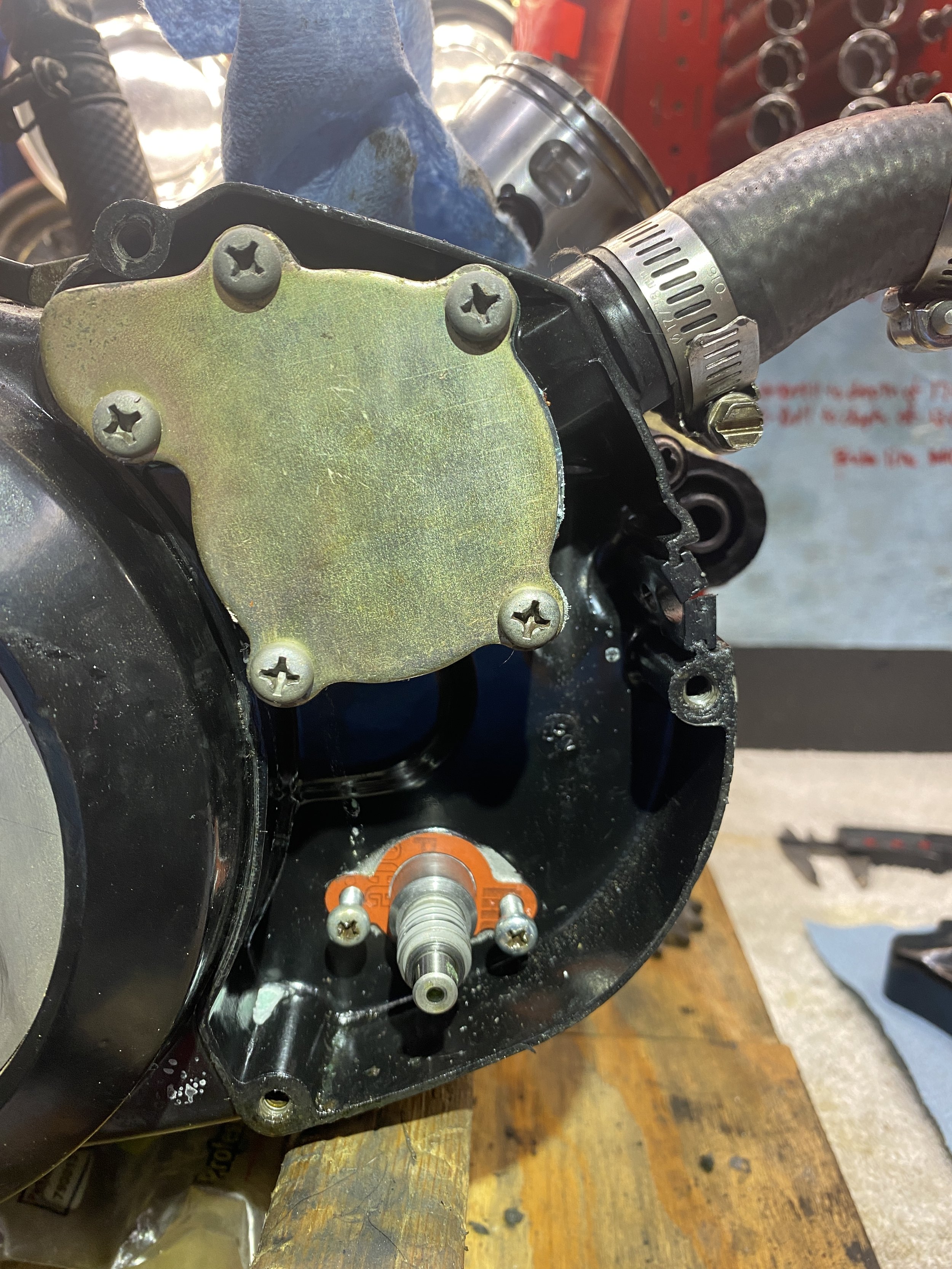

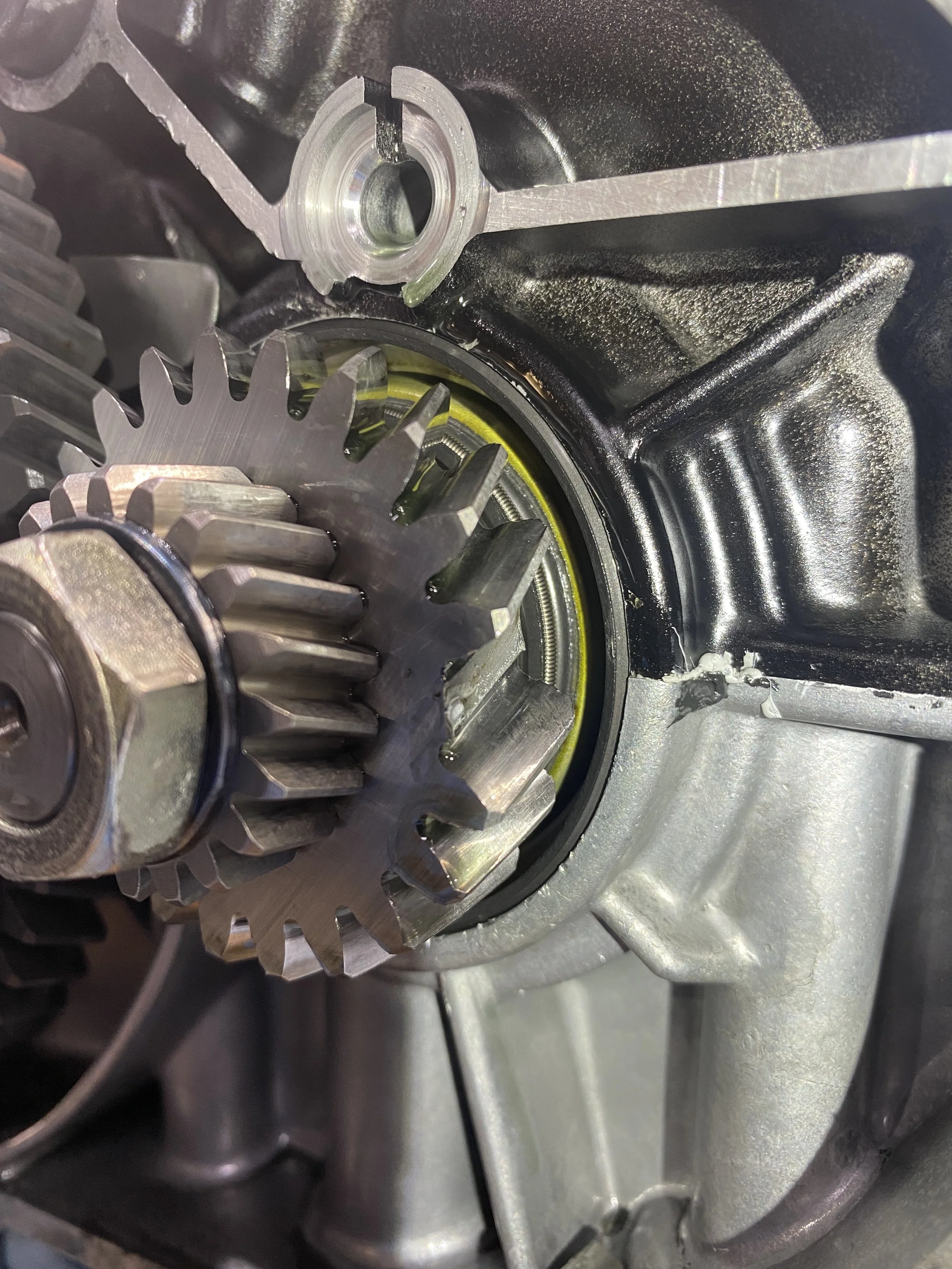

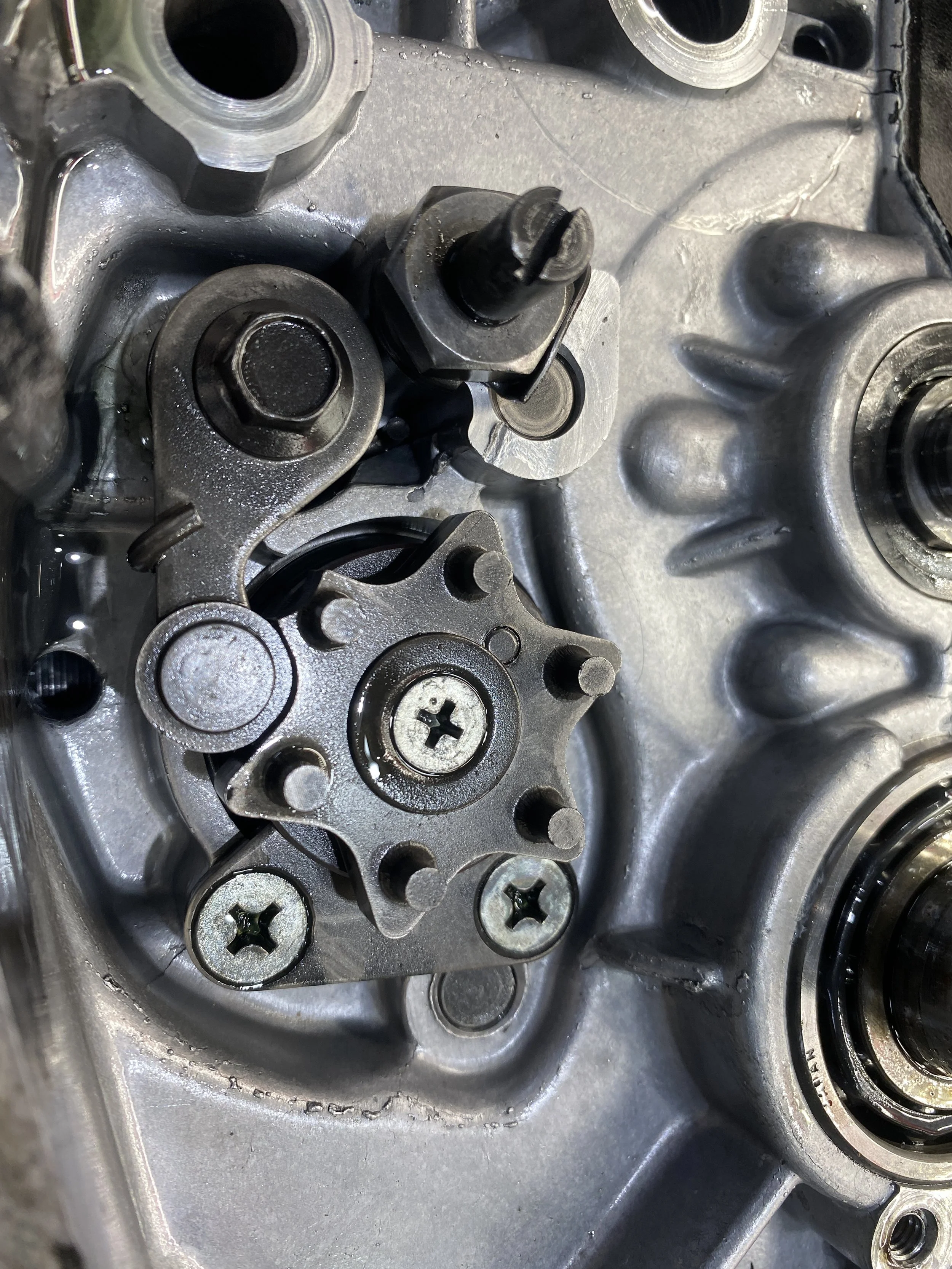

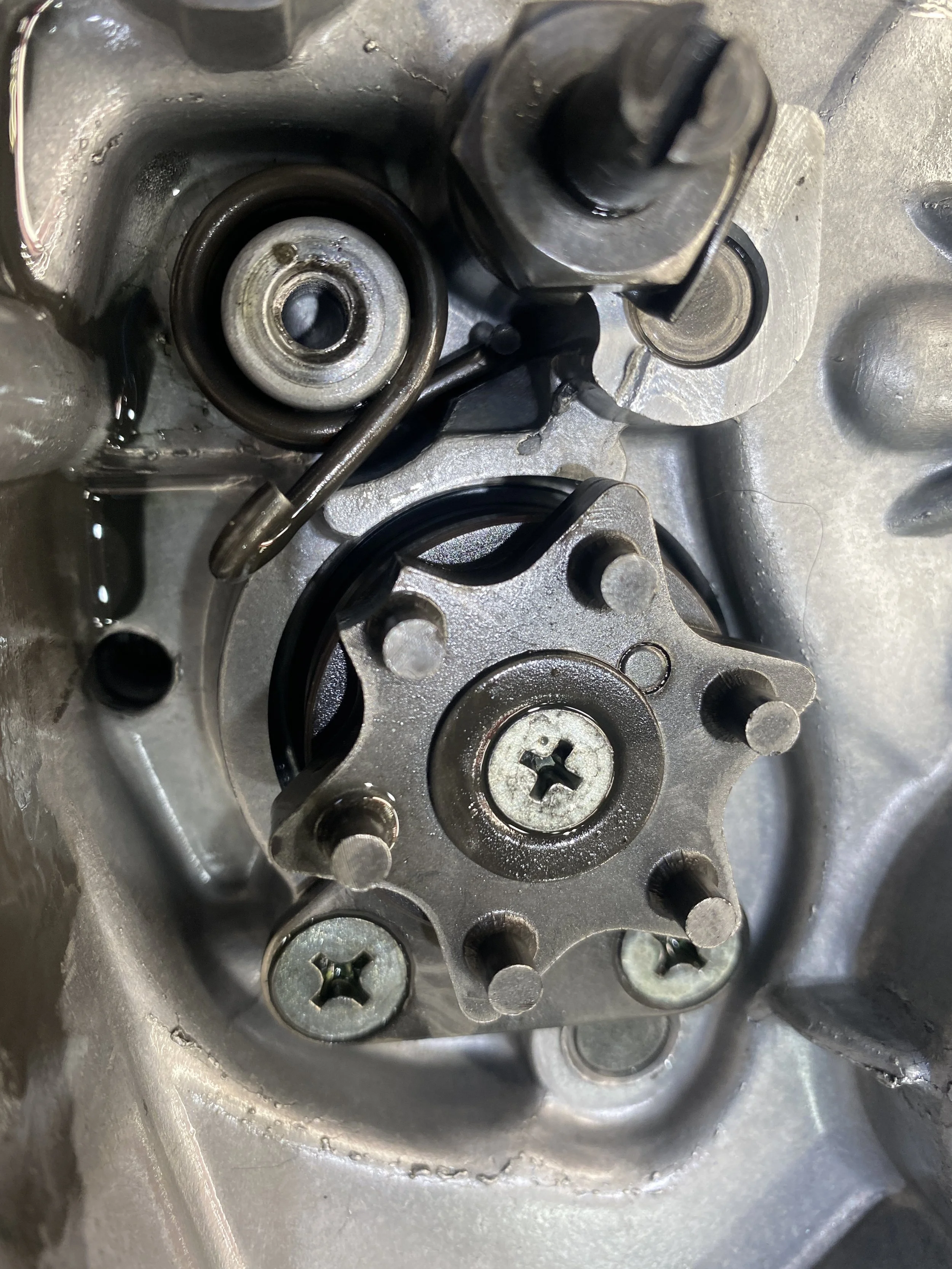

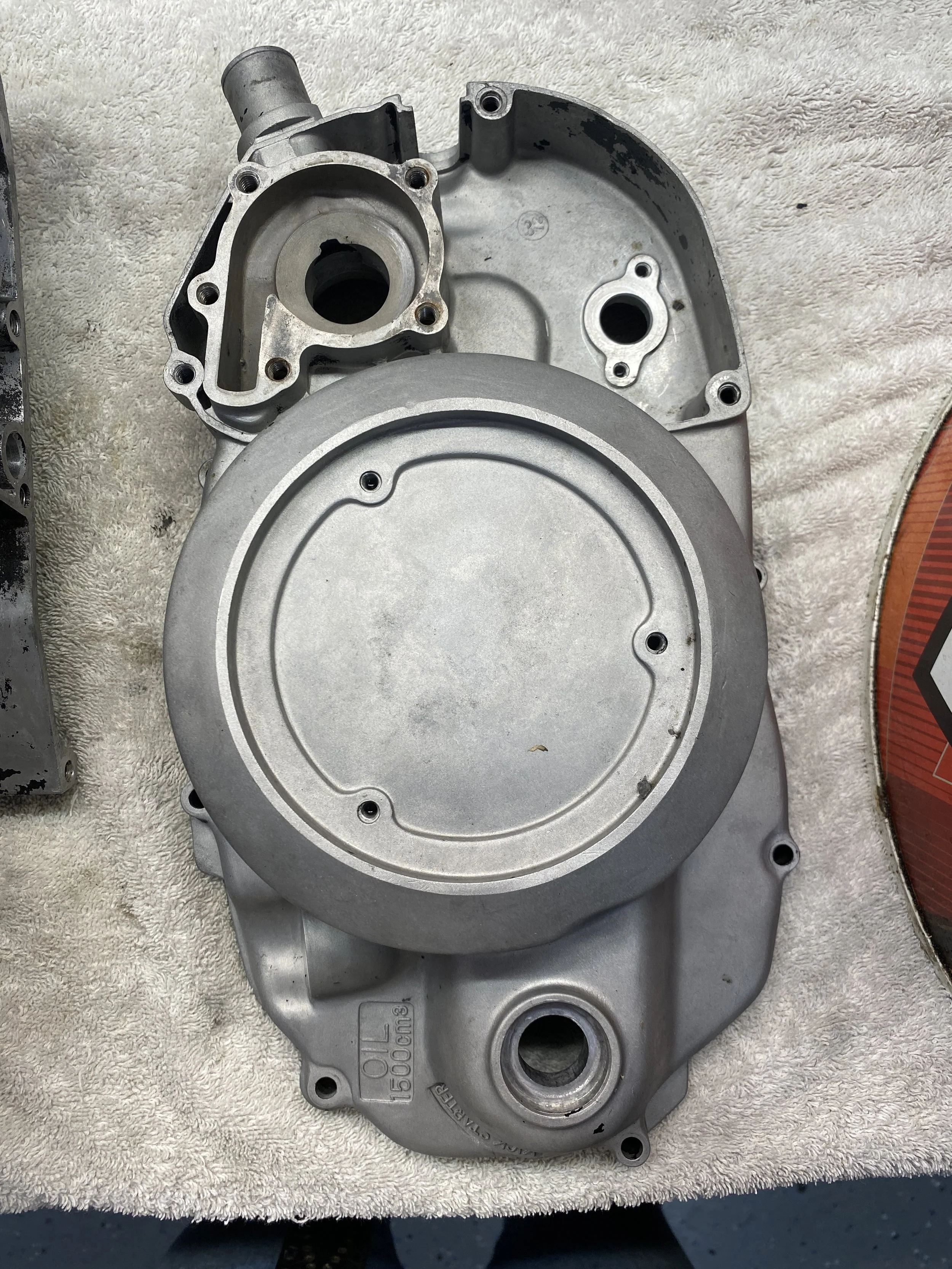

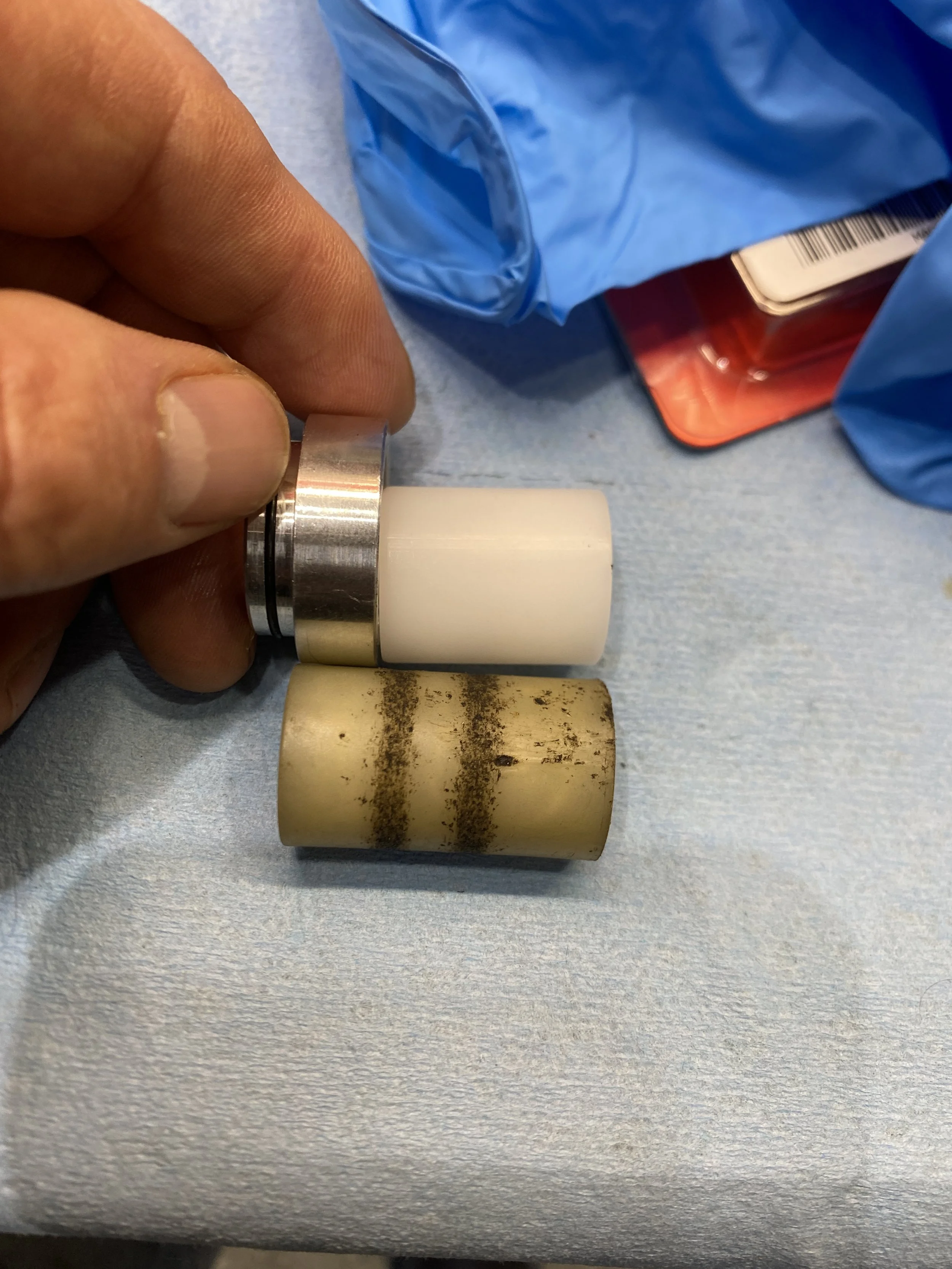

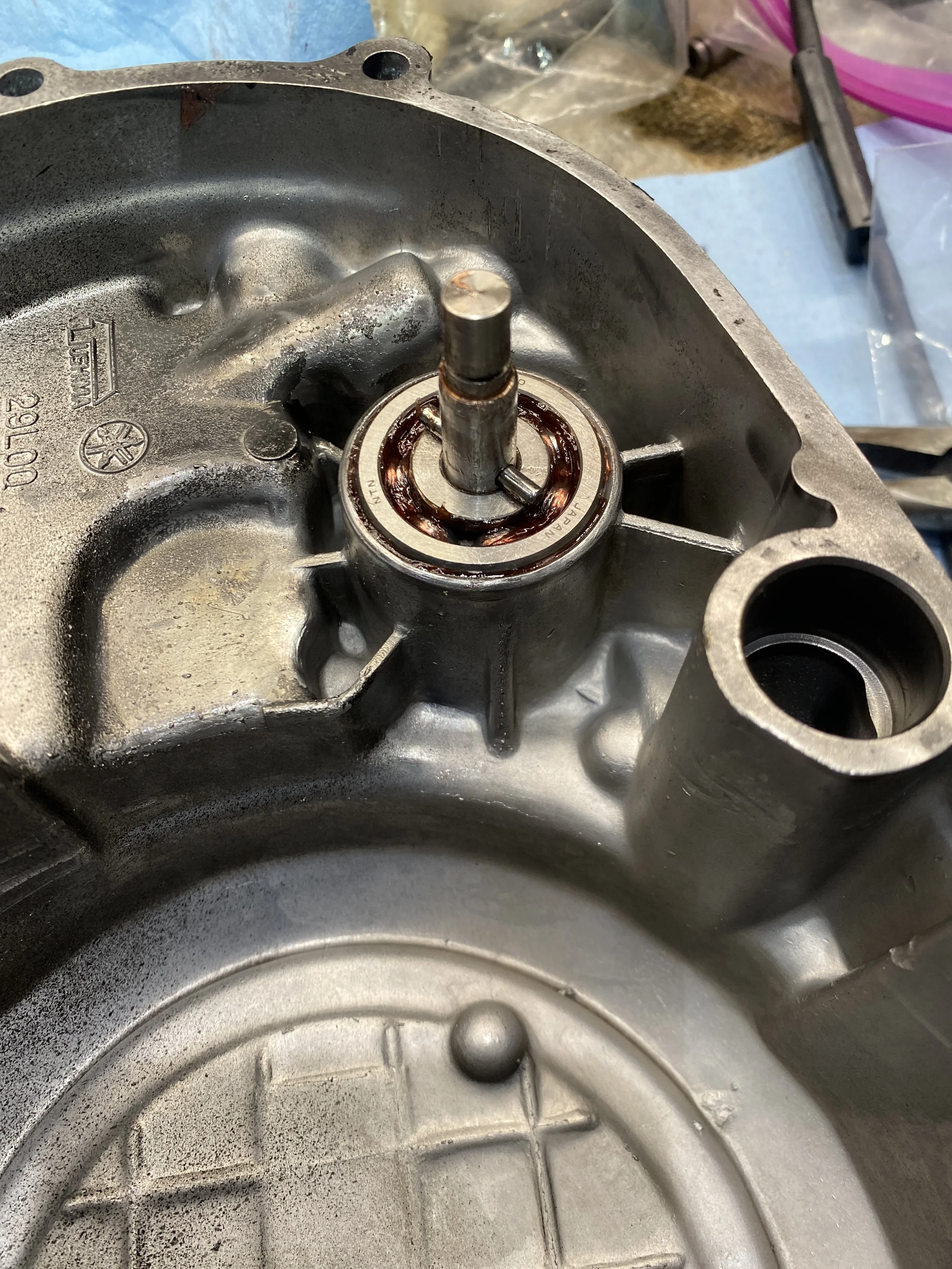

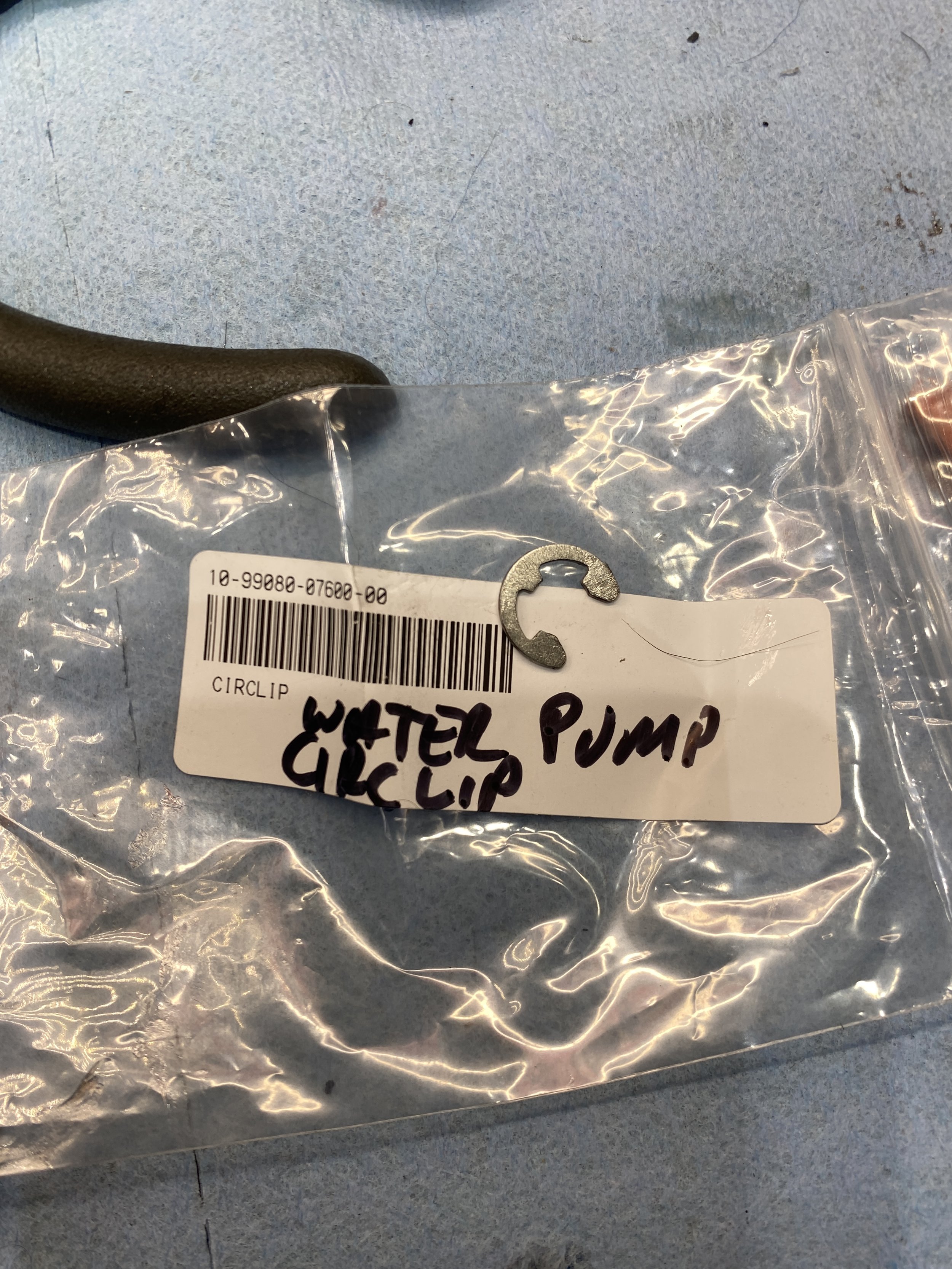

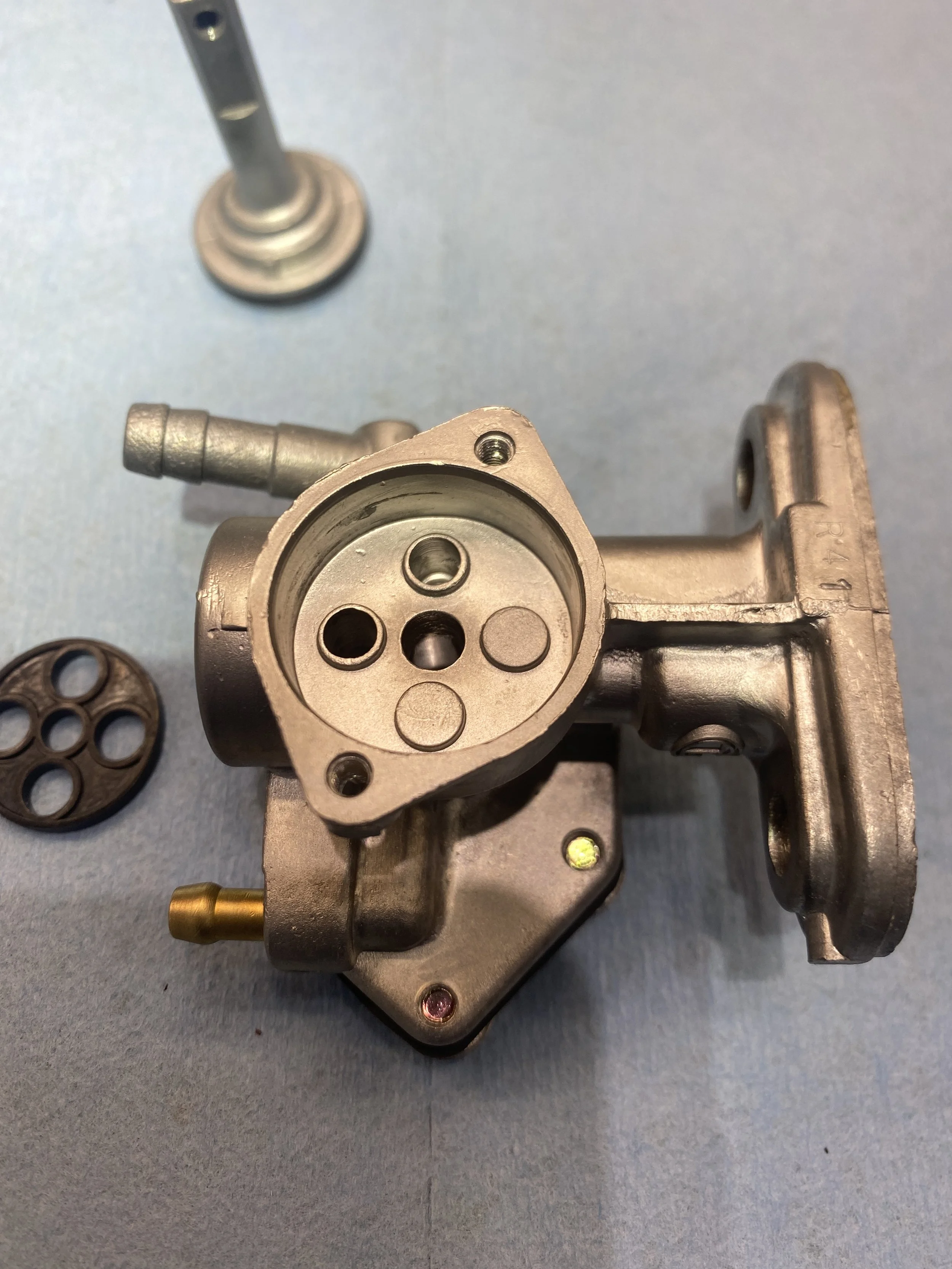

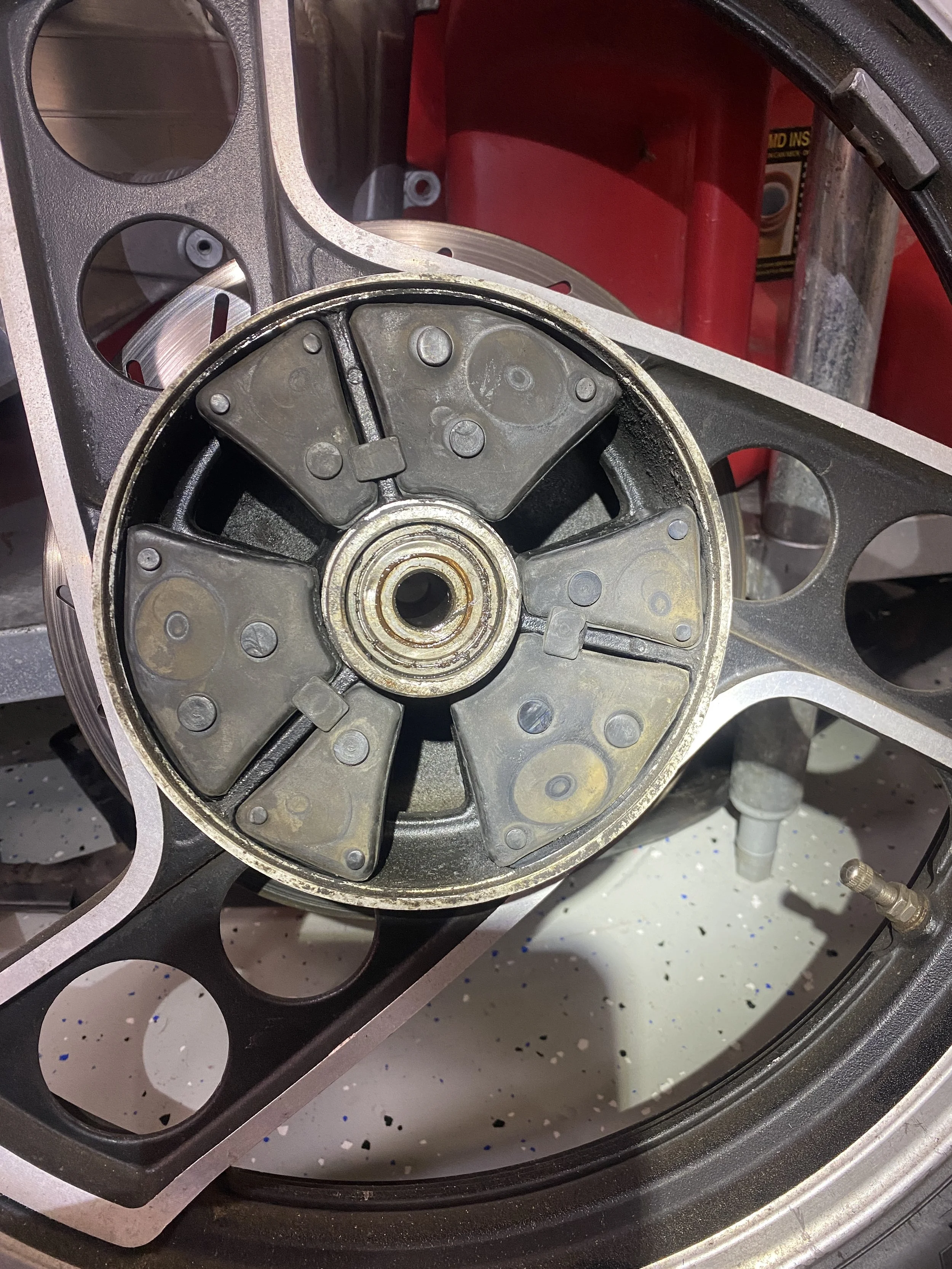

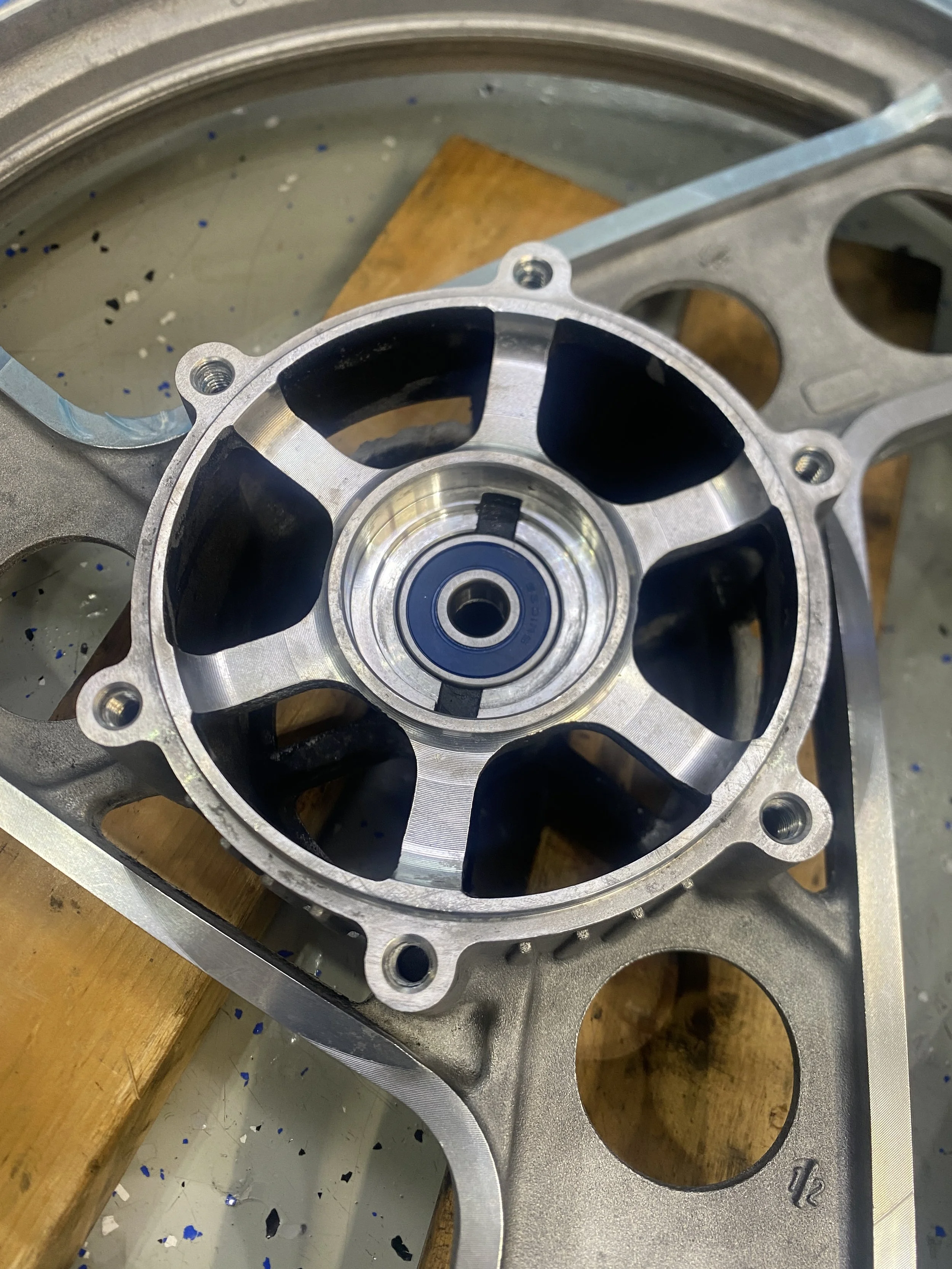

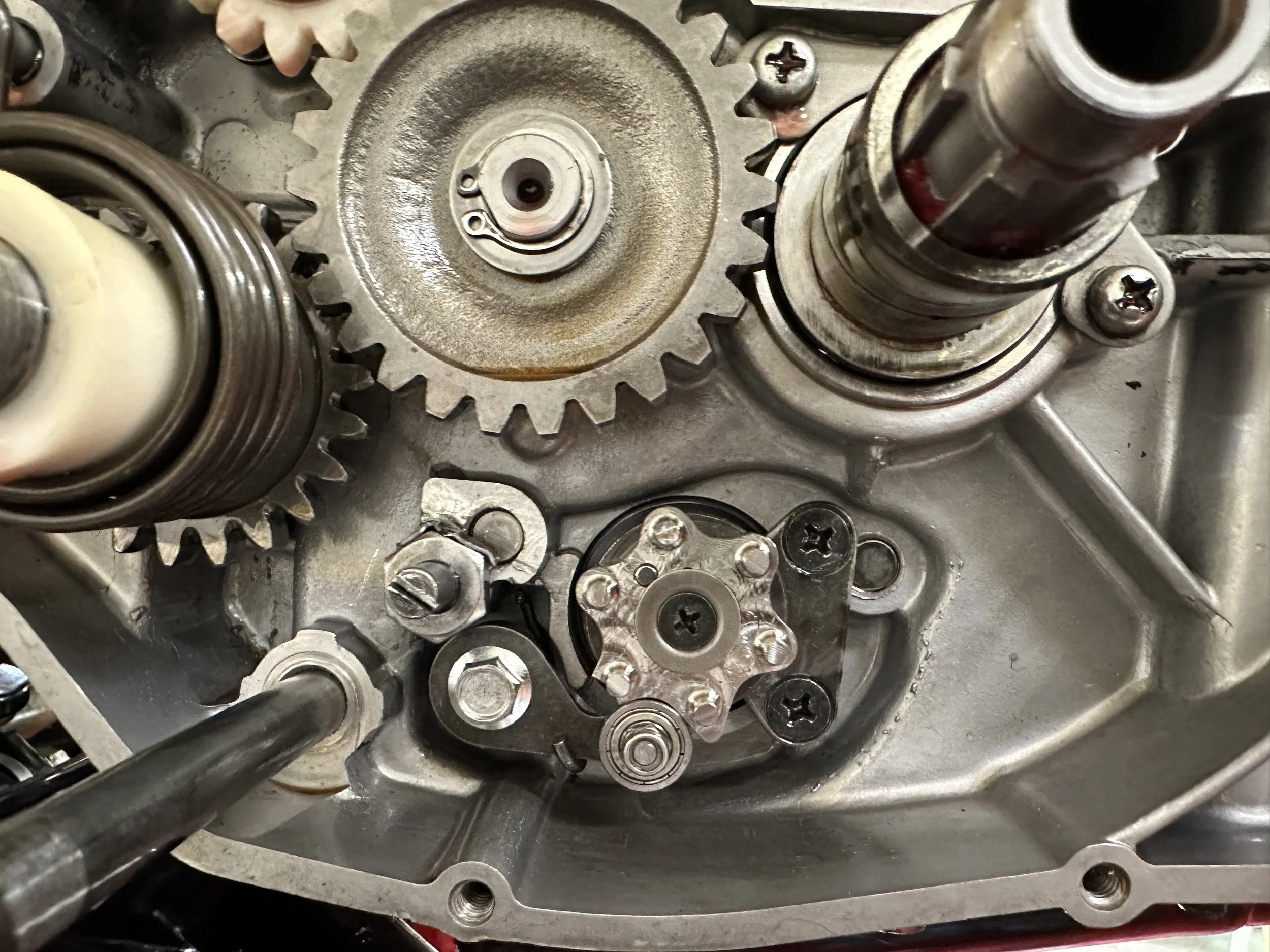

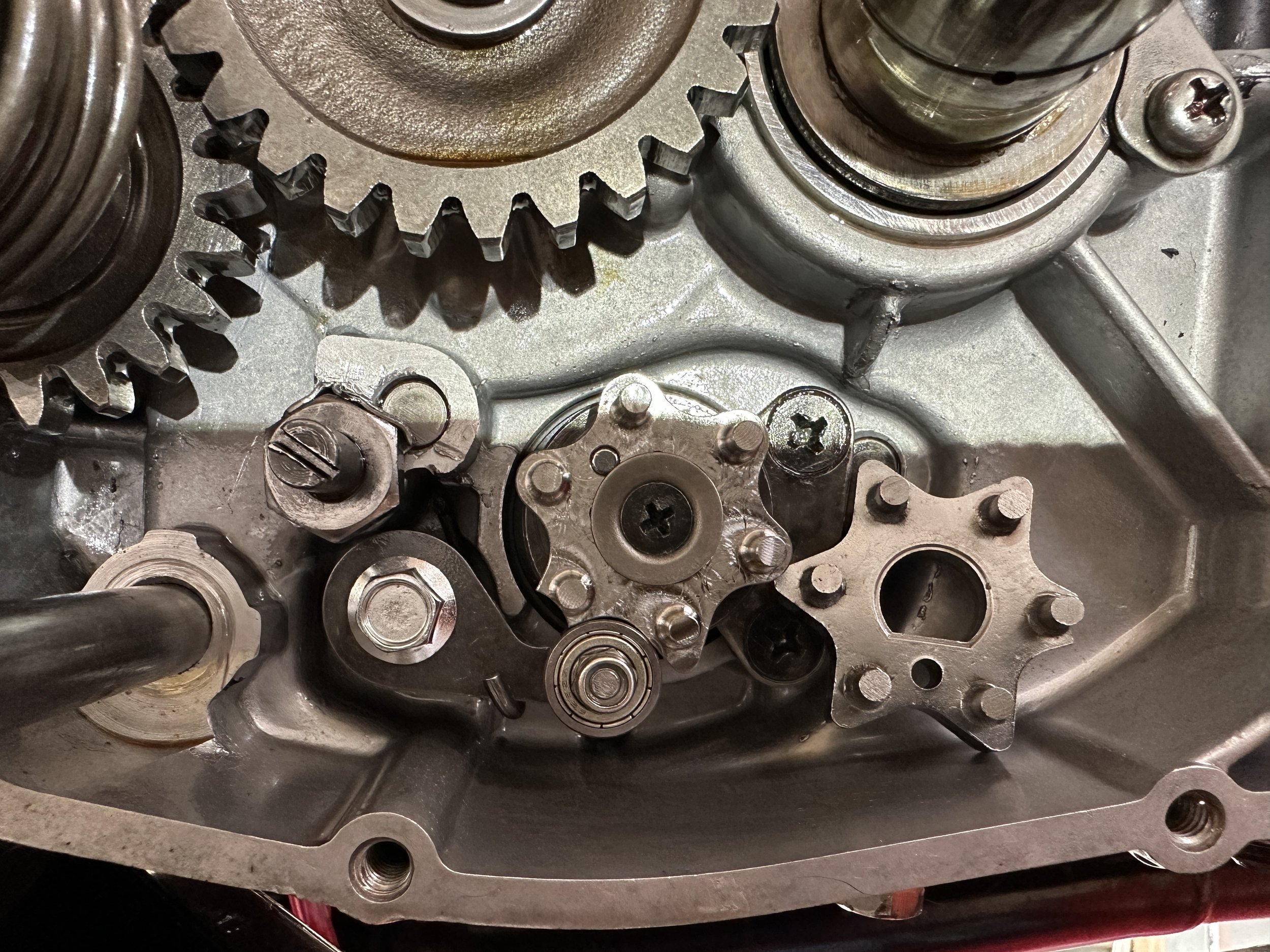

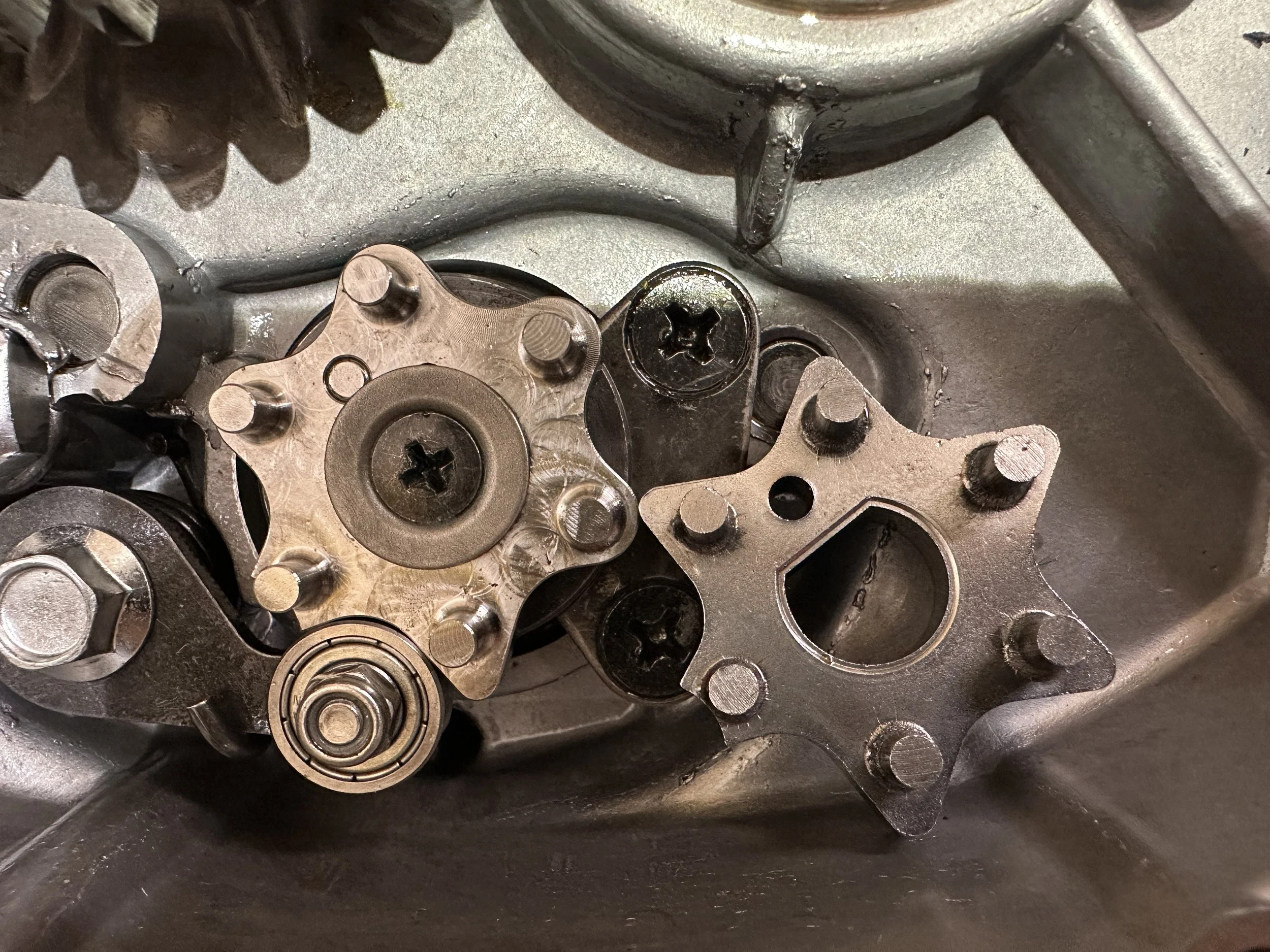

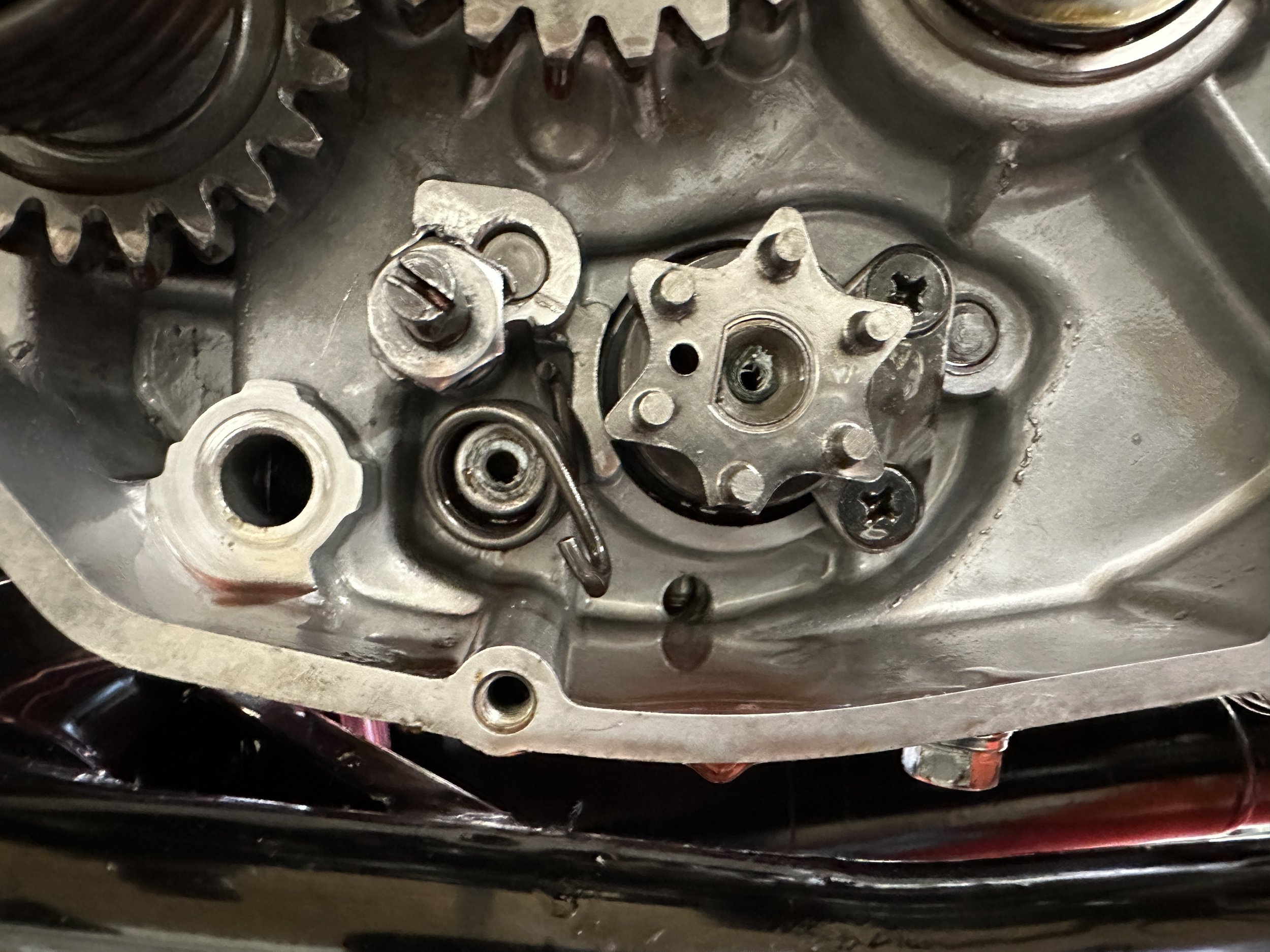

I've replaced a couple of these impellers before with the hardened metal versions from Norbo. Strange that the waterpump casing screws look untouched.

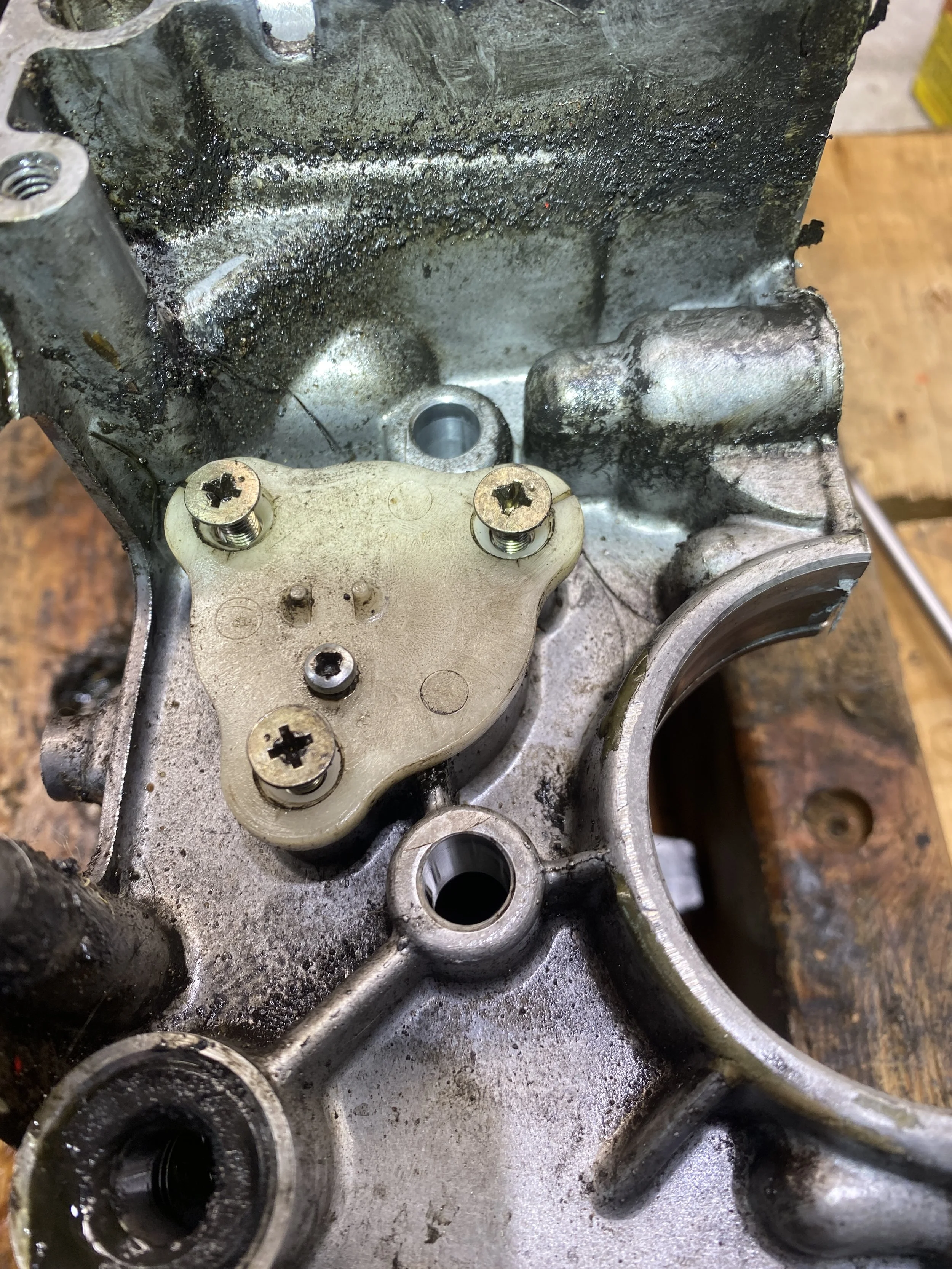

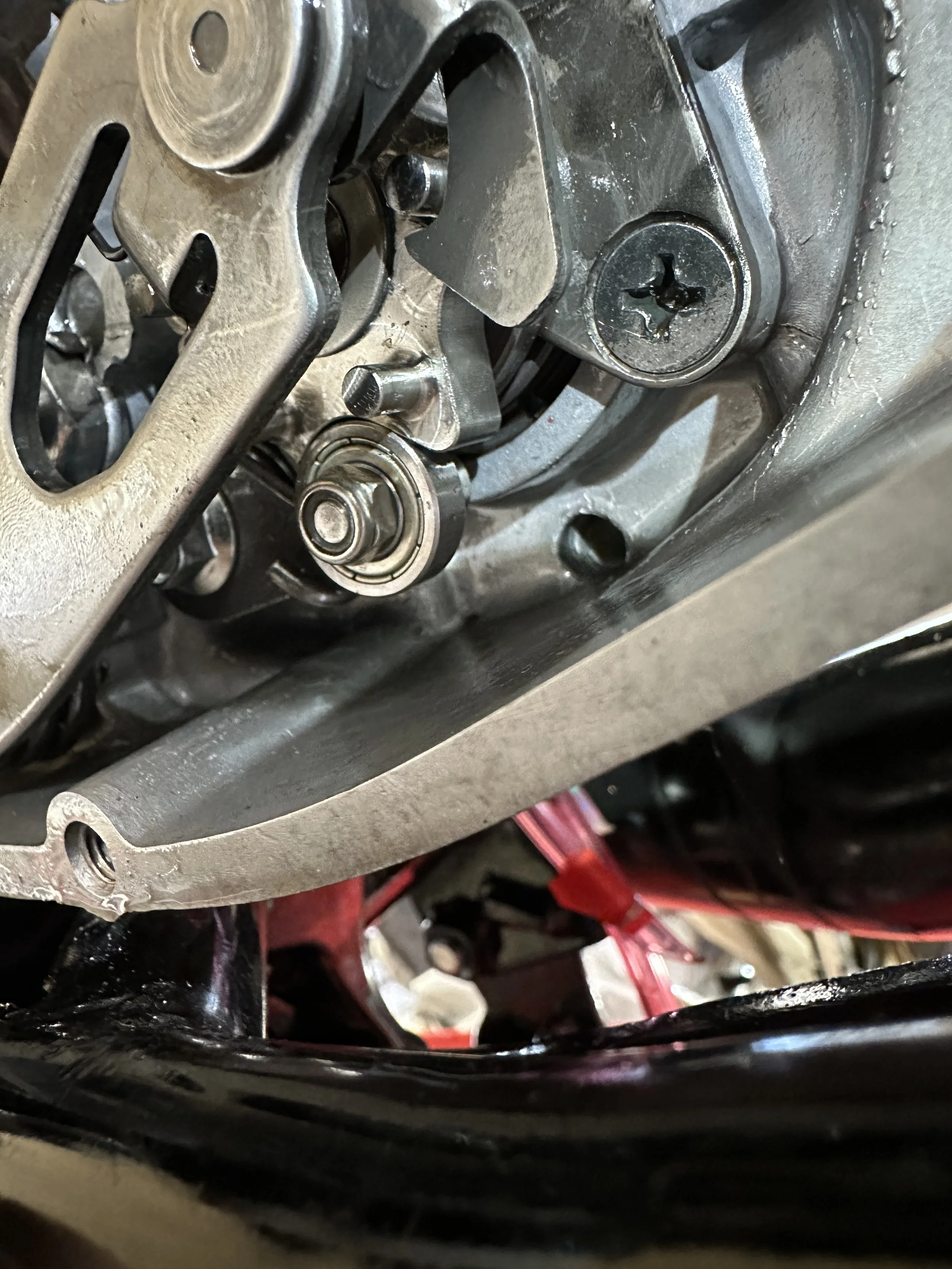

Unless the PPO was a fastidious mechanic and had a great set of JIS's, these screws have not seen a screwdriver since the factory....they are typically hard to remove and having the durability of cheese, it's hard not to disfigure them...case in point...

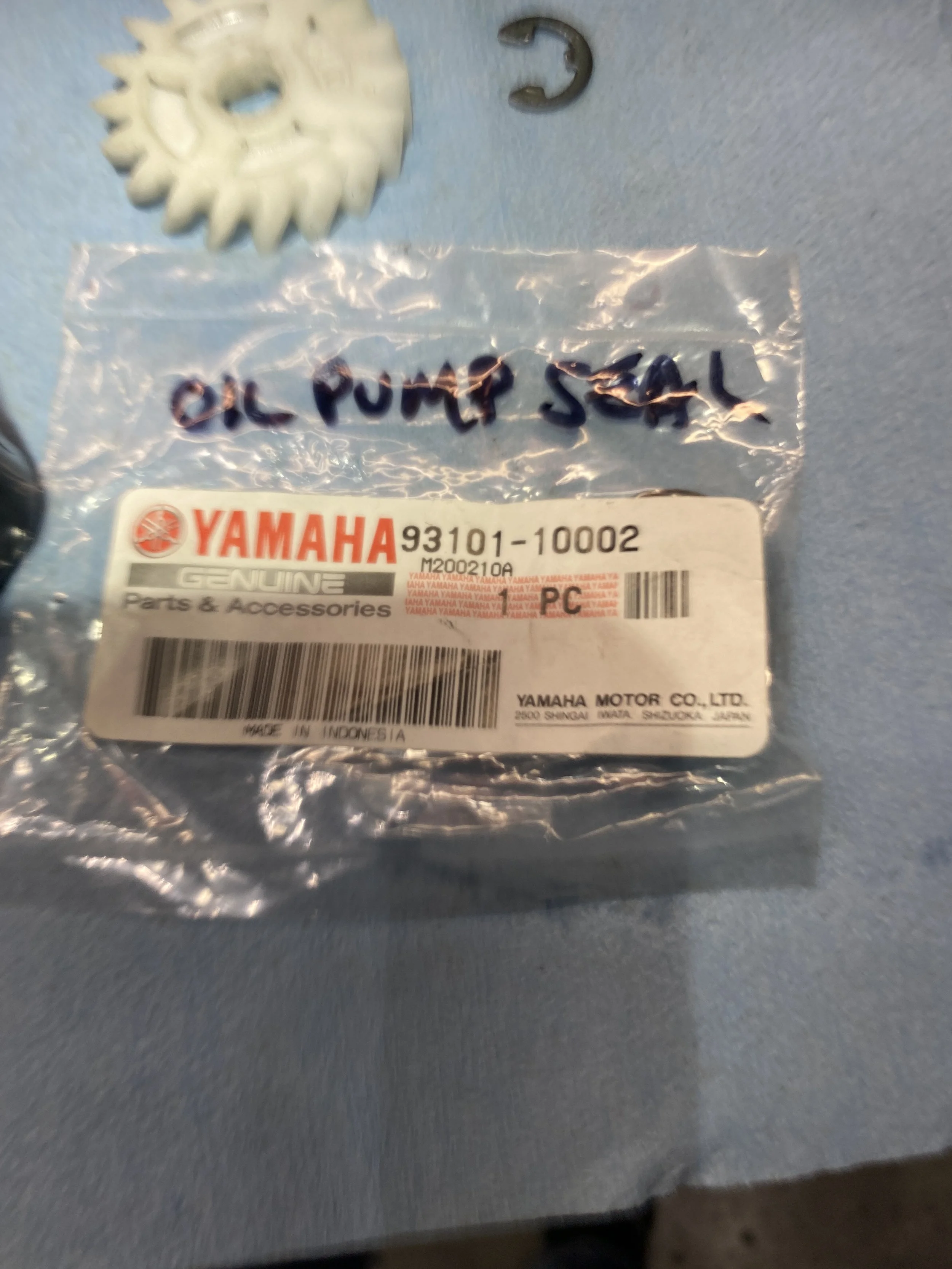

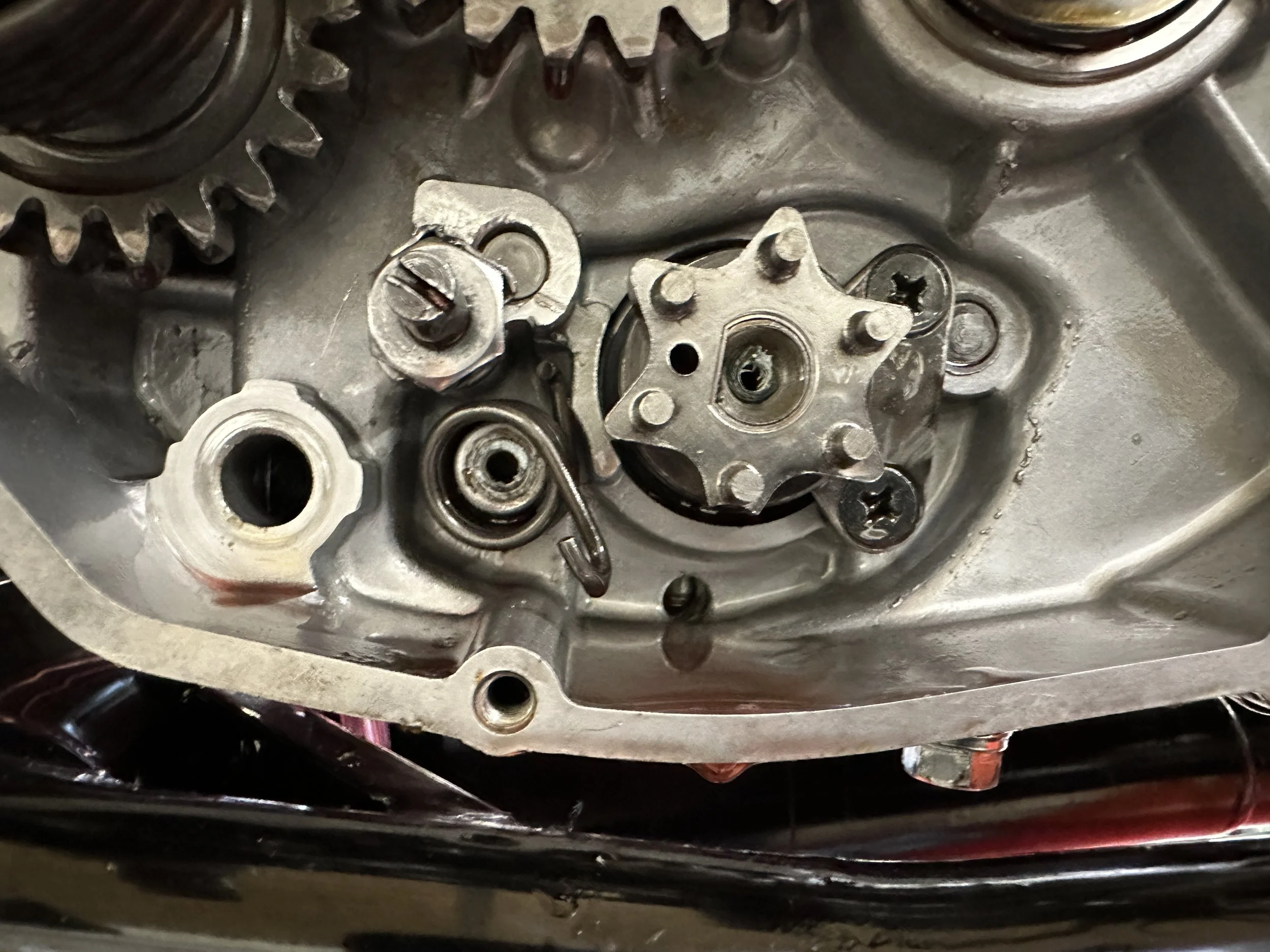

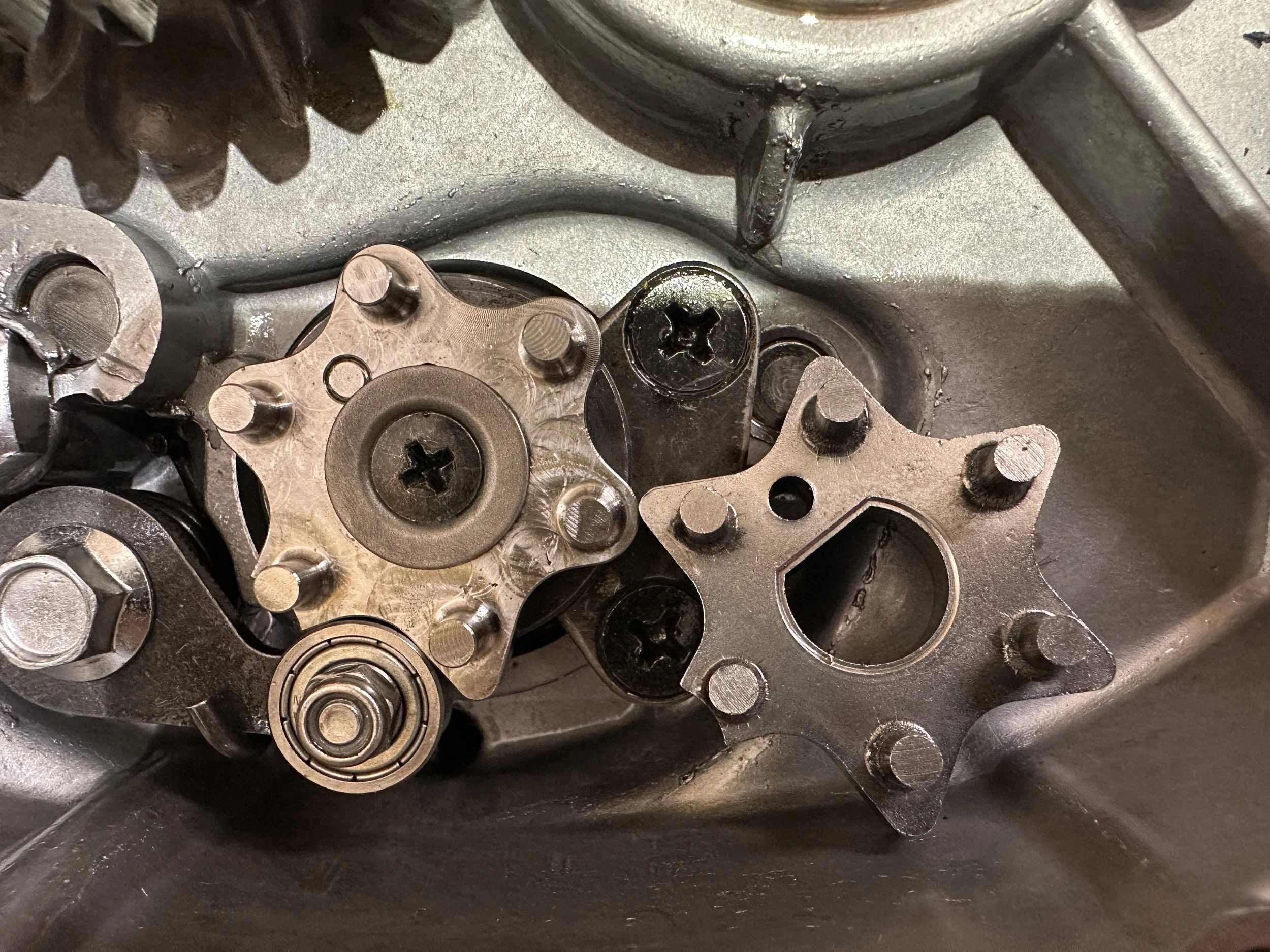

....the mounting screws of the oil pump...you can tell someone's been there before.

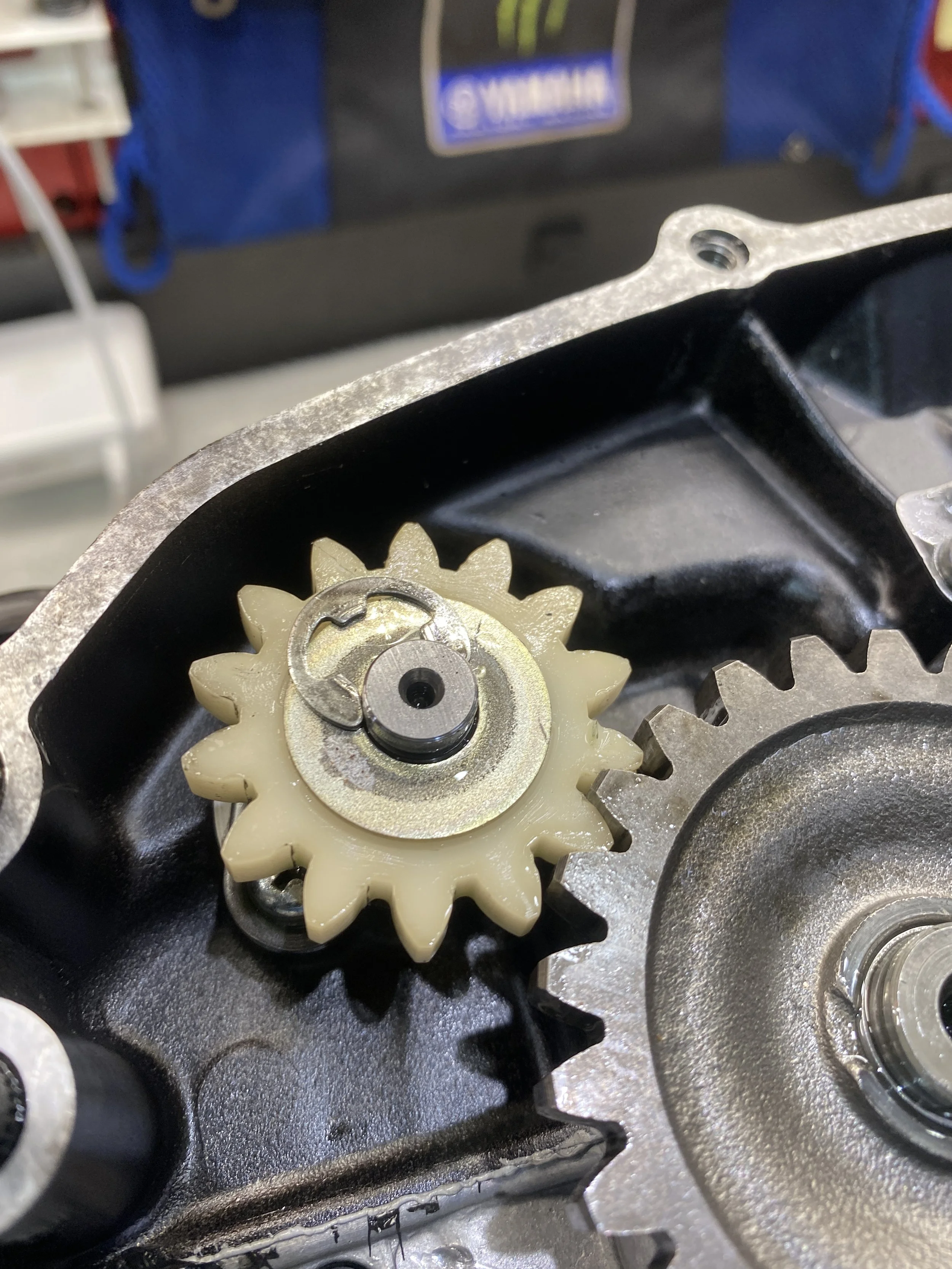

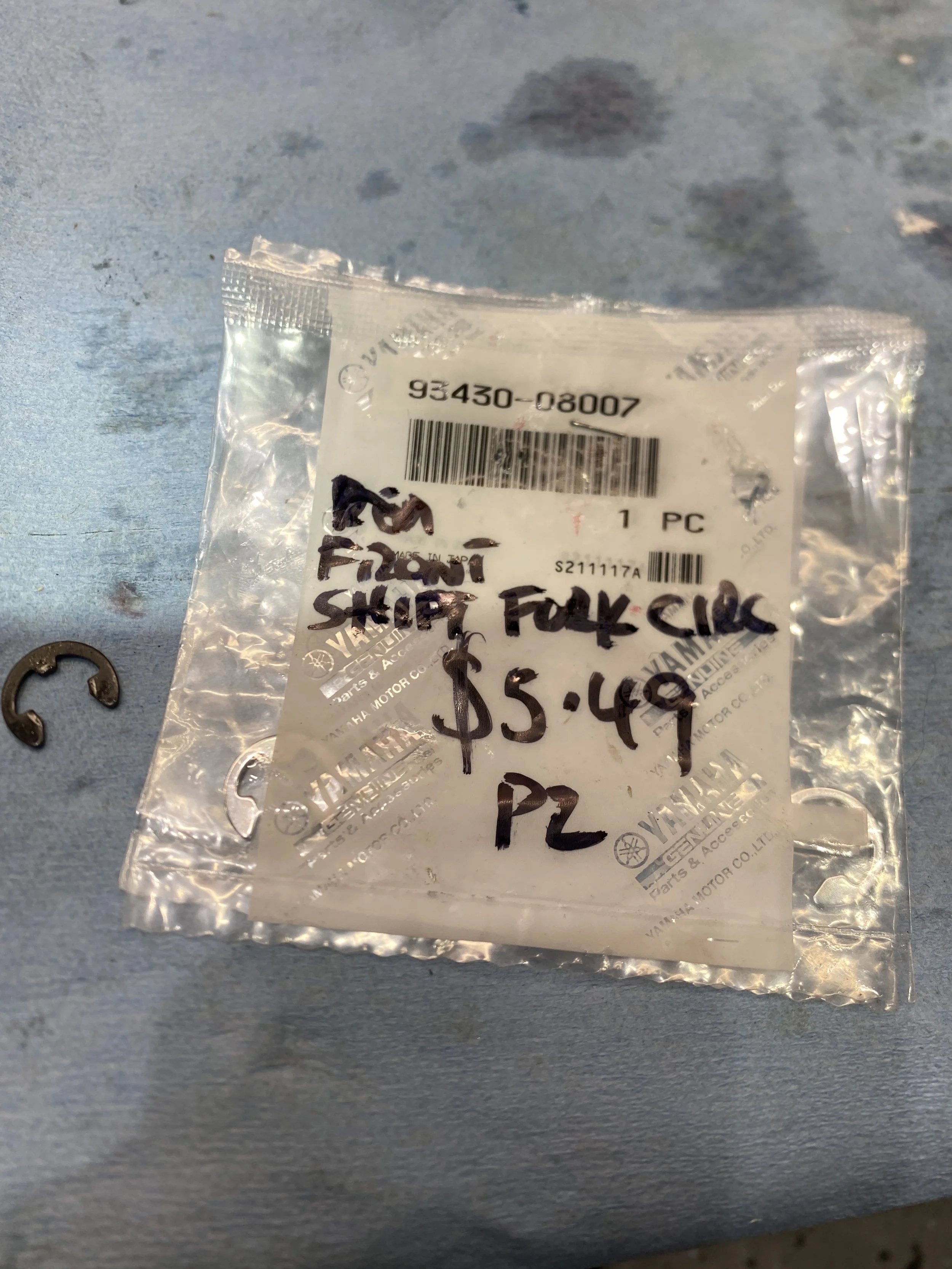

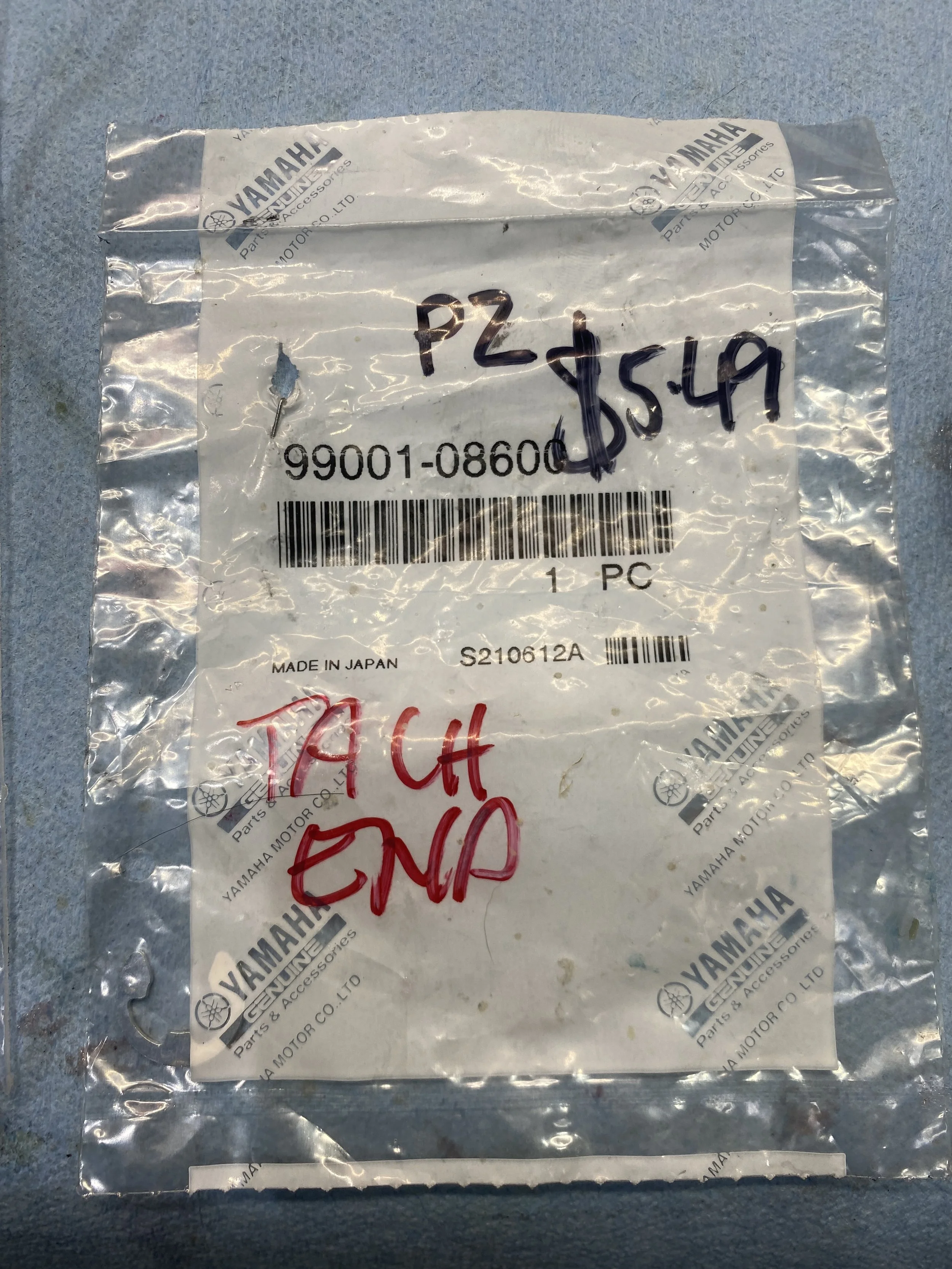

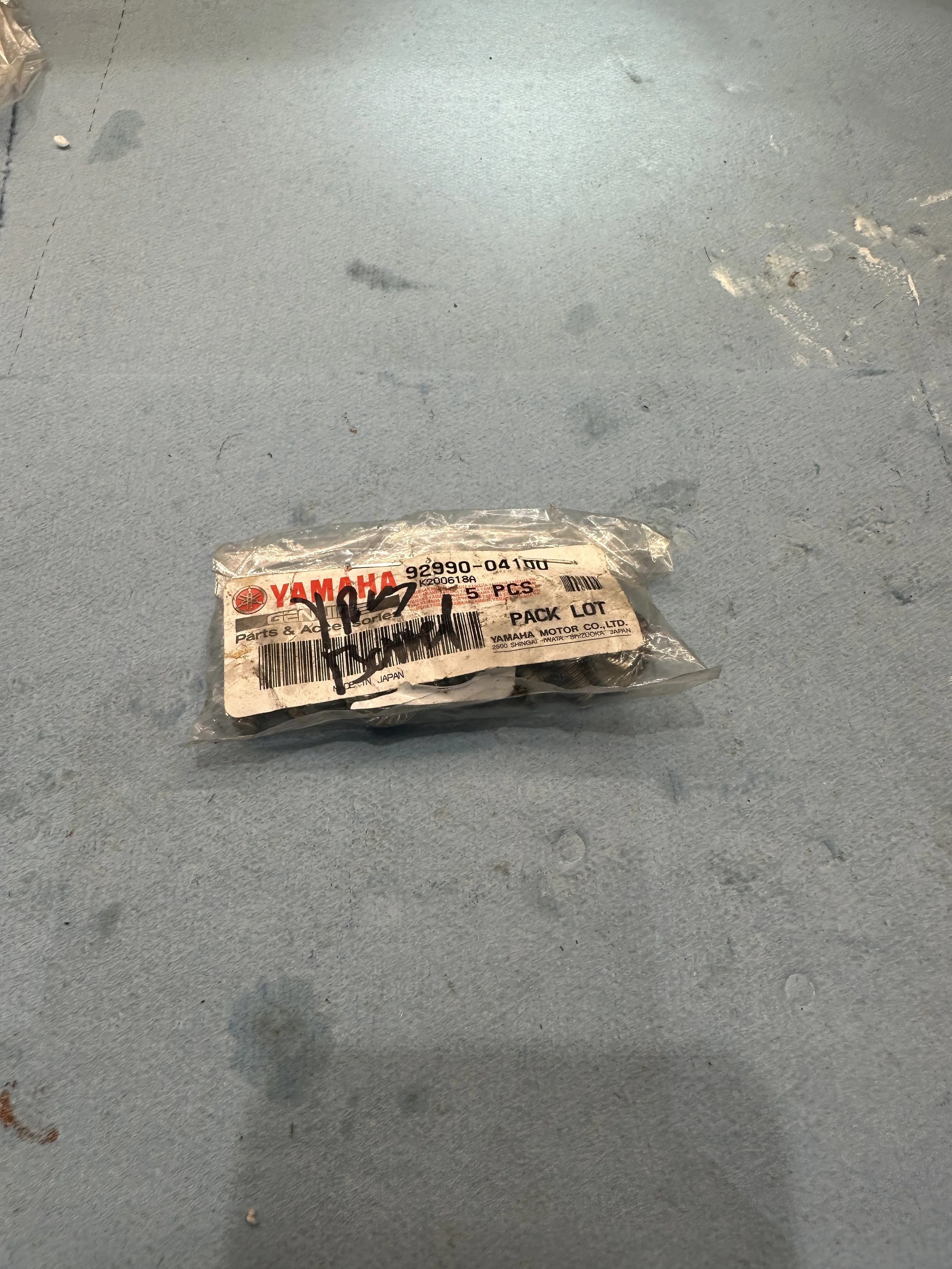

A quick Googling of this part number shows that this is packaging for a brand new oil pump worm gear. That's a used one in the packet. curious what happened there. Oil pump looks good.....

....took it off and sending it to oil pump specialist Arrow from the RDLC Forum for a refurb.....8 month wait!

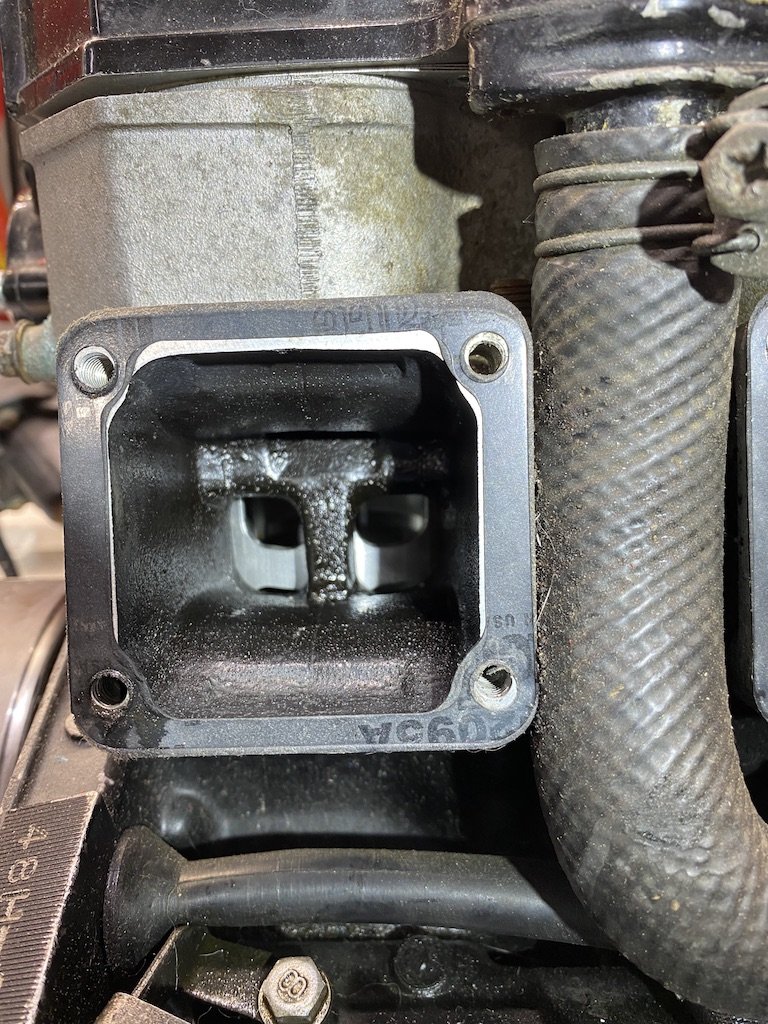

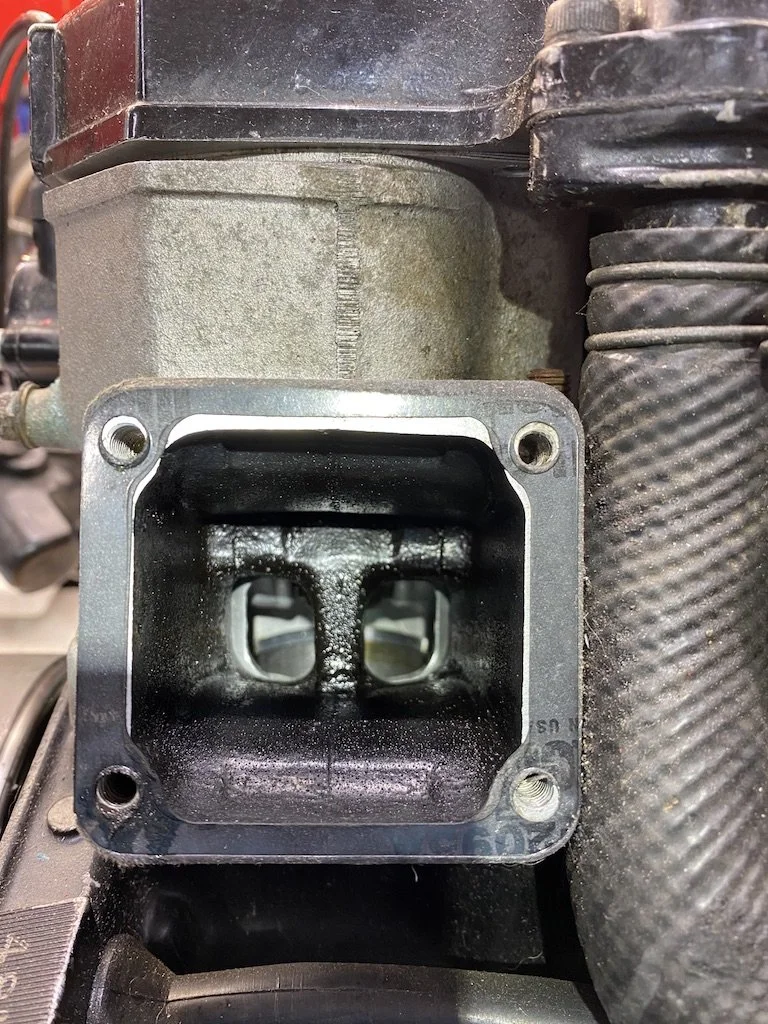

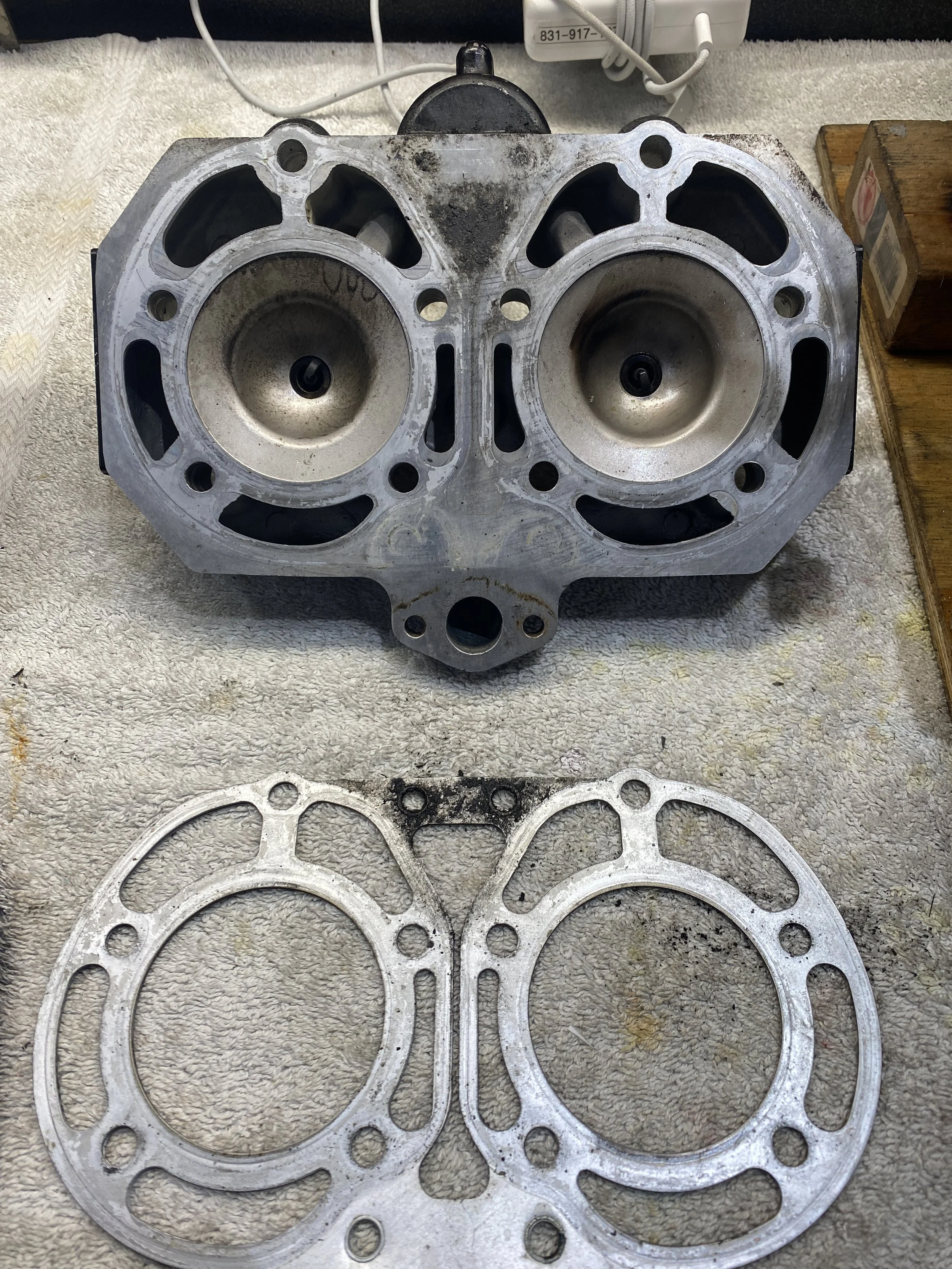

These look like the OEM factory reed petals and stop plates- must be something else in the motor now....

...that supposedly works better with a bright shiny spacer seen here ....perhaps to stop the tips of the aftermarket reeds from hitting the intake side of the sleeve. We will see in time.

OEM metal reed gaskets with Yamabond?

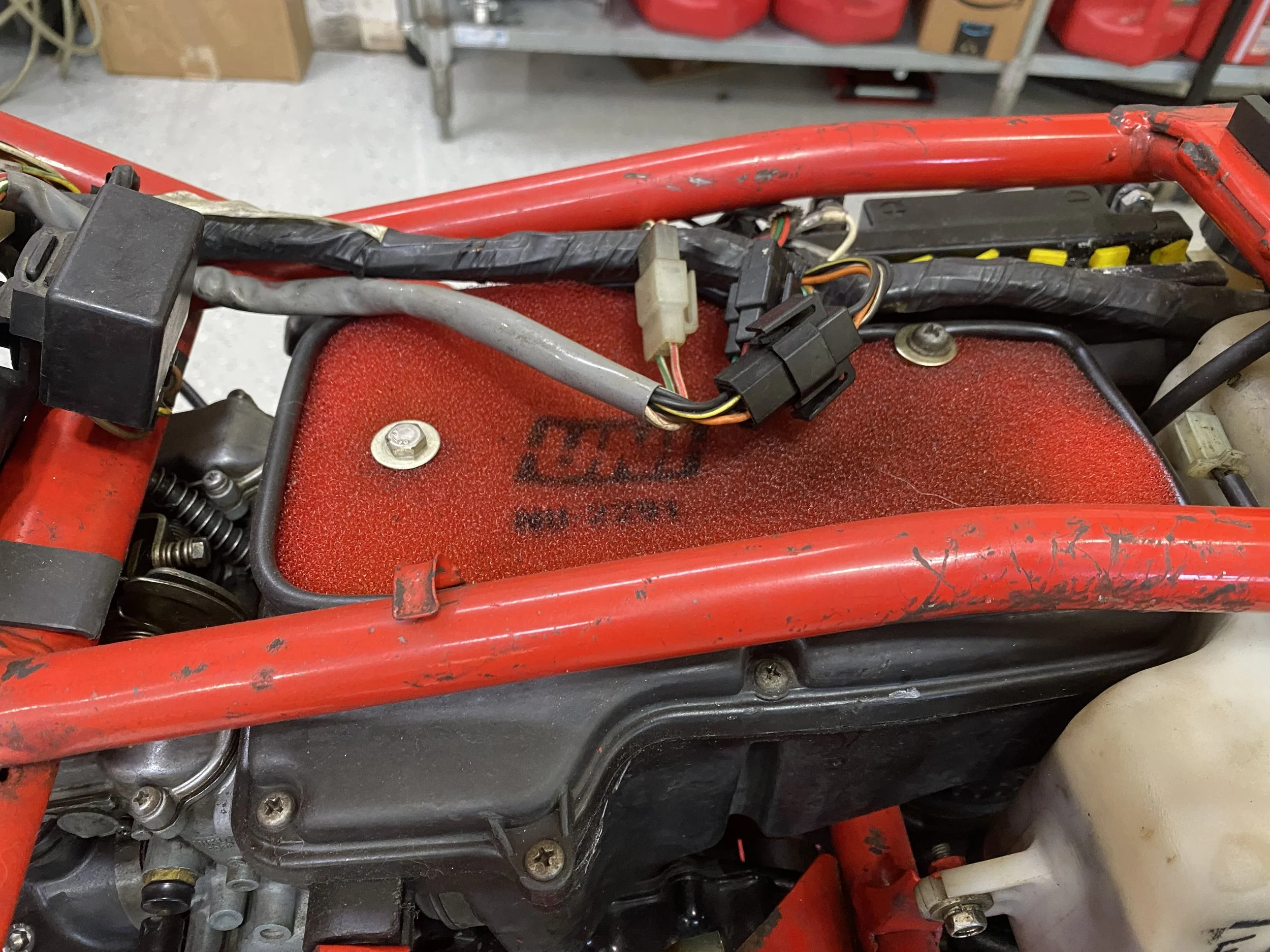

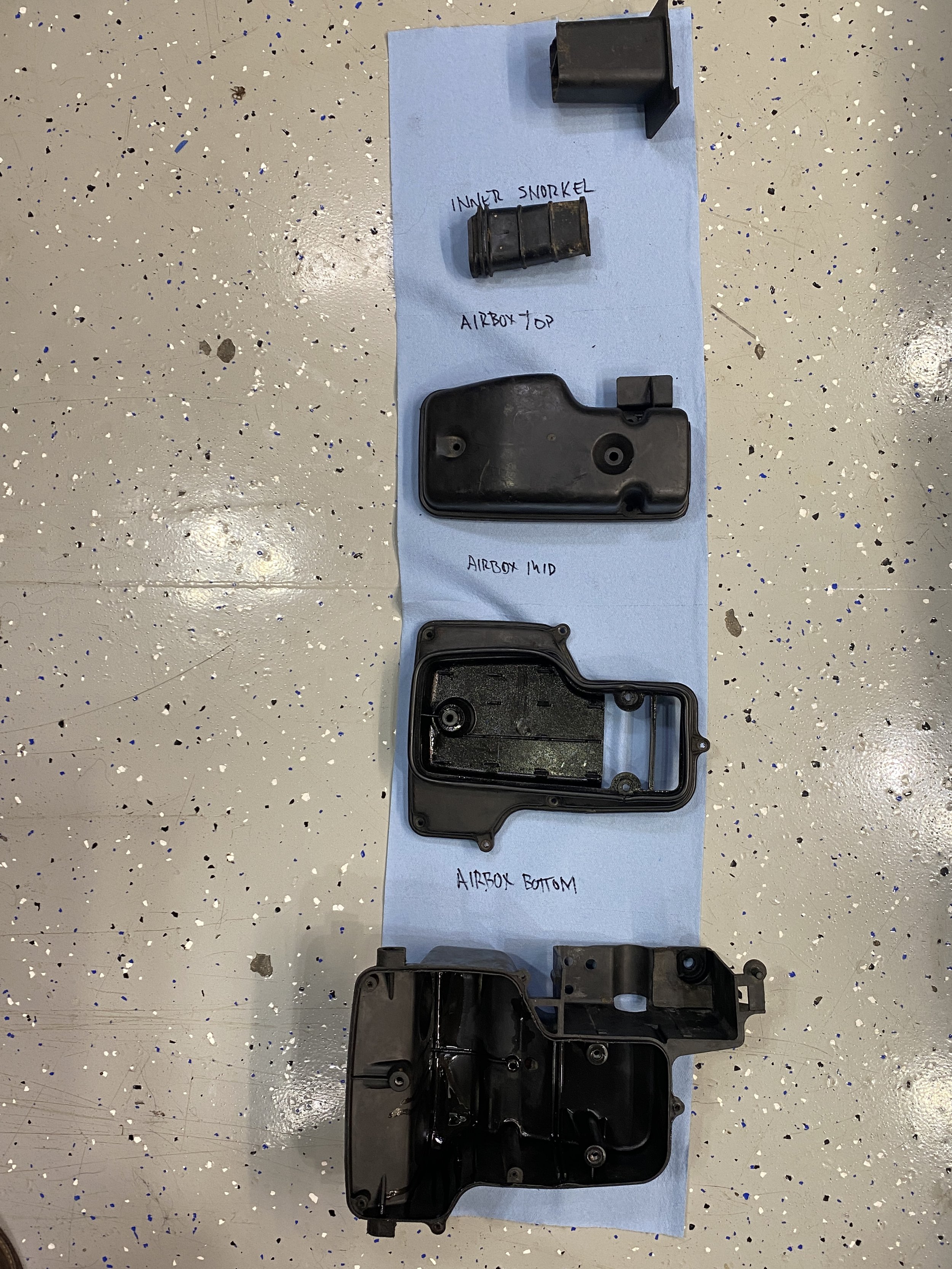

The top off the airbox?

Yes....it was running without. Will be intersting to see what the jetting is....

This isn't from a coordinated plug chop or anything but I think you can safely say it's not running lean.

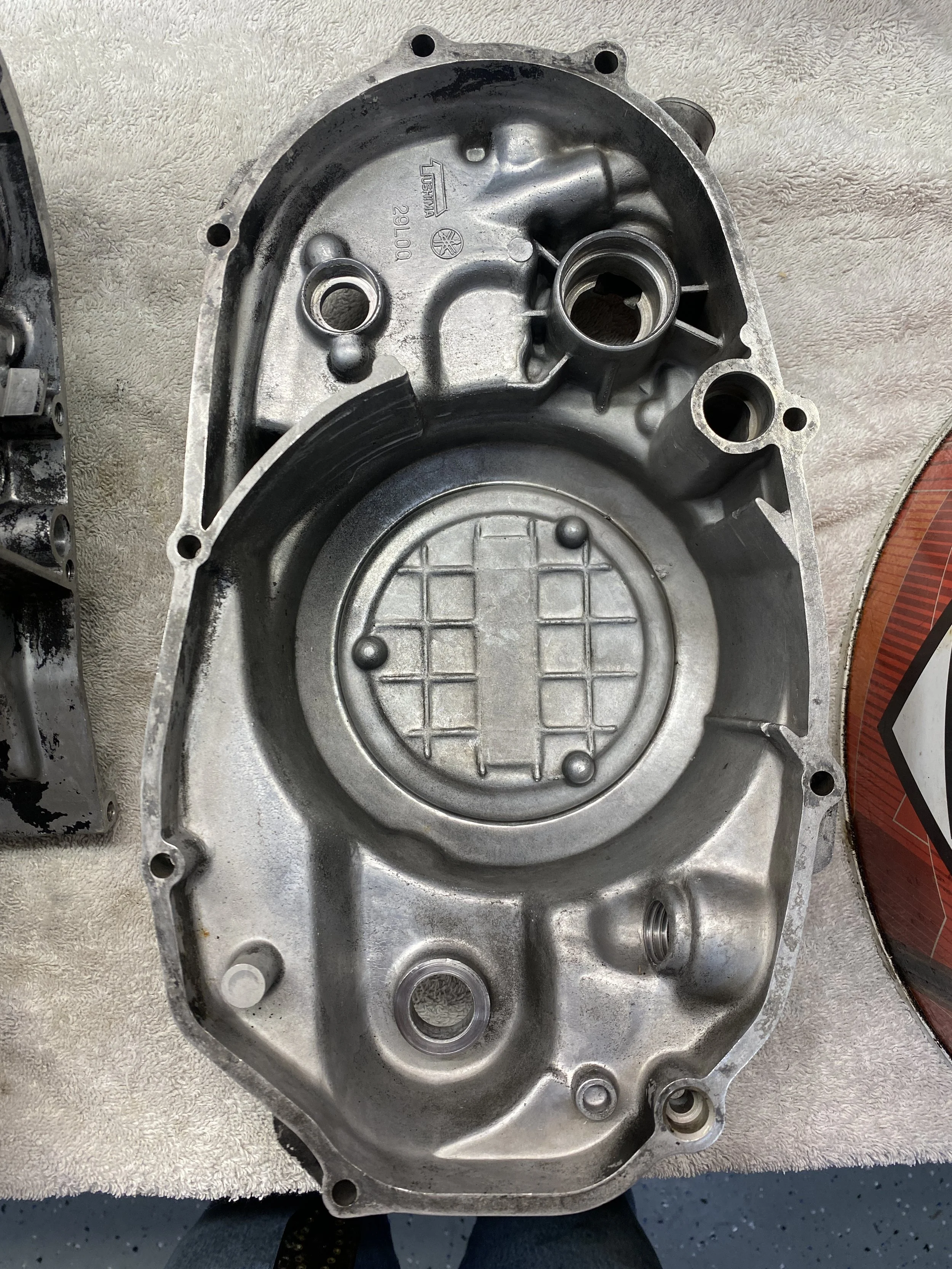

This road rashed cover was in the box of spares...new ones are available from Norbo at https://www.rdlccrazy.co.uk/

....replaced with the tuning forks emblem. Will need a new water & oil pump cover too....can see light through it.

What's this from.....?

Aha! maybe this is fixable.

A closer inspection of the tank tells me that....

....I should really consider getting a replacement....but not from India.. A good friend of mine told me that the RZ250 tanks are exactly the same...and Japan is awash with them. I've got time.

I recognize these but can't put my finger on where I've seen them before.

After some months of inactivity, Thanksgiving came along and gave me room to breathe…and get back in it.

you have to admit....from this angle it's hard to see what needs done to it....

or even...from this angle...

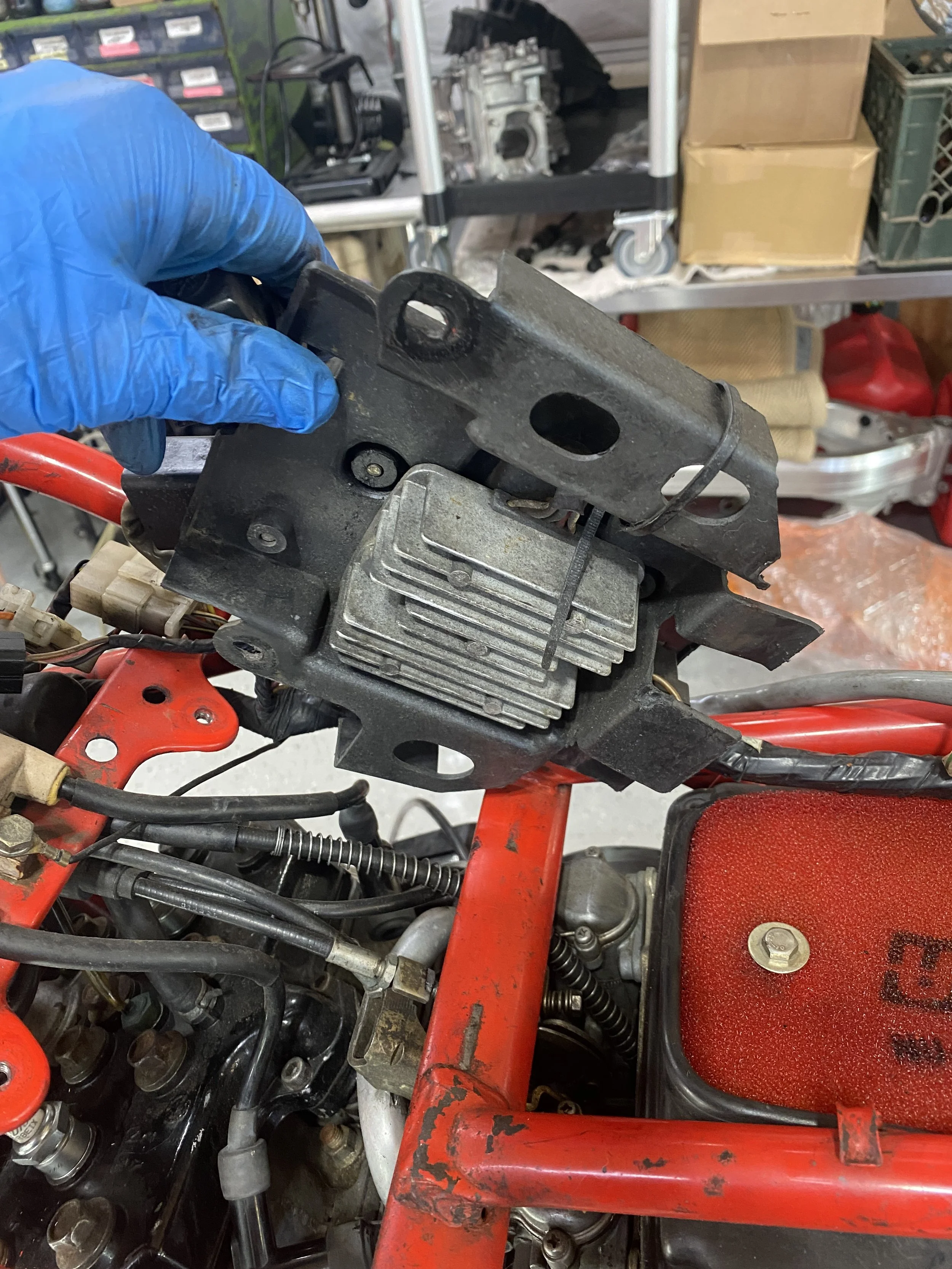

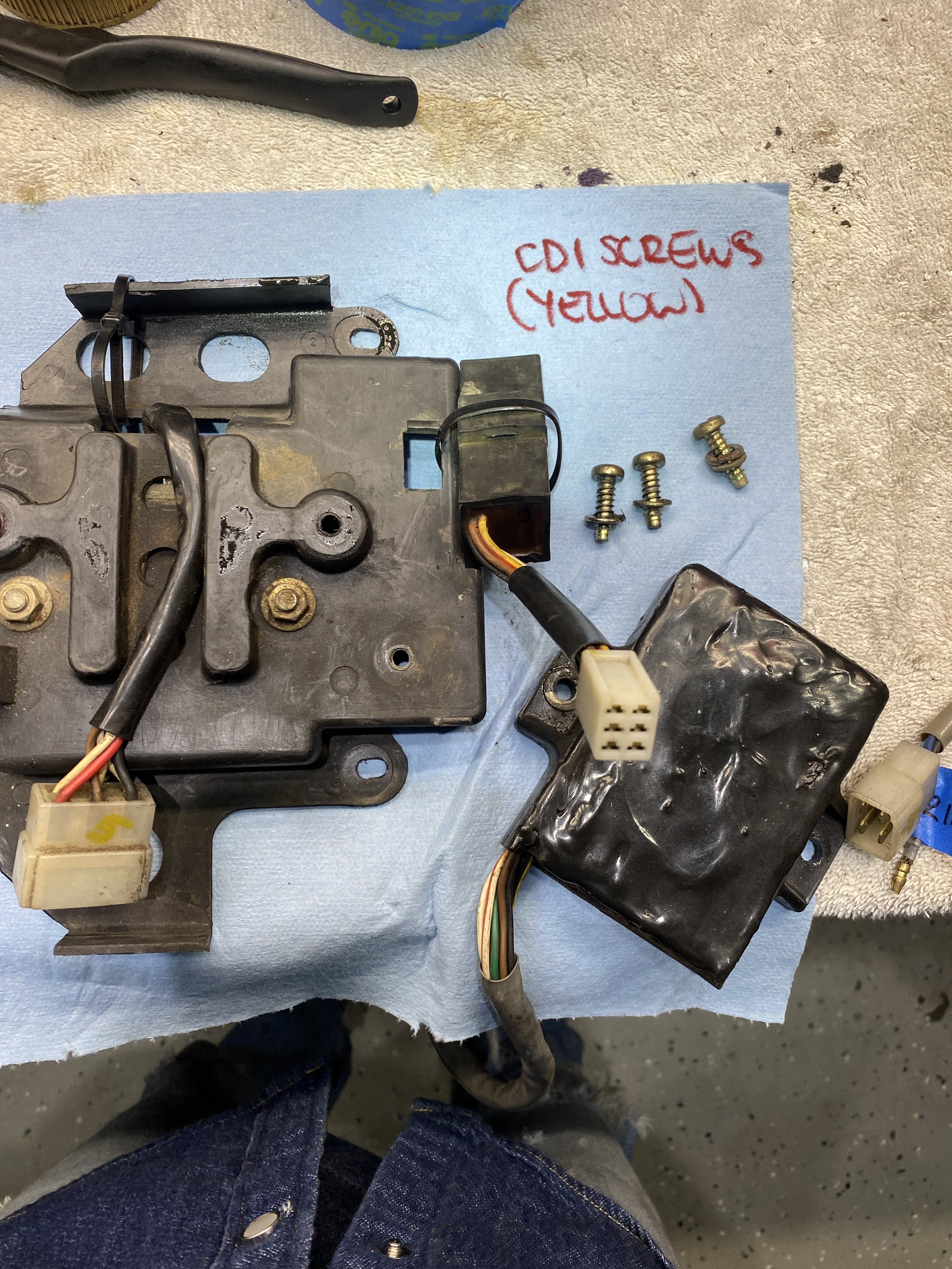

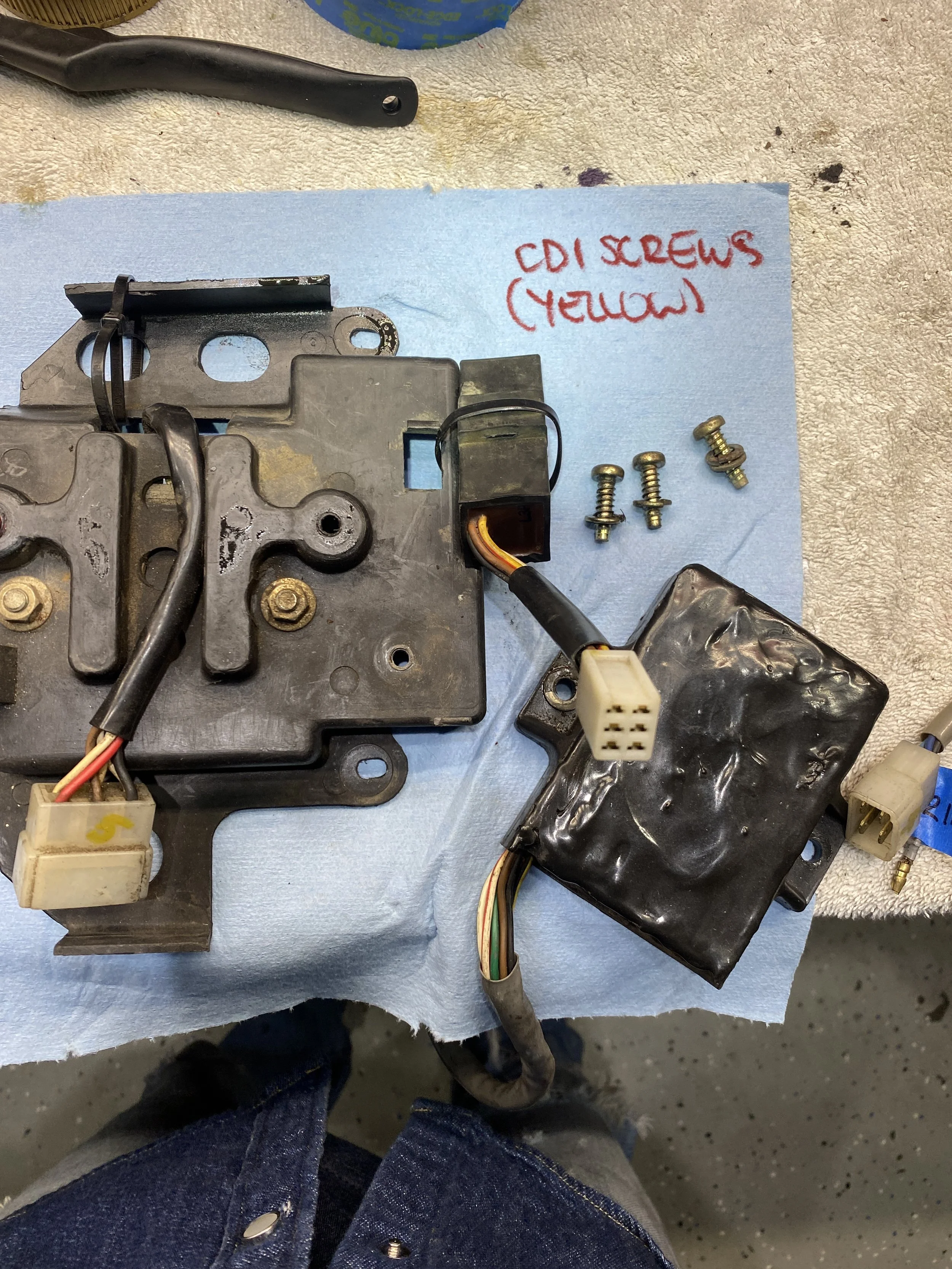

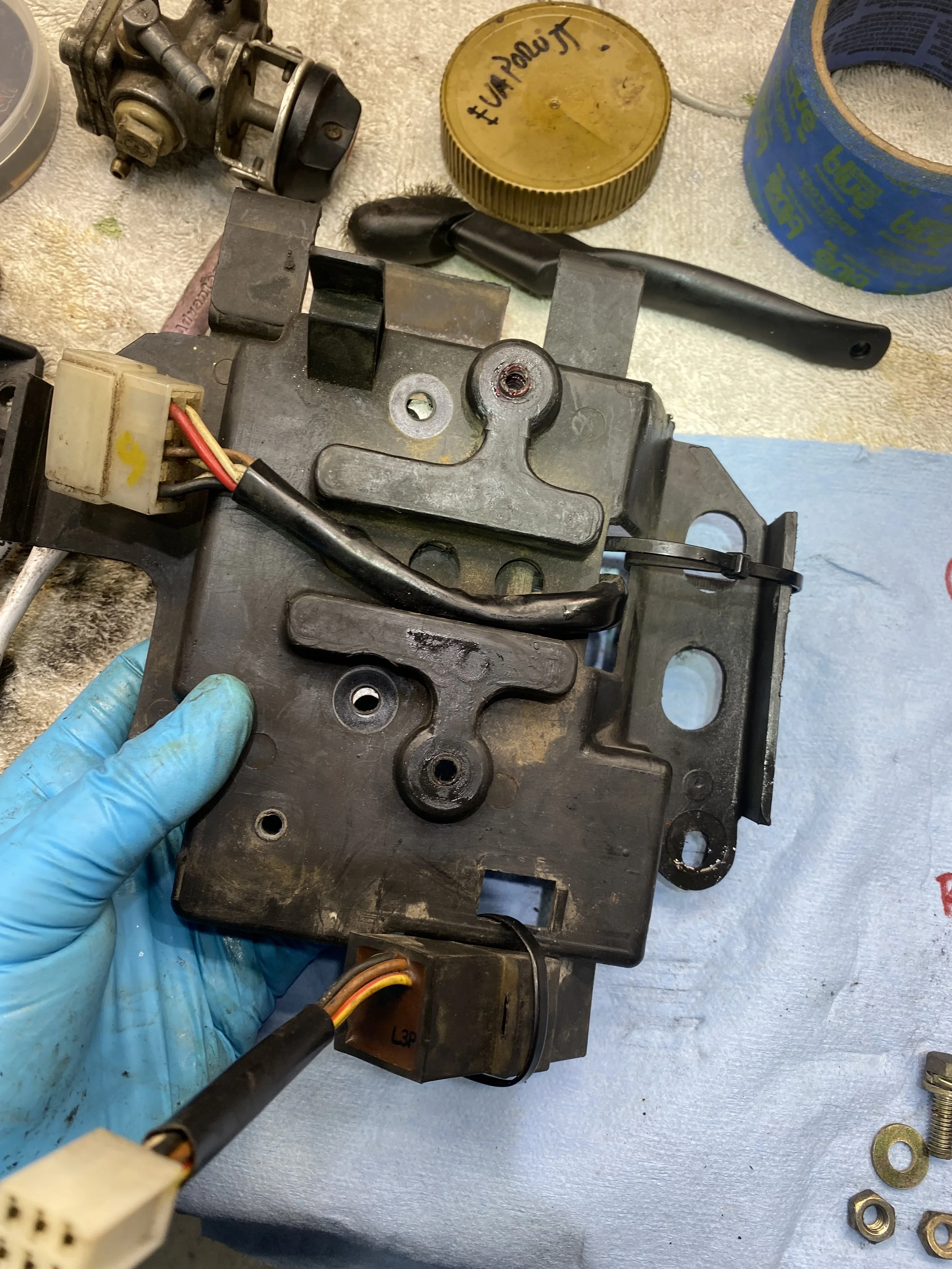

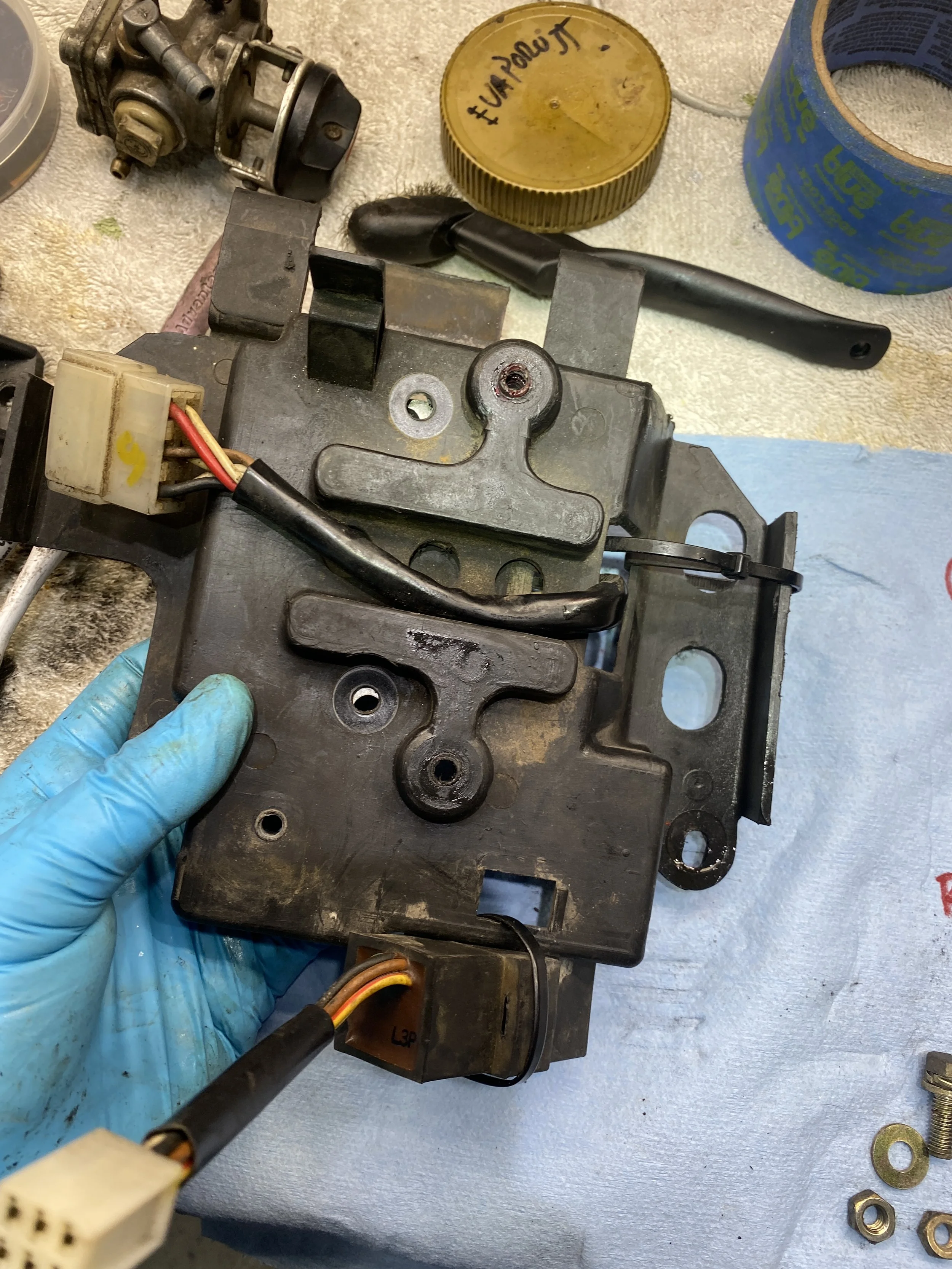

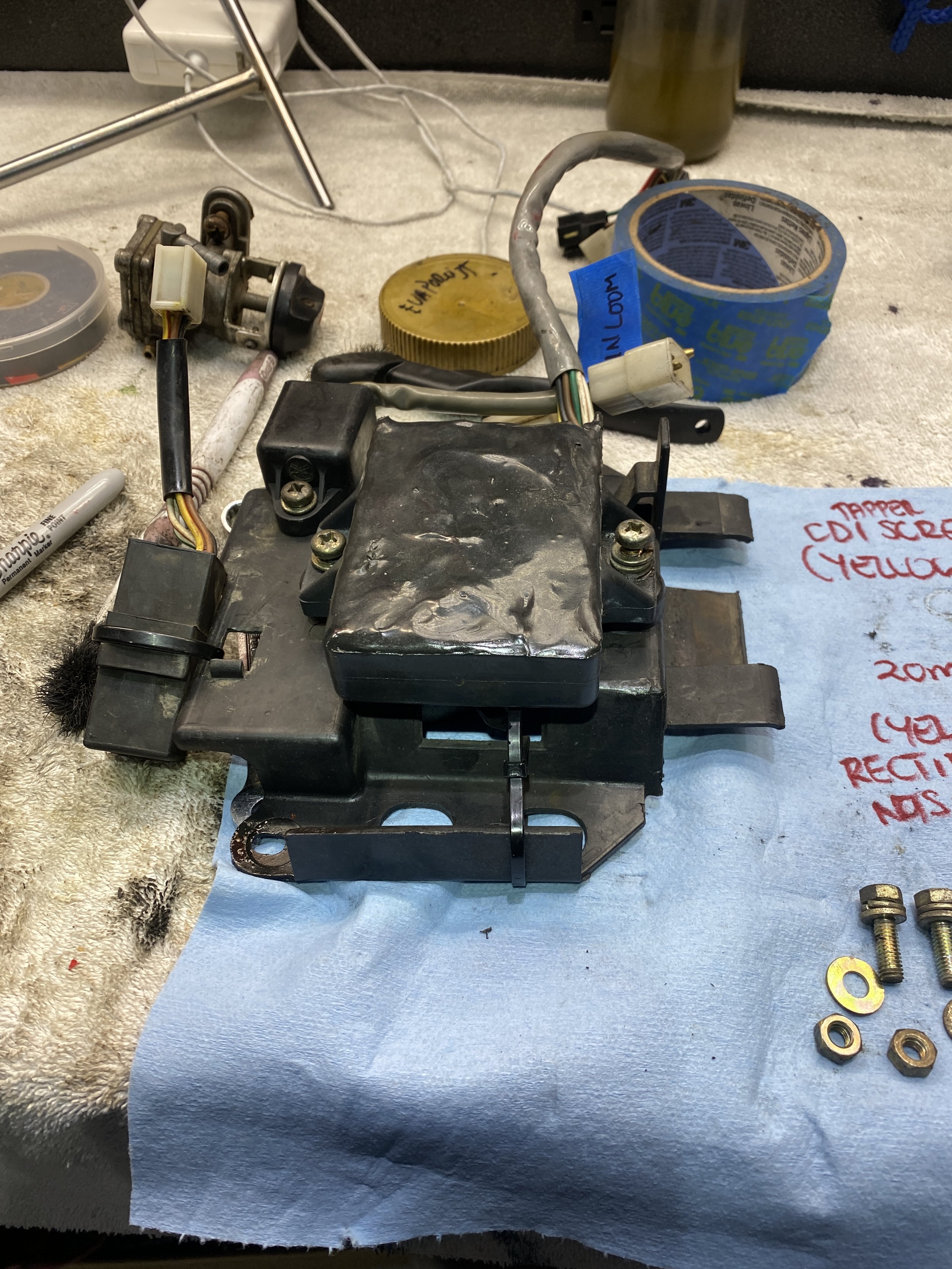

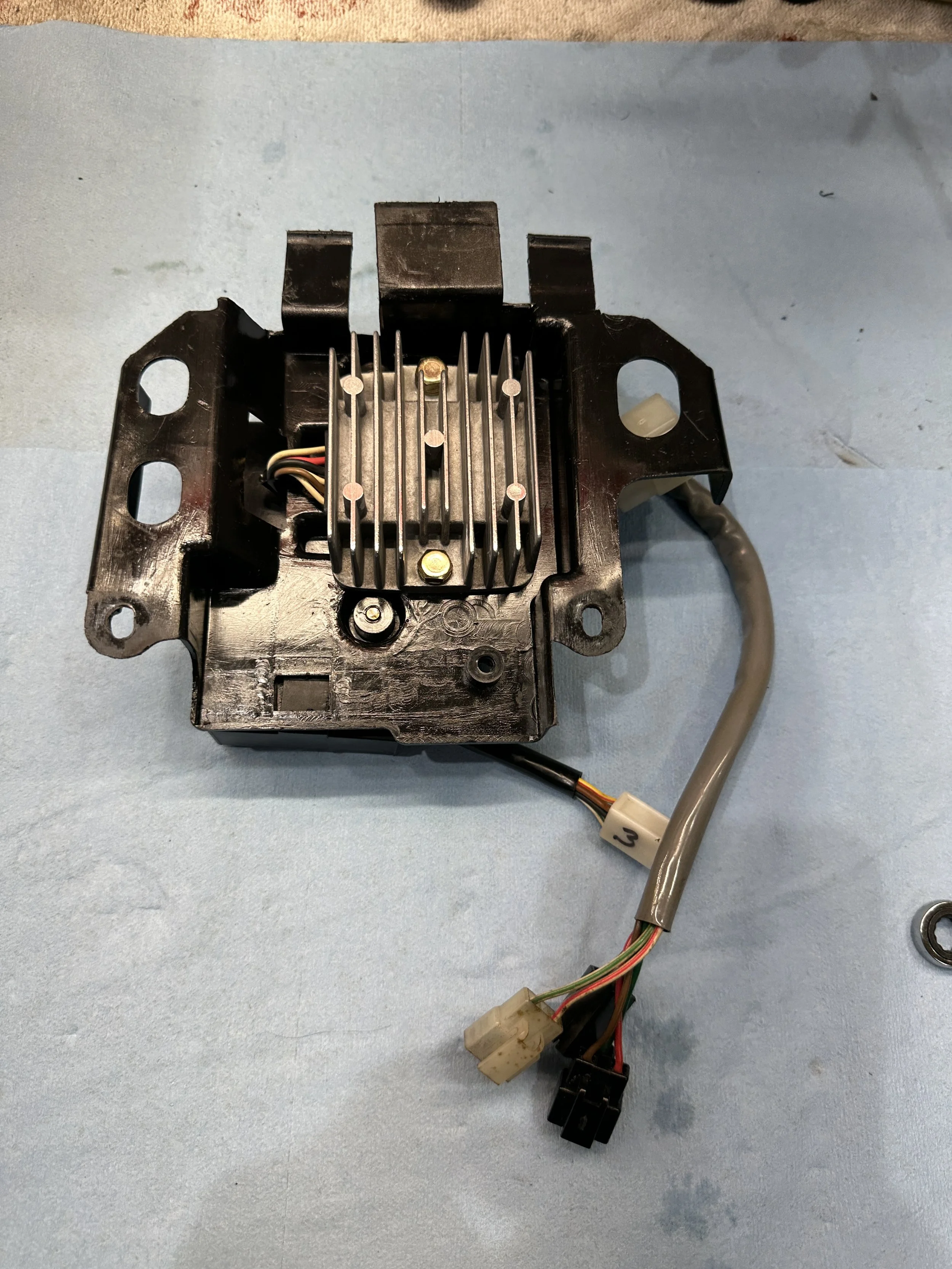

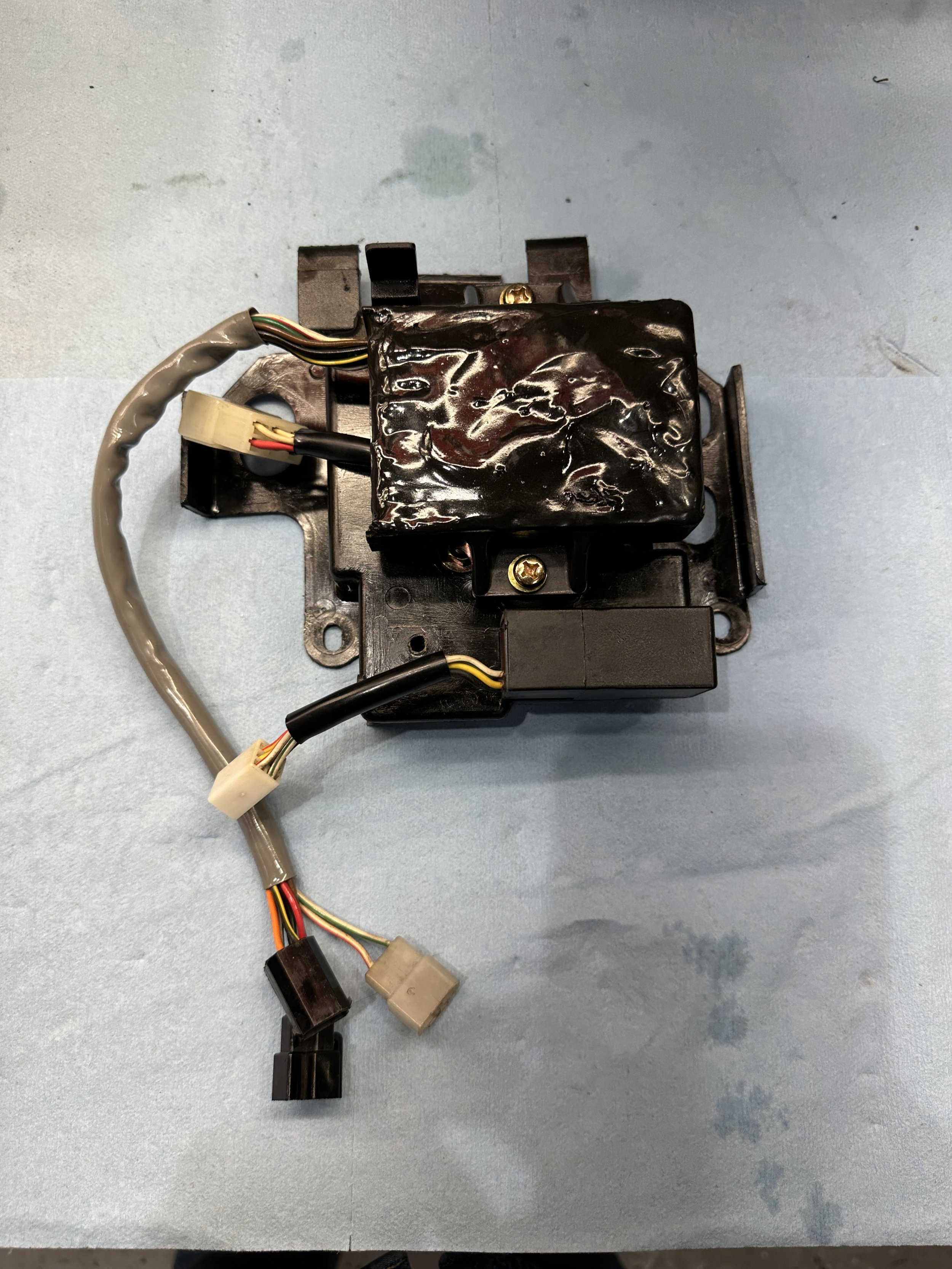

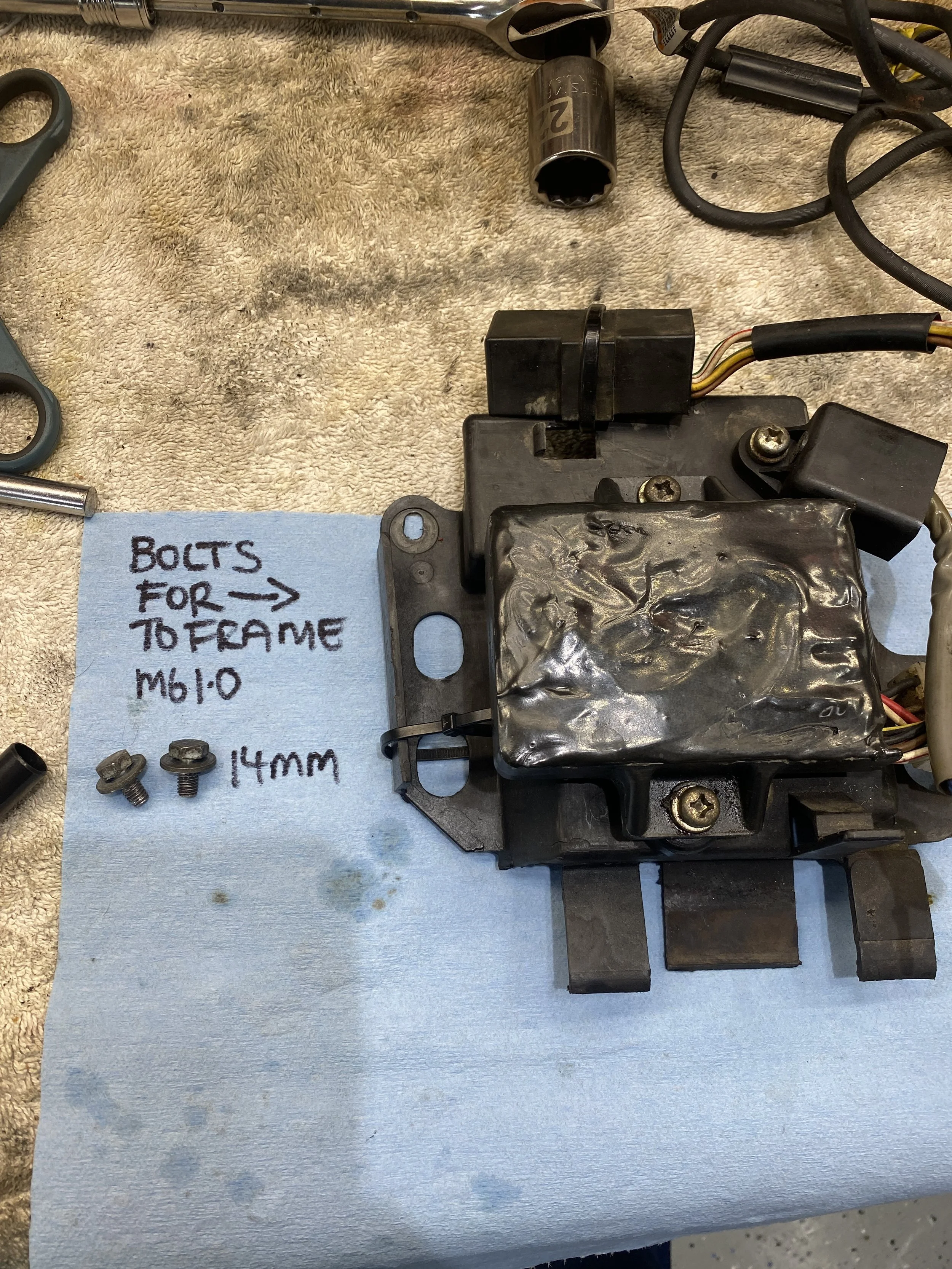

Something doen't look right with the CDI unit. What is this hardened goo? It could be a sign of the common fix that these early YPVS models required...the reattachment of dry soldered joints.

The airfilter top came with the bike...just wasn't attached....

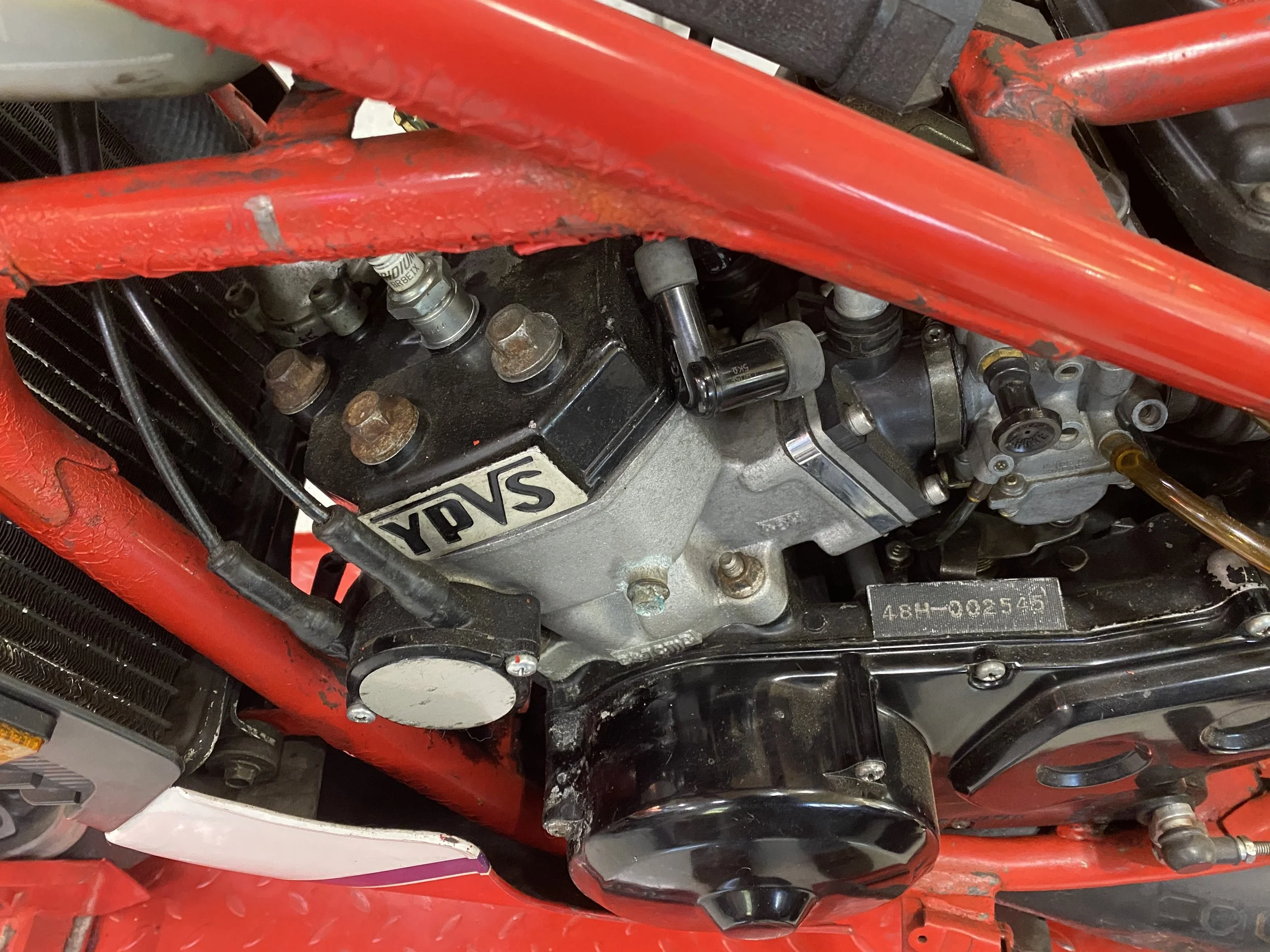

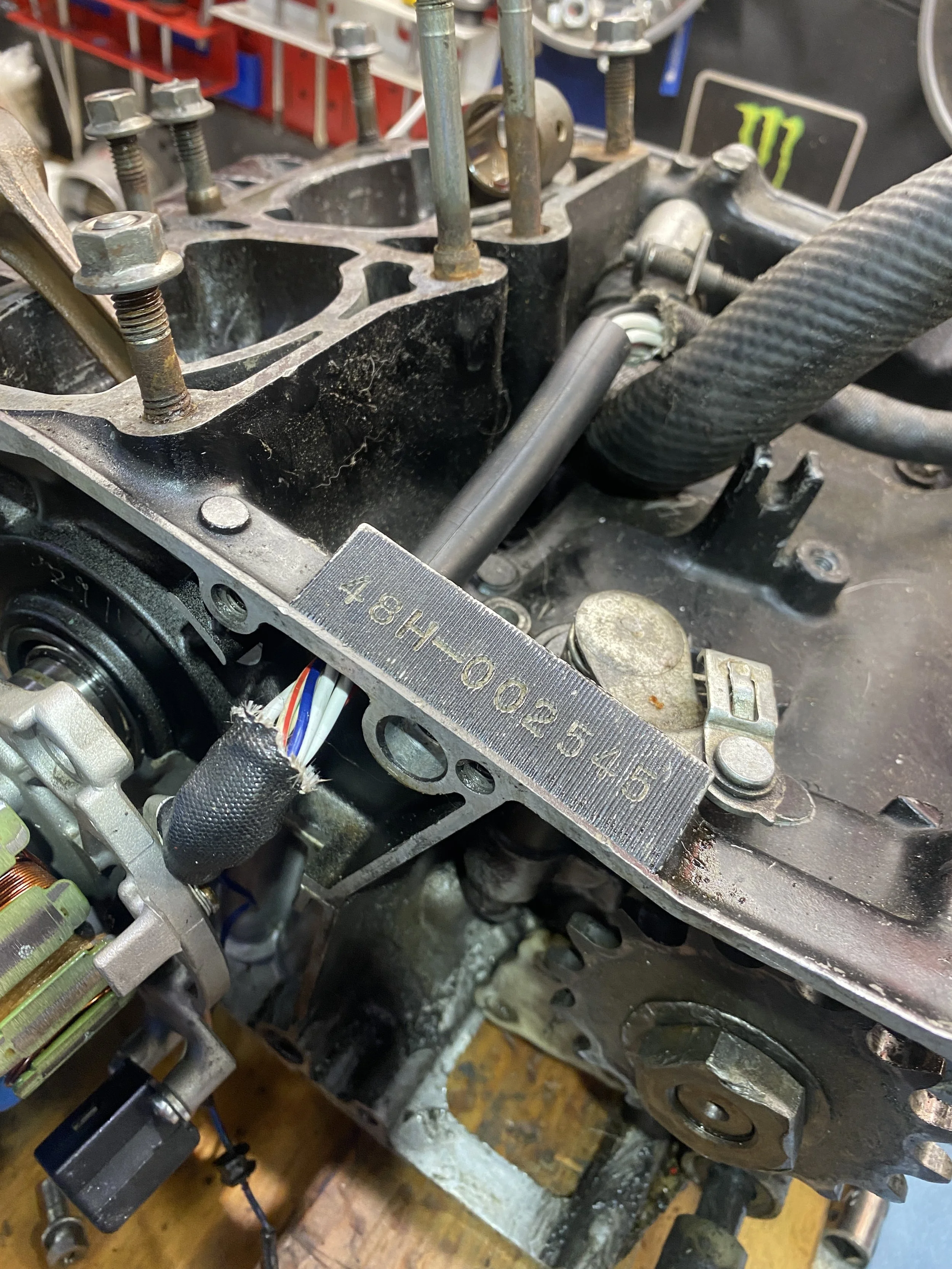

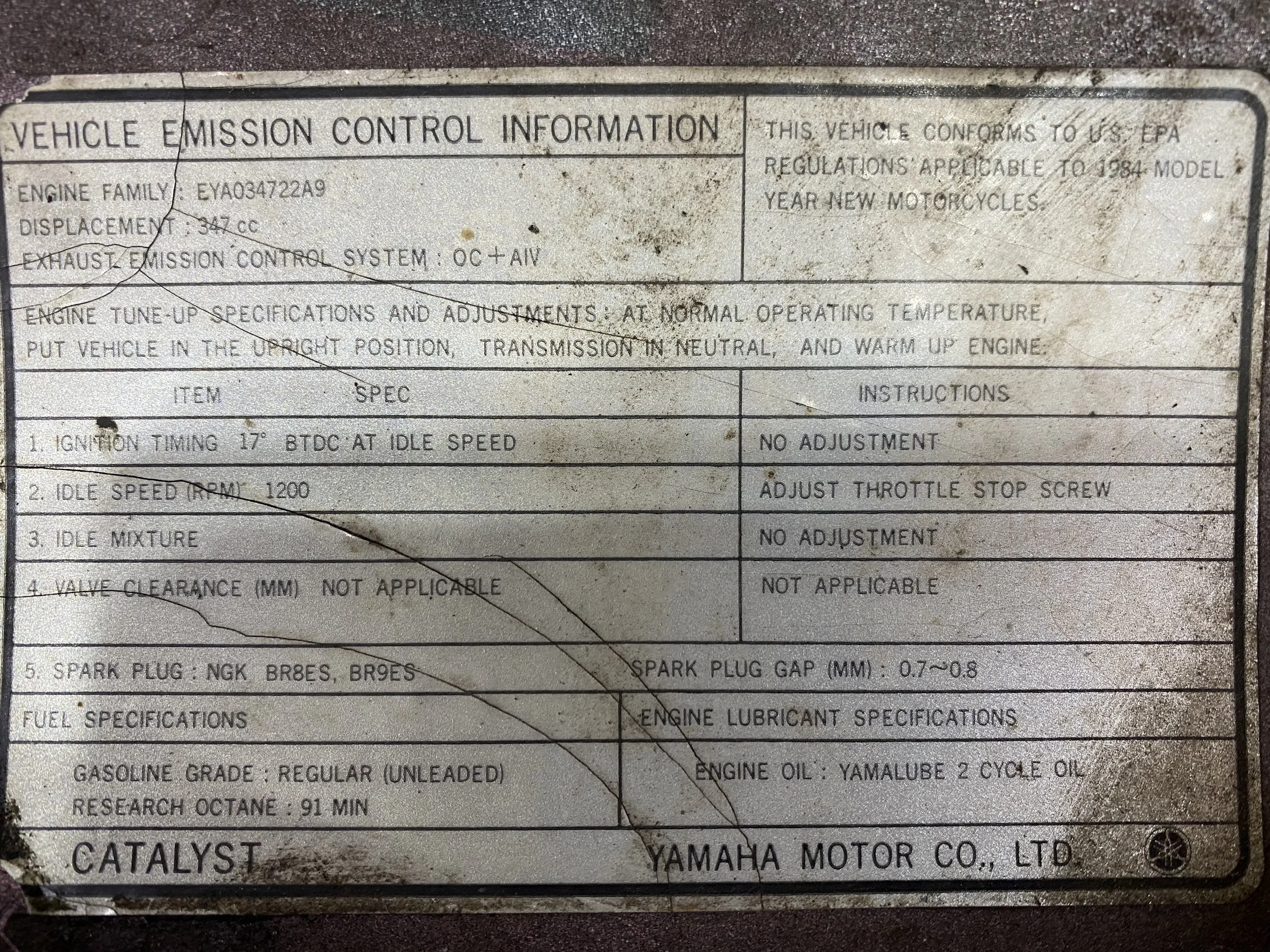

48H prefix is evidence of a USA market model....although sometimes parts are as hard to find as a JDM bike...

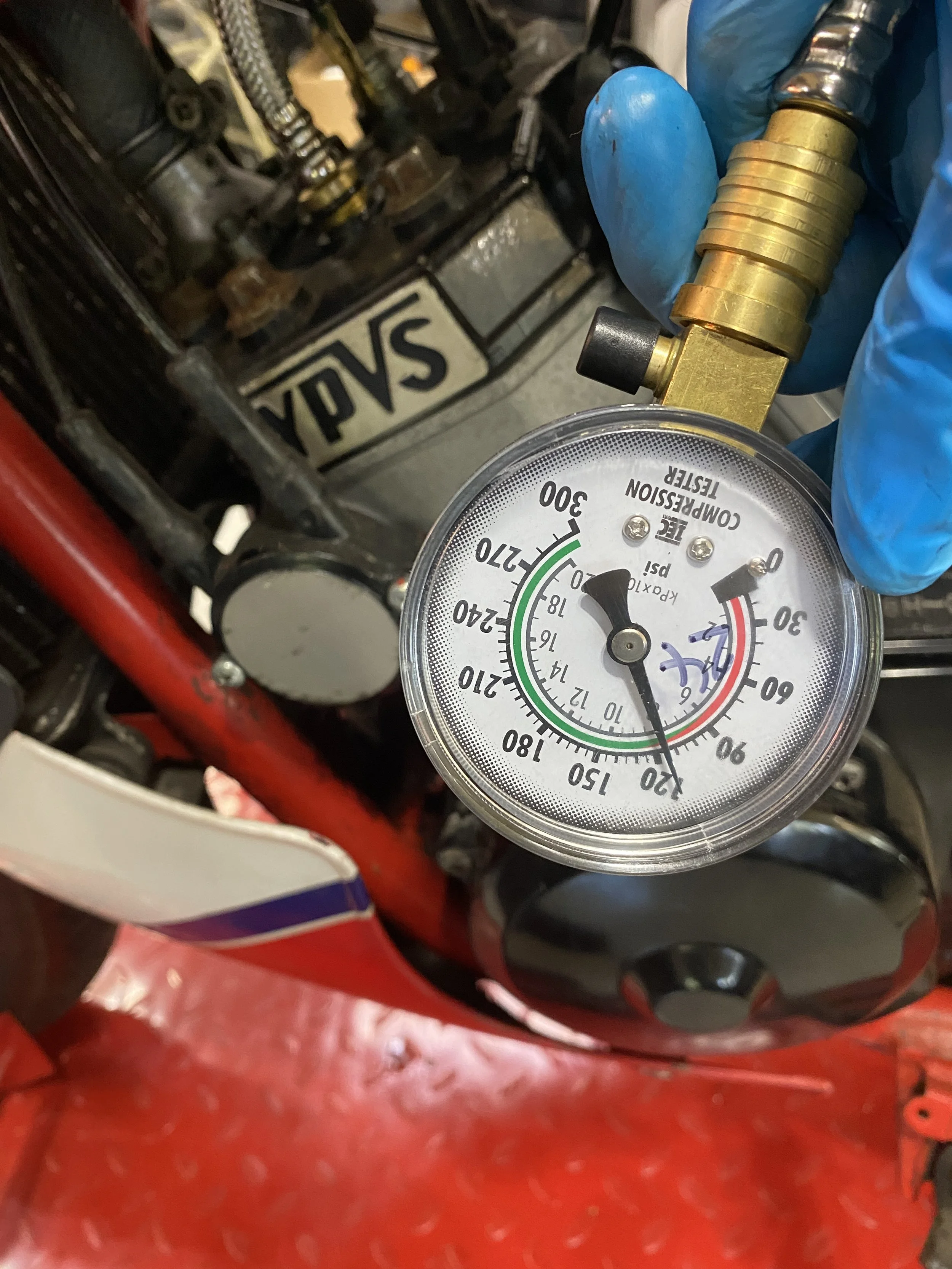

Did a compression check.....equal readings from both cylinders...good sign.

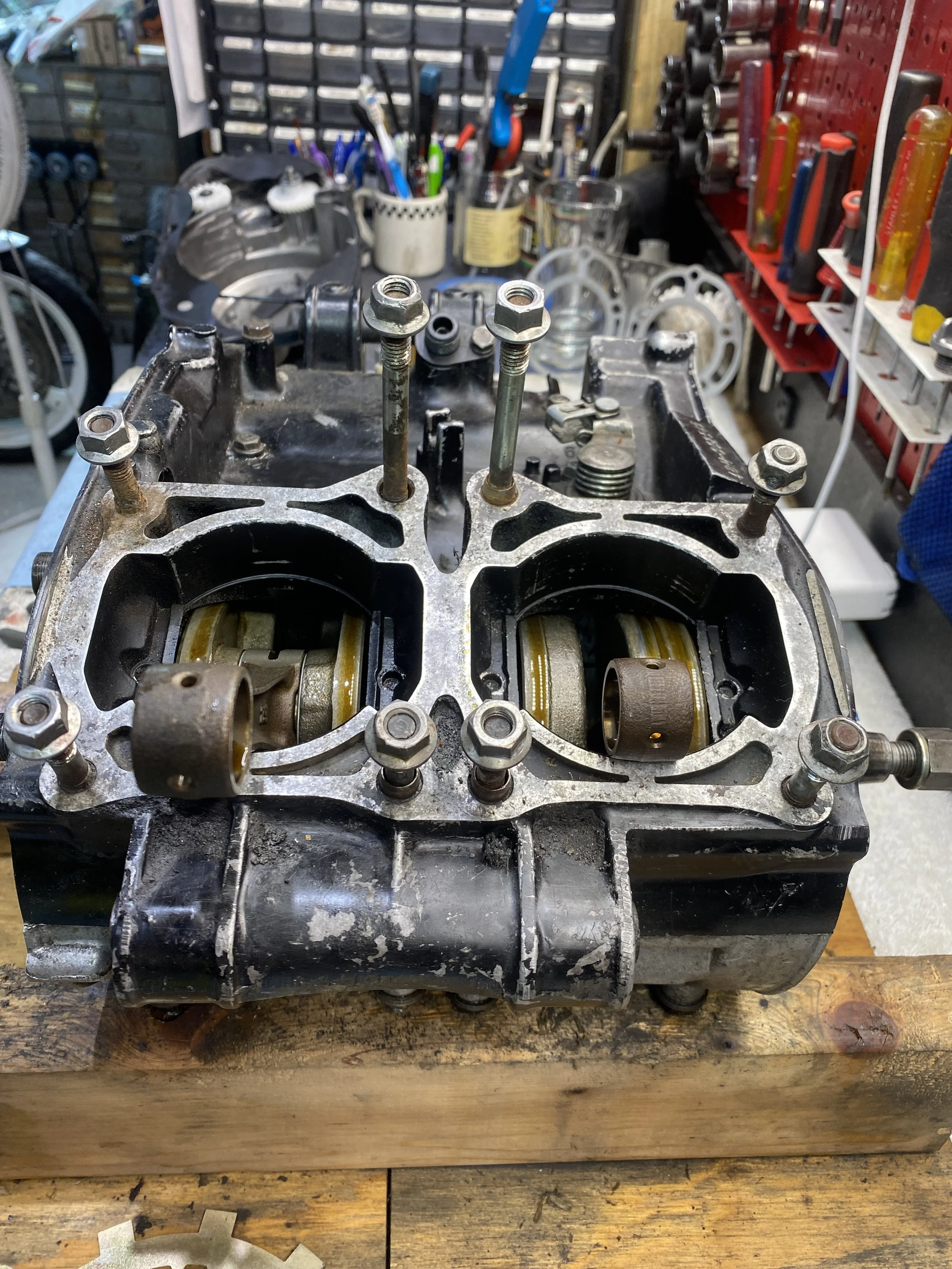

120 per side= normal....no need to mess with....however dying to see if pistons are oversized....really want to send to PJME for a rebore...

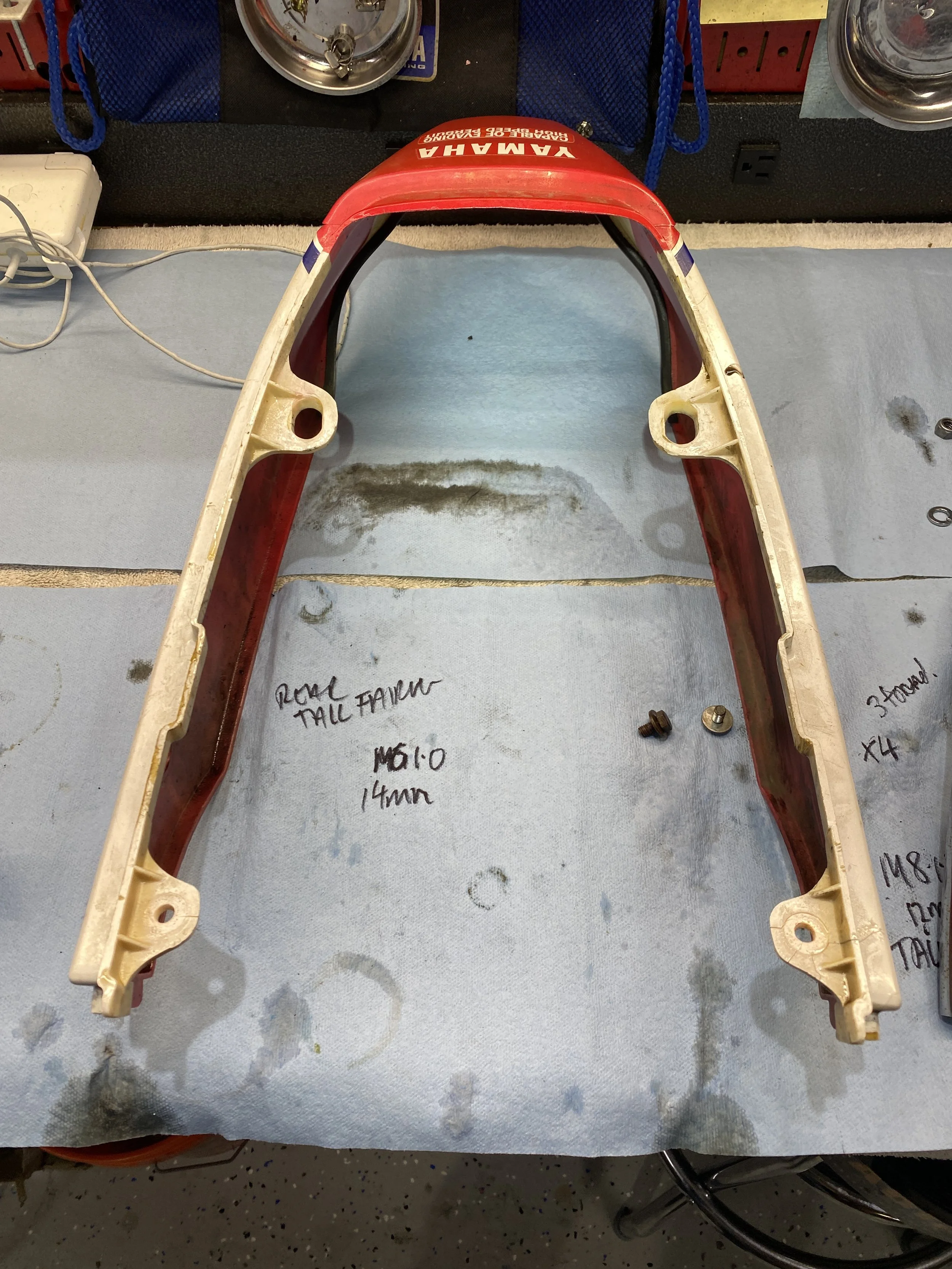

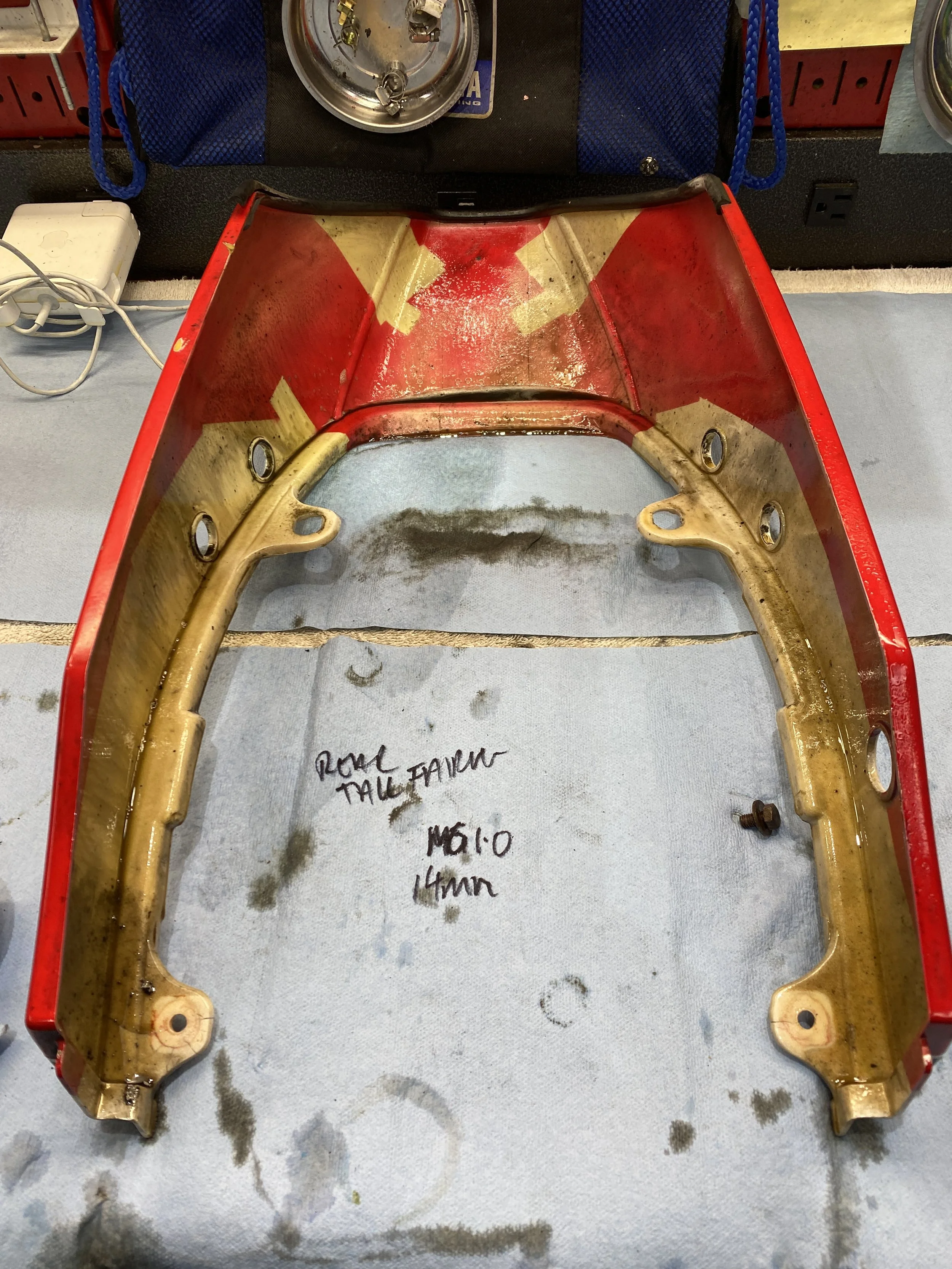

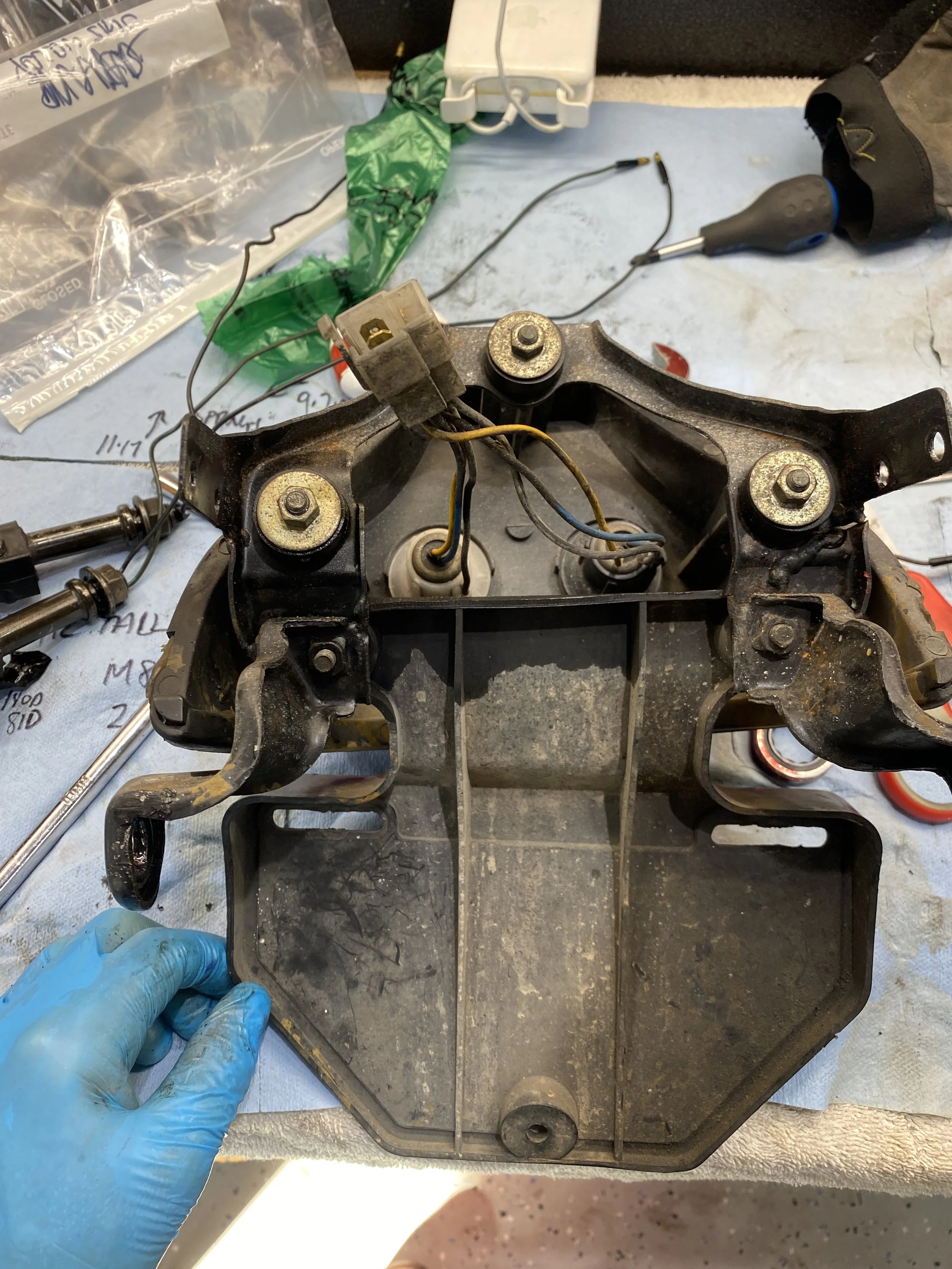

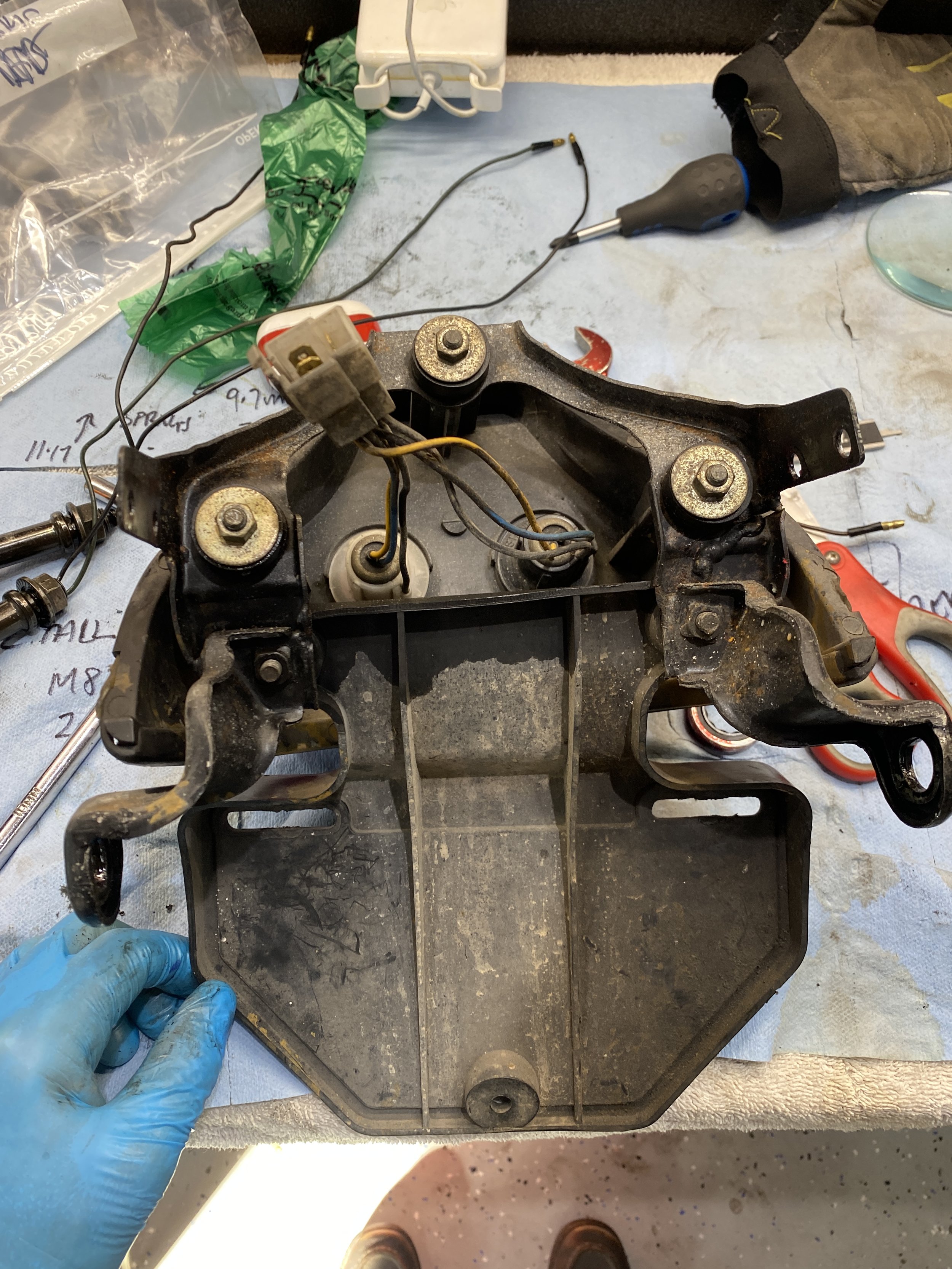

tail came off...

a bit rough on places....

closer look at the CDI box....

no official explanation....but the bike ran well so not going to worry about it just yet....could go Zeeltronic I guess.

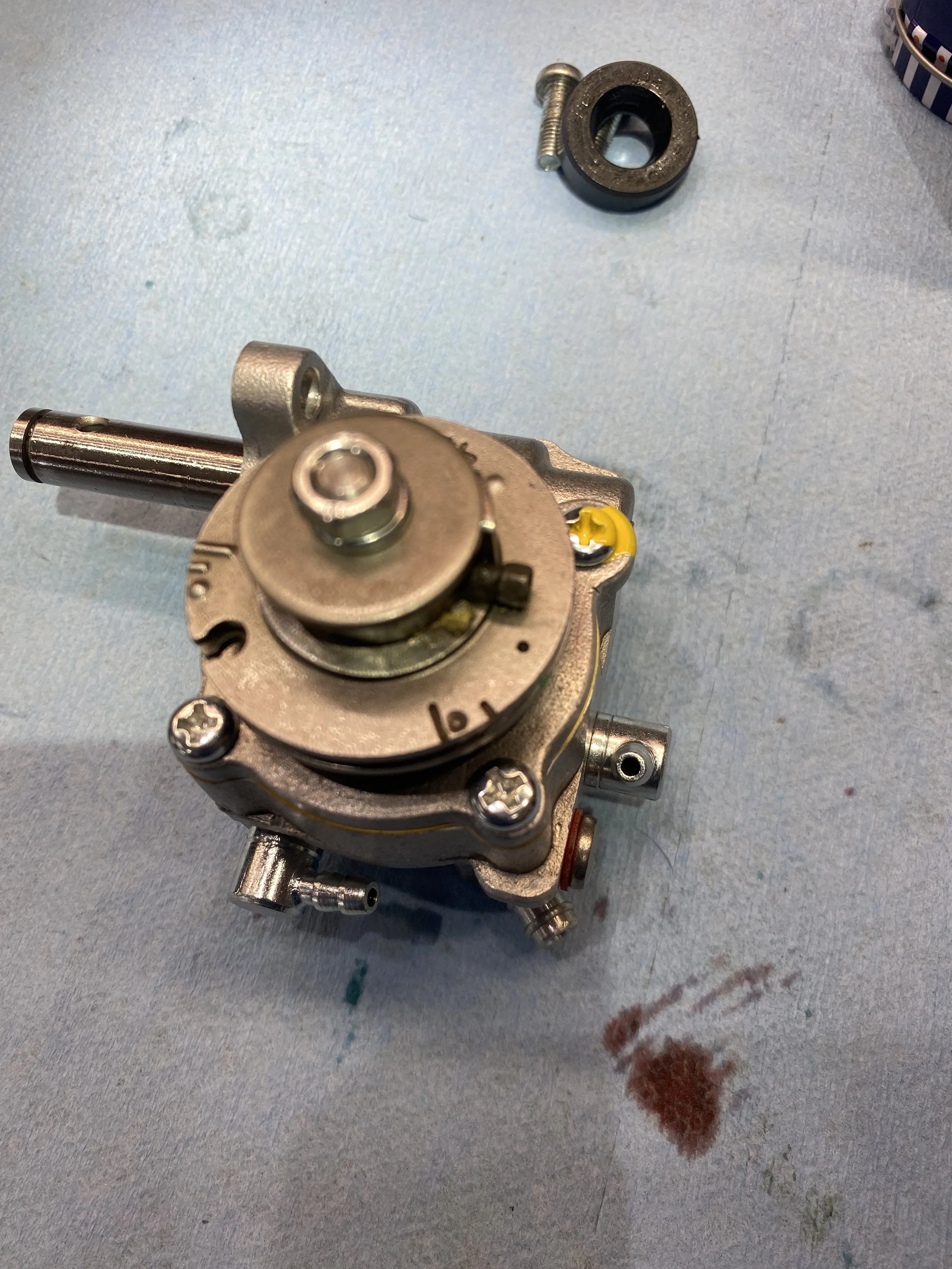

Oil pump is going to be detached and sent for a visit to Arrow....near Liverpool.

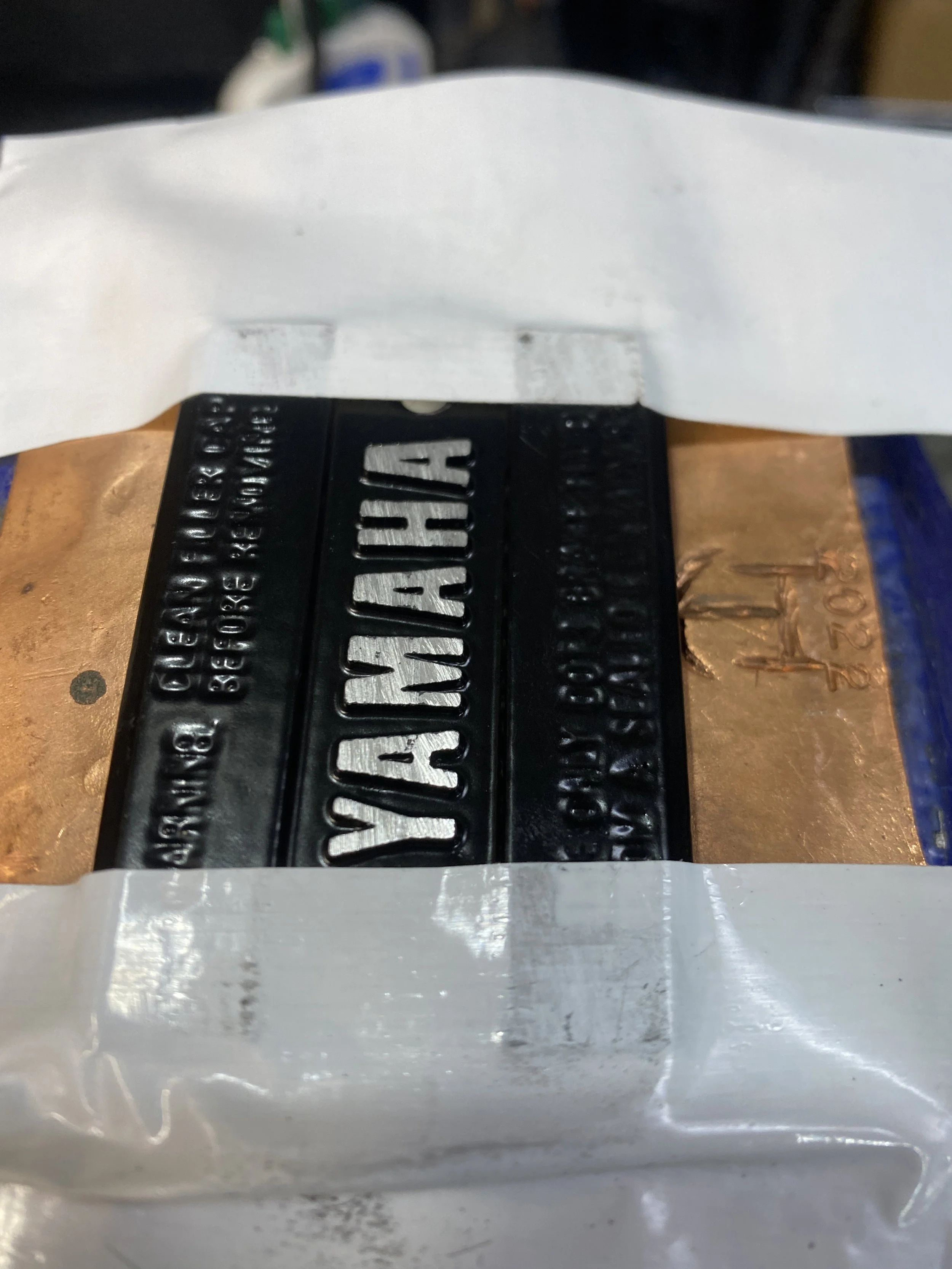

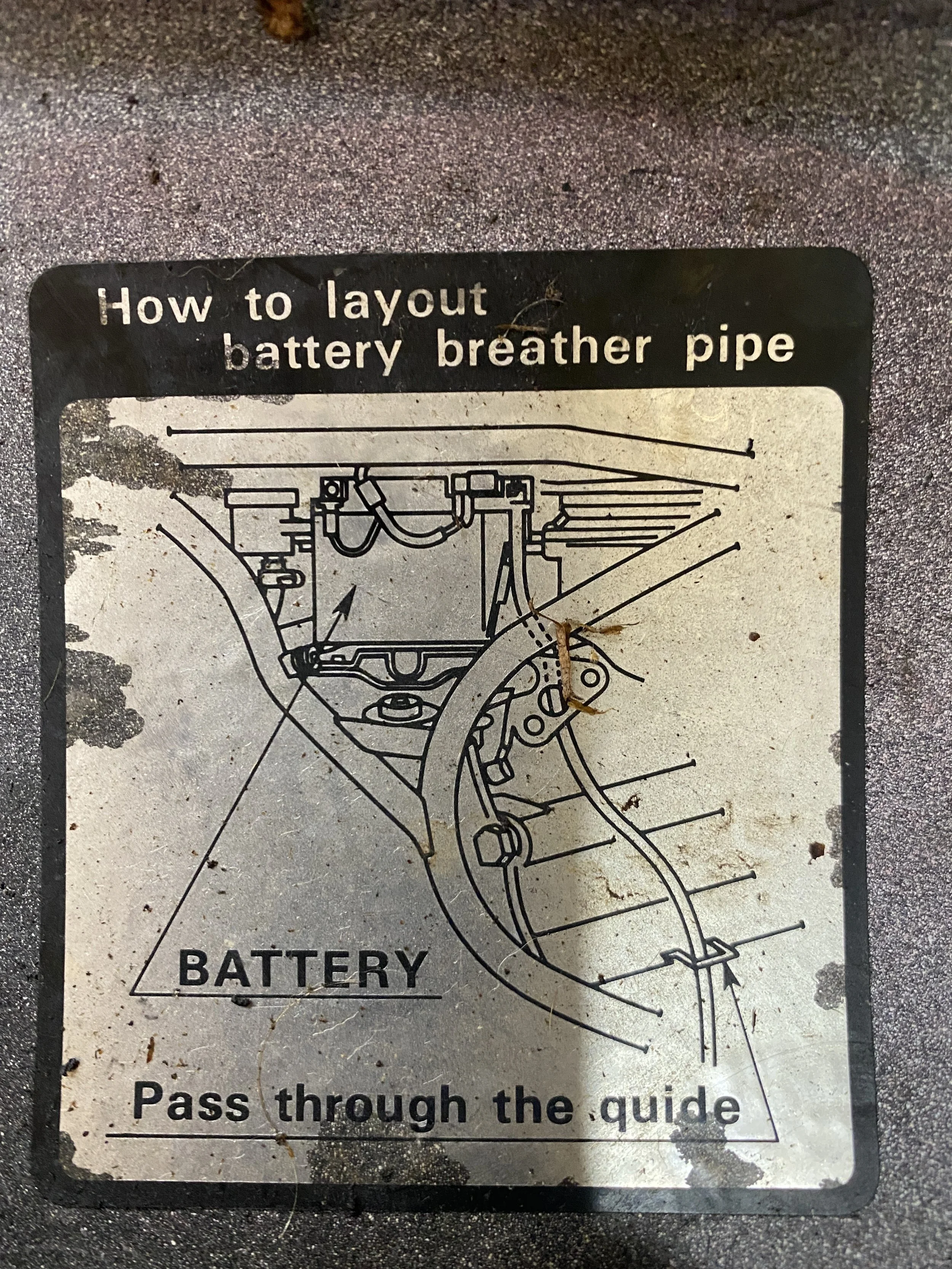

reminder to find someone who can replicate this sticker on that horizontal bar which says....

....all this...

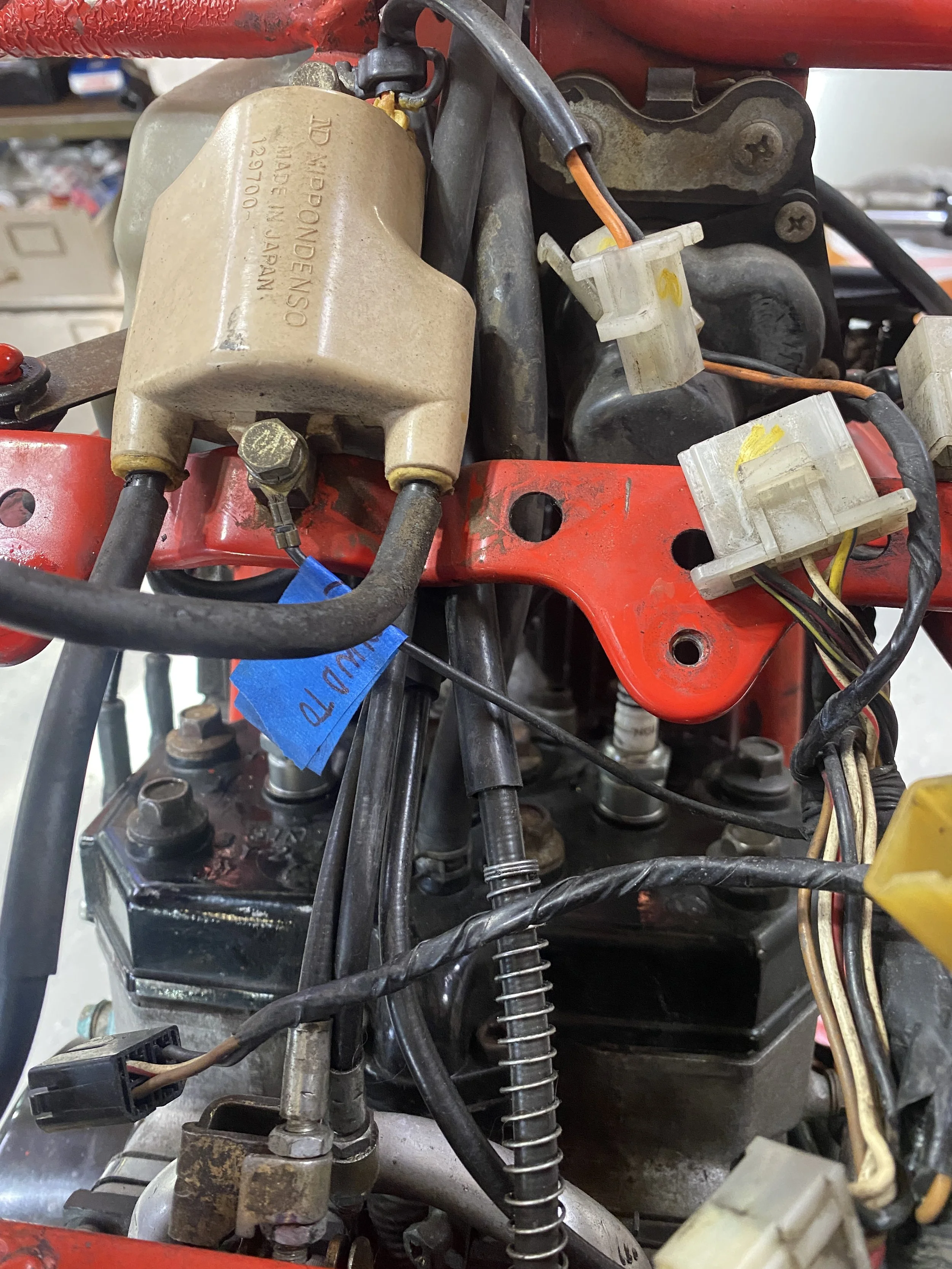

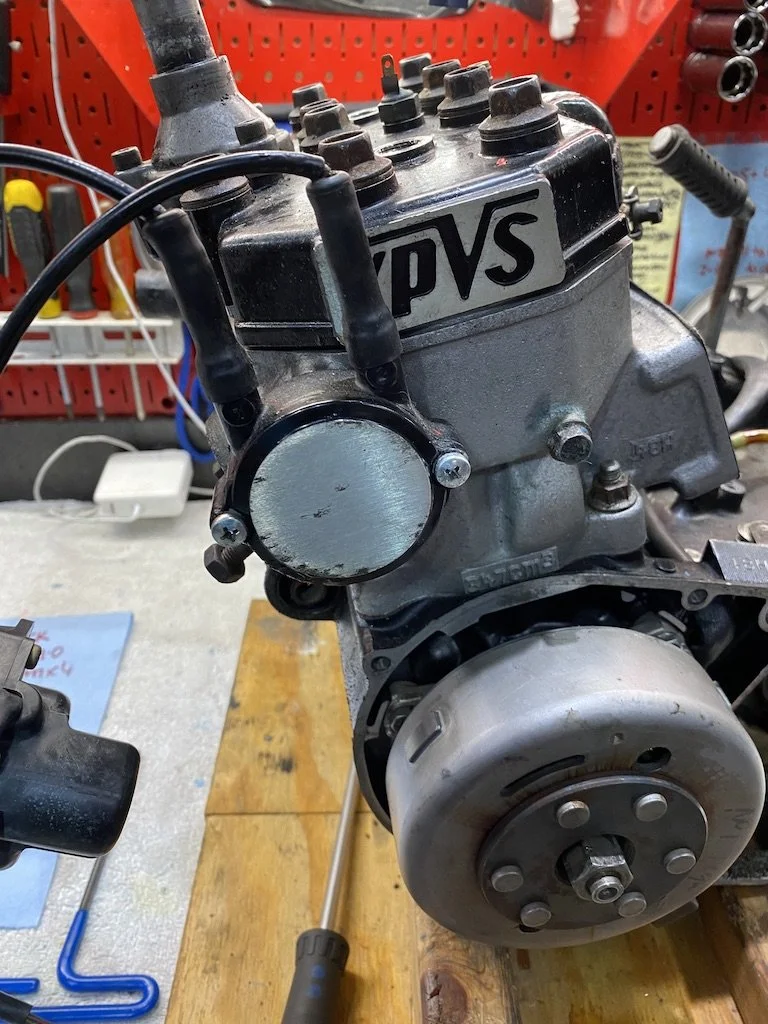

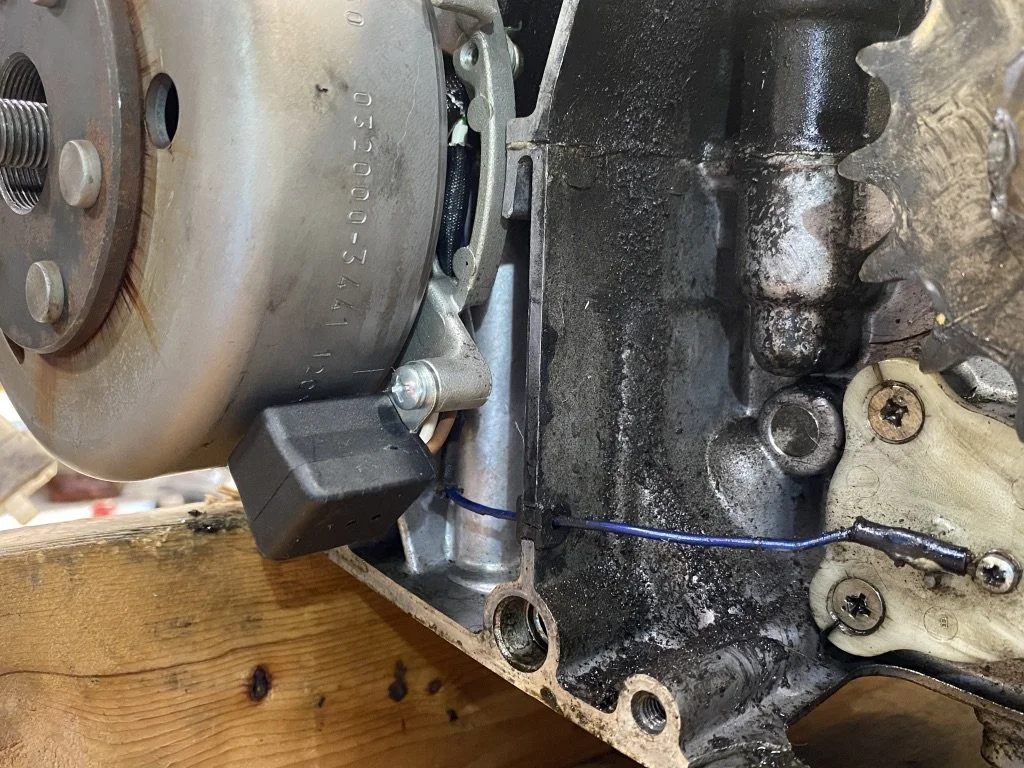

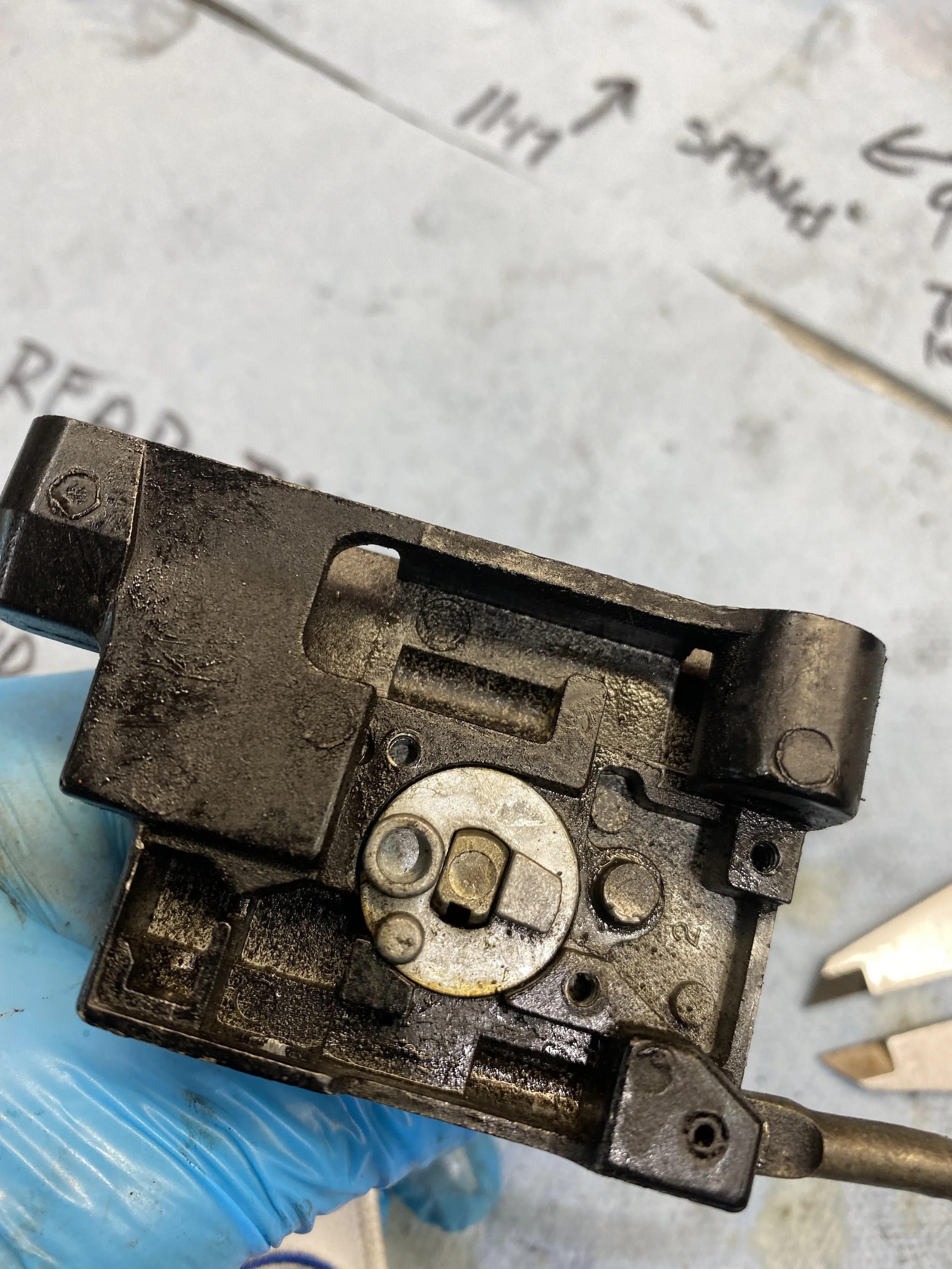

The Yamaha Power Valve System Brain..."a computerized mechanical control unit which detects the ignition frequency and determines the required turning angle of the valve. In this way the valve moves upward and downward out of the exhaust port."

Guard dog?

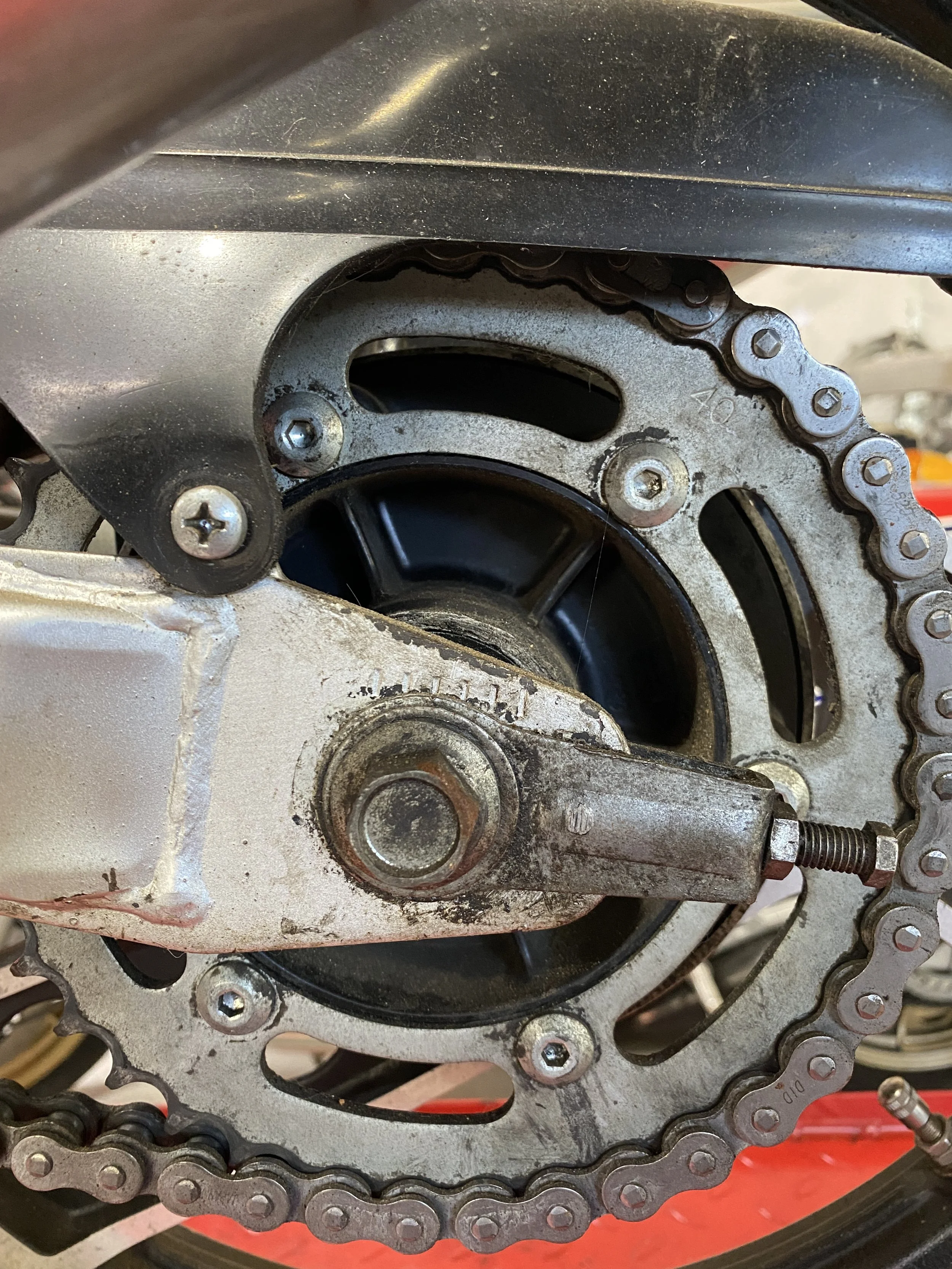

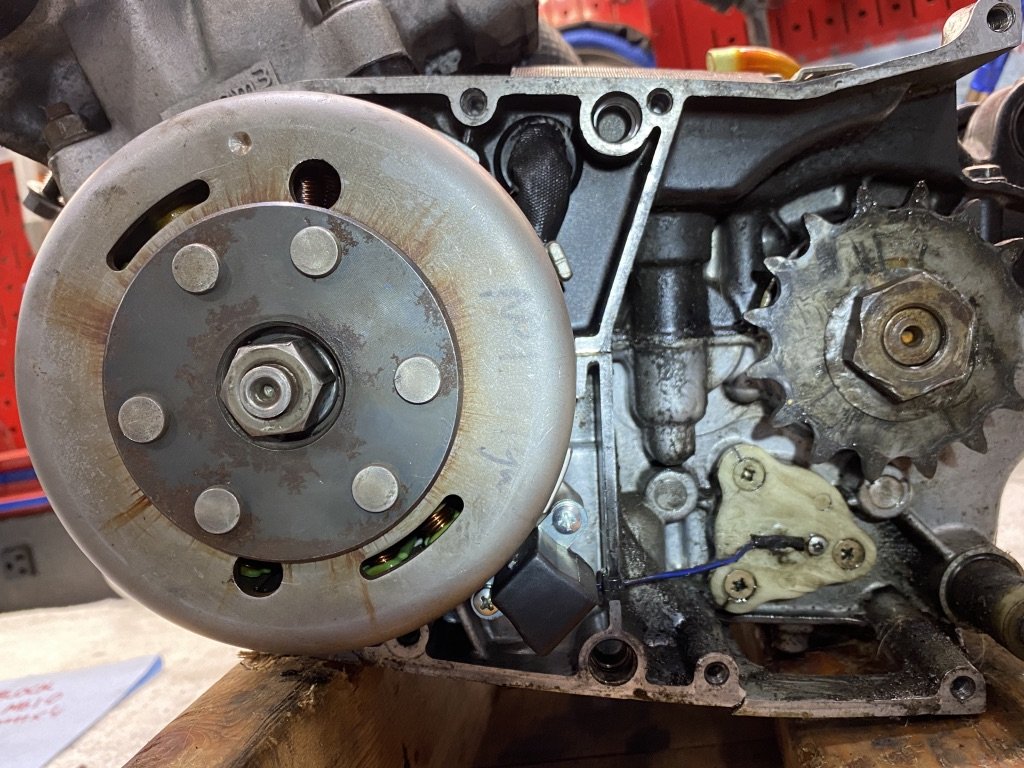

That's a 40 tooth sprocket. The standard is 39.

Belly pan bolts....mismatched....probably will be retired.

I'm still not convinced the barrels came out of the factory like this...

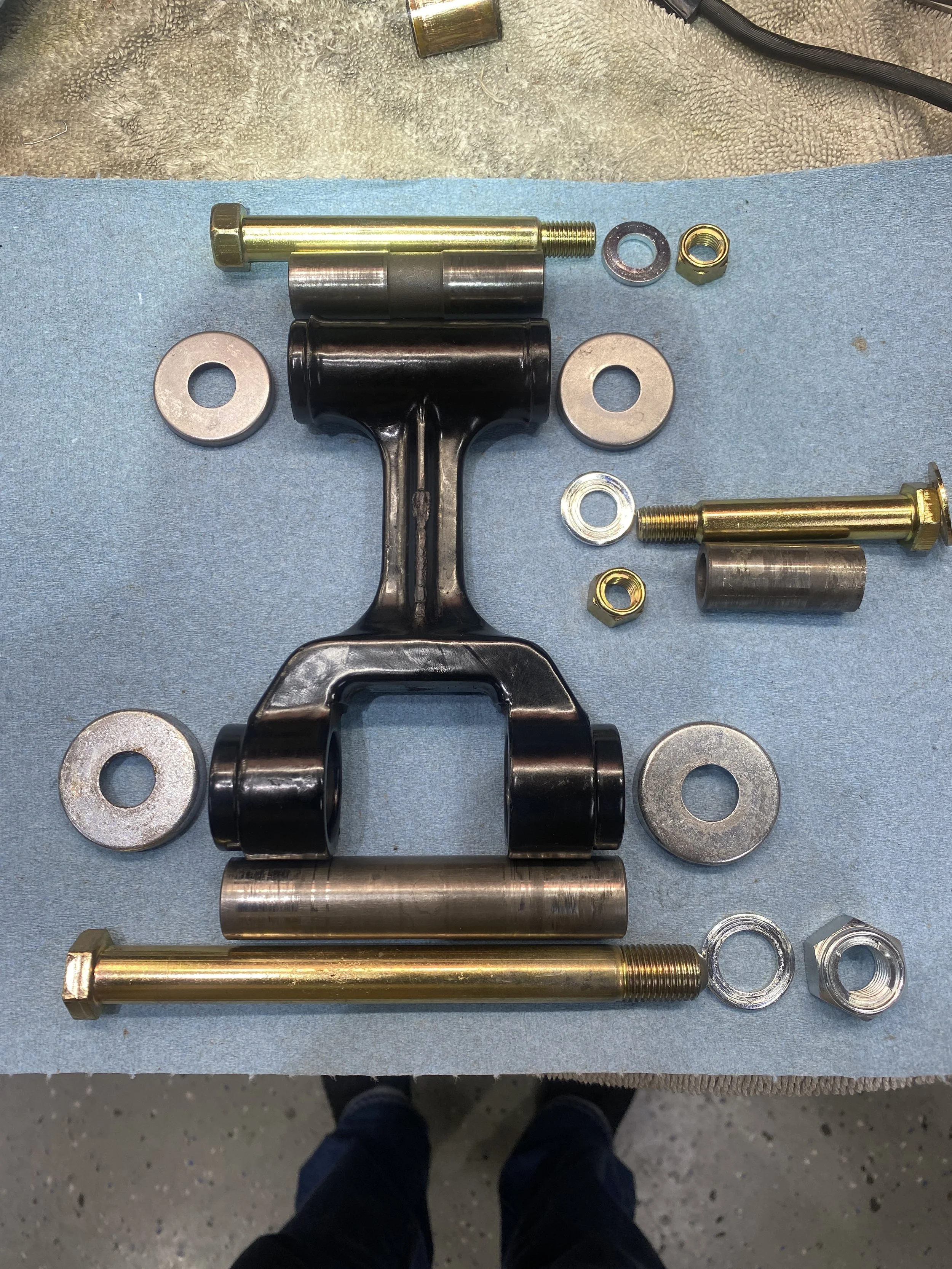

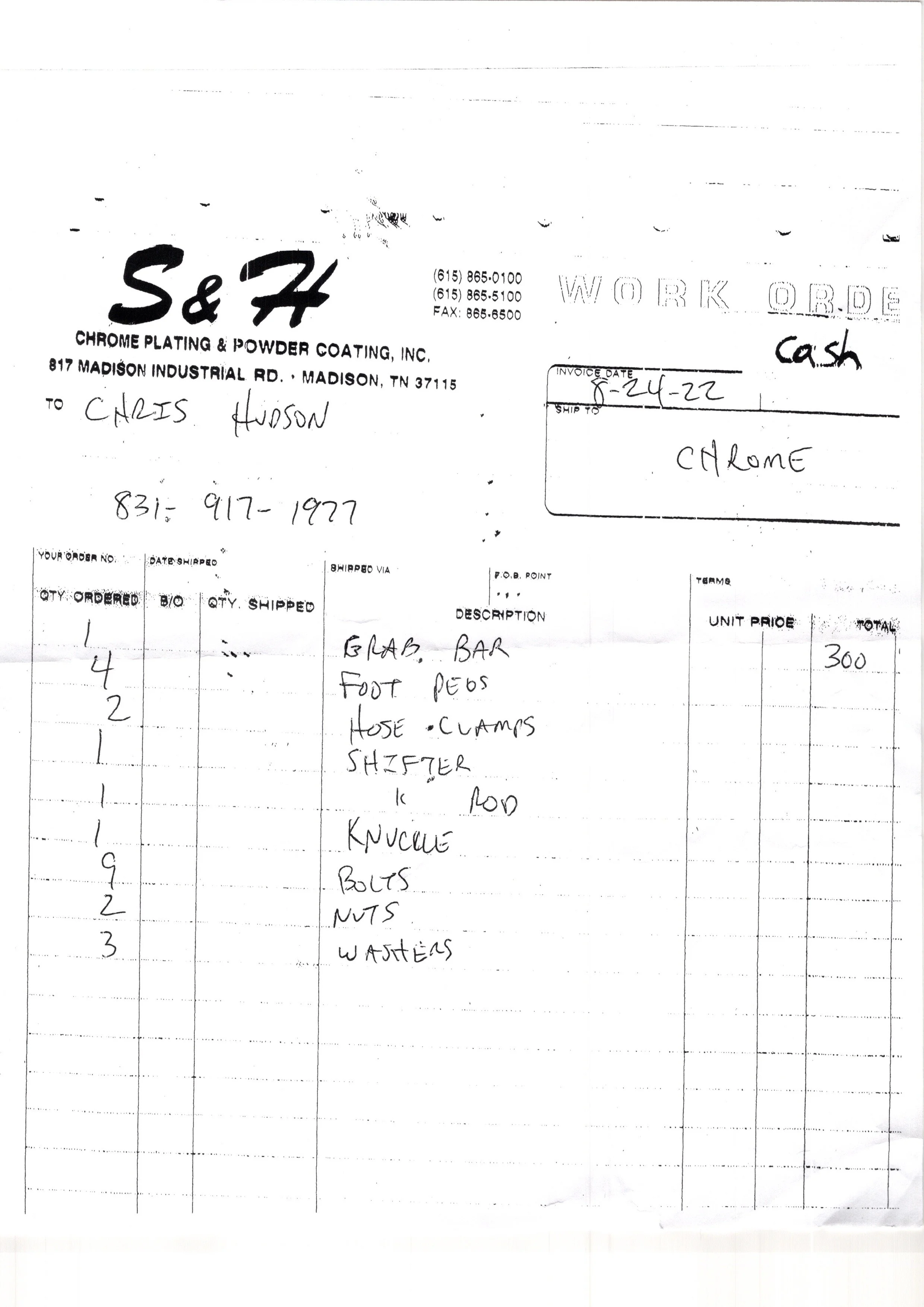

Grab bar: to the powder coaters. Bolts: to the platers.

Can't quite believe I'm going to this extent, but I want everything to look as if it's rolled off the showroom floor in 1984...even on the inside? twat.

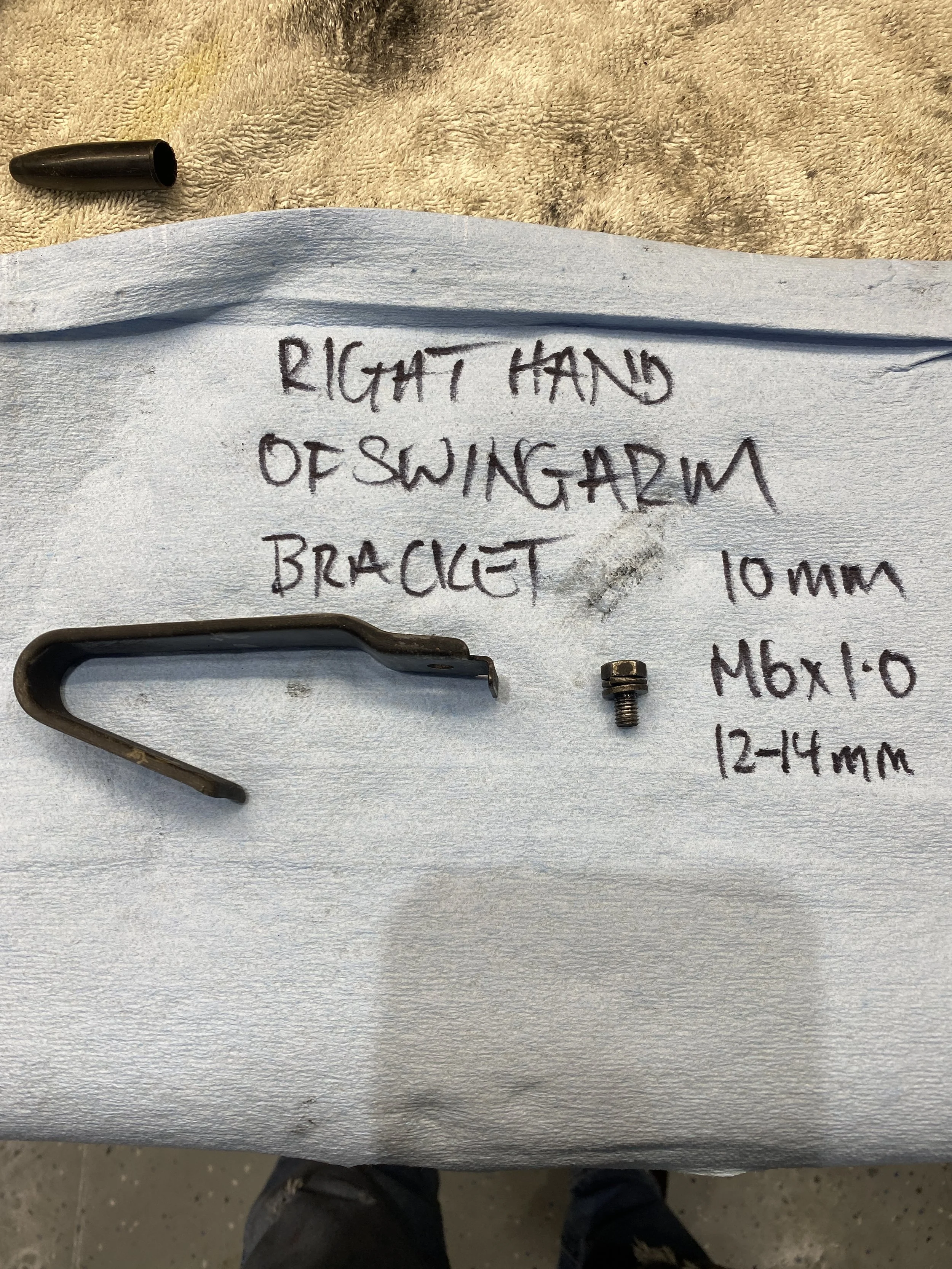

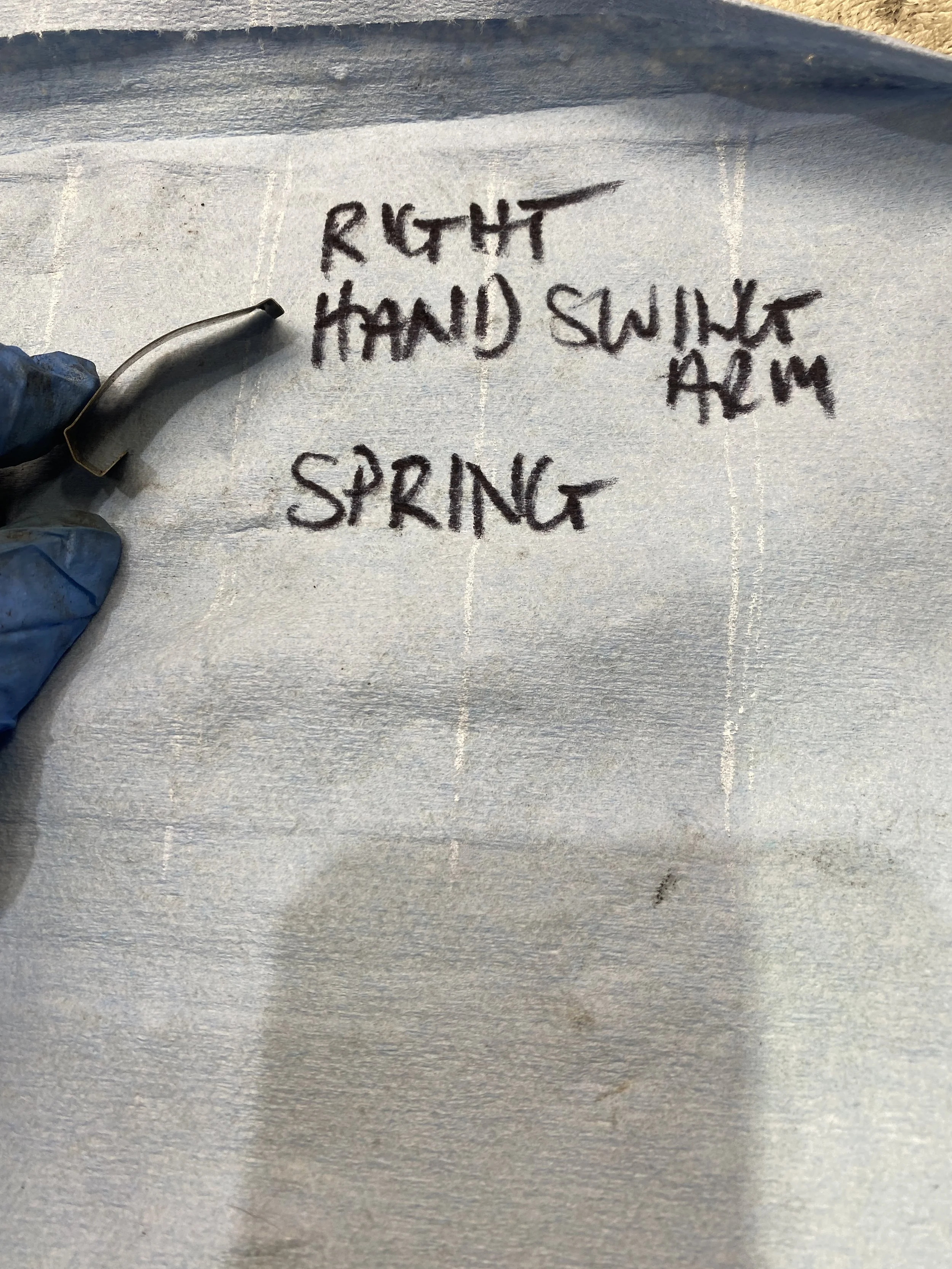

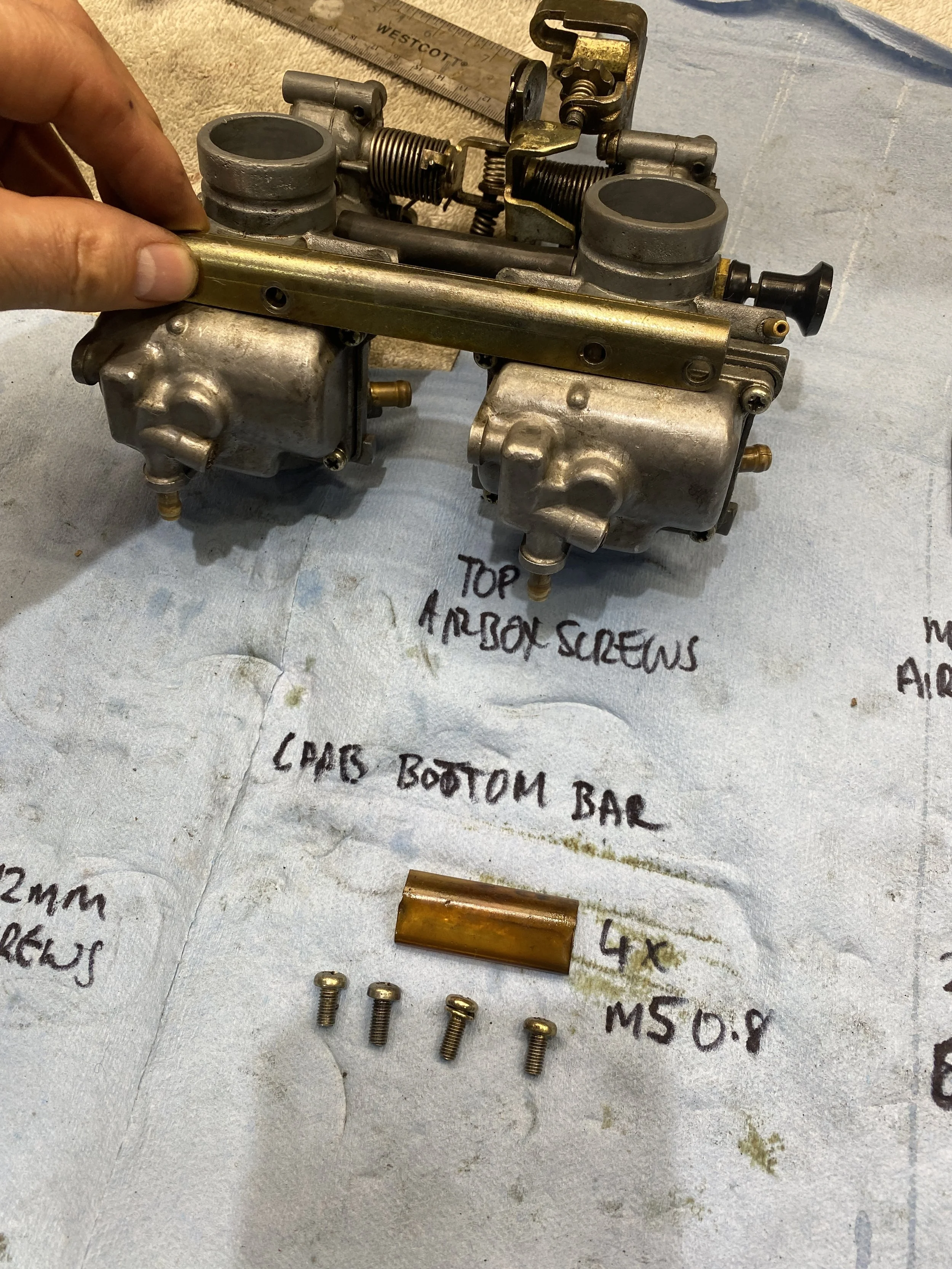

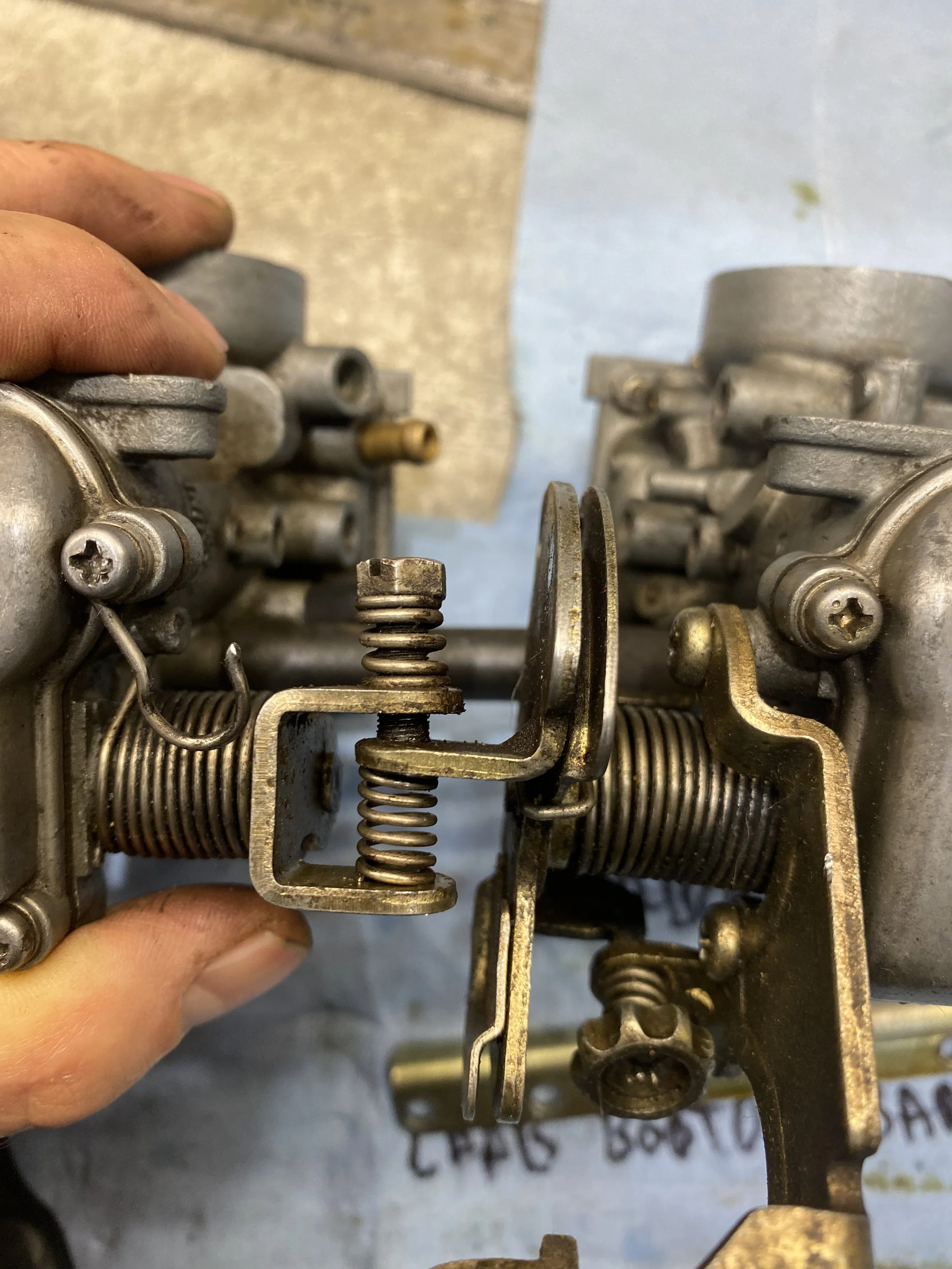

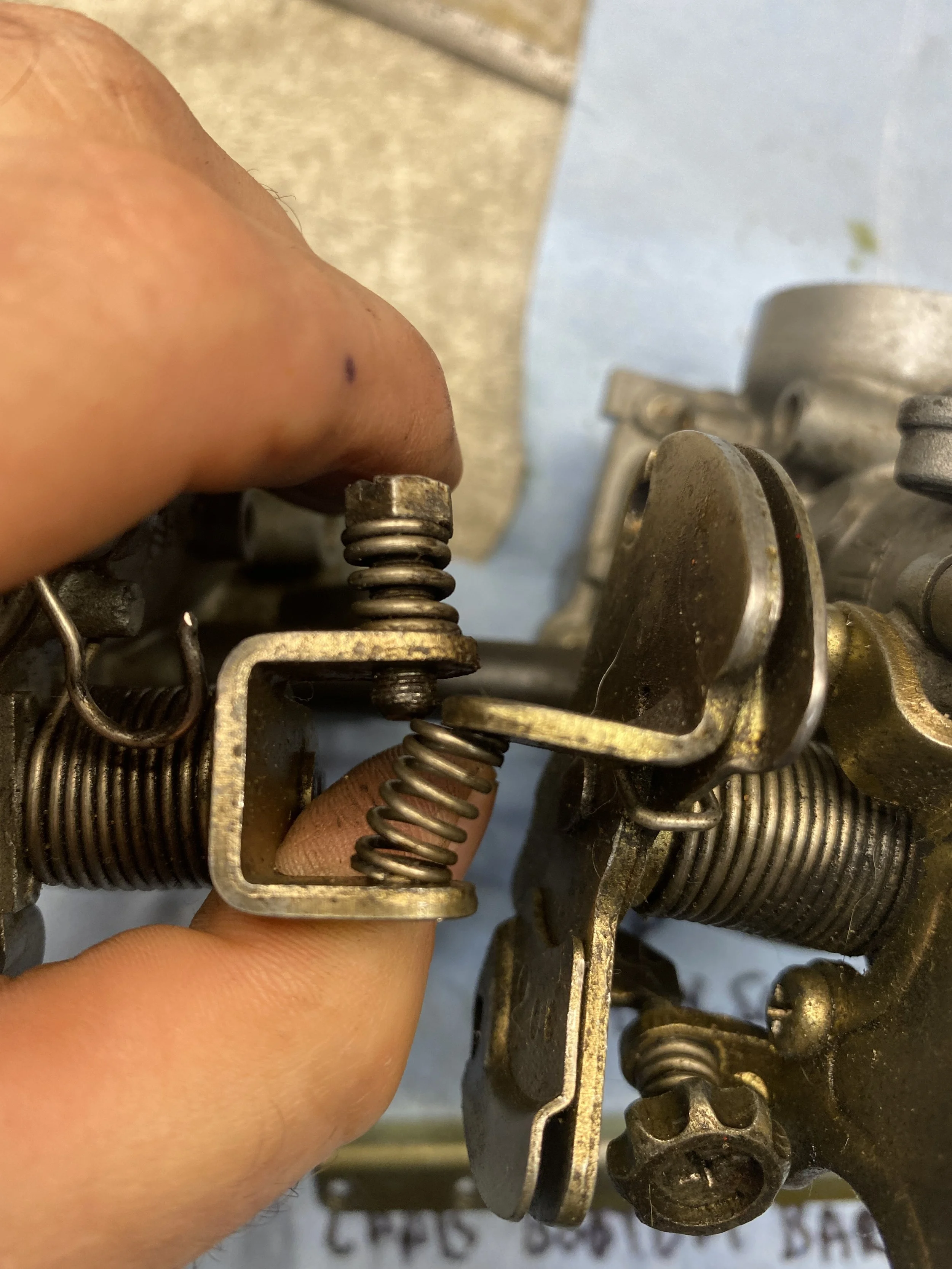

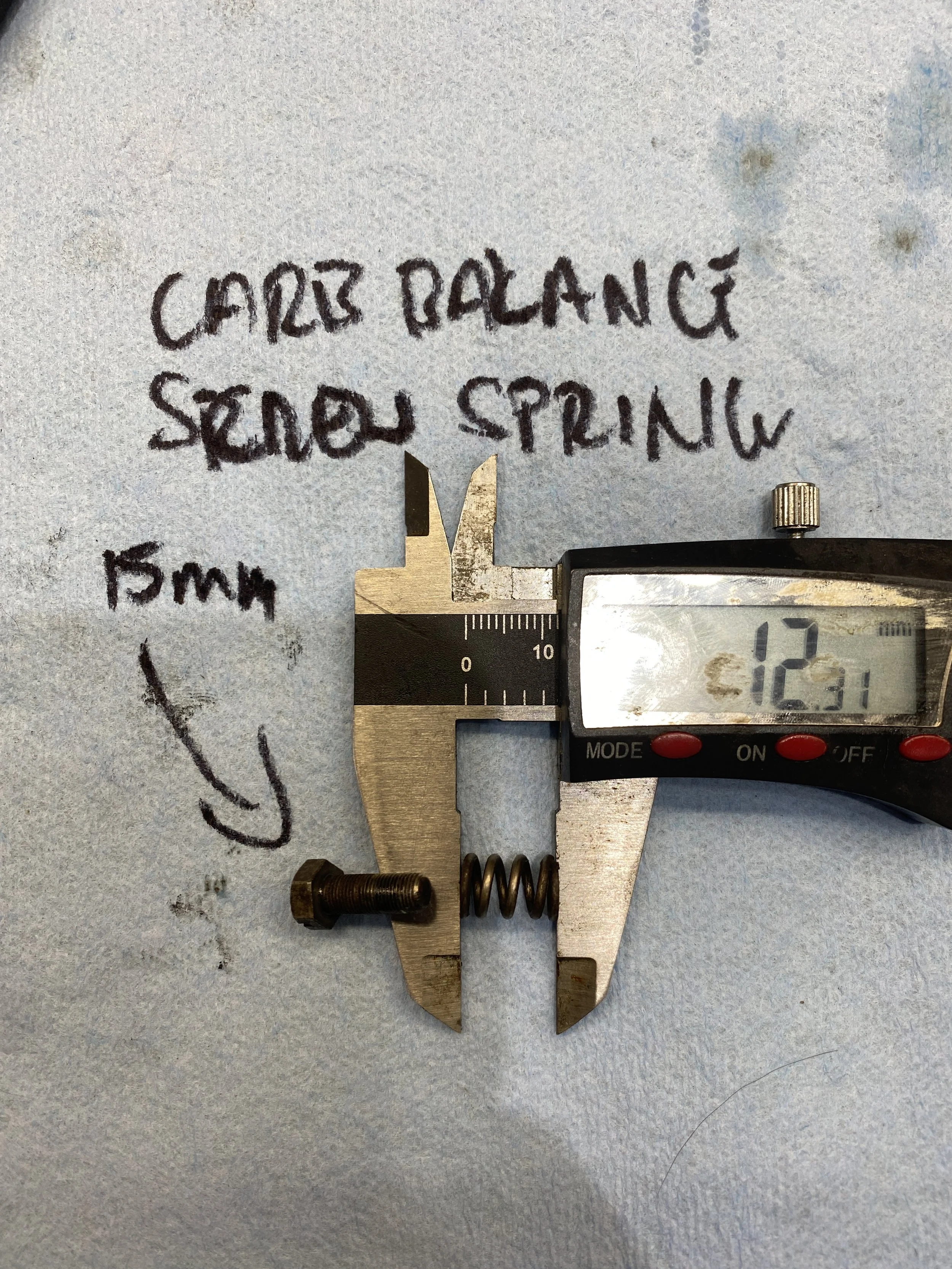

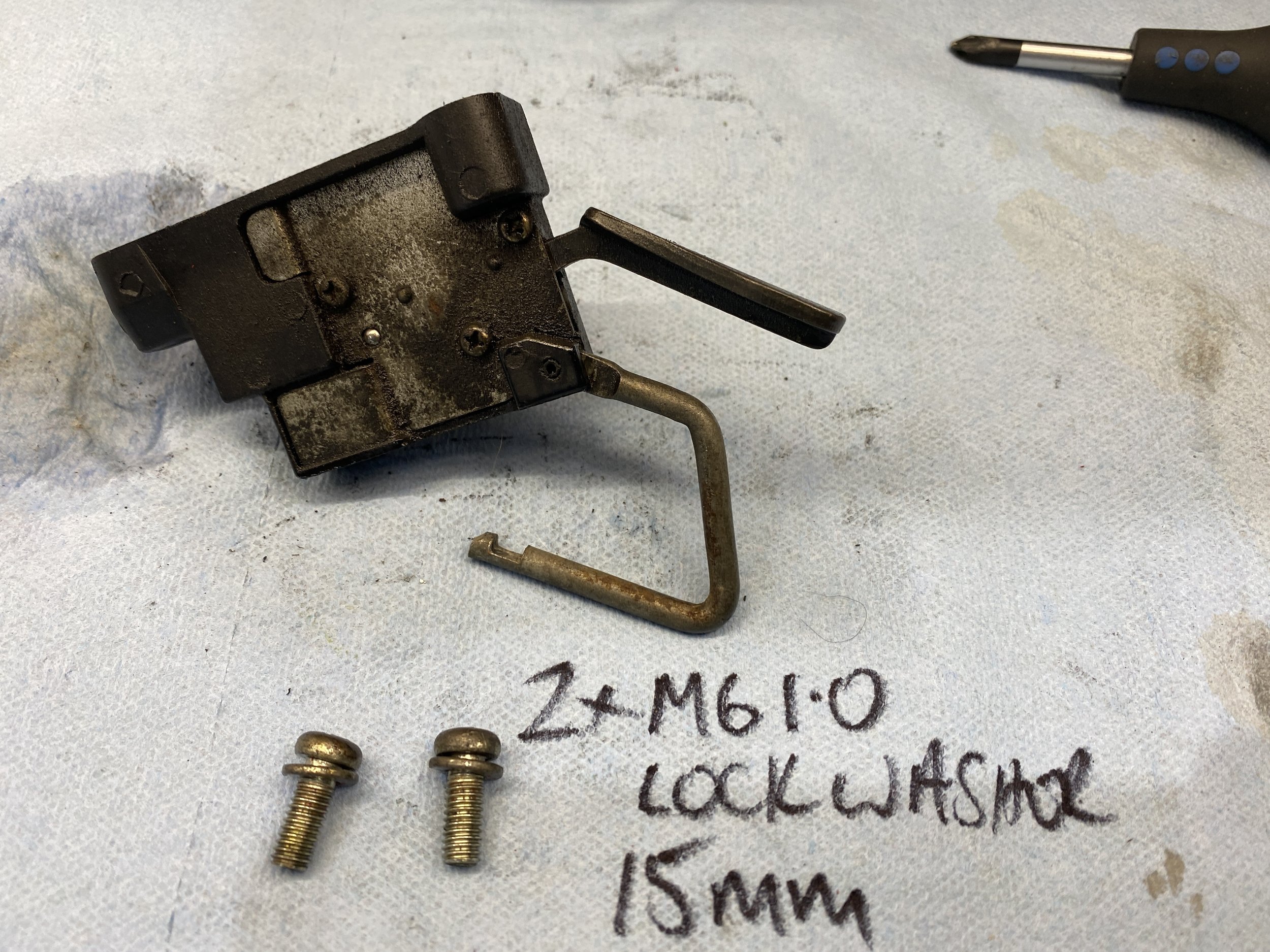

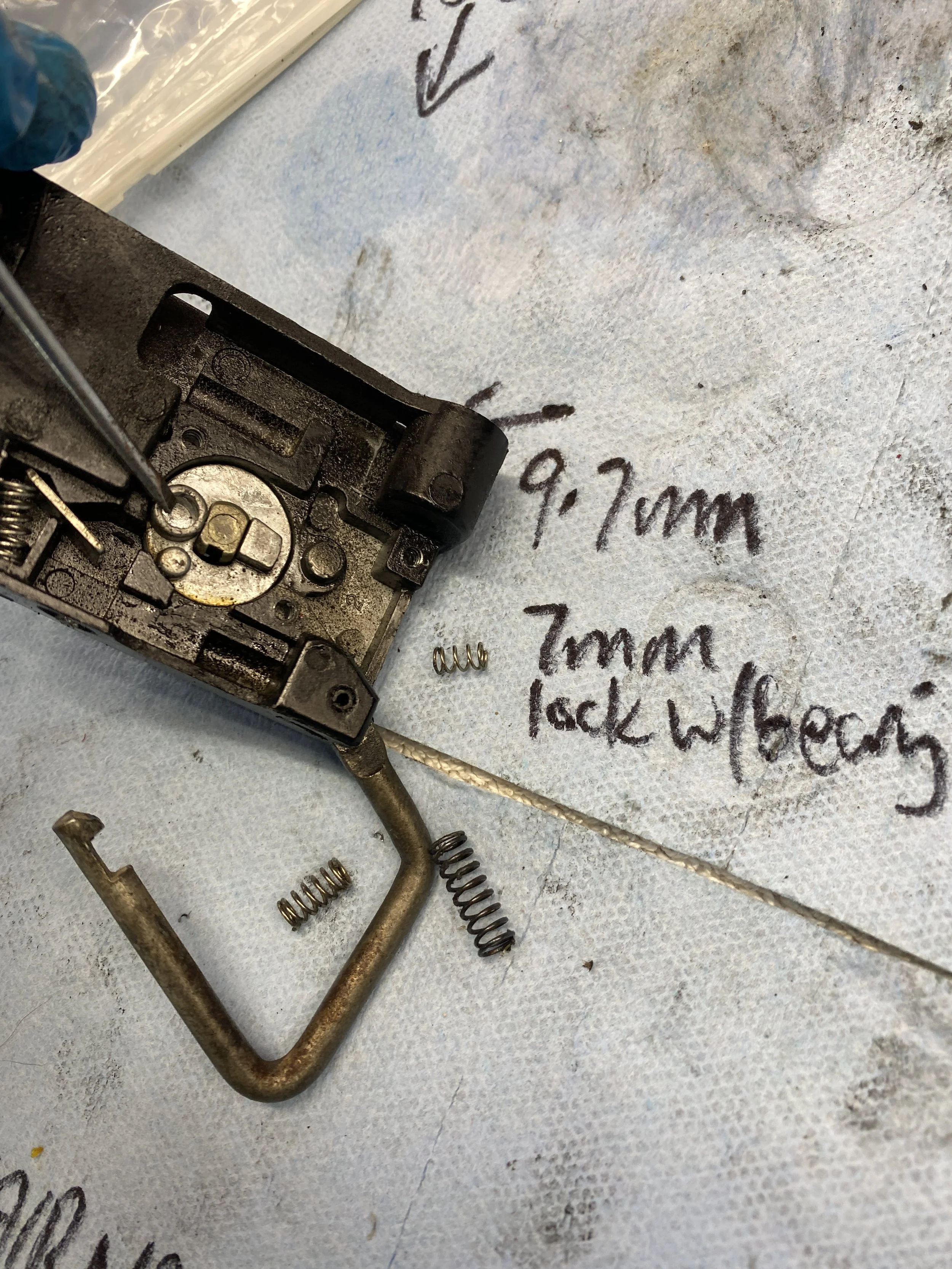

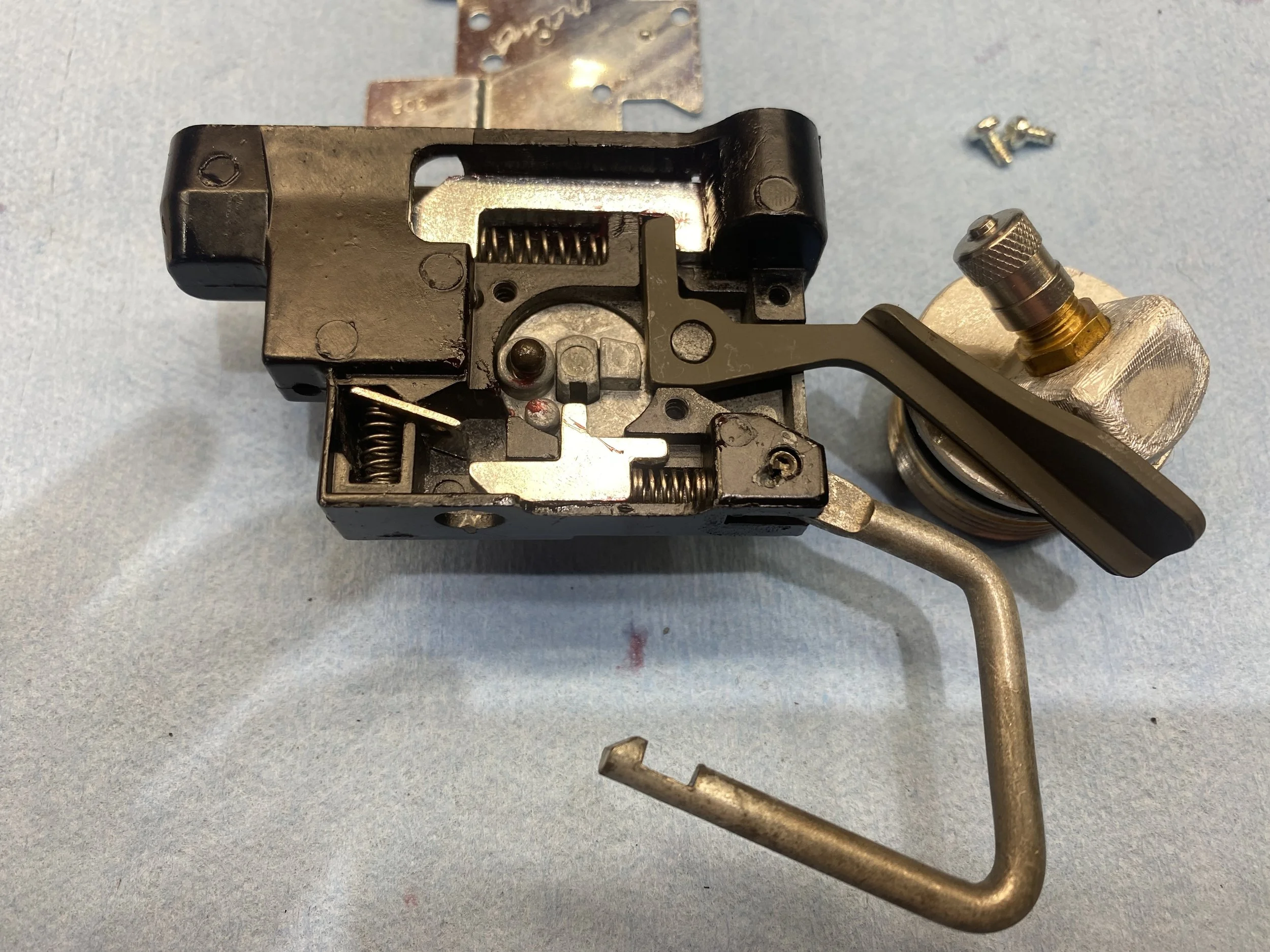

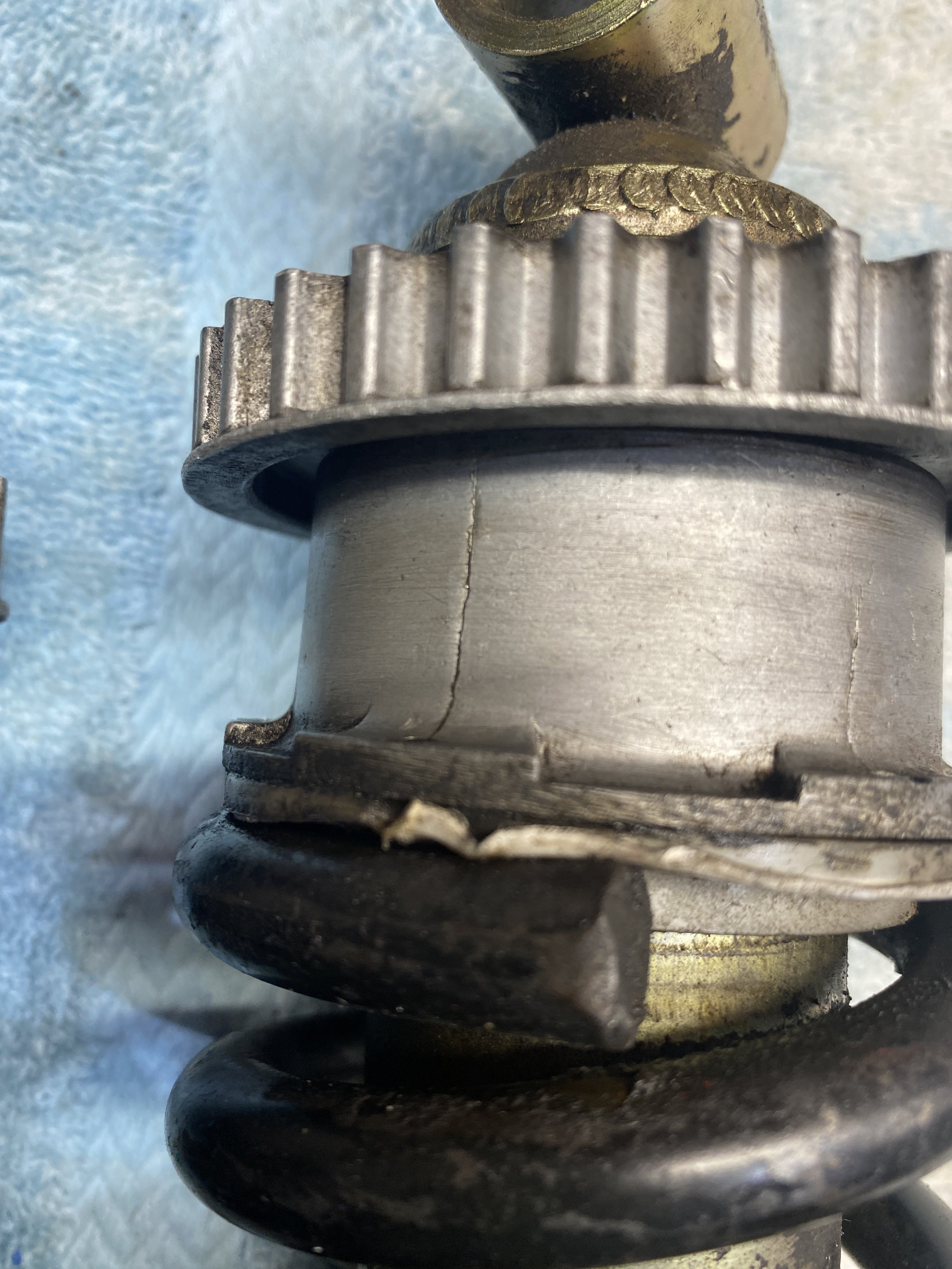

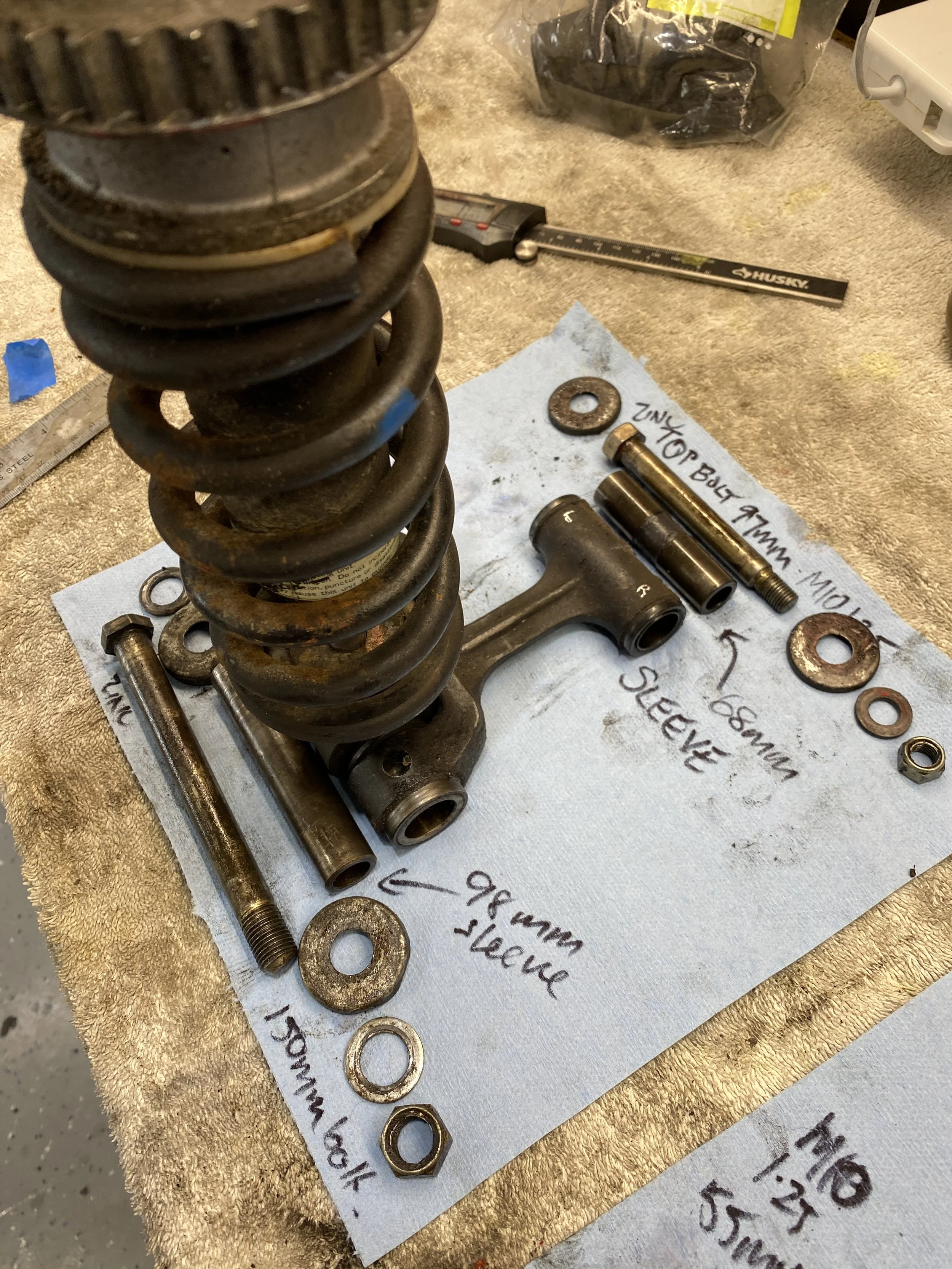

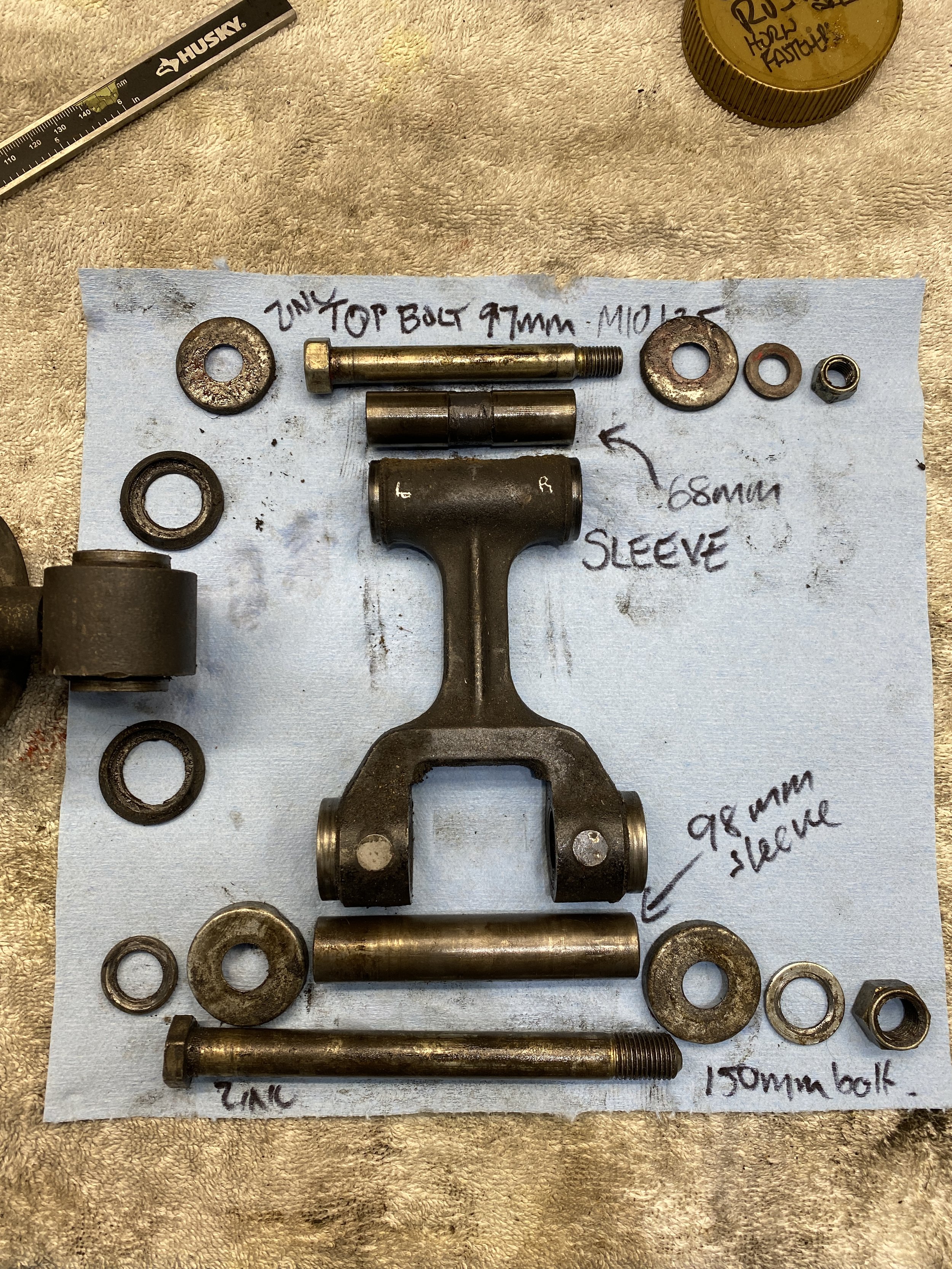

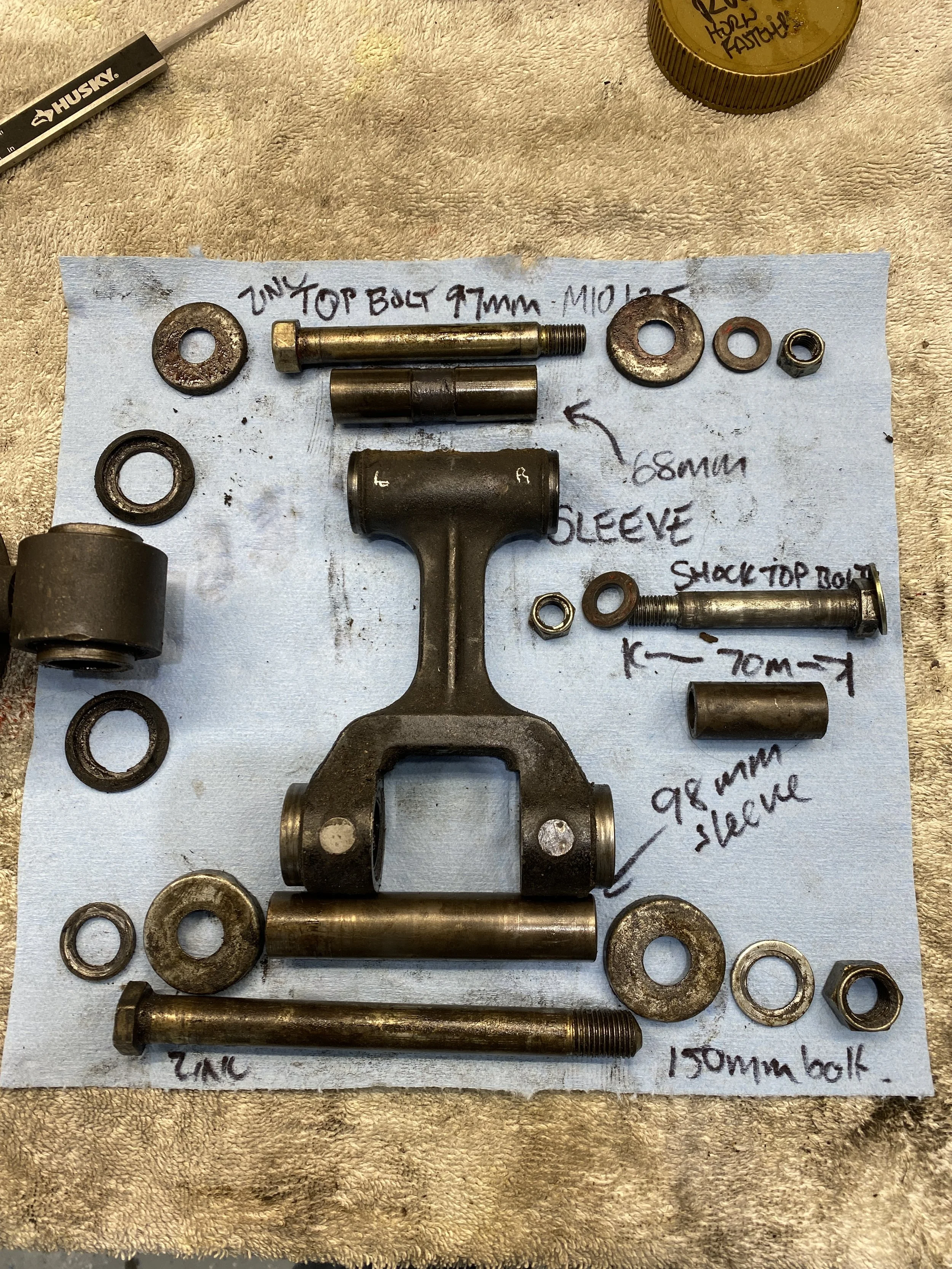

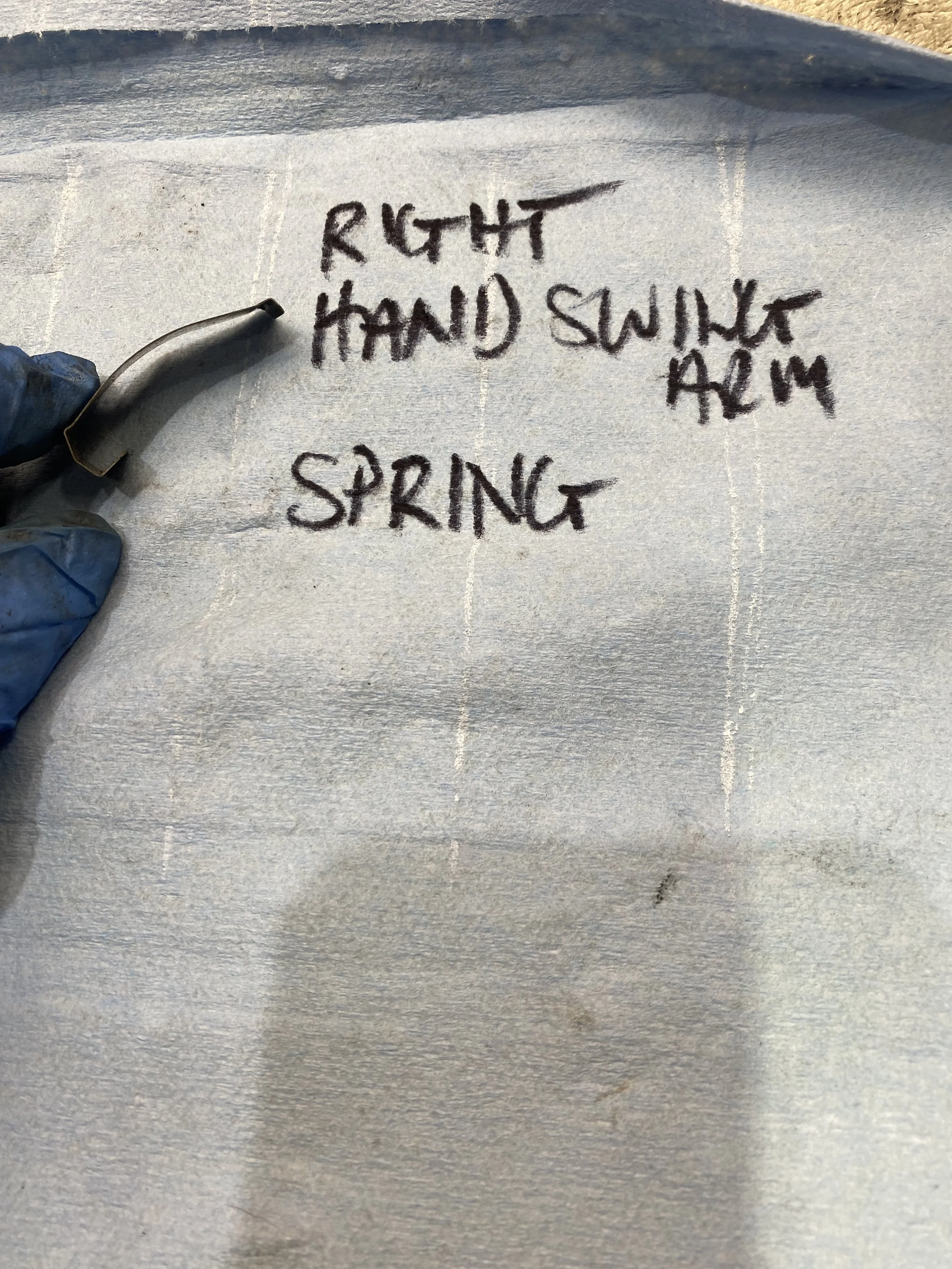

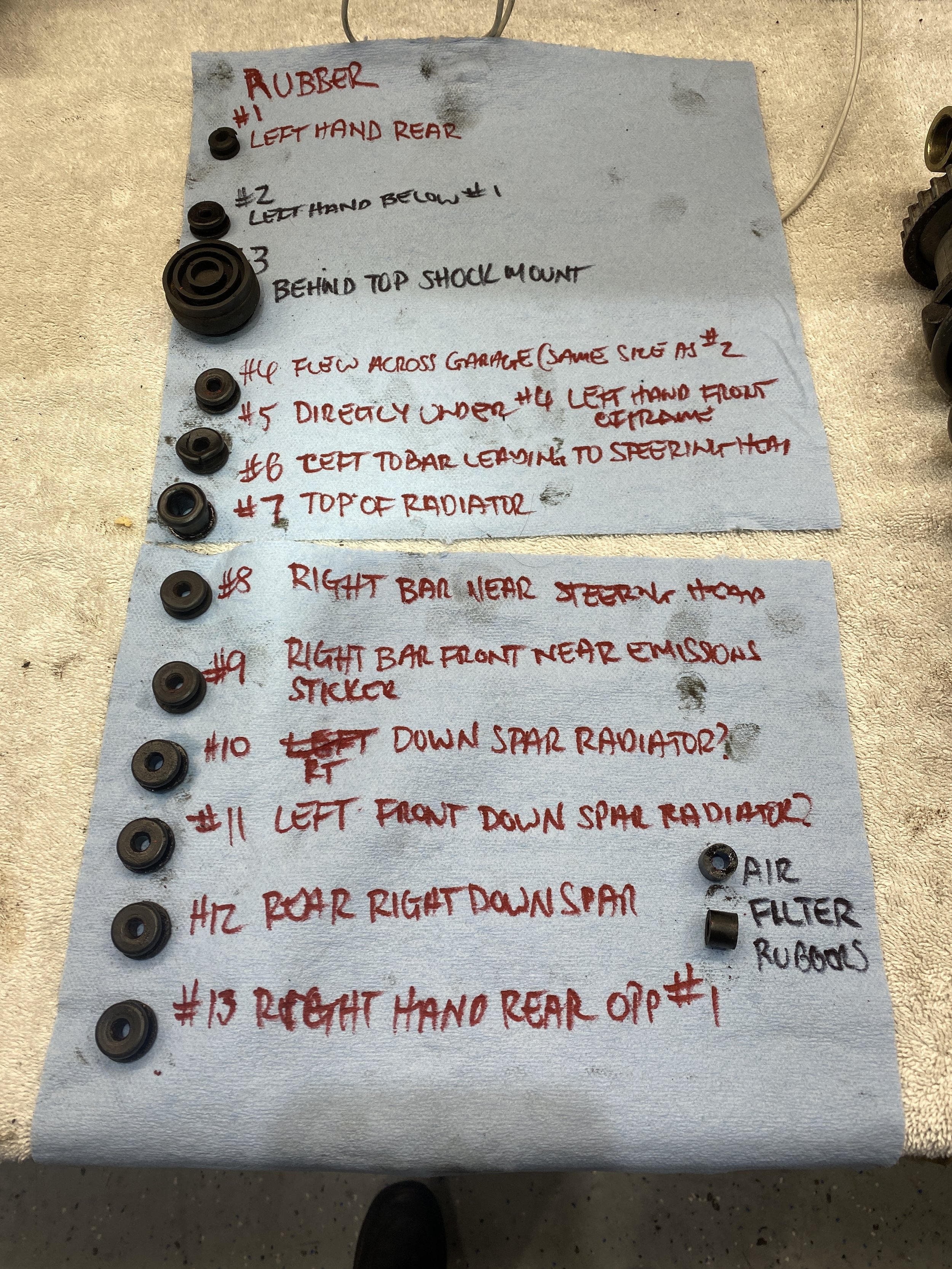

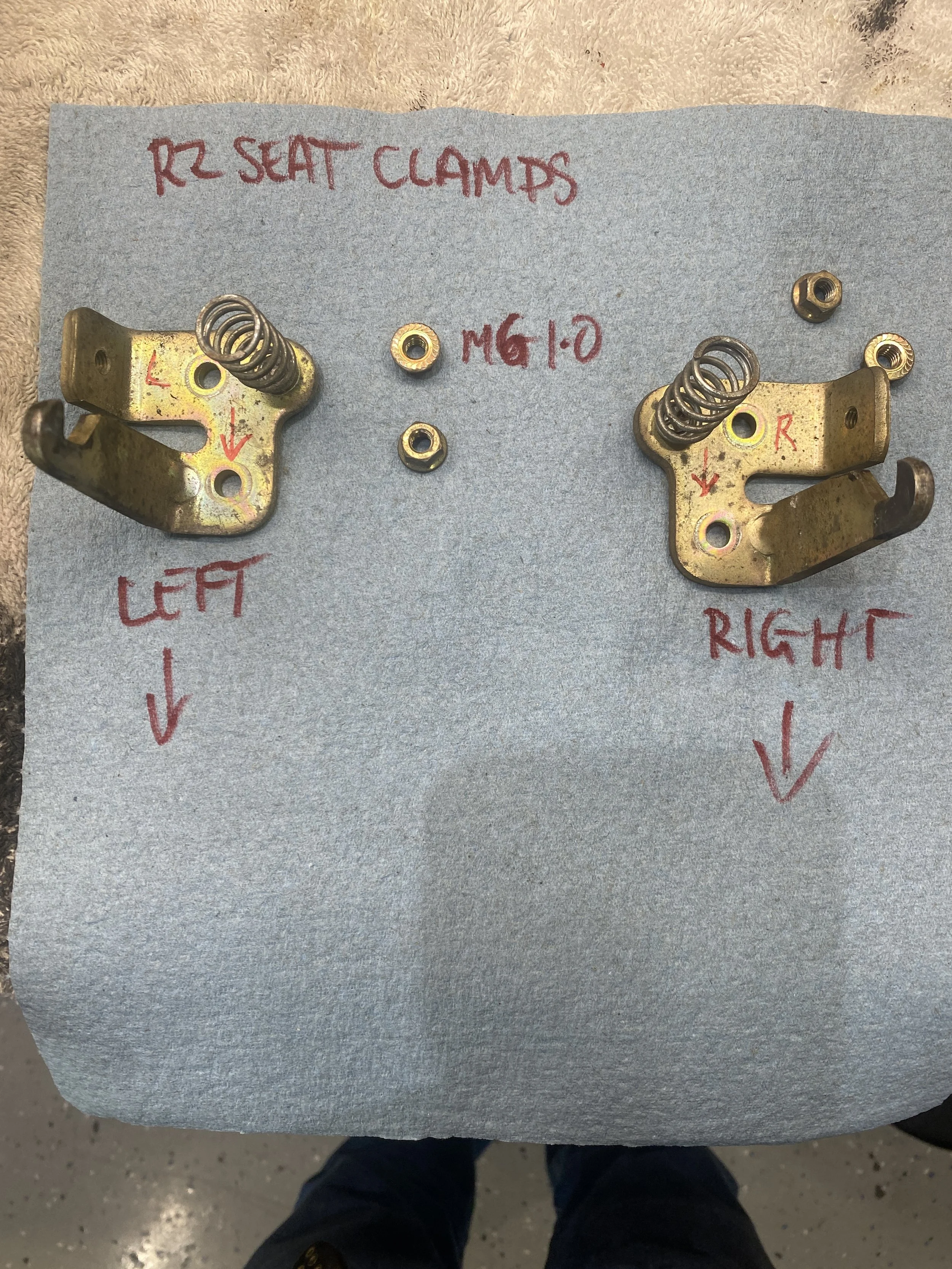

making sure I know which springs go where...

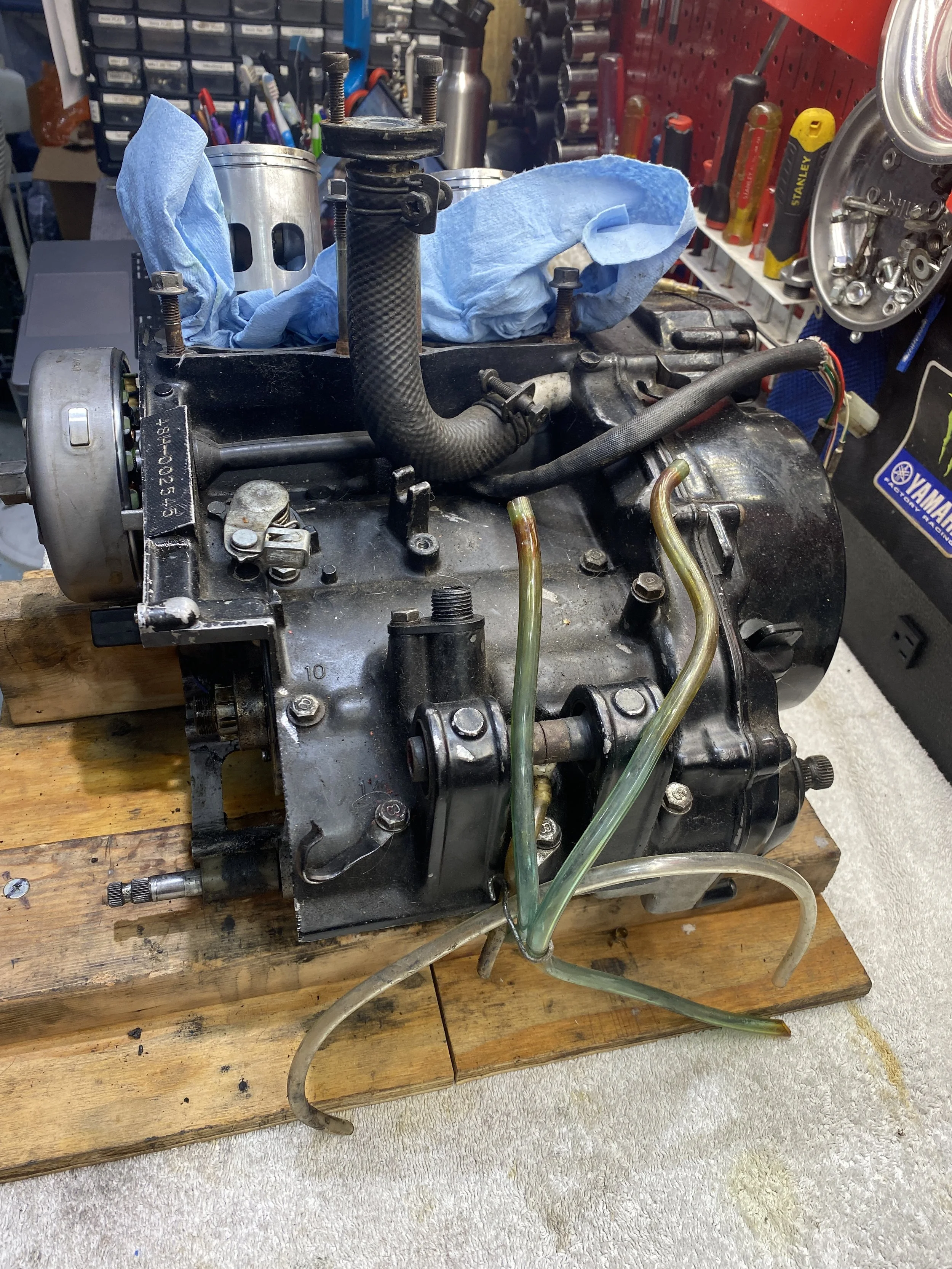

Remembering to drain the oil before I take the engine out....an hour of heat applied first.

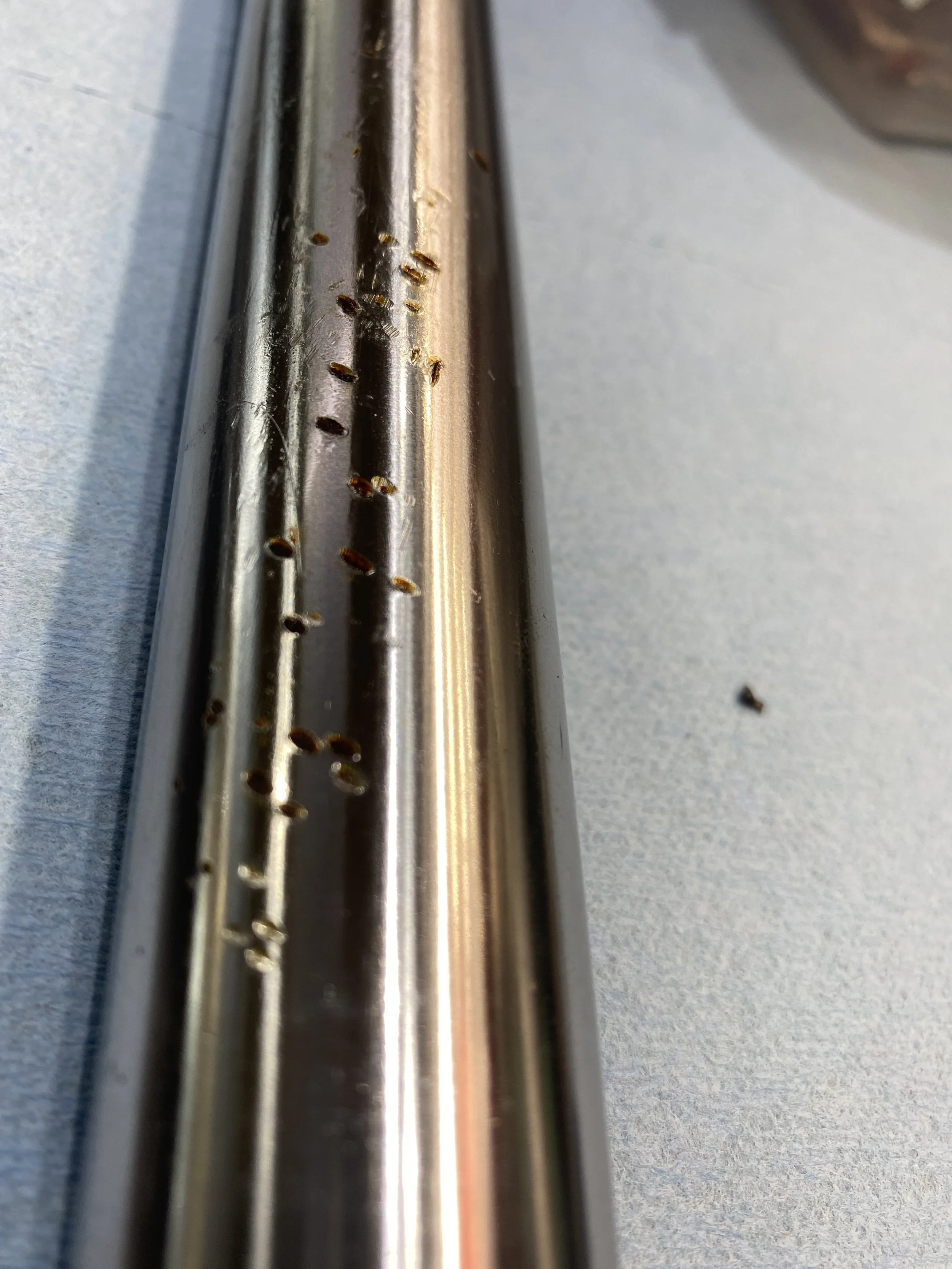

conclusive evidence that this bike was ridden in the rain! That will never happen again.

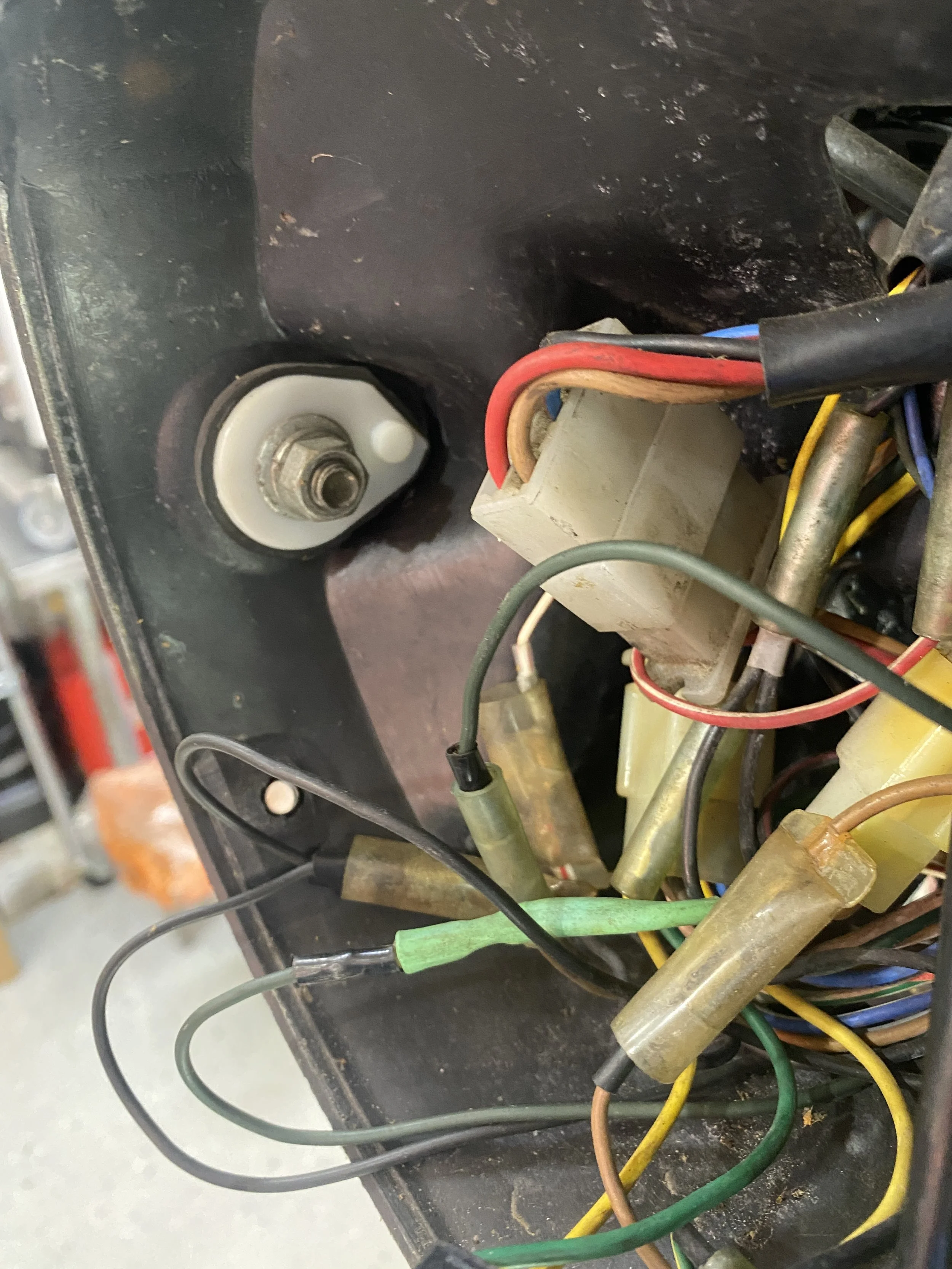

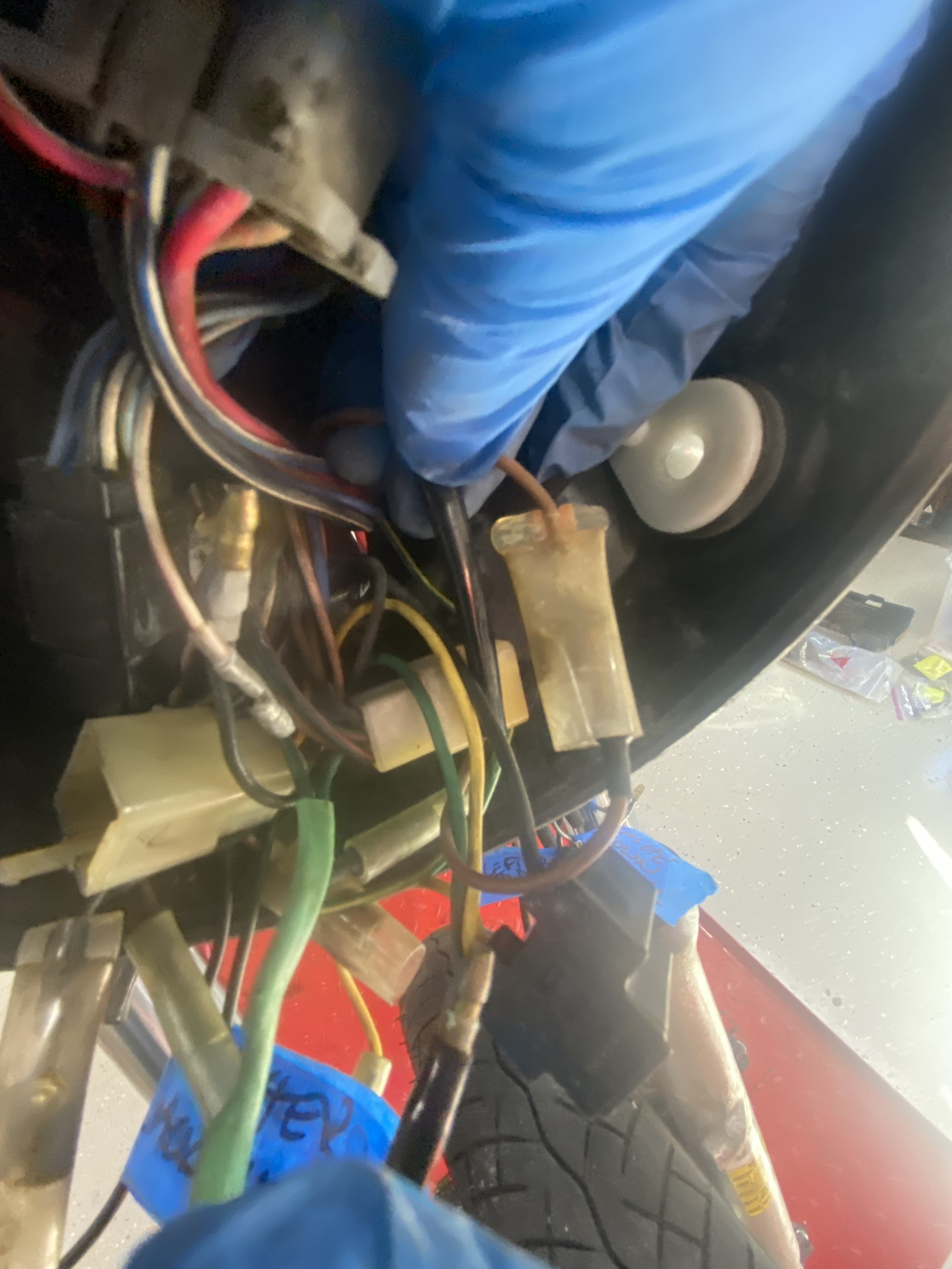

I need a blank for this big hole in the switchgear where the headlight switch would be...in some territories...

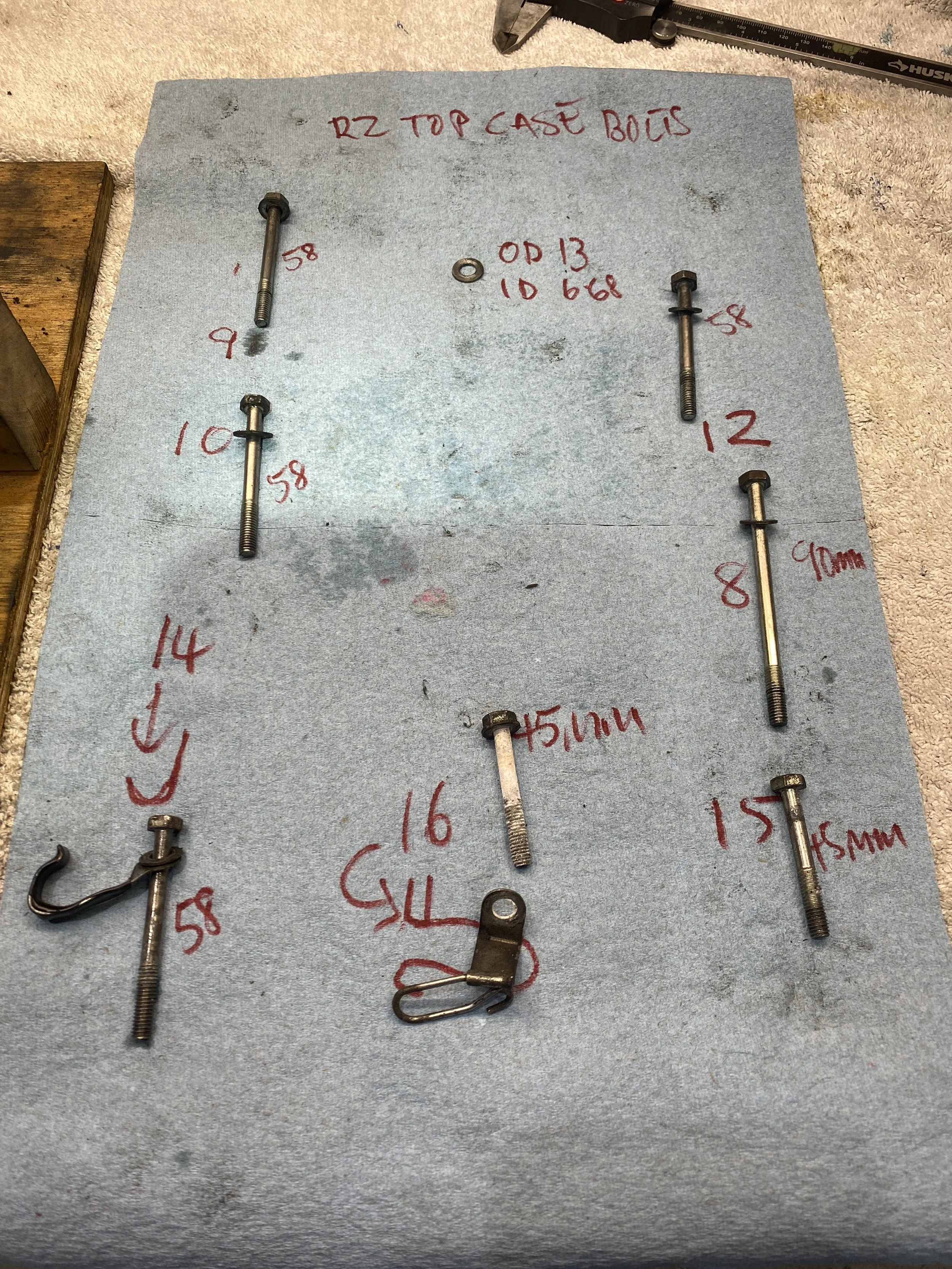

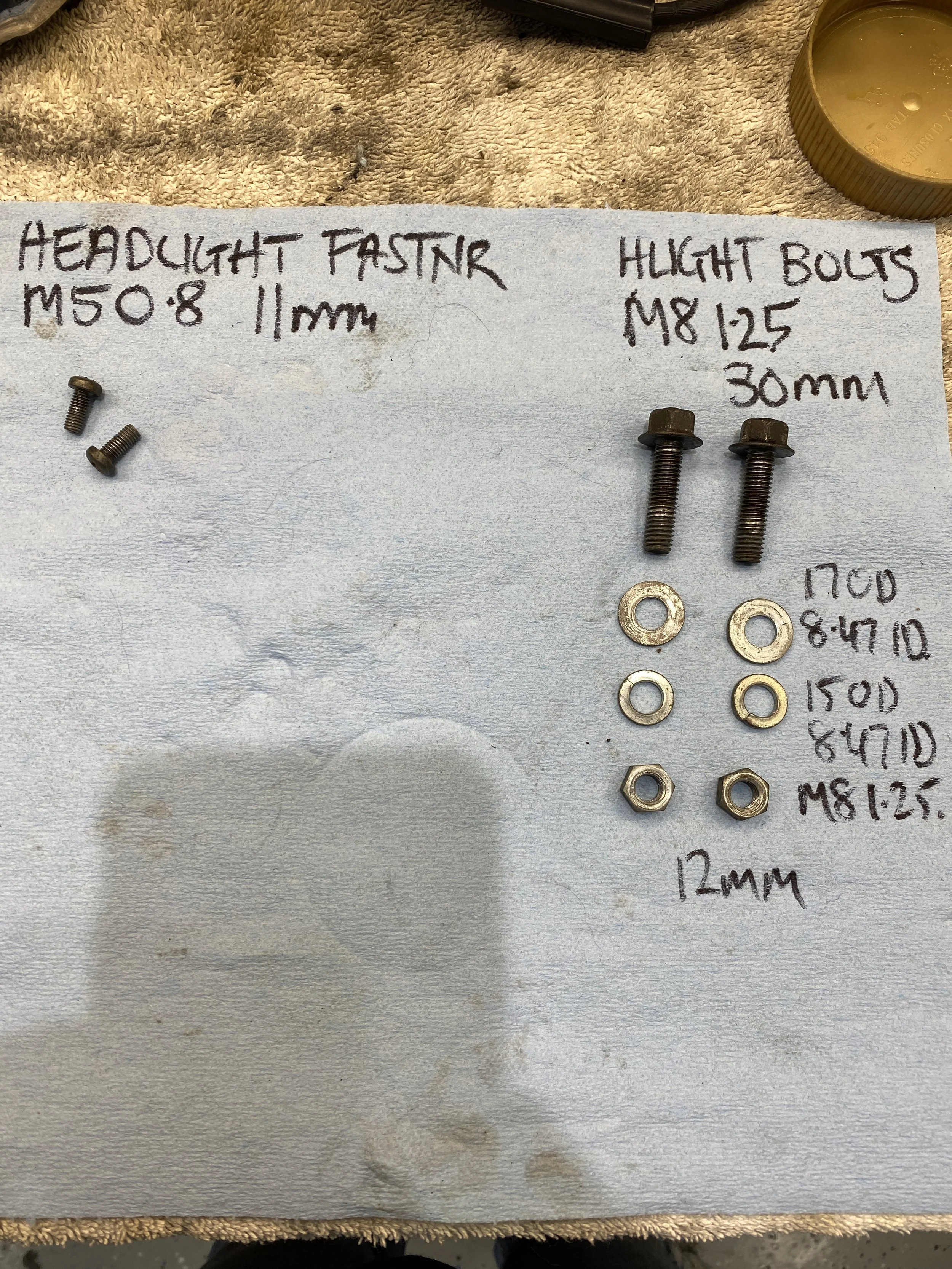

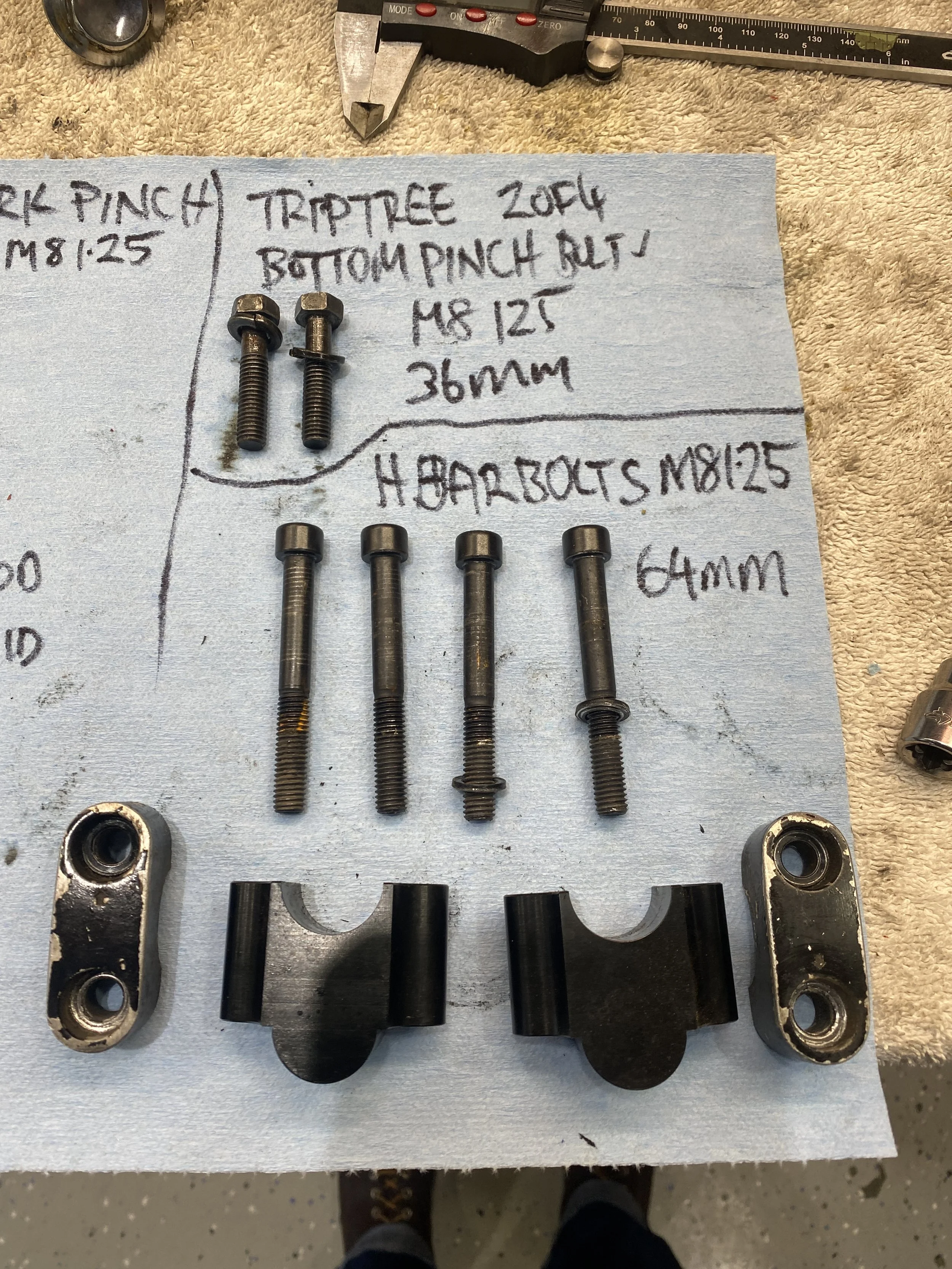

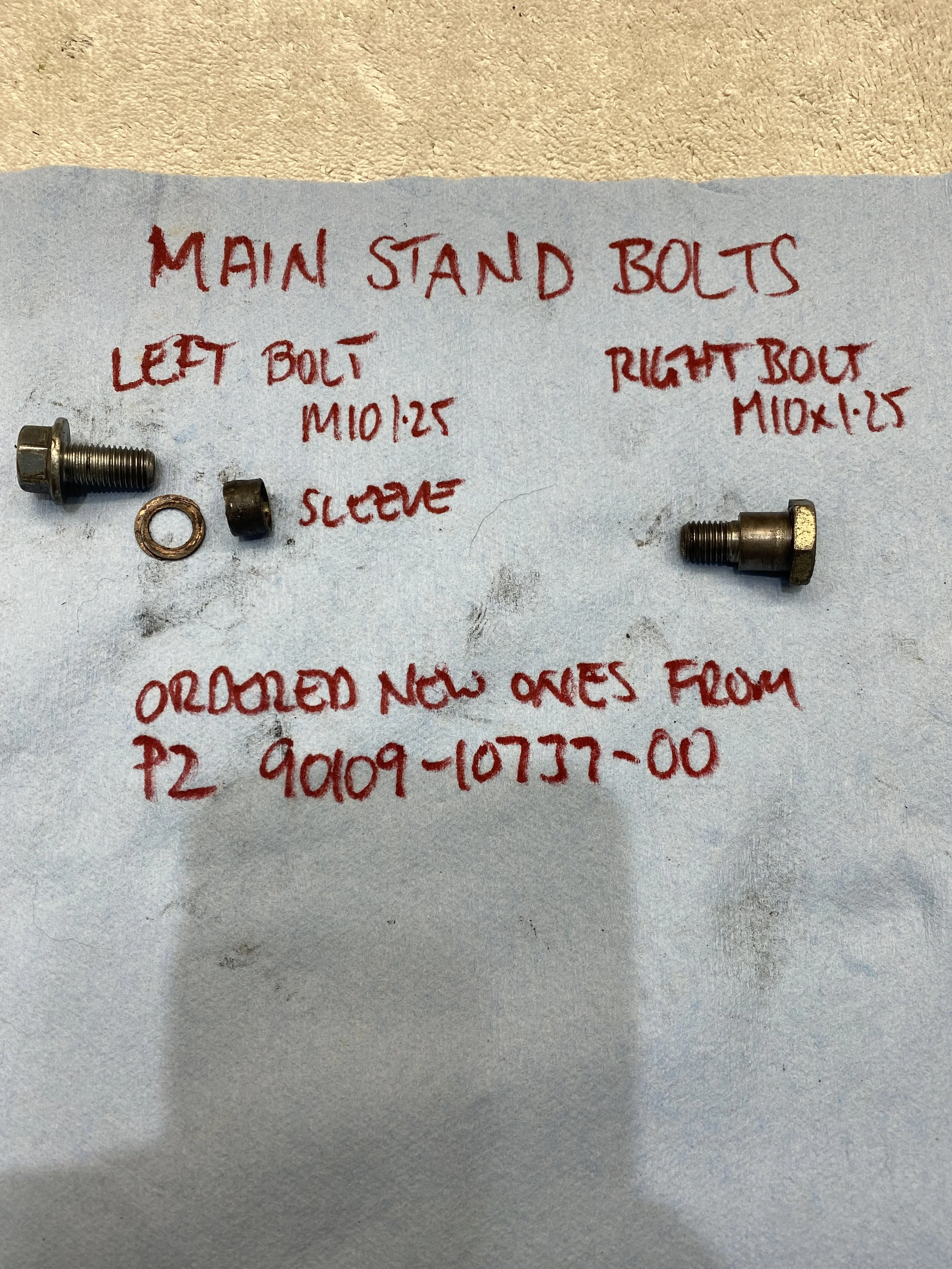

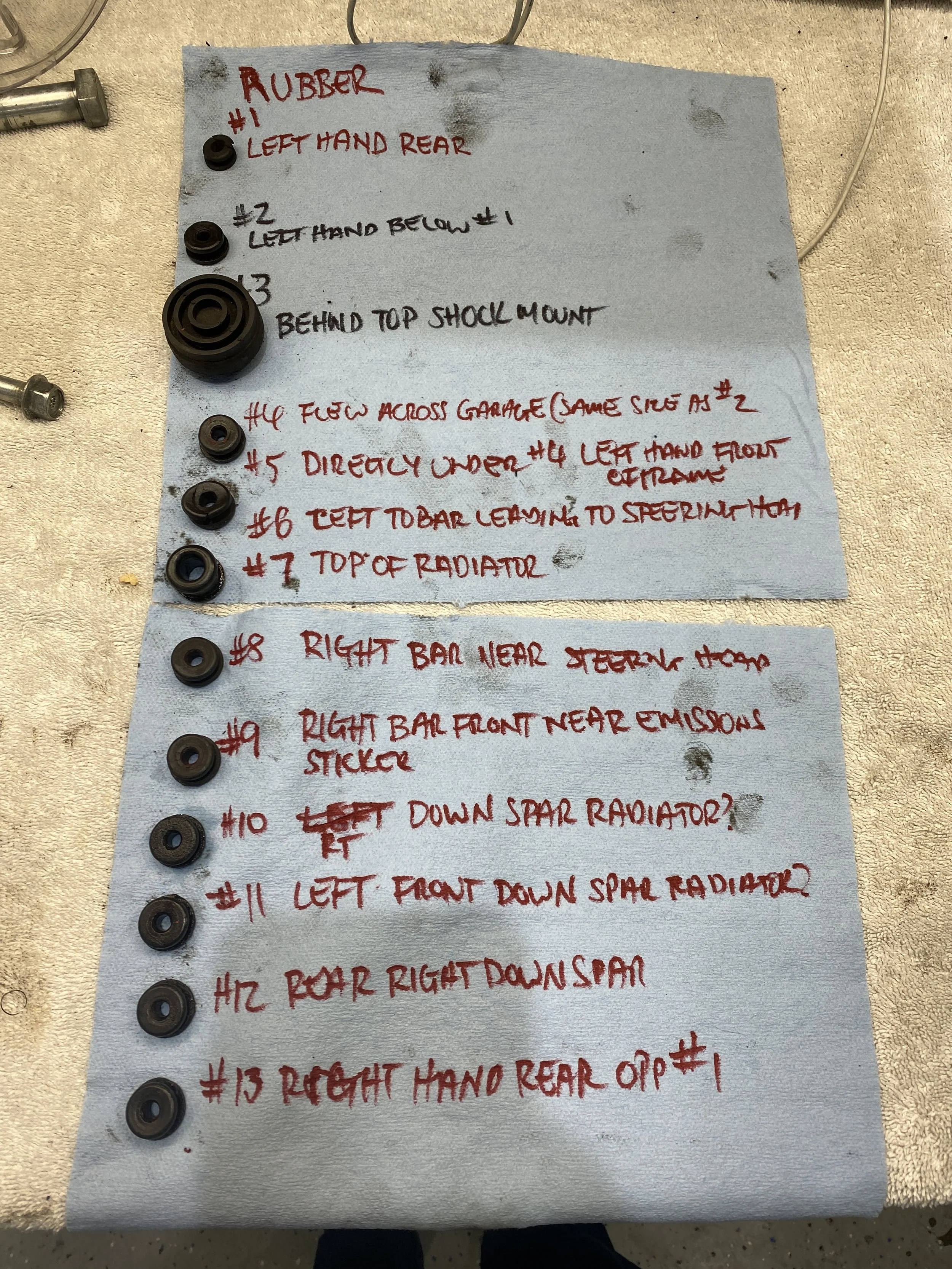

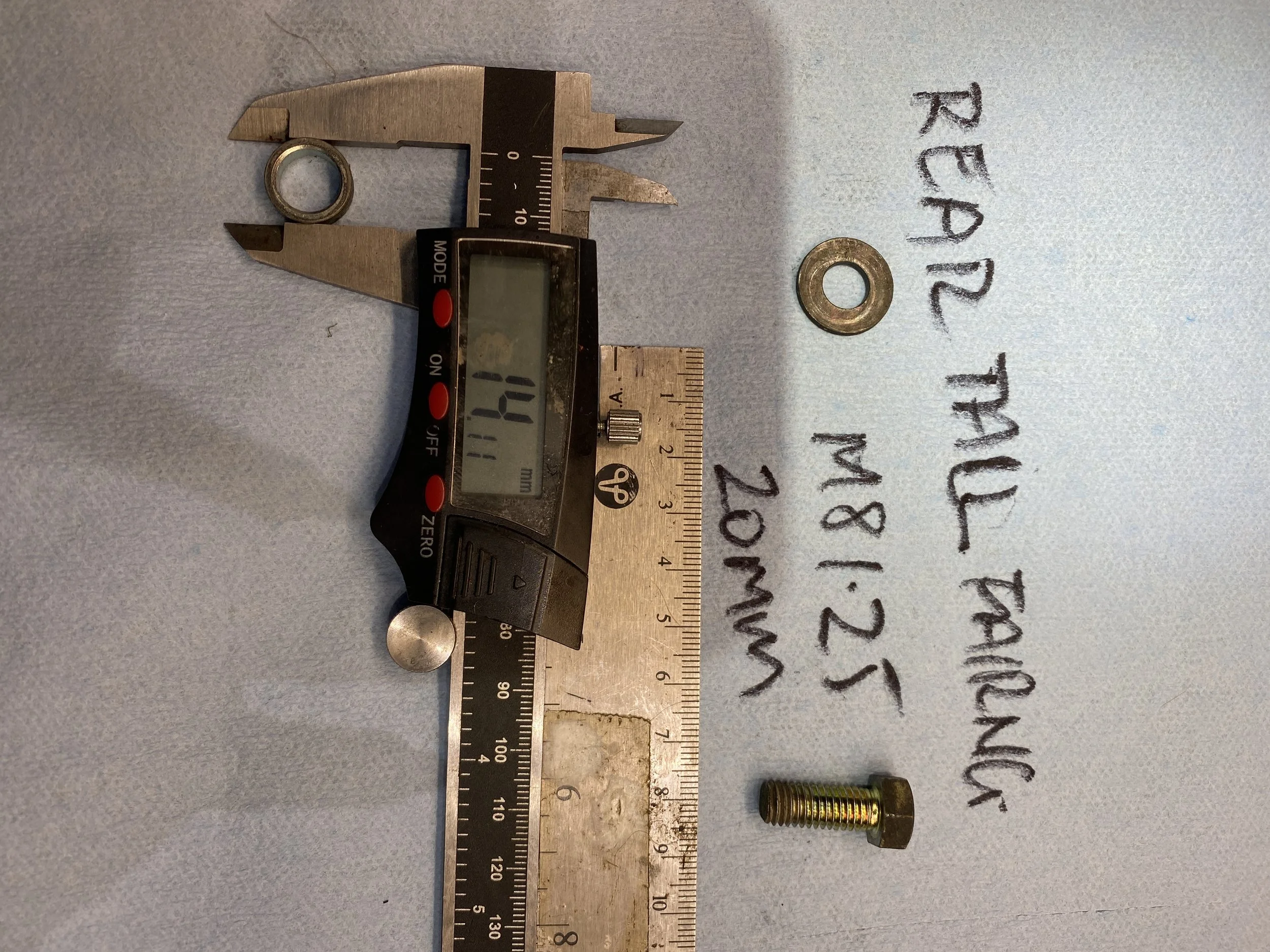

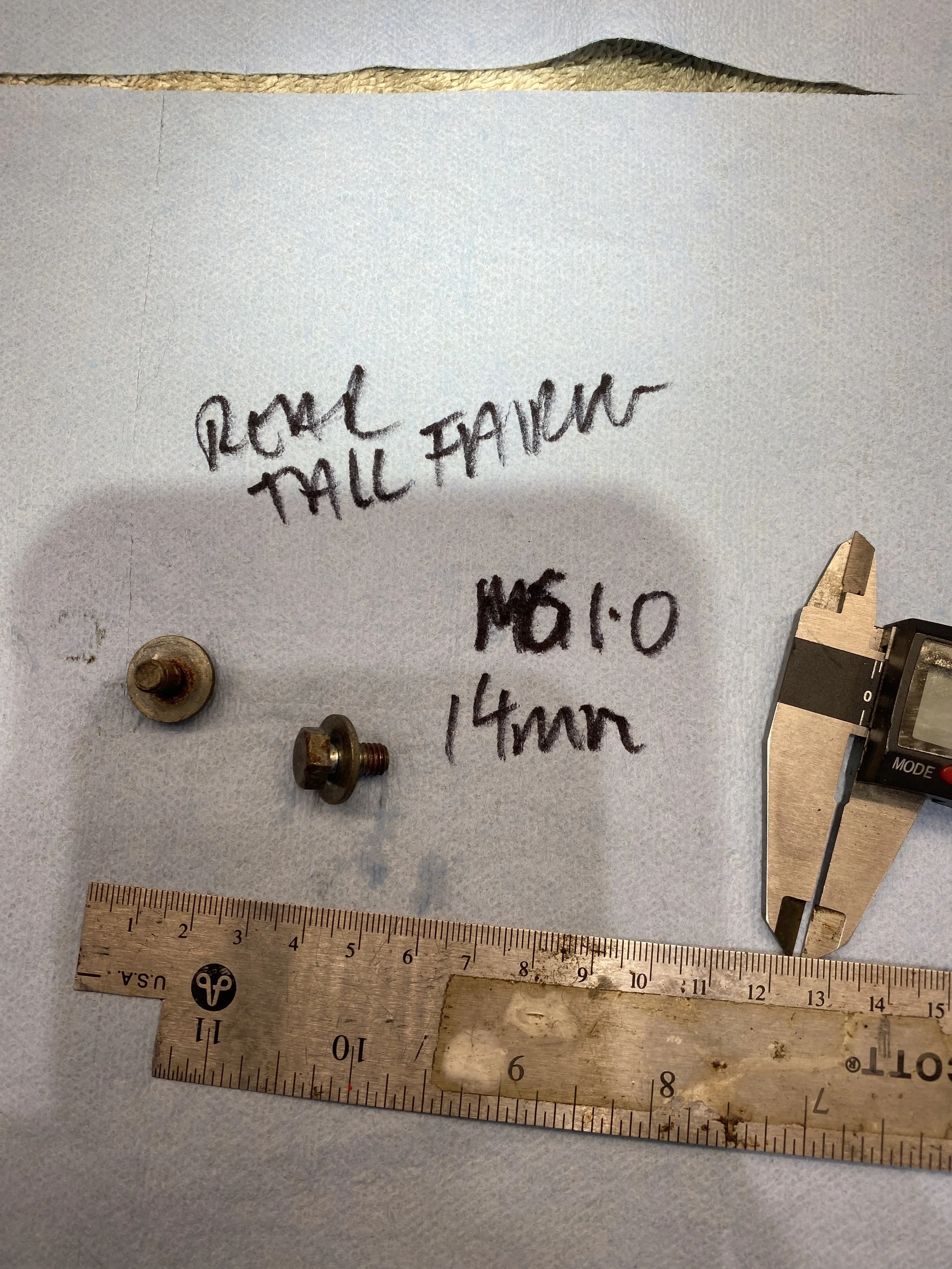

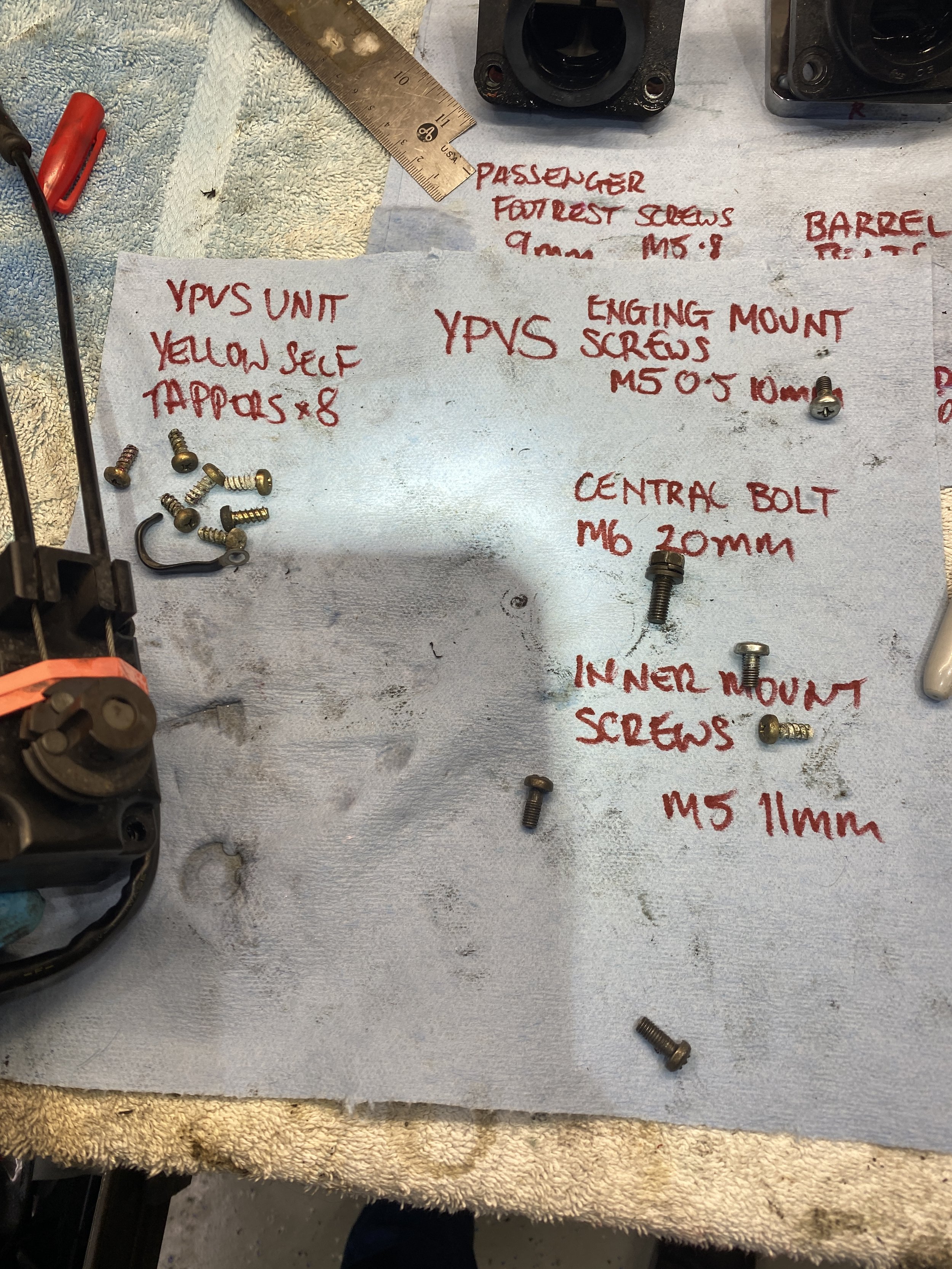

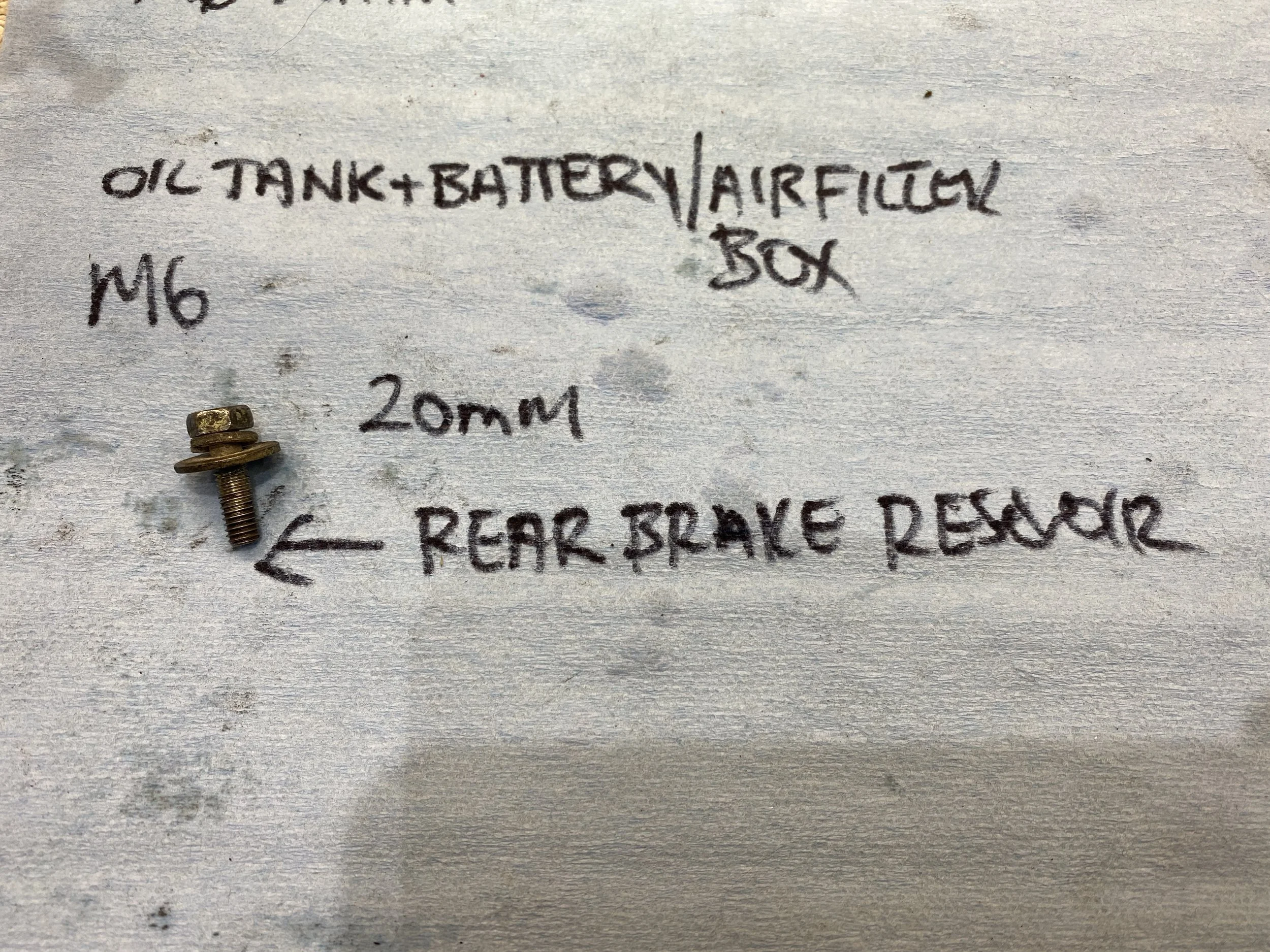

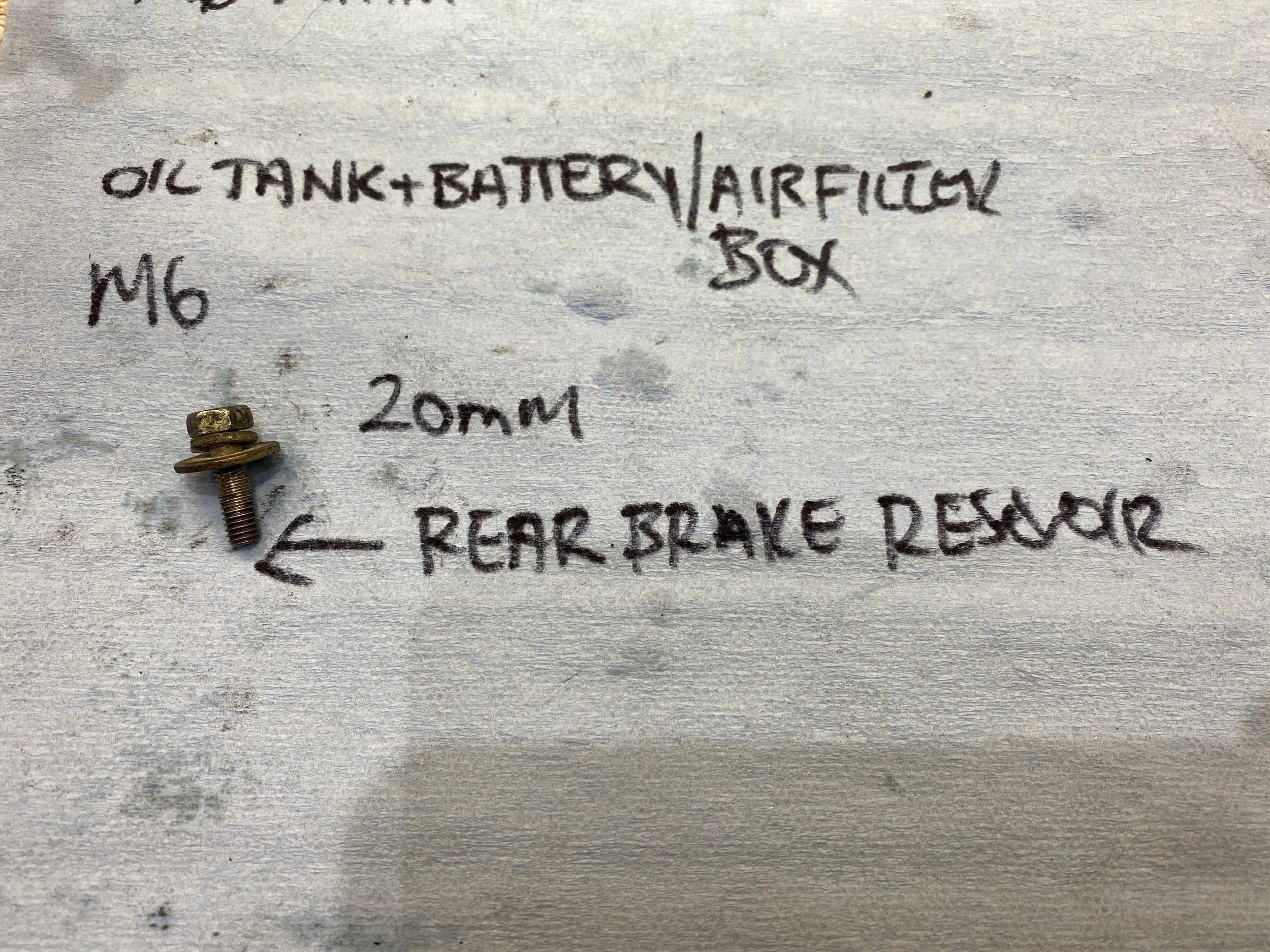

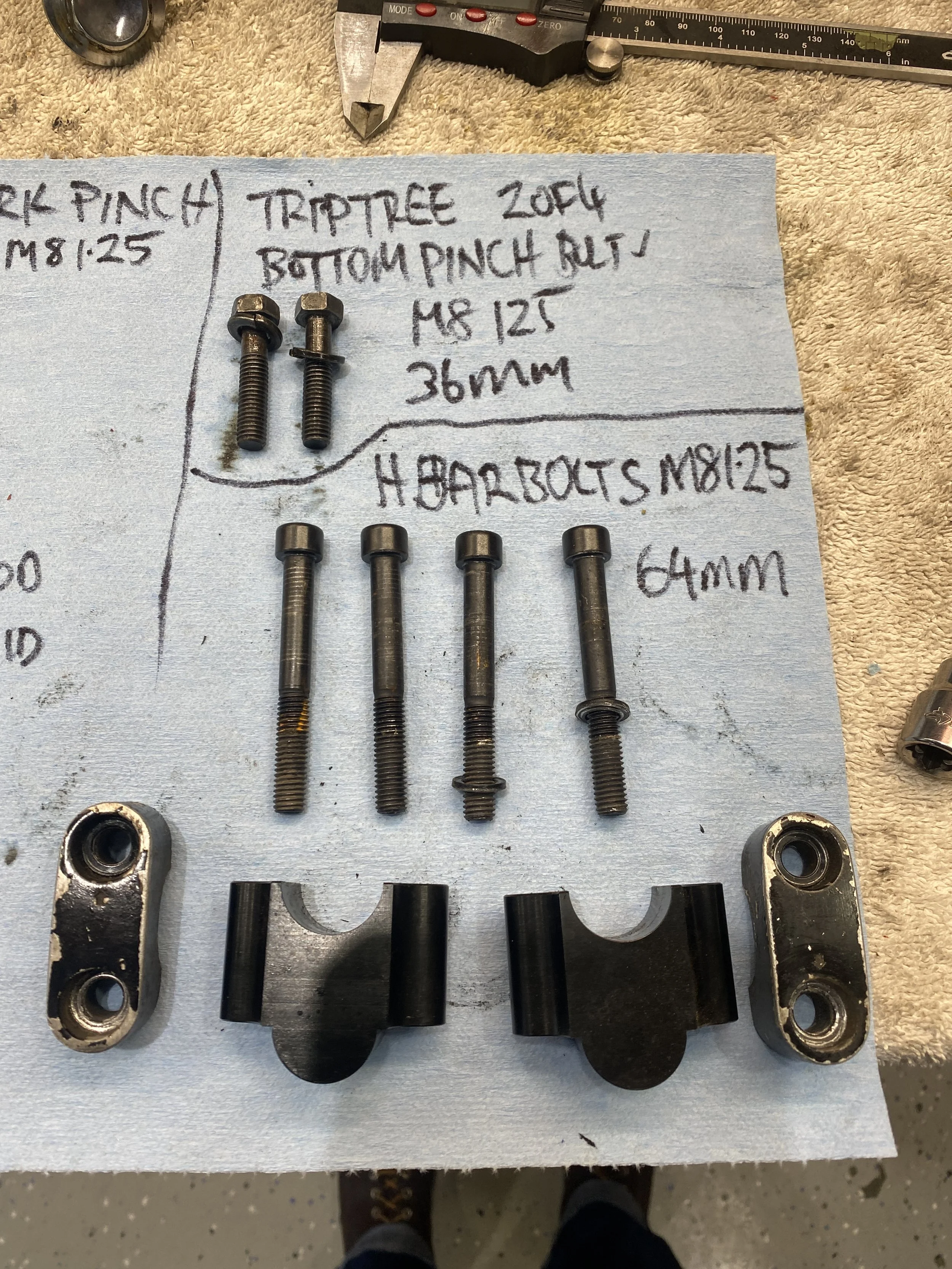

More notes.

Matching numbers.....

.....always something to hold onto when the amount of money you spend on a bike crosses the line of what it's worth and plunges deep into the red...

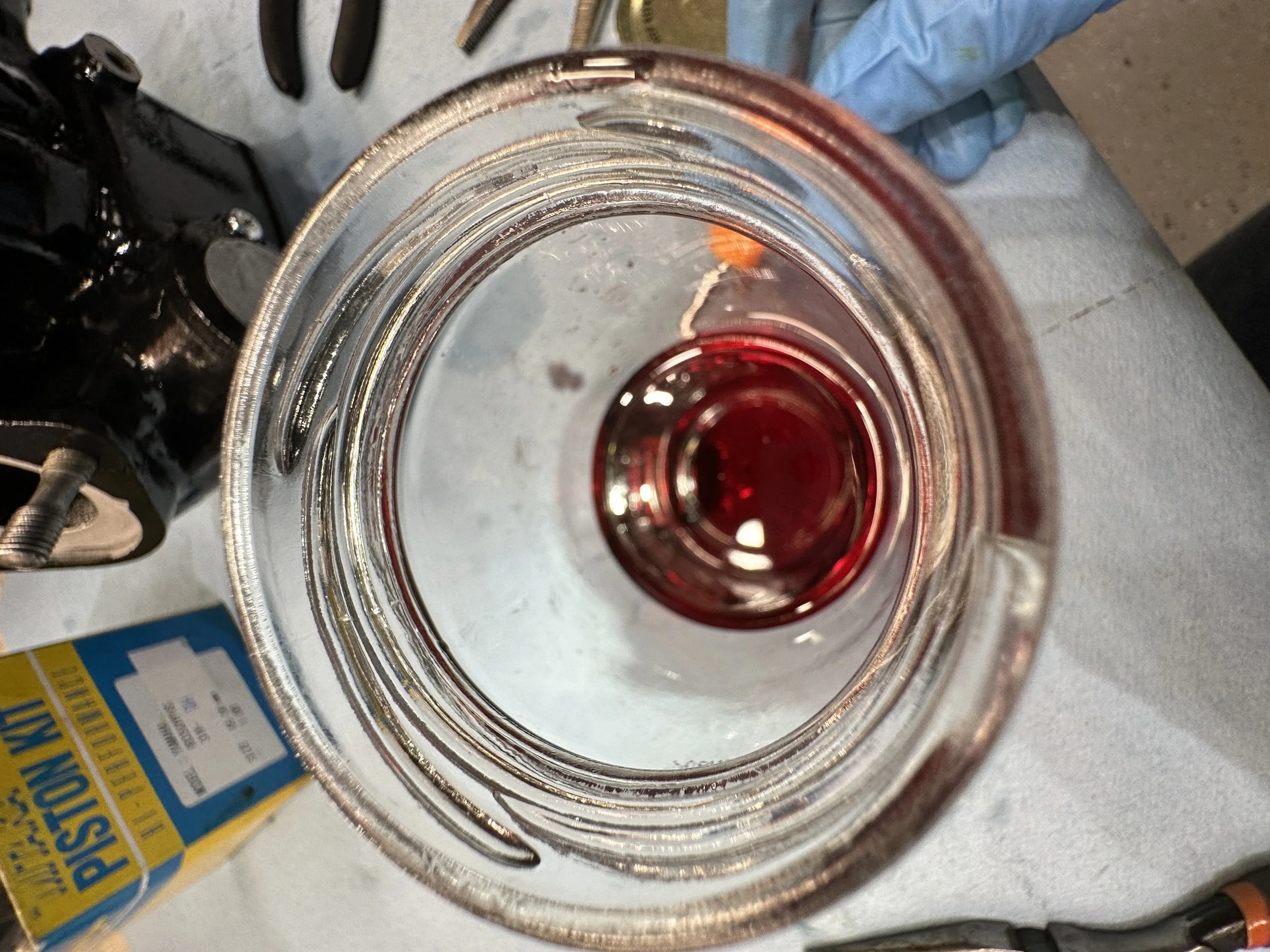

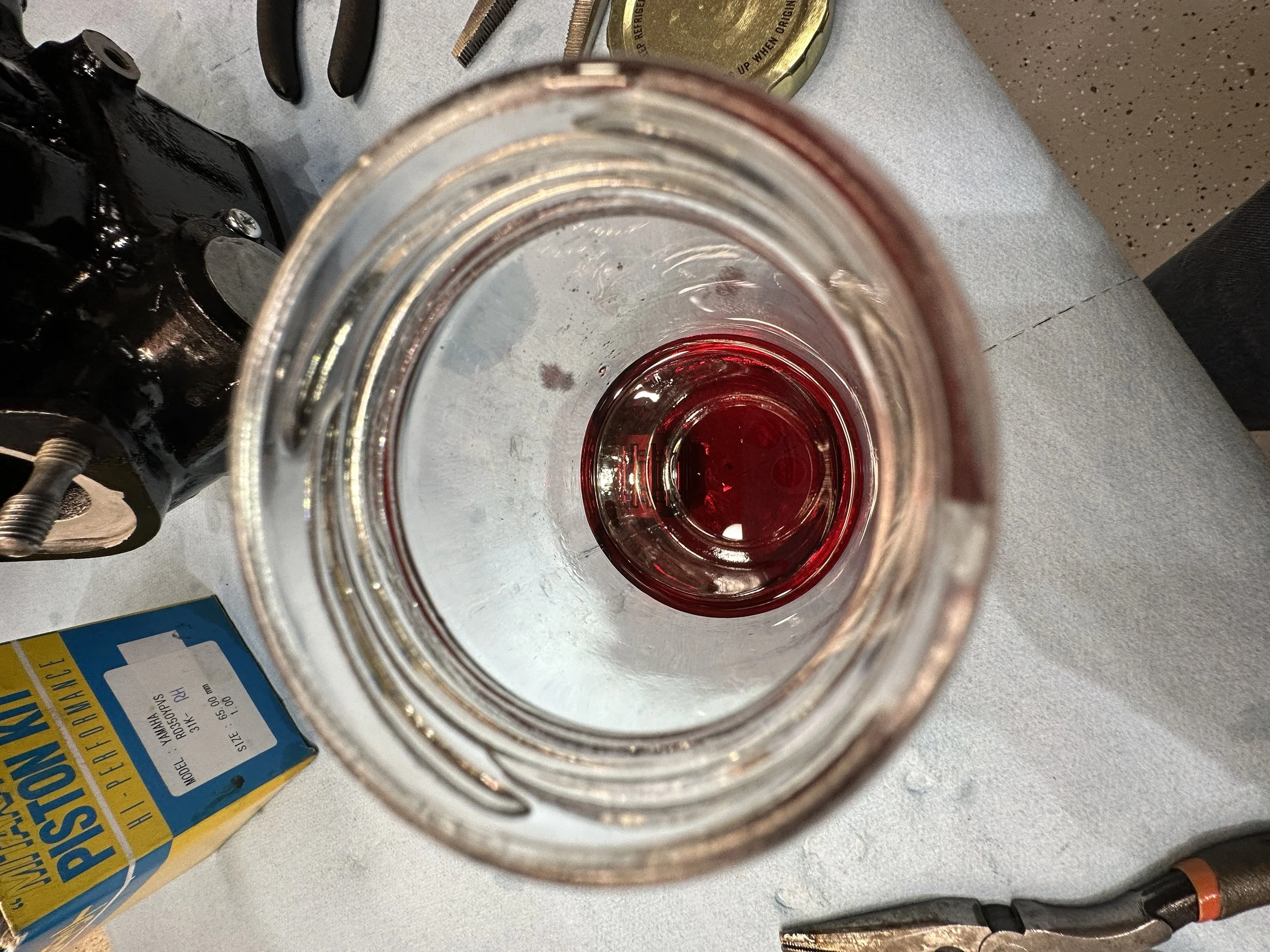

oil looks good. Remarkably green and no flecks....

whatever....

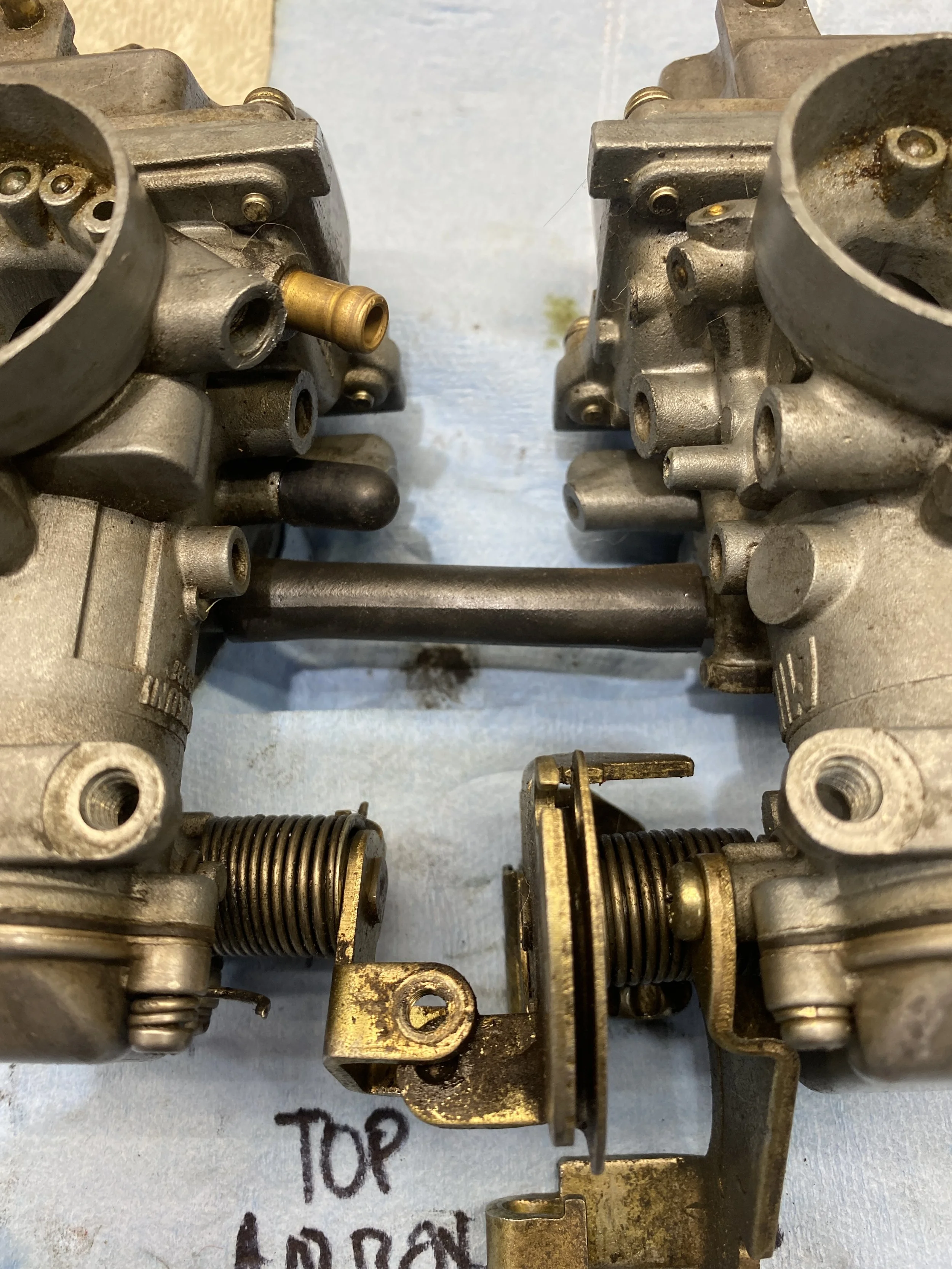

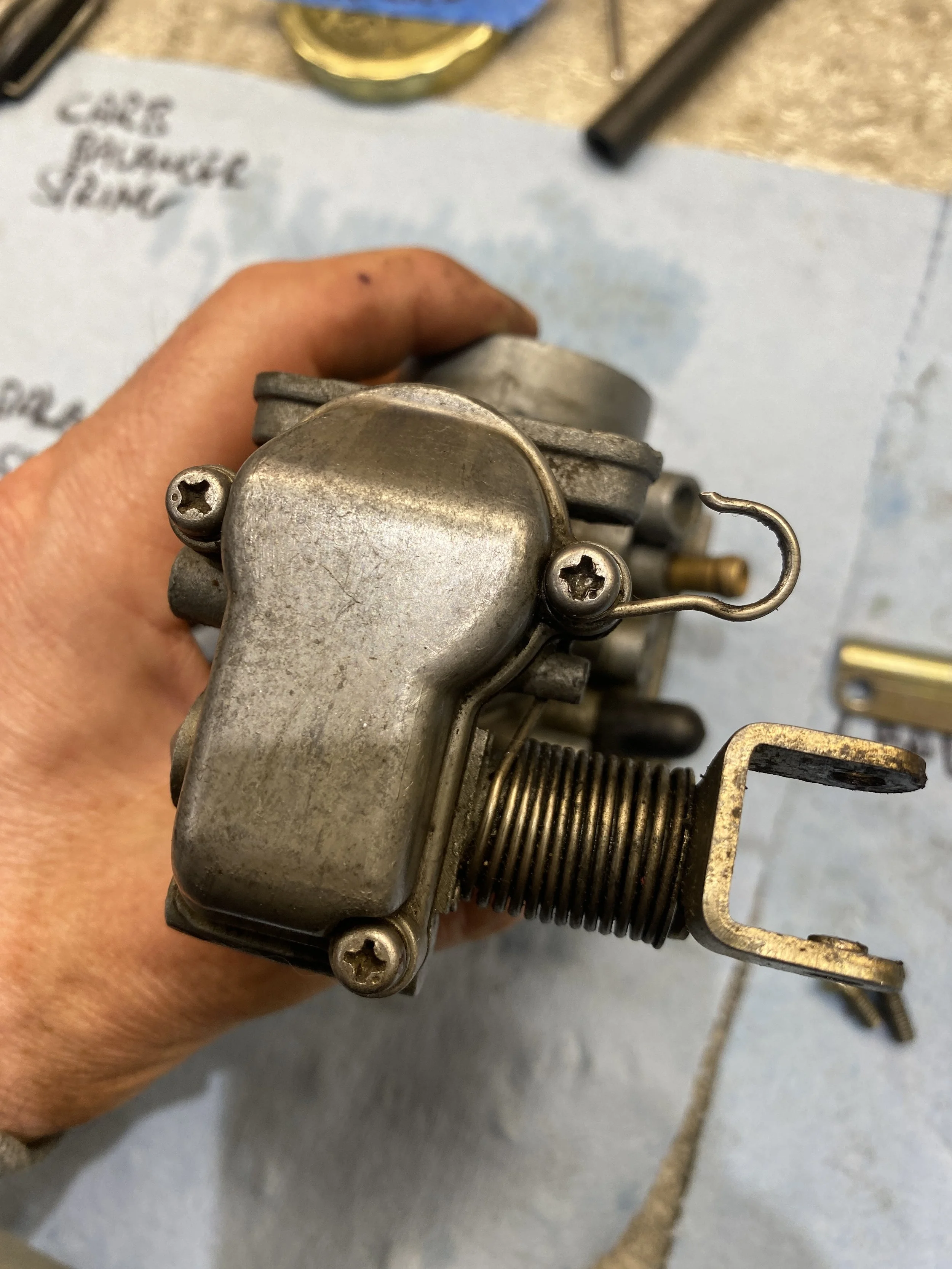

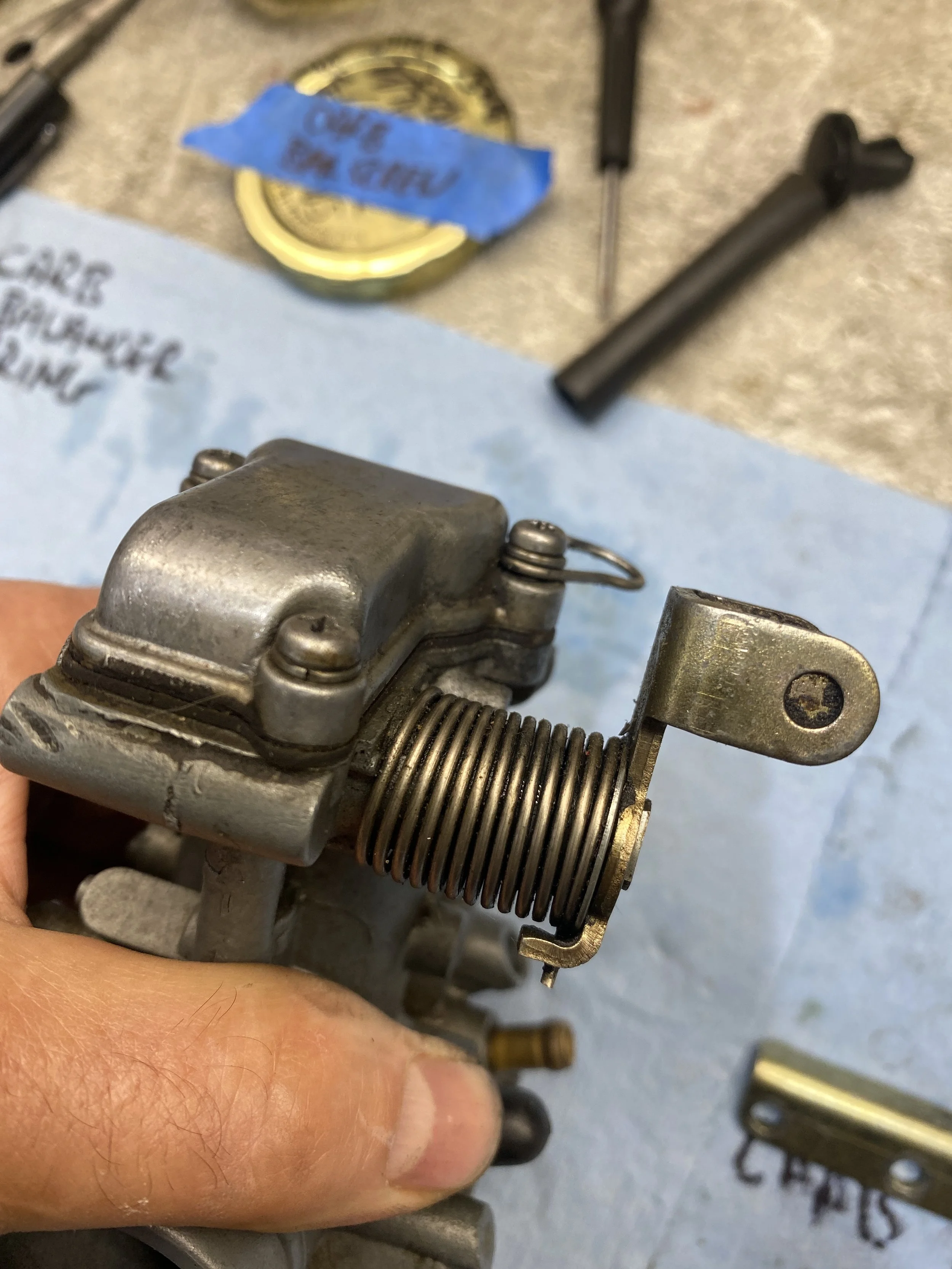

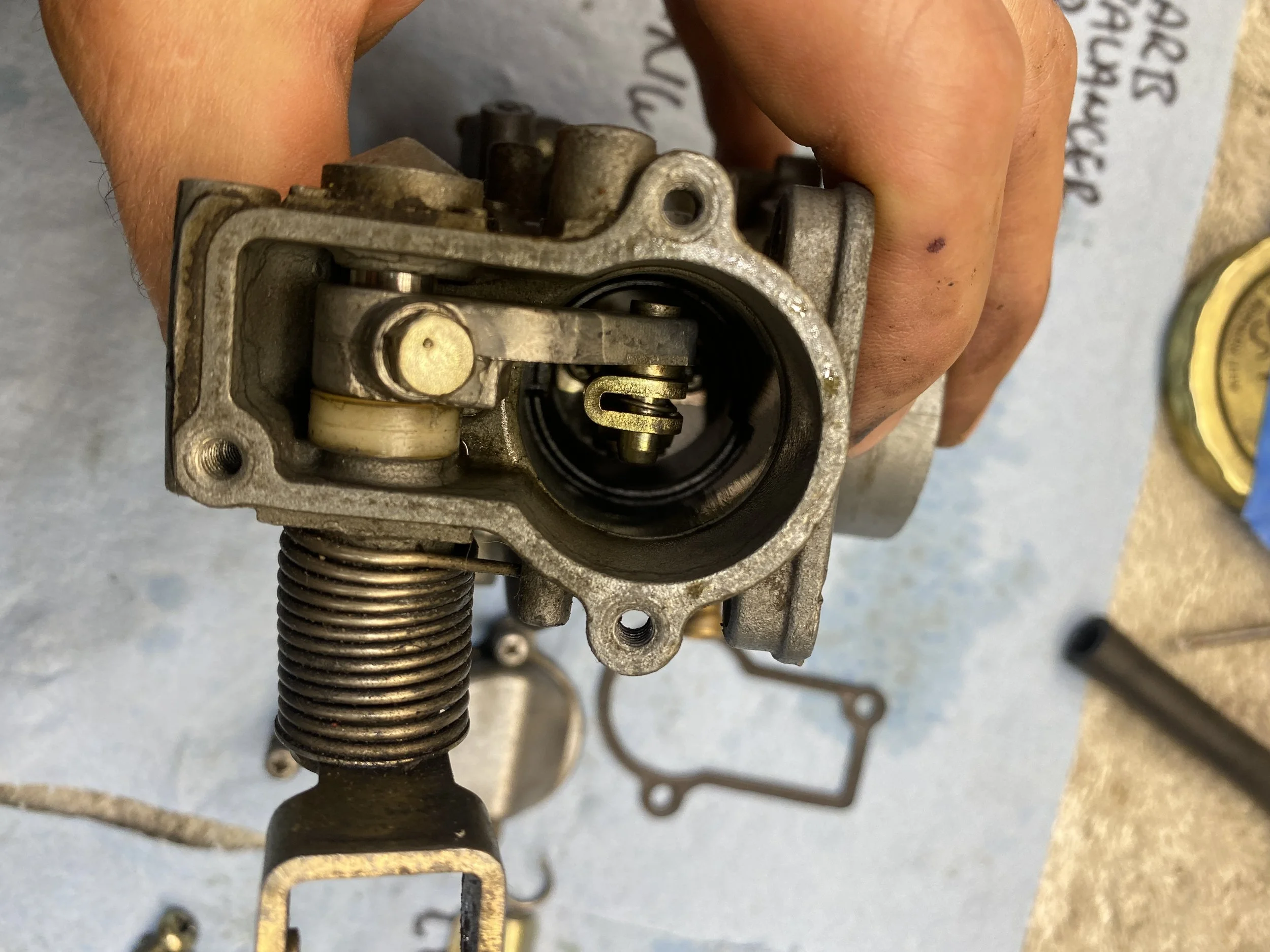

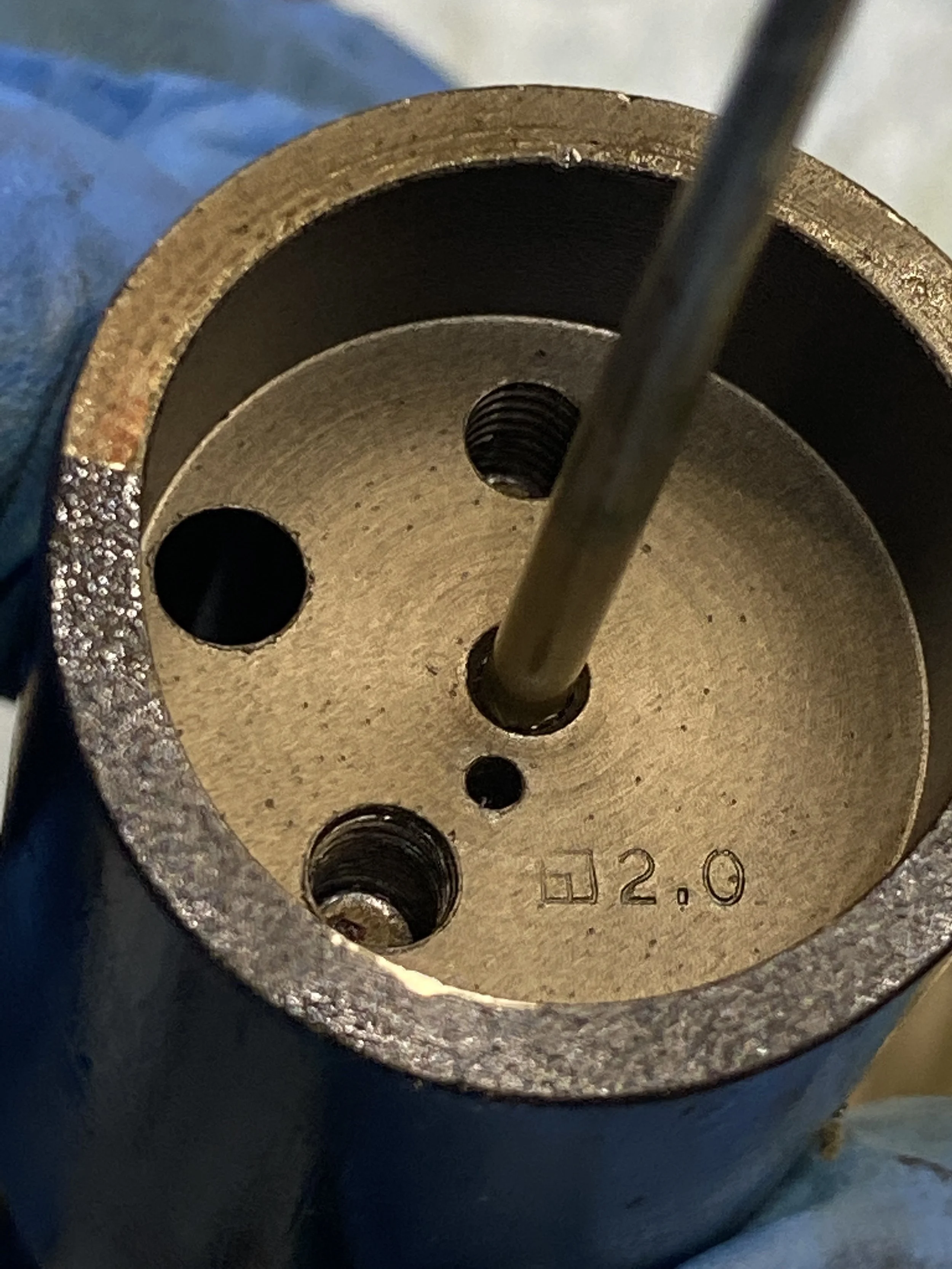

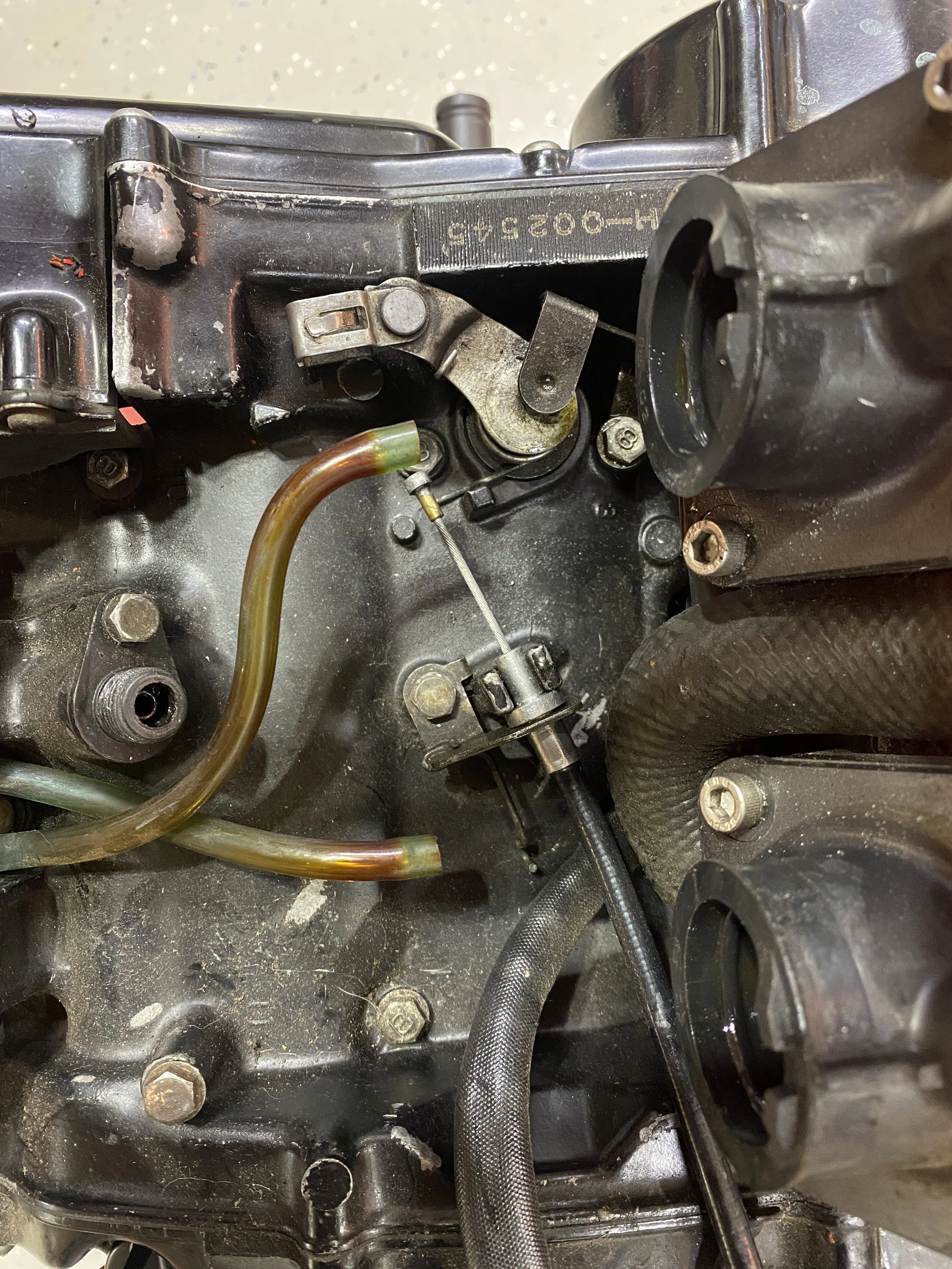

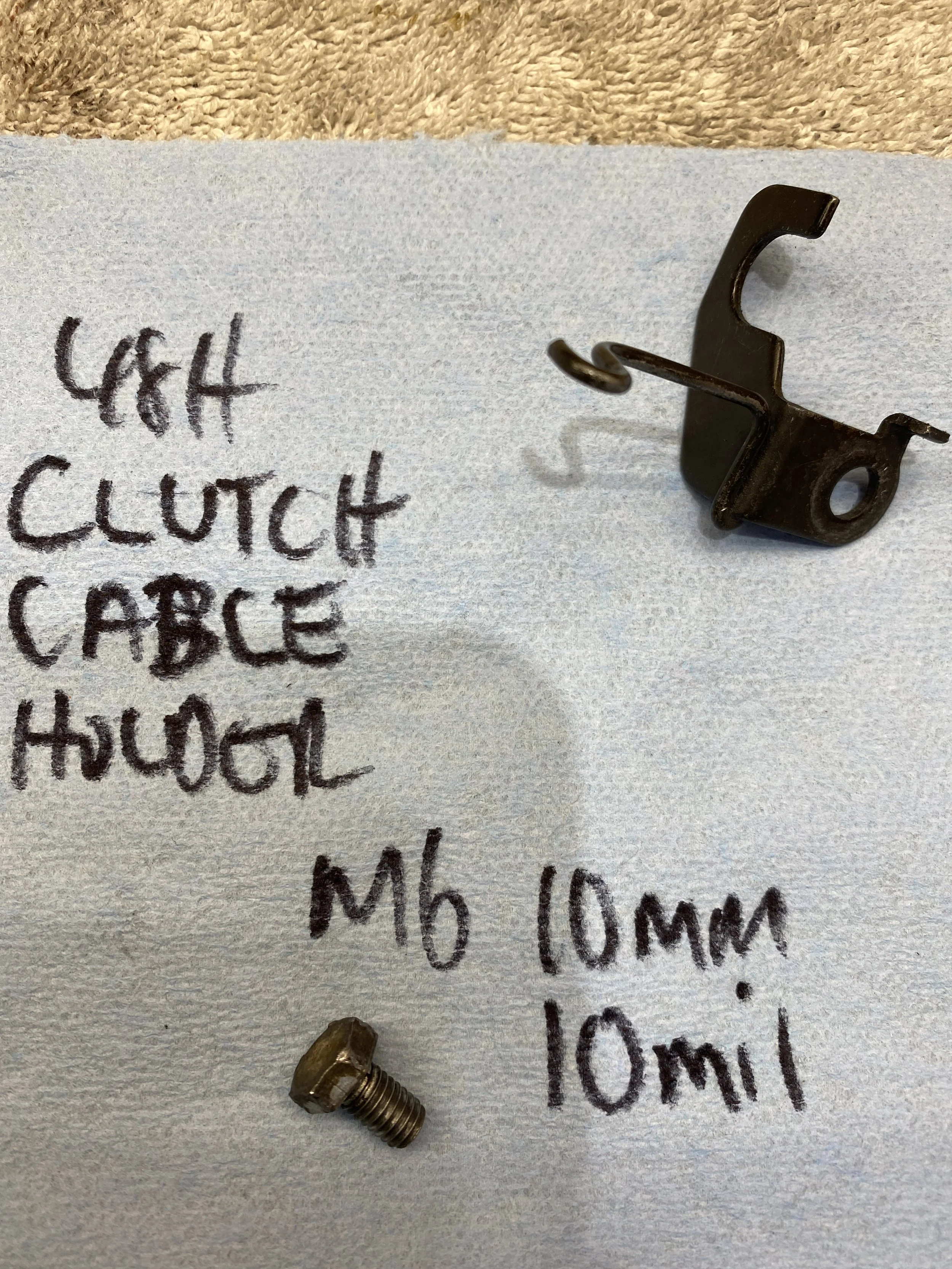

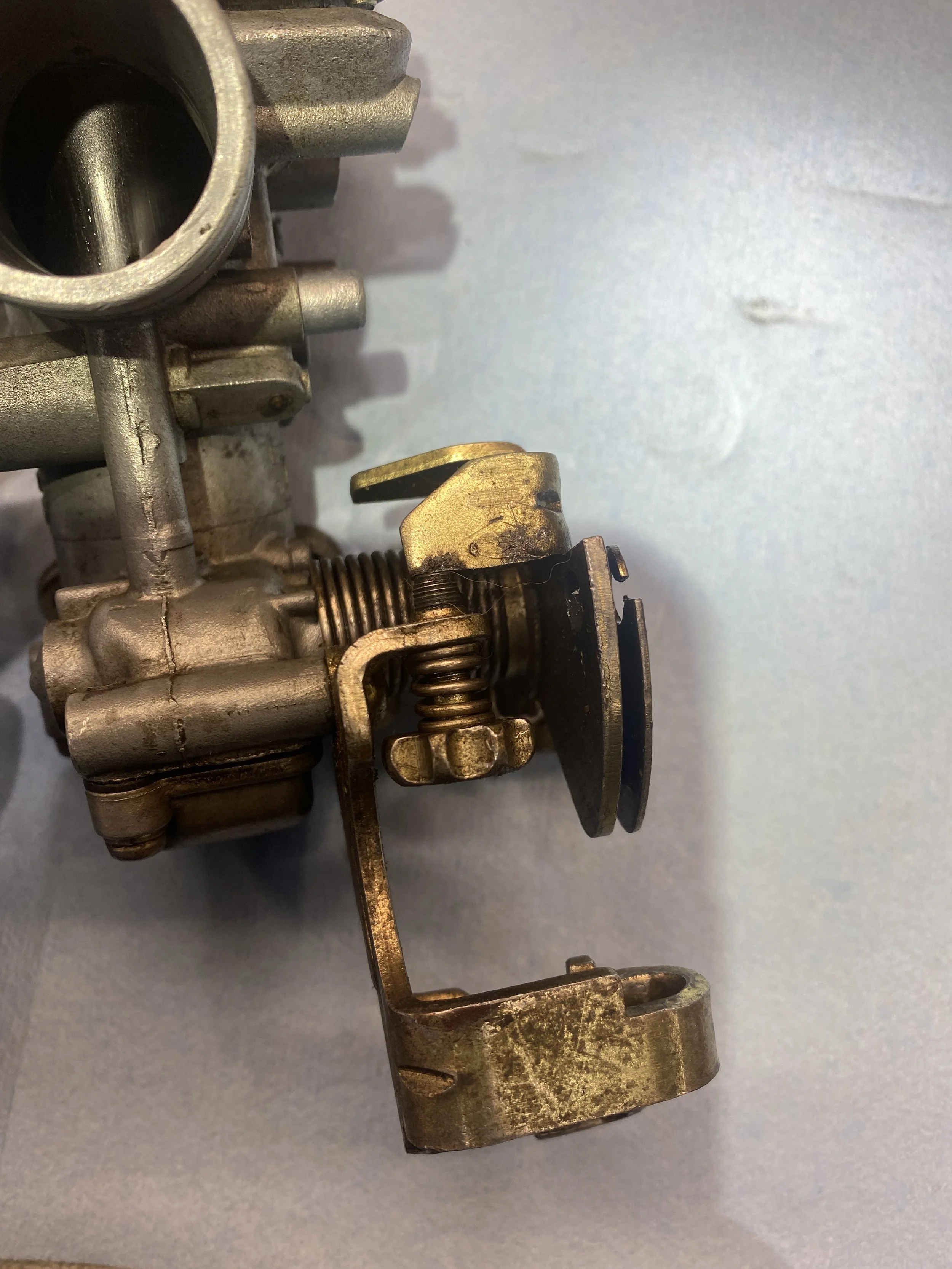

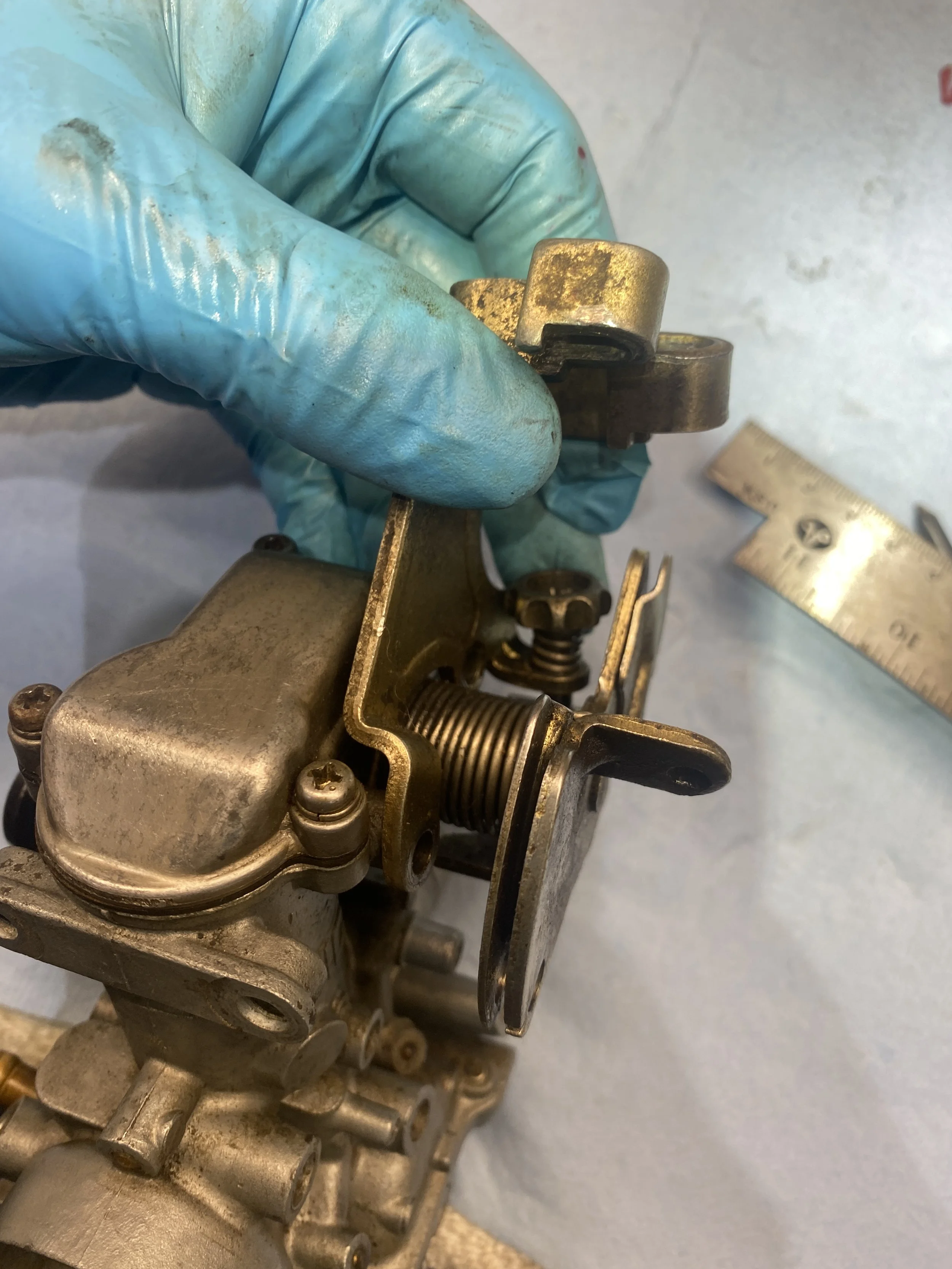

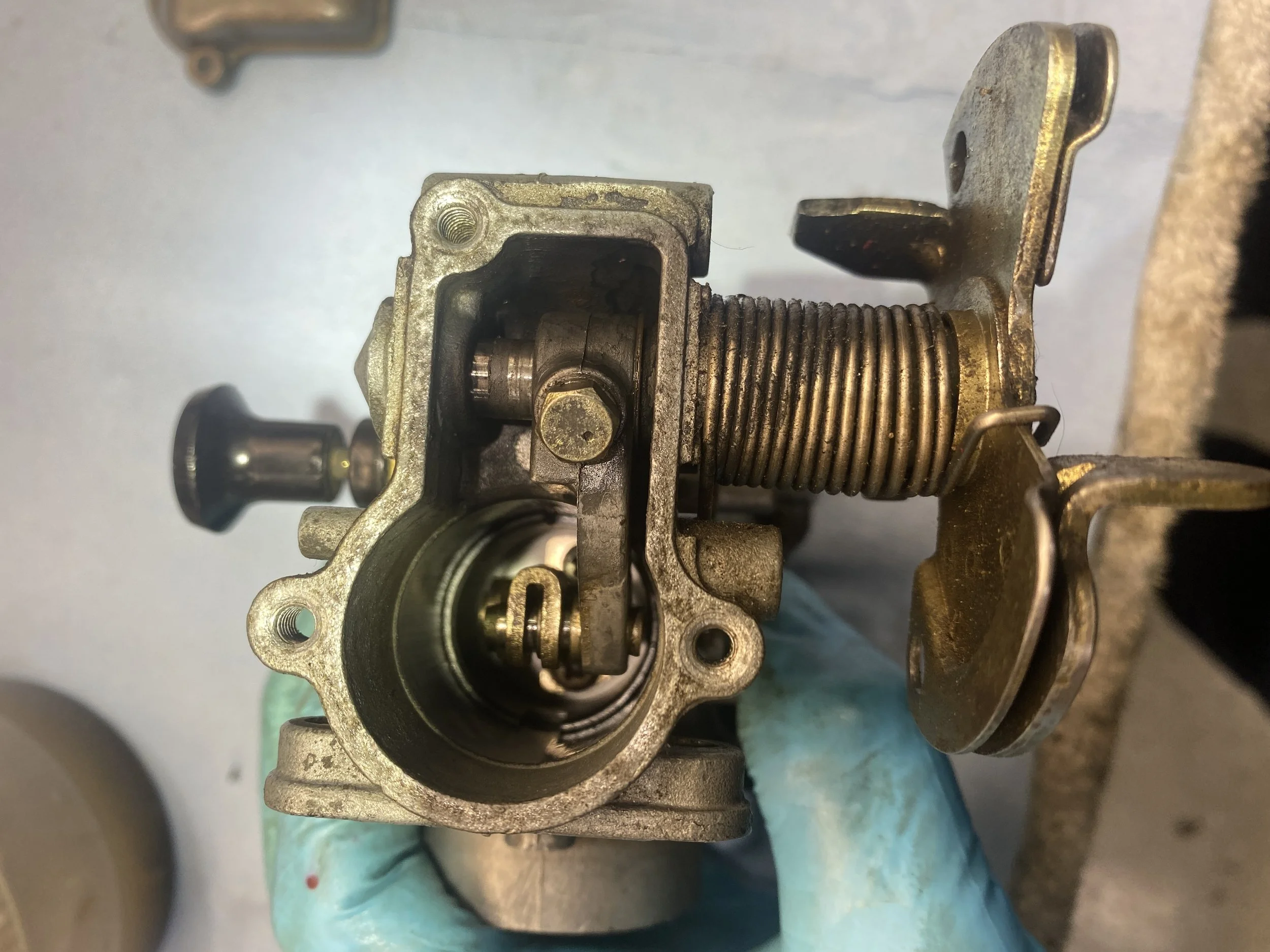

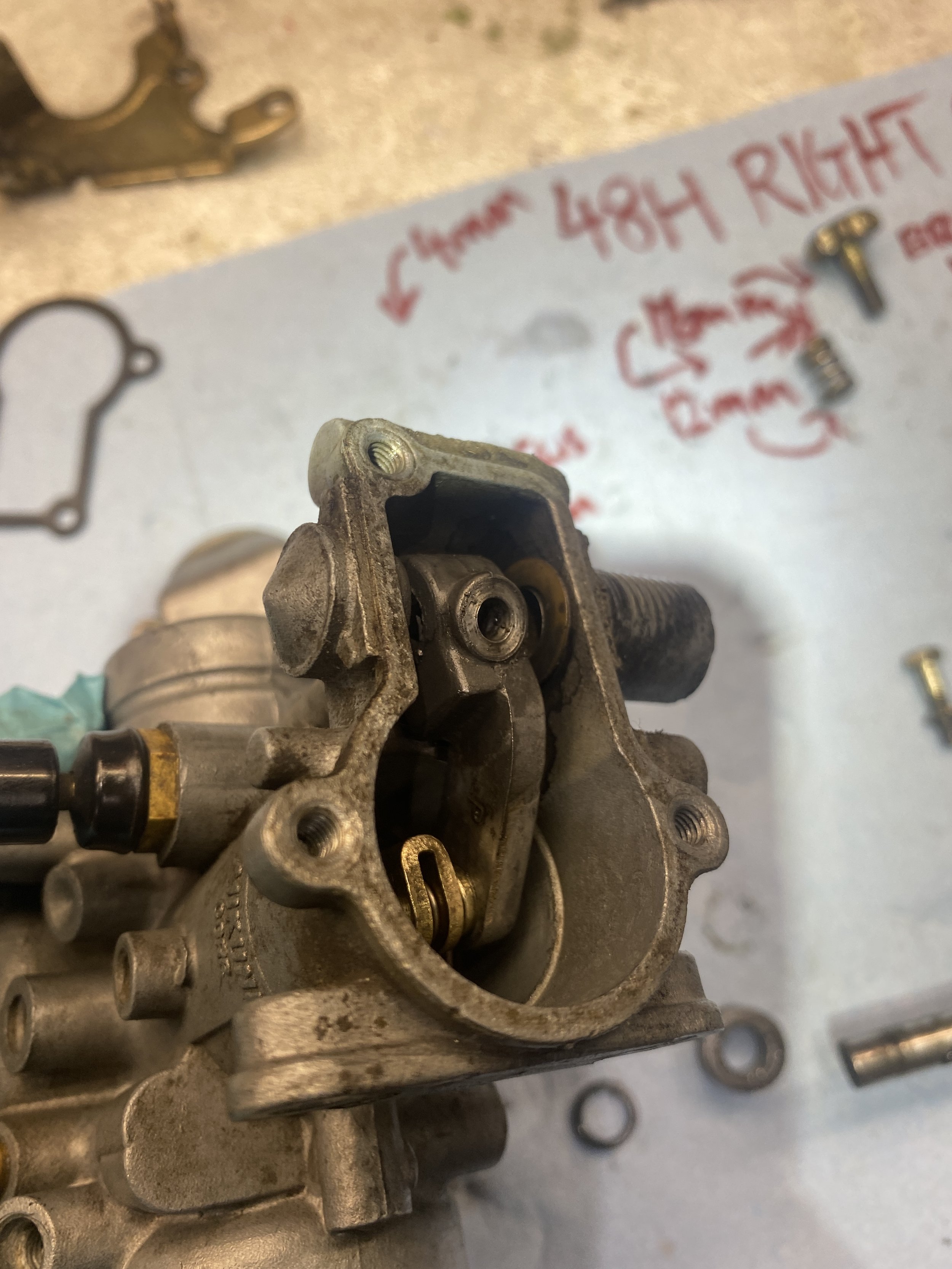

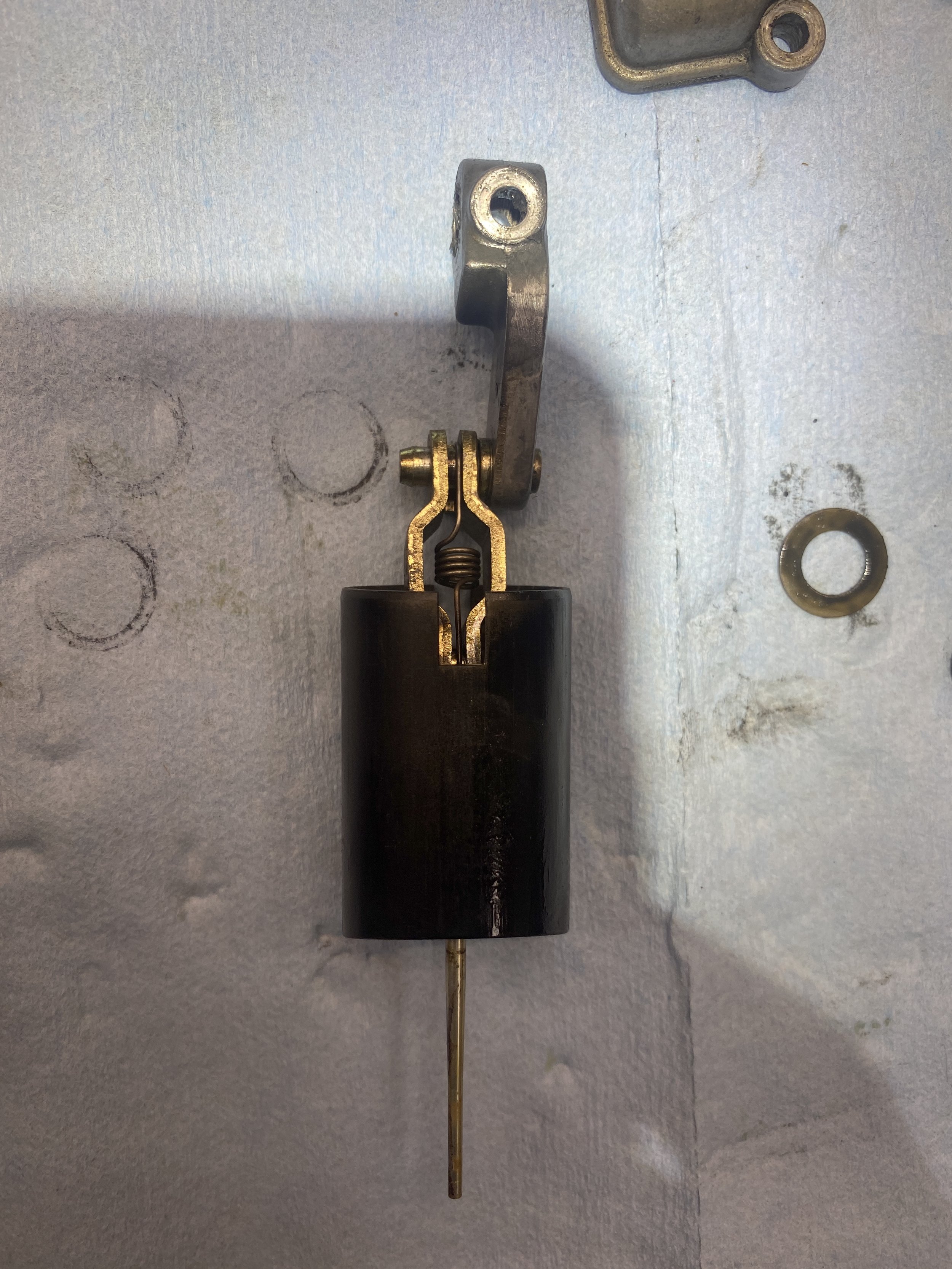

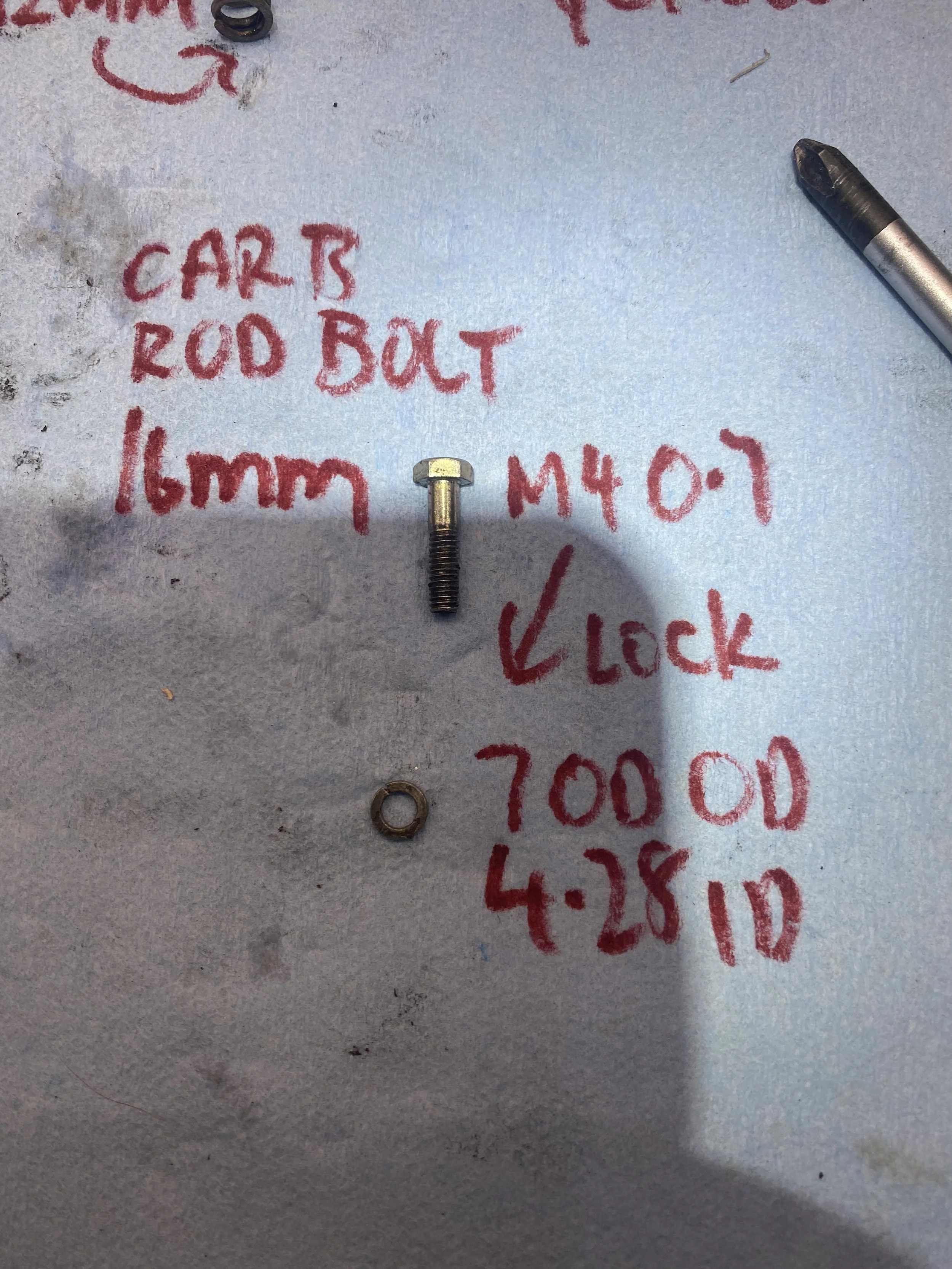

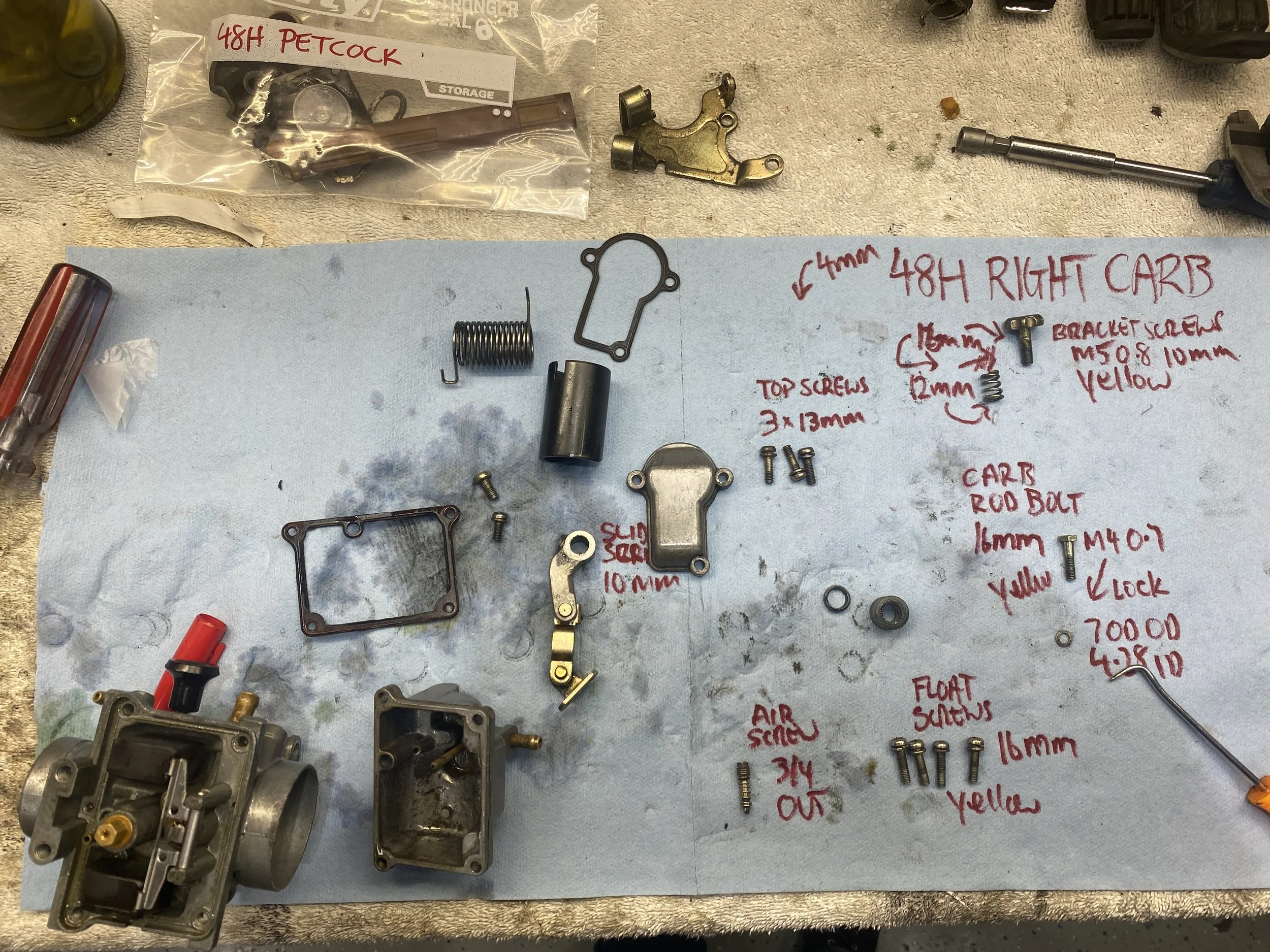

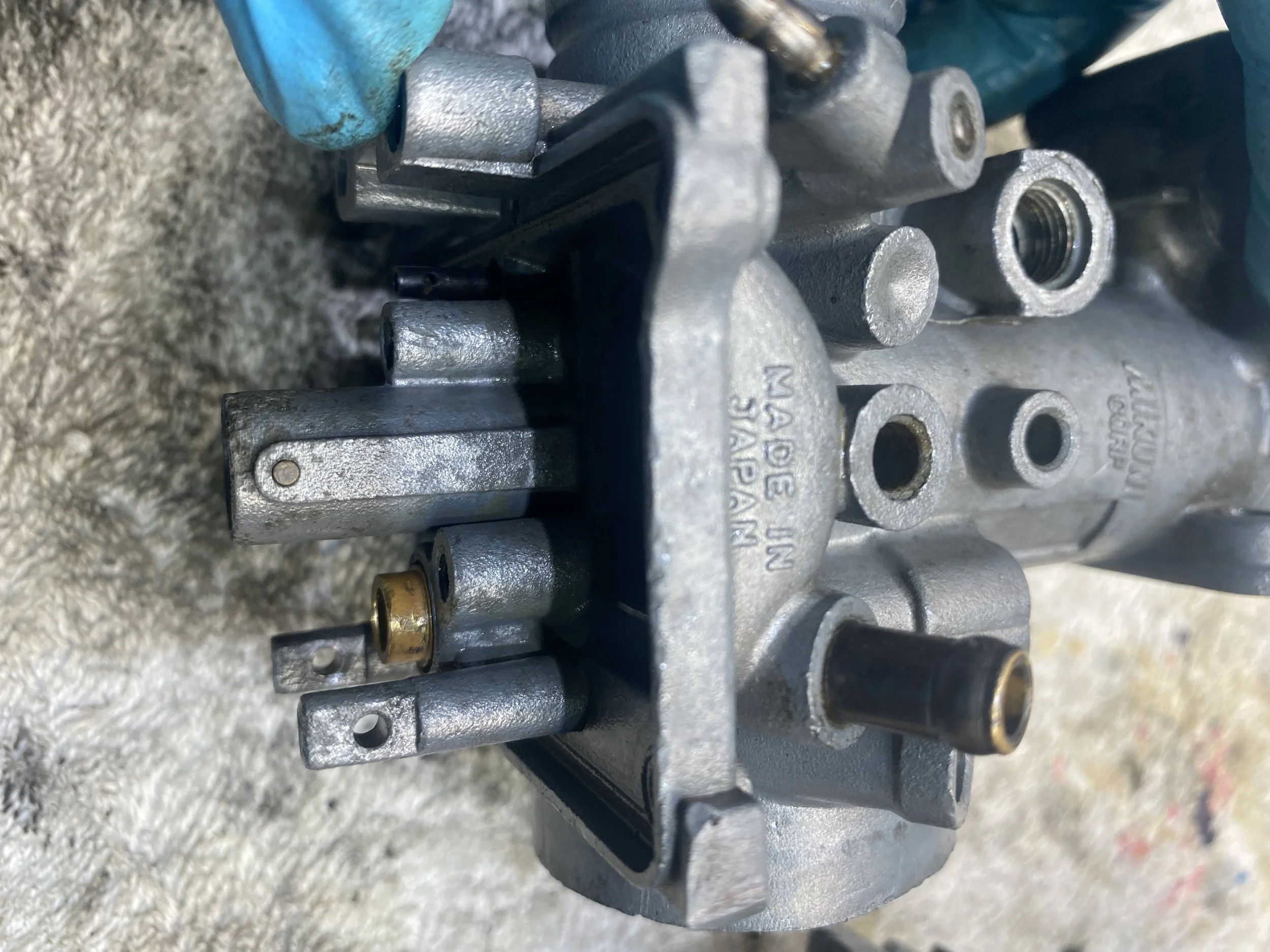

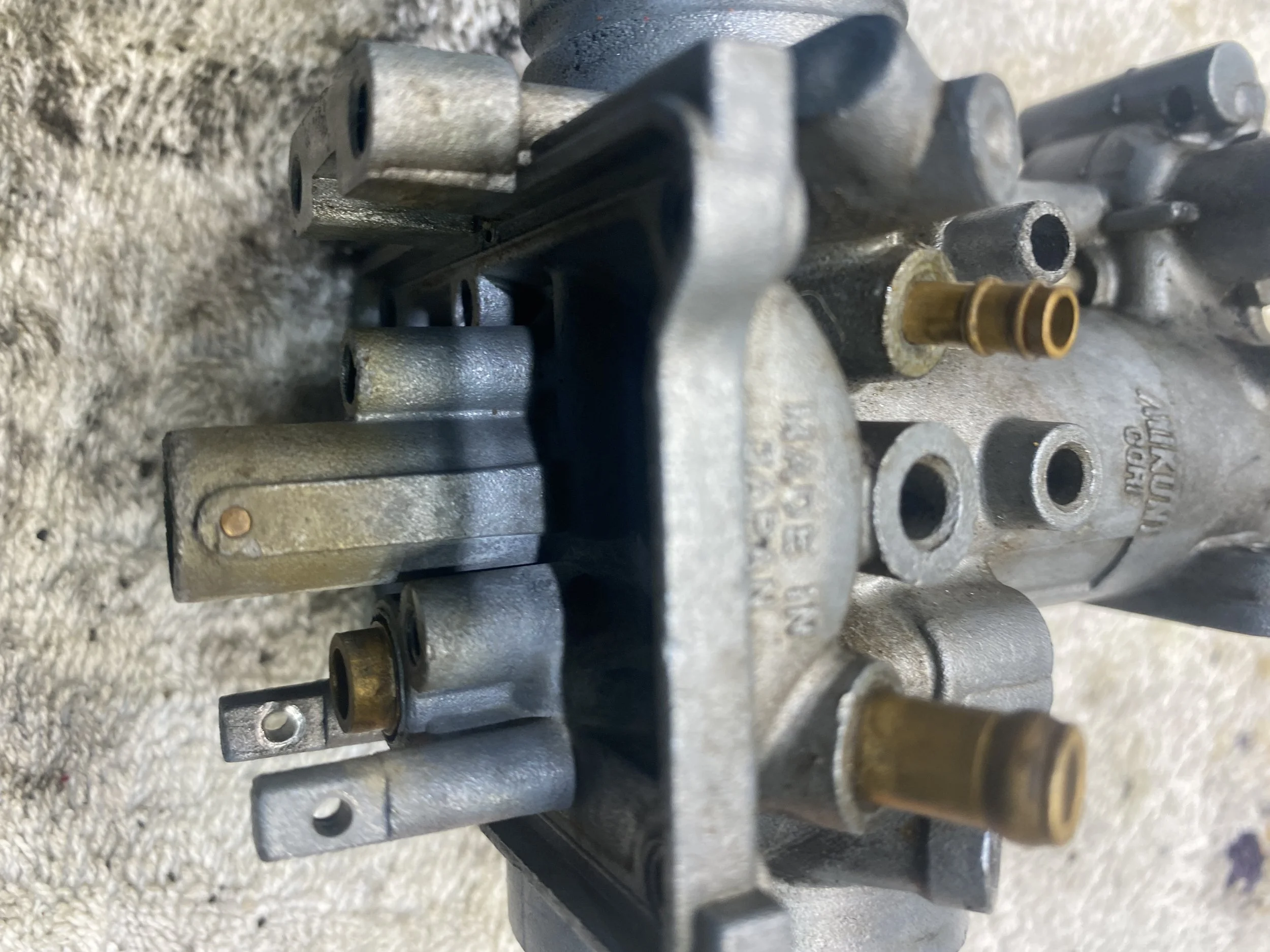

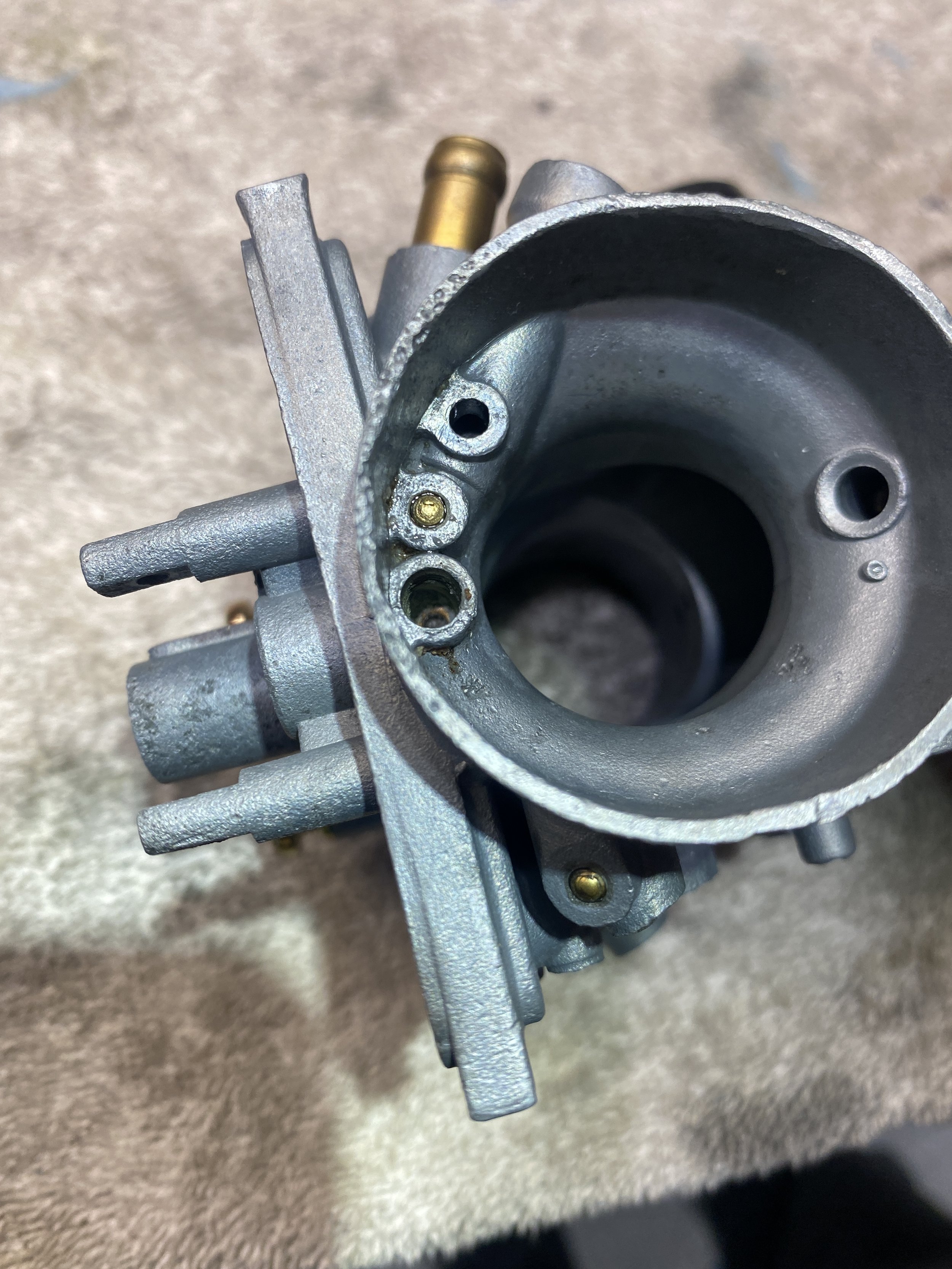

And Now: The right hand carb

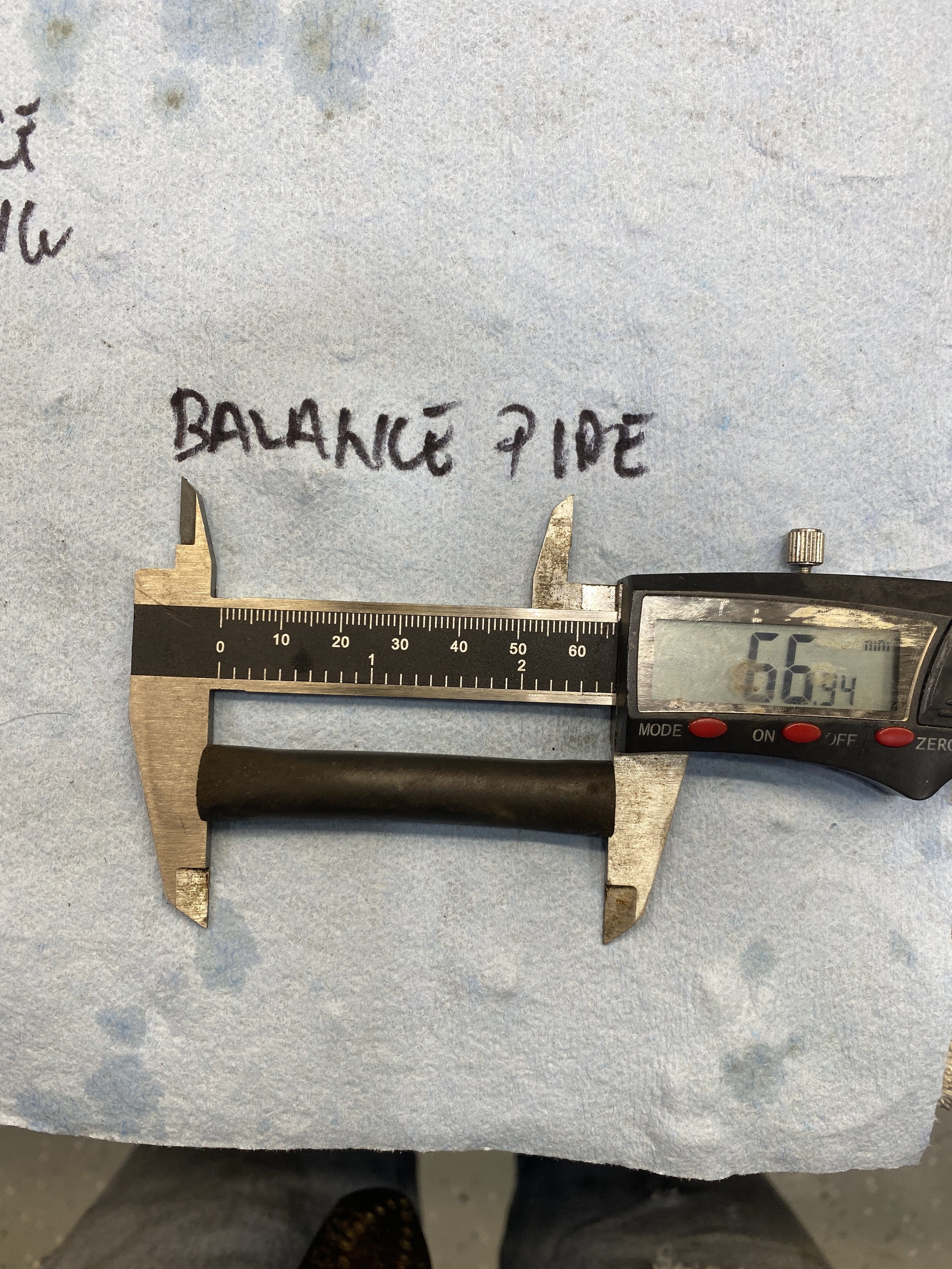

Carb Reassembly

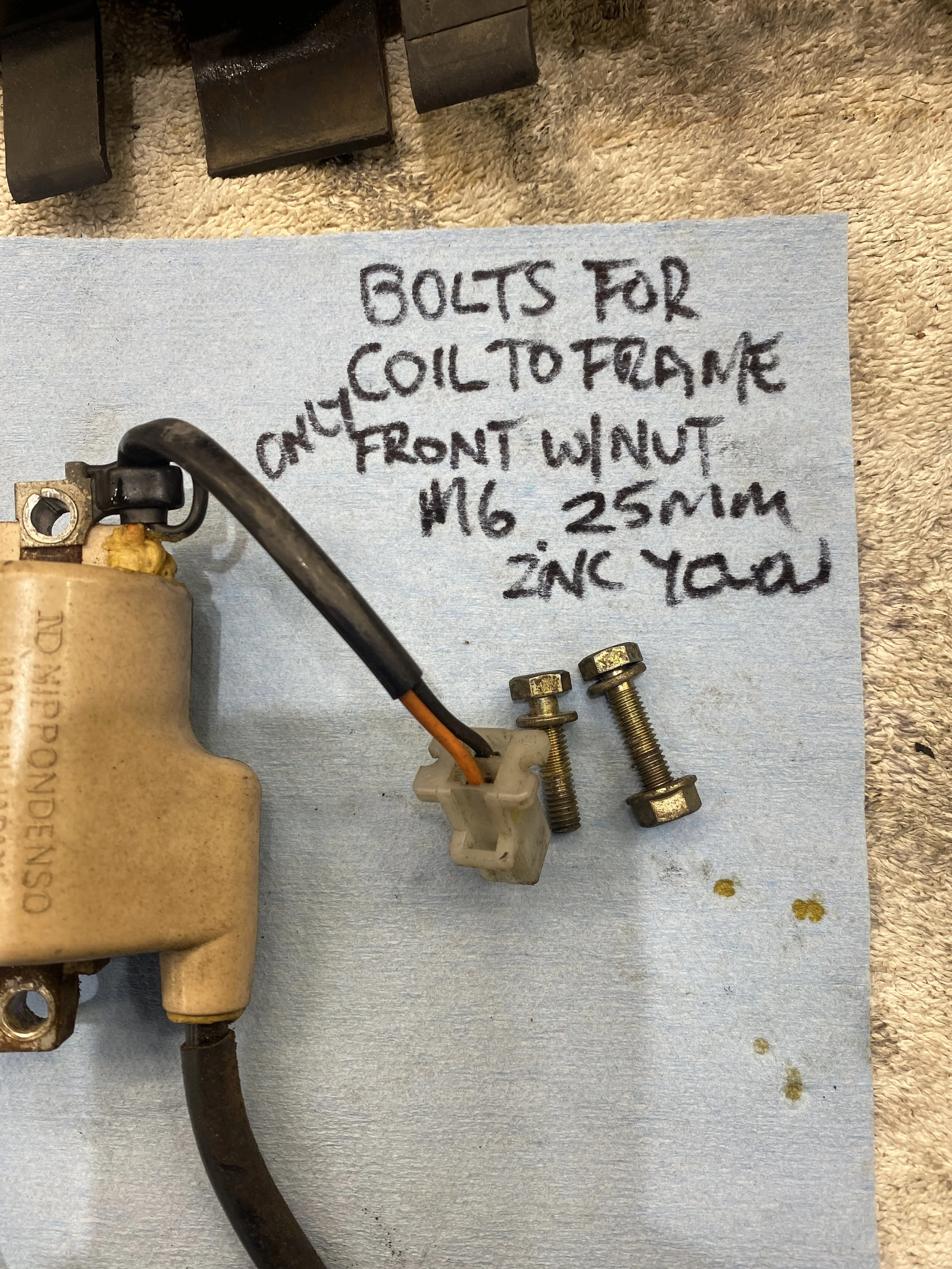

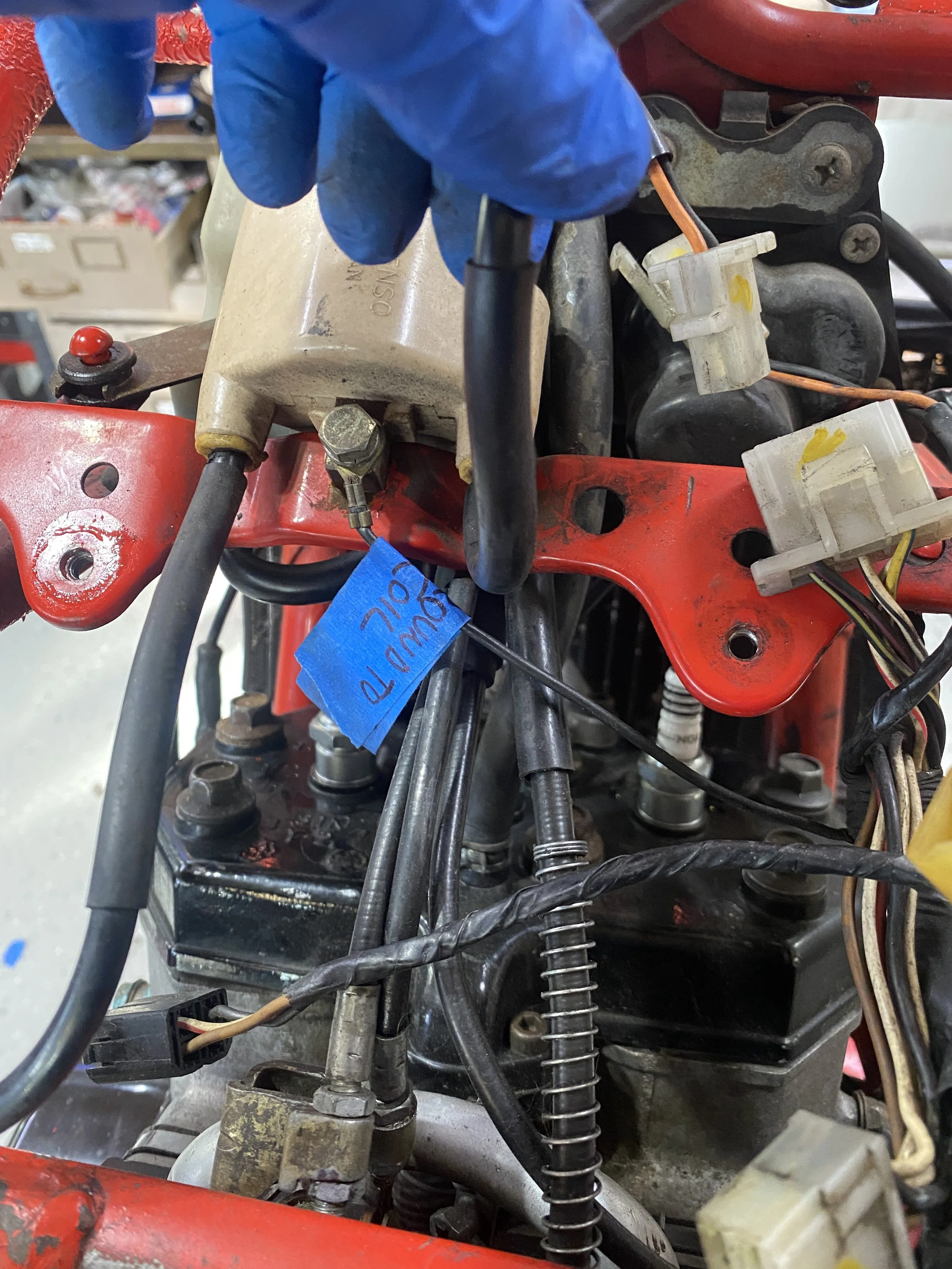

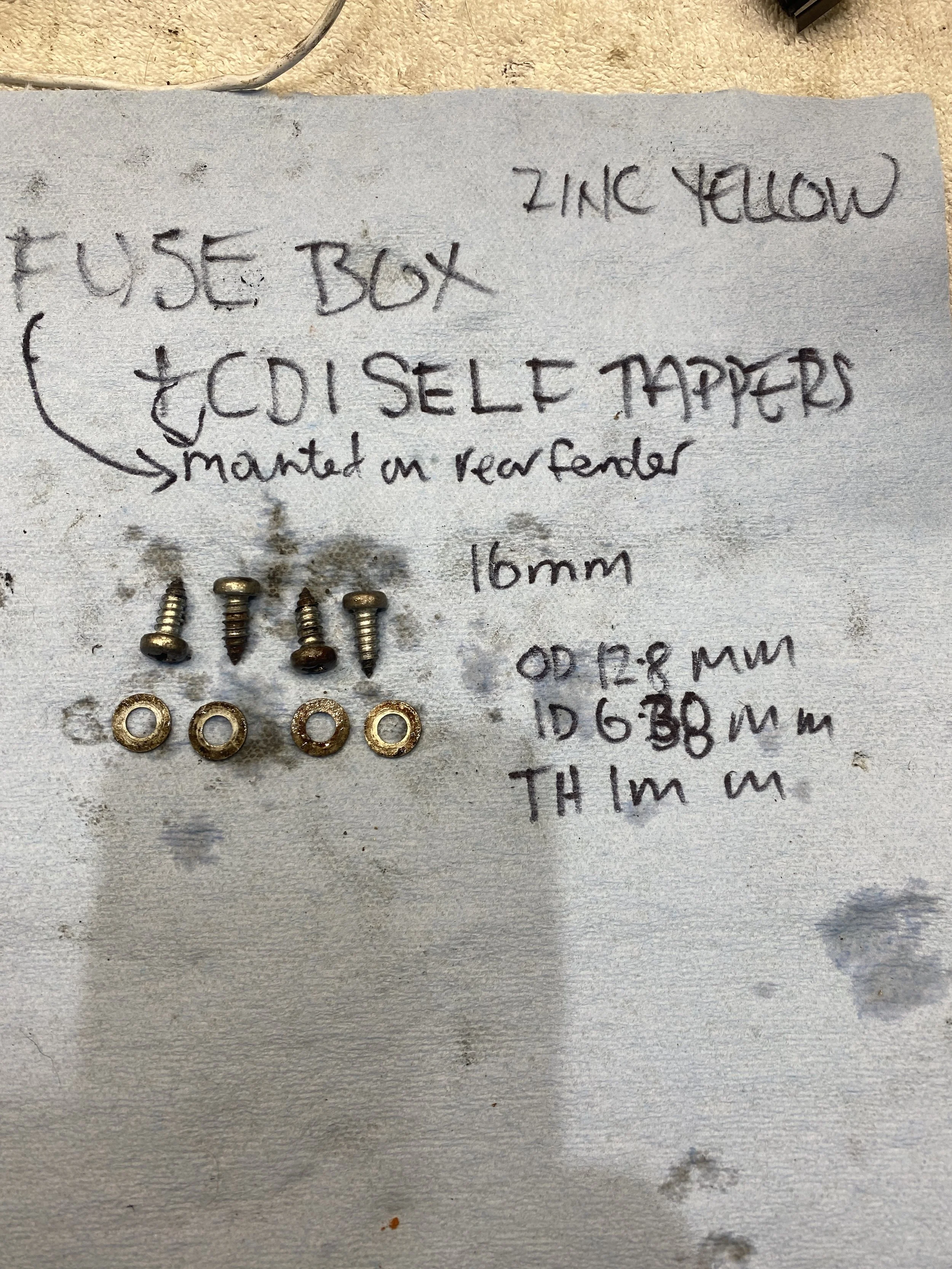

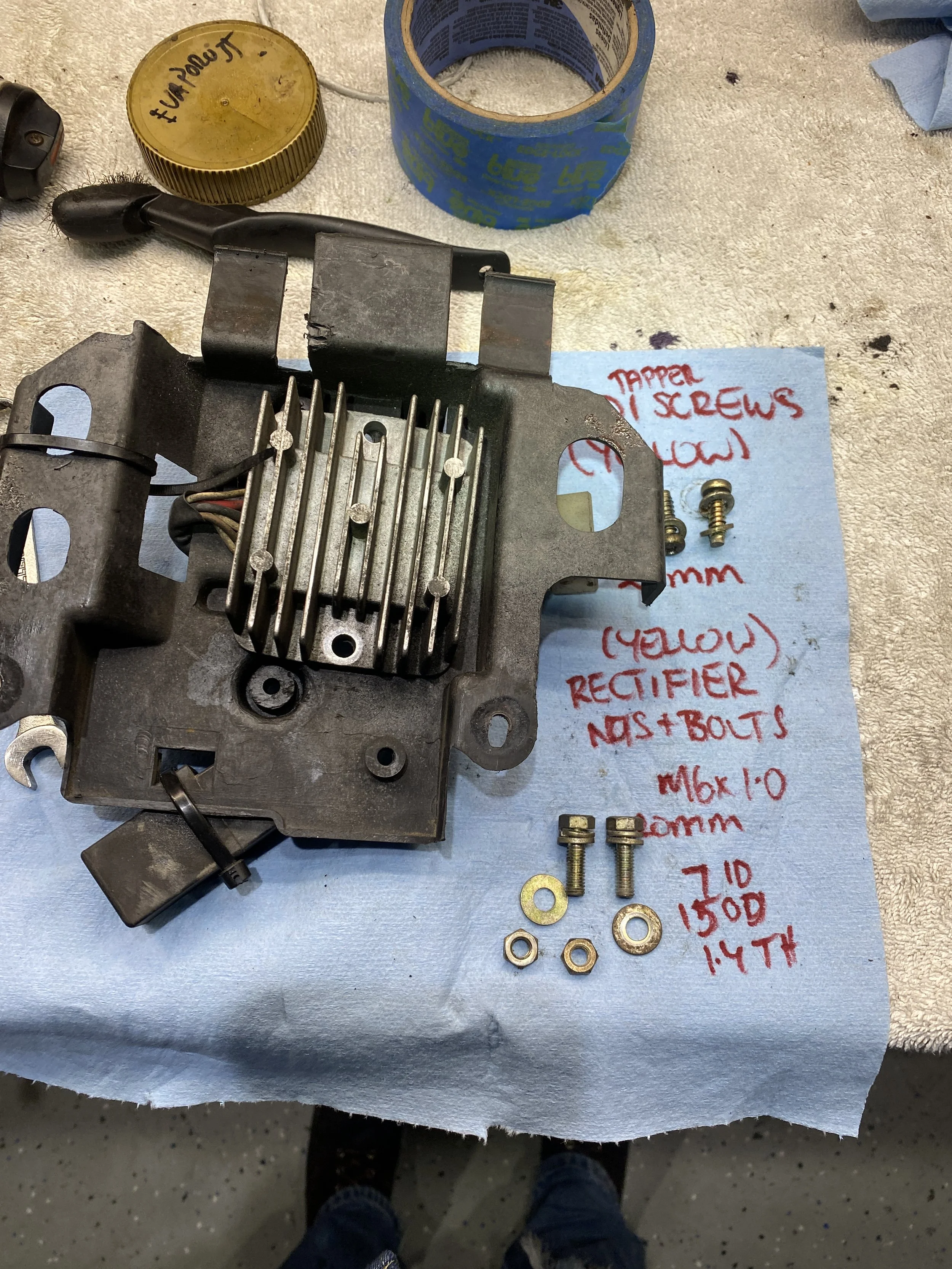

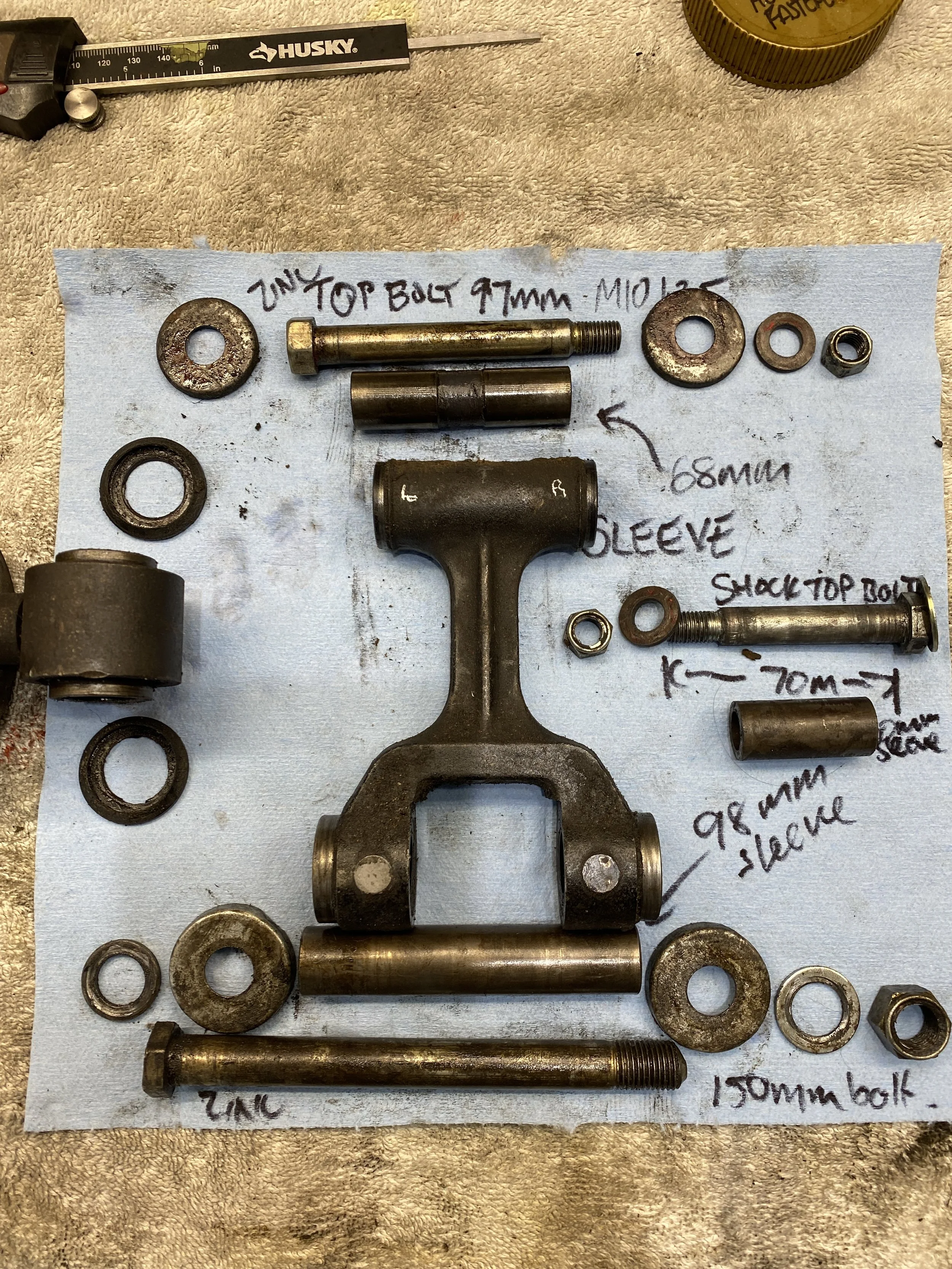

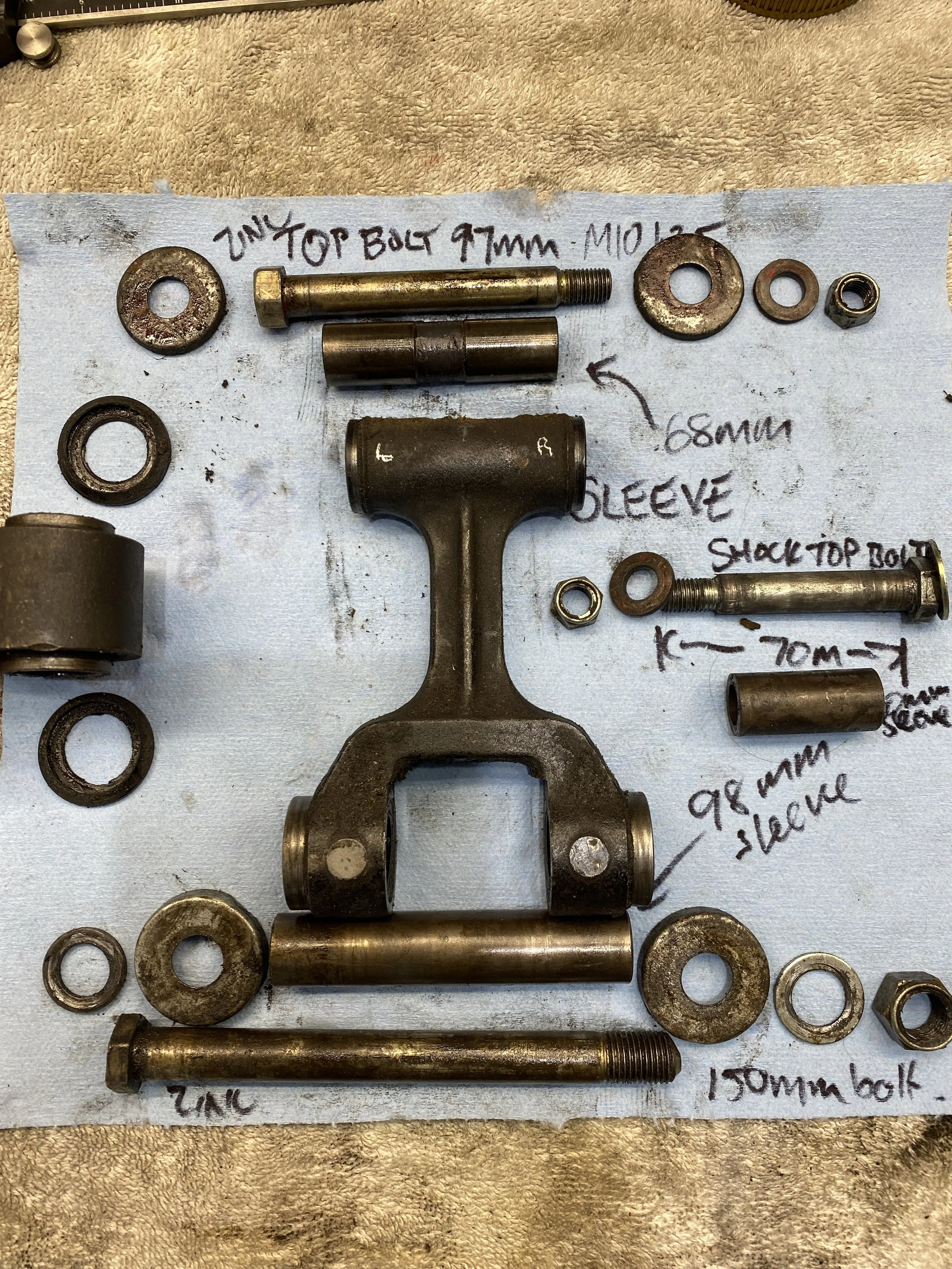

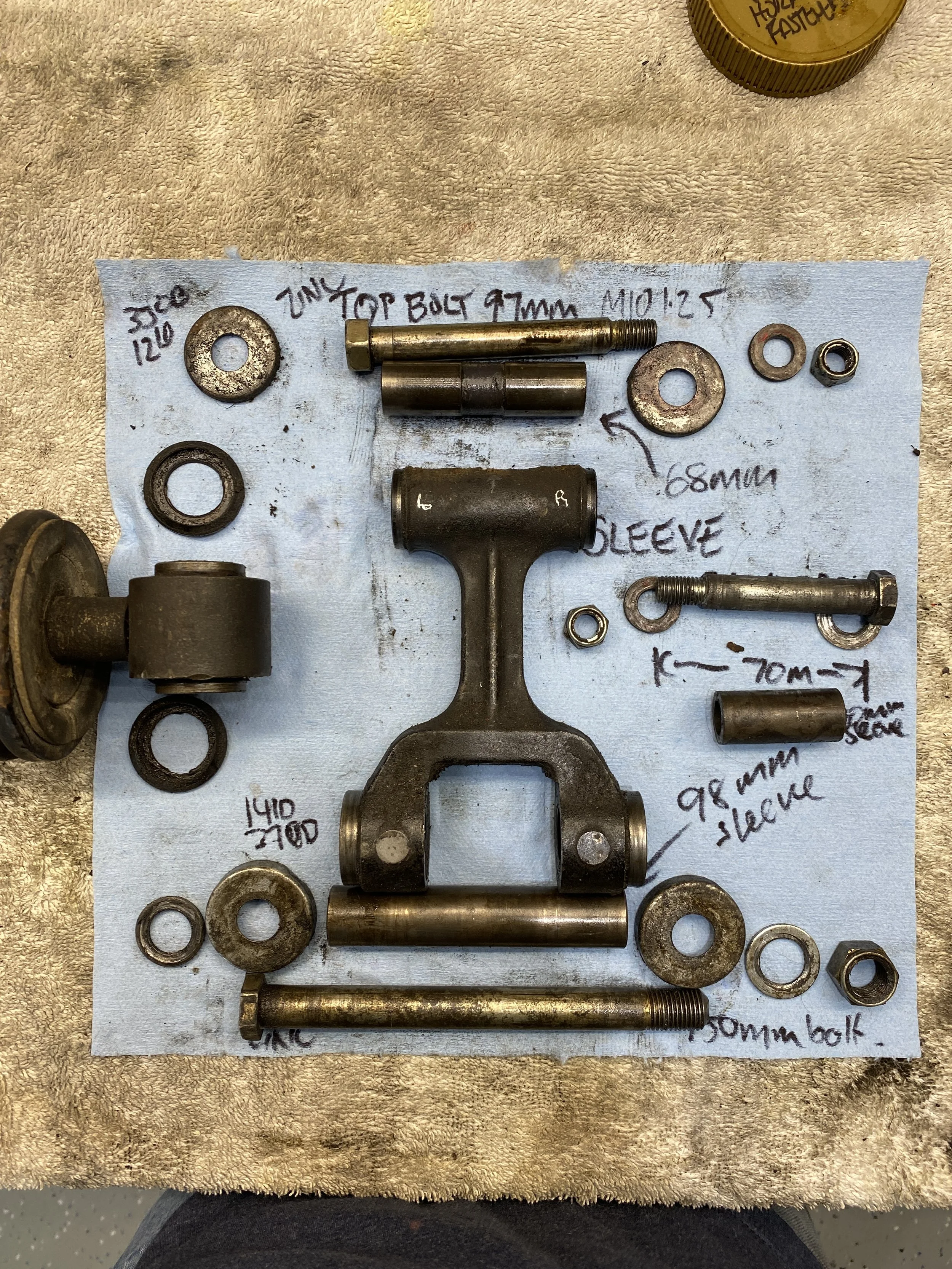

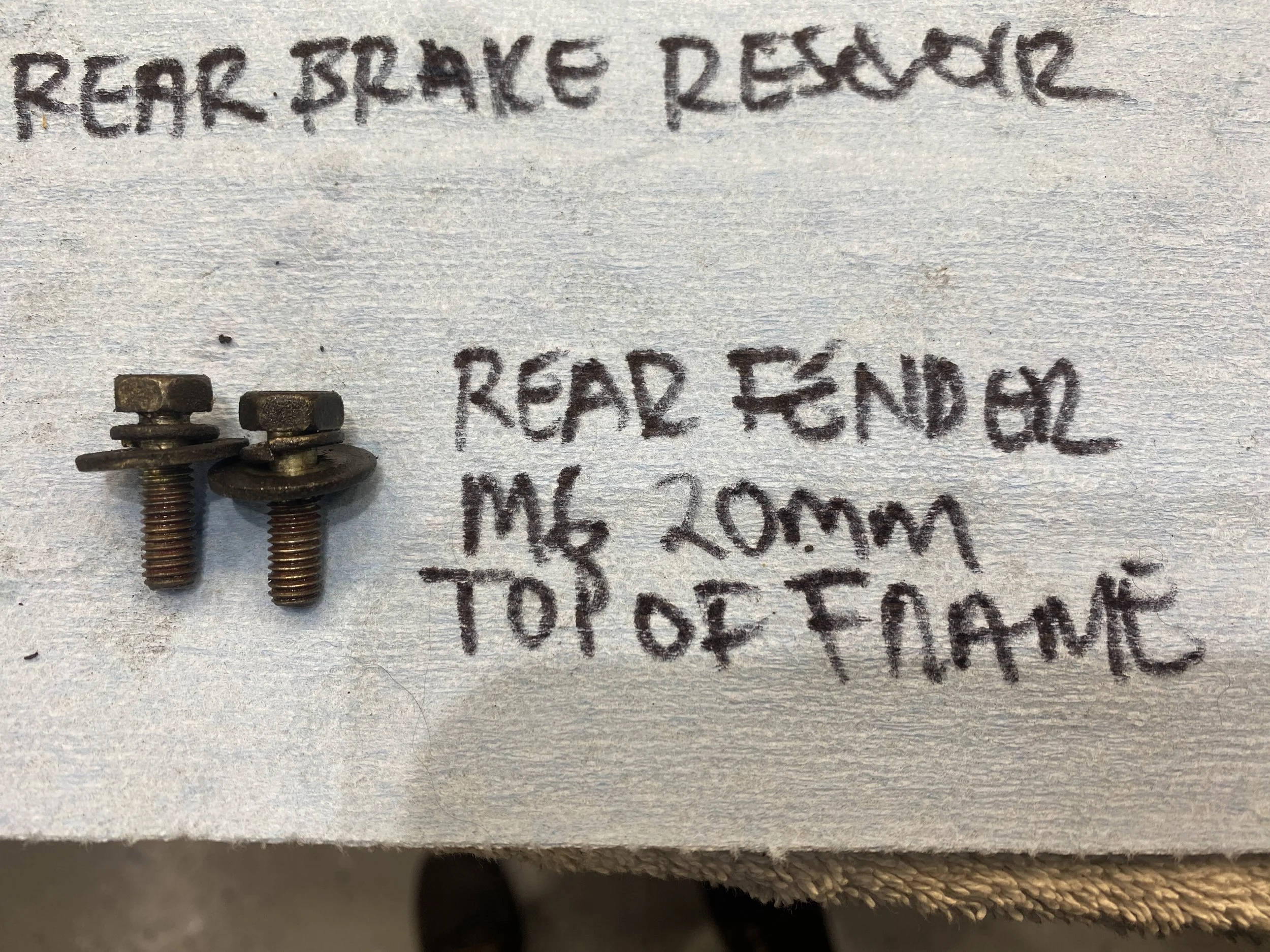

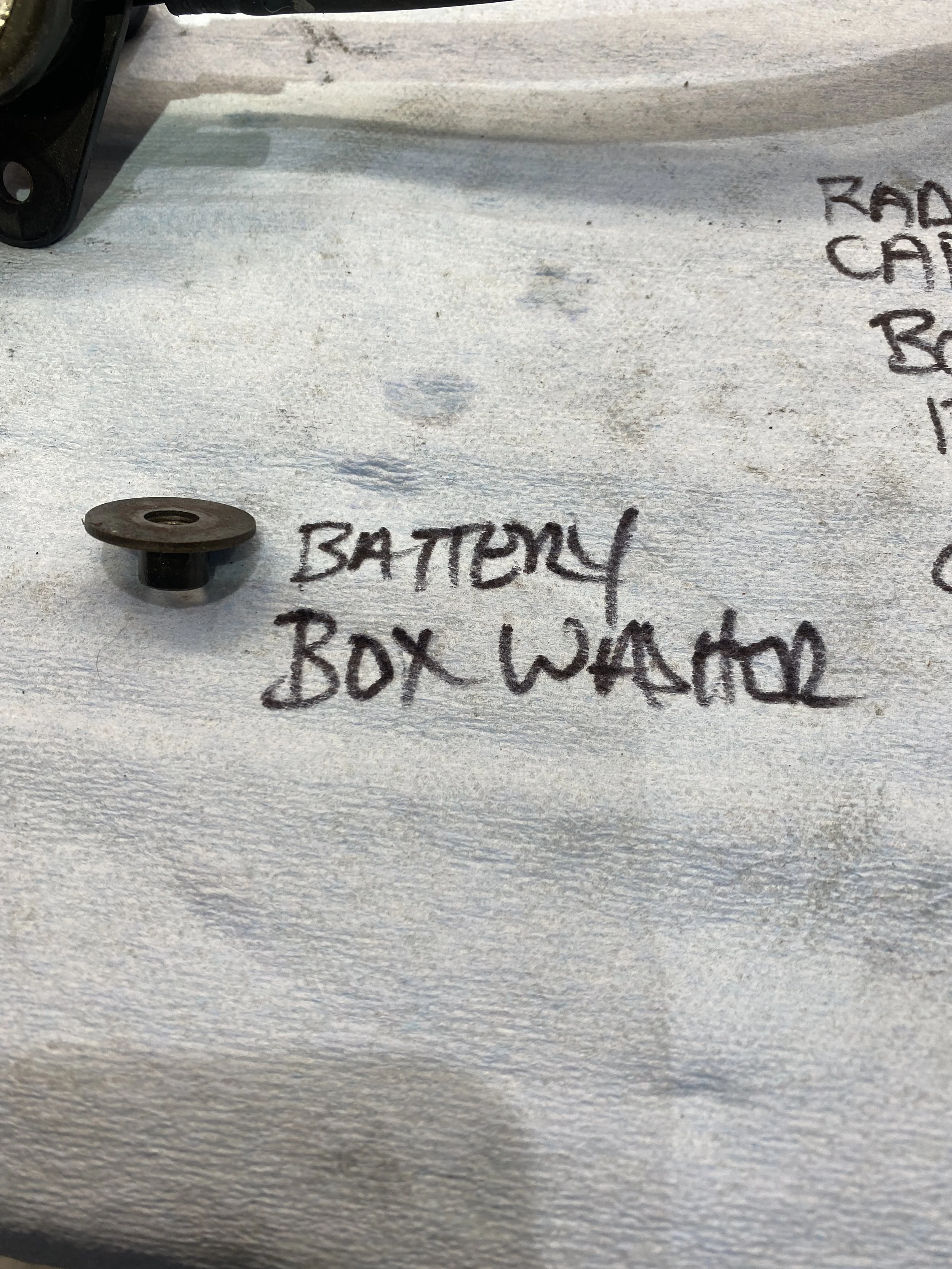

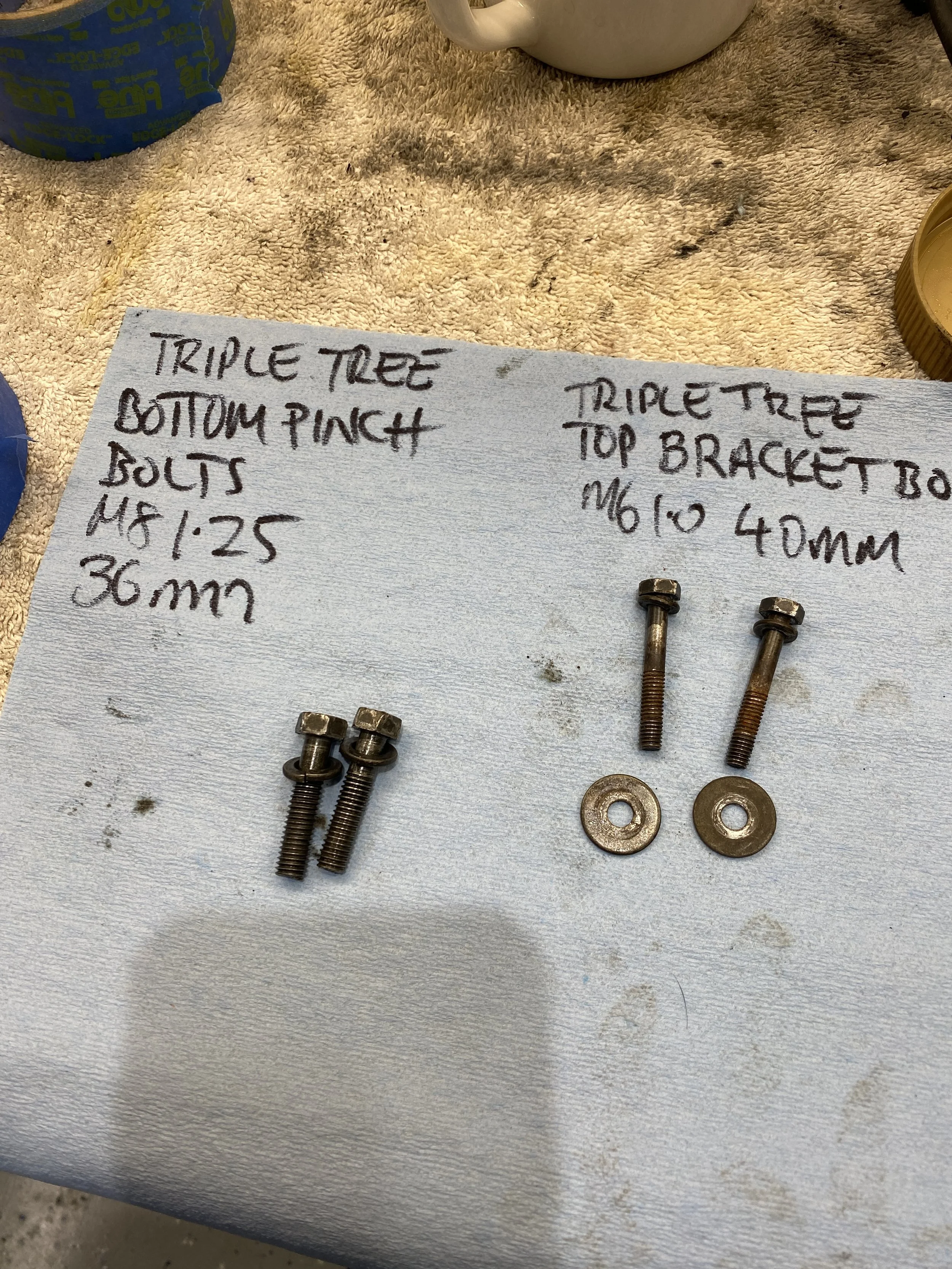

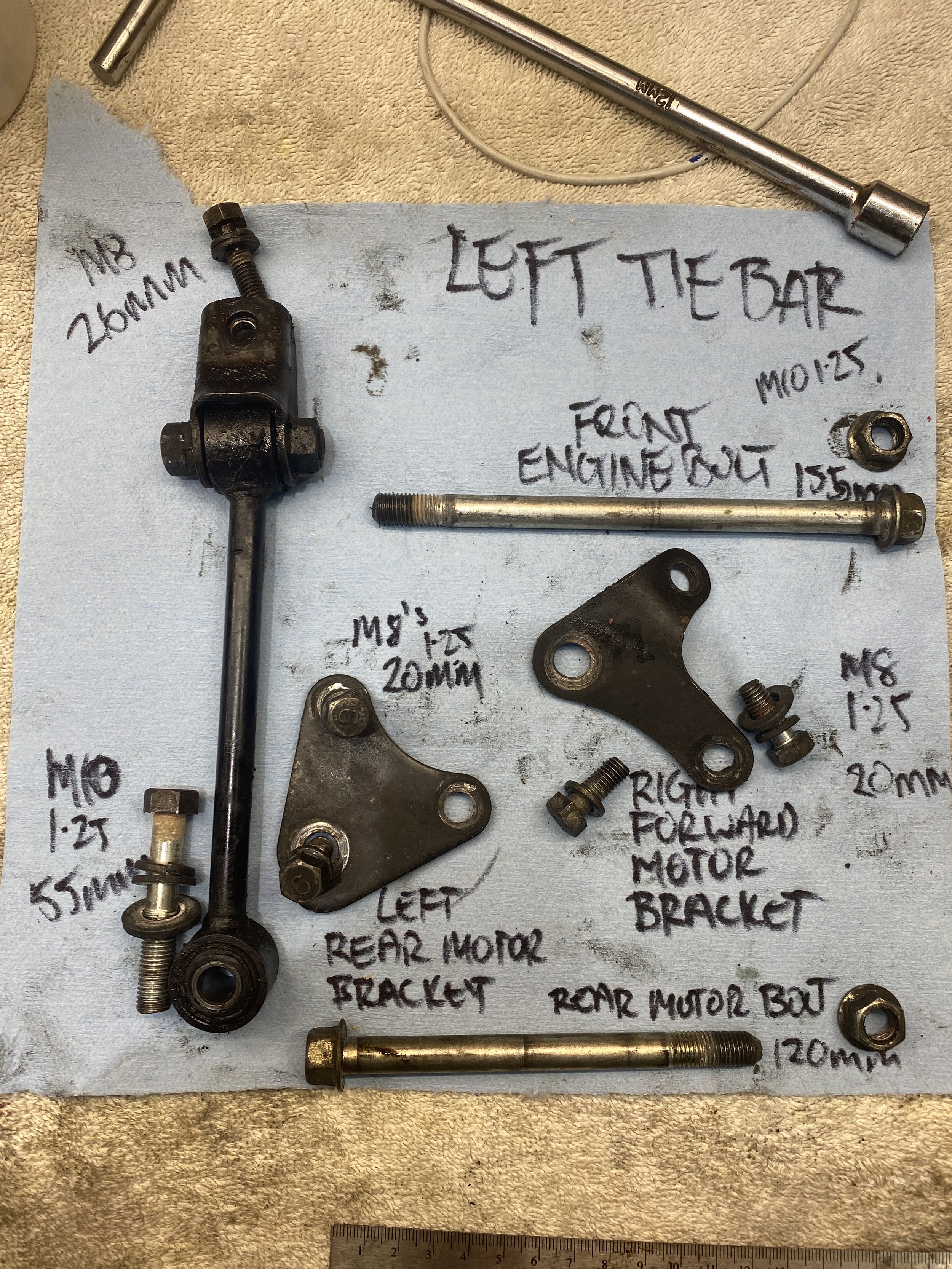

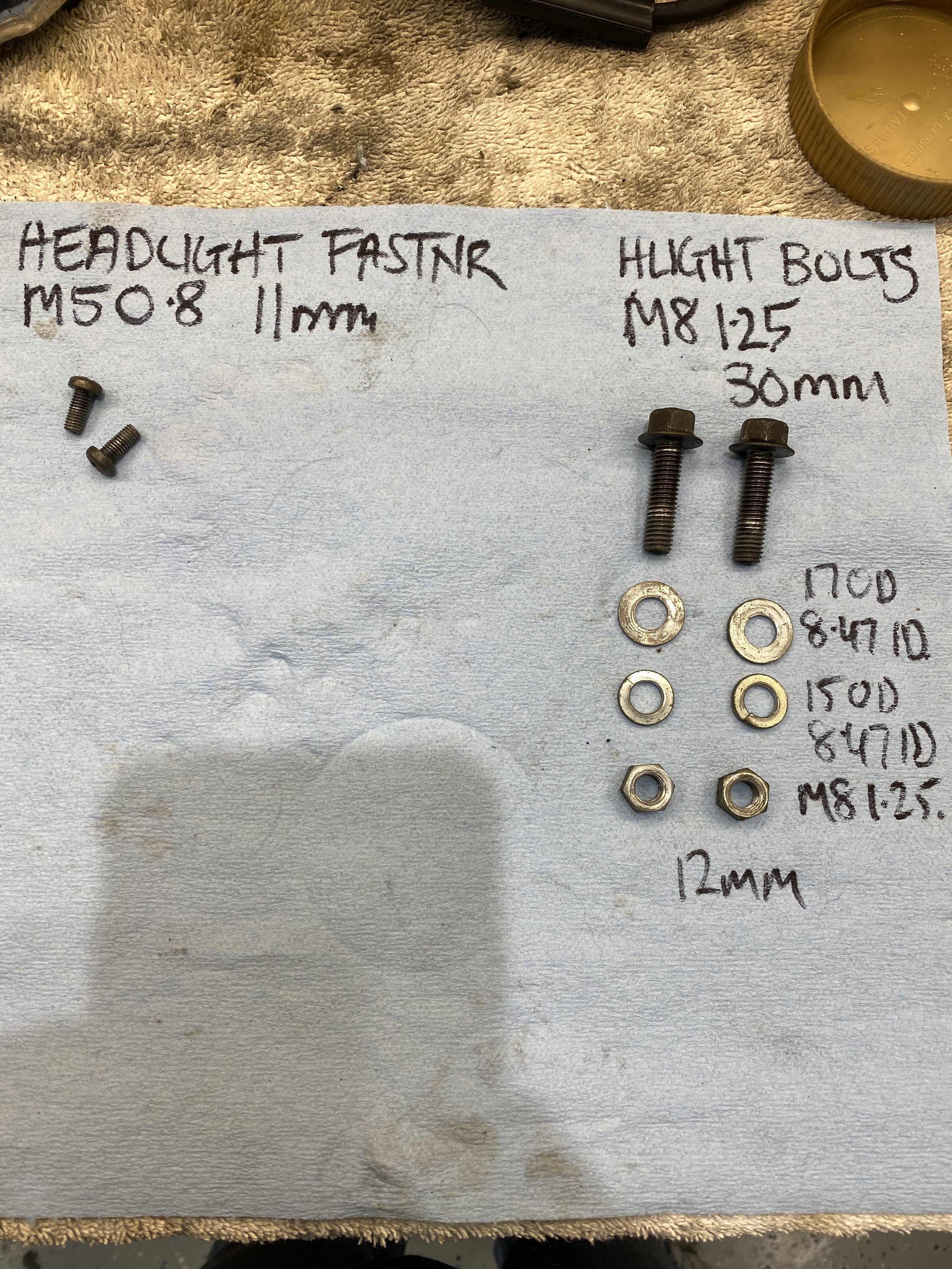

Beginning to sort out the new yellow zinc plated fasteners....

...and put them in the right places.

Cleaning the air screw....very black.

Dismantling the slide just to check size of screws as I am missing one in the other slide. These are M5's with spring washers.

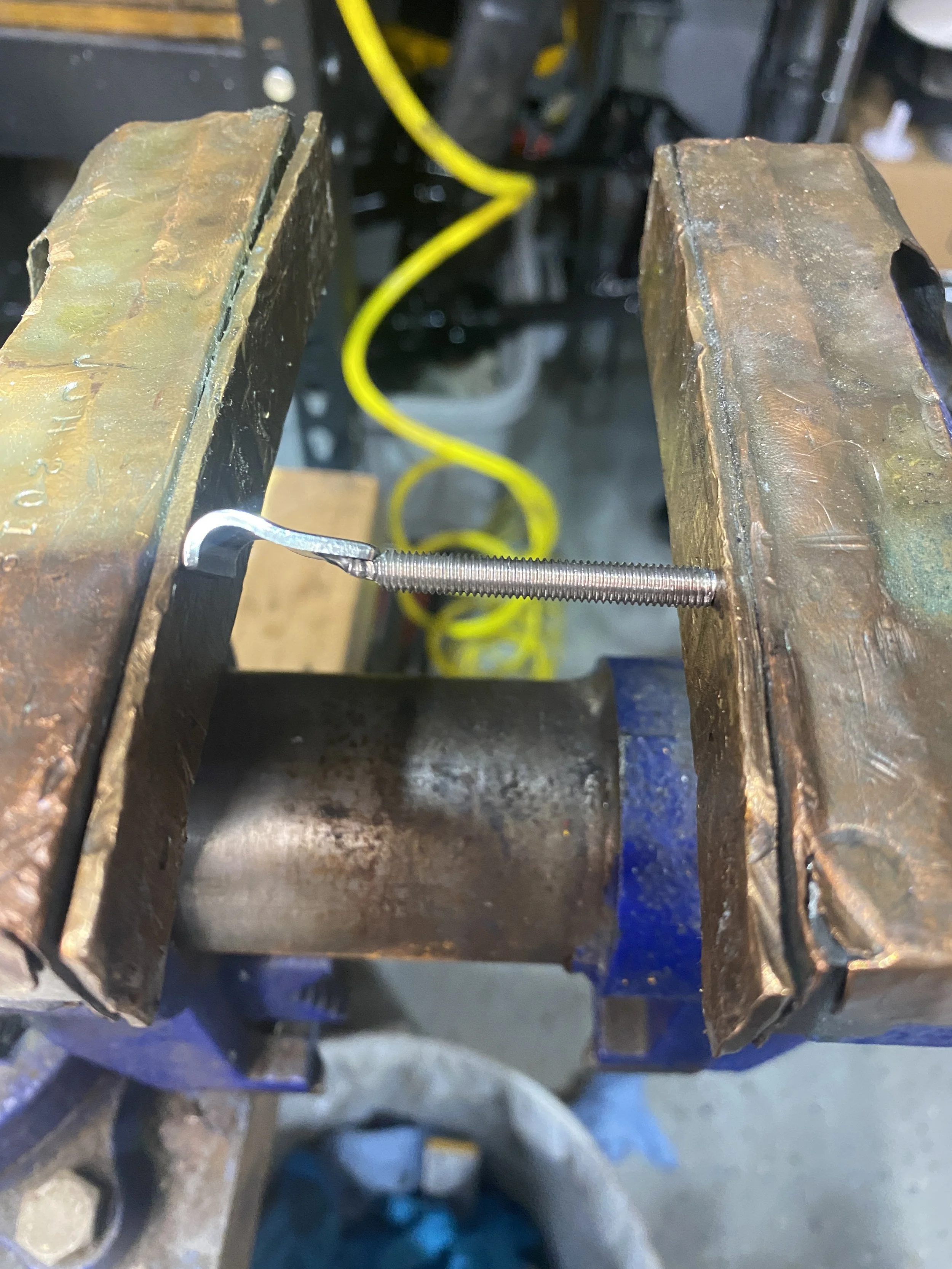

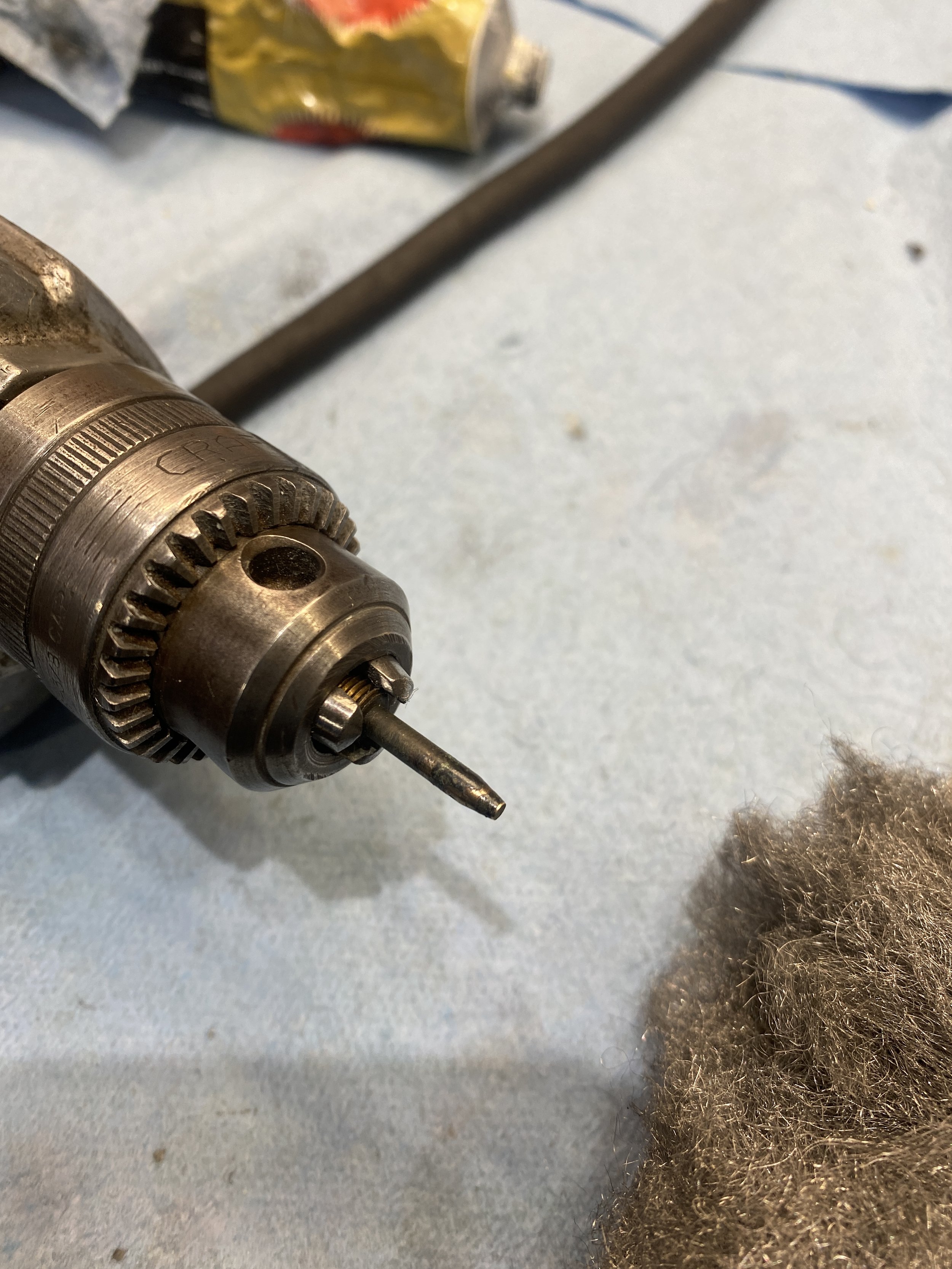

This is a task I've put off forever primarily because failure seemed likely, but I proved myself wrong. Behind this brass ball is an air circuit that can get clogged with debris. The only way to clean it is to remove this brass ball. Some say the best way is to drill a hole in it, screw in a self-tapper and wiggle it out. This is me trying another method.

Locate your smallest drill bit. 1/16 is the smallest I have on hand.

Ideally you want to first punch a dent right in the middle of the ball without pushing it farther in....both are near impossible. Luckily, to be successful, the hole doesn't have to be exactly centered...just about 2.5mm deep....

....mix up a little epoxy...

...carefully fill the tiny hole with epoxy, drop the end of the drill bit in there and wipe off the excess....you don't want to glue the whole ball in there!

6-8 hours later, remove excess epoxy from around the site with a small pointed pick, flash the area around the ball with a bit of heat and.....slowly wiggle it out....perhaps with tiny blast of carb cleaner for lubrication.

You can barely see in there some dirt around not so shiny brass ring. Blasted it out with carb cleaner/air/carb cleaner/air. The exit of this chamber is in the needle valve cylinder.

Another view...not incredibly dirty but I think the task is worth doing if only to eliminate it off the list when it comes to inevitable fueling issues.

Then carefully red loctite it back in place...if you want it to look nice...put the drilled hole on the other side, but make sure all remnants of dried up epoxy are gone otherwise you are creating a problem rather than fixing it. My lifestory #178.

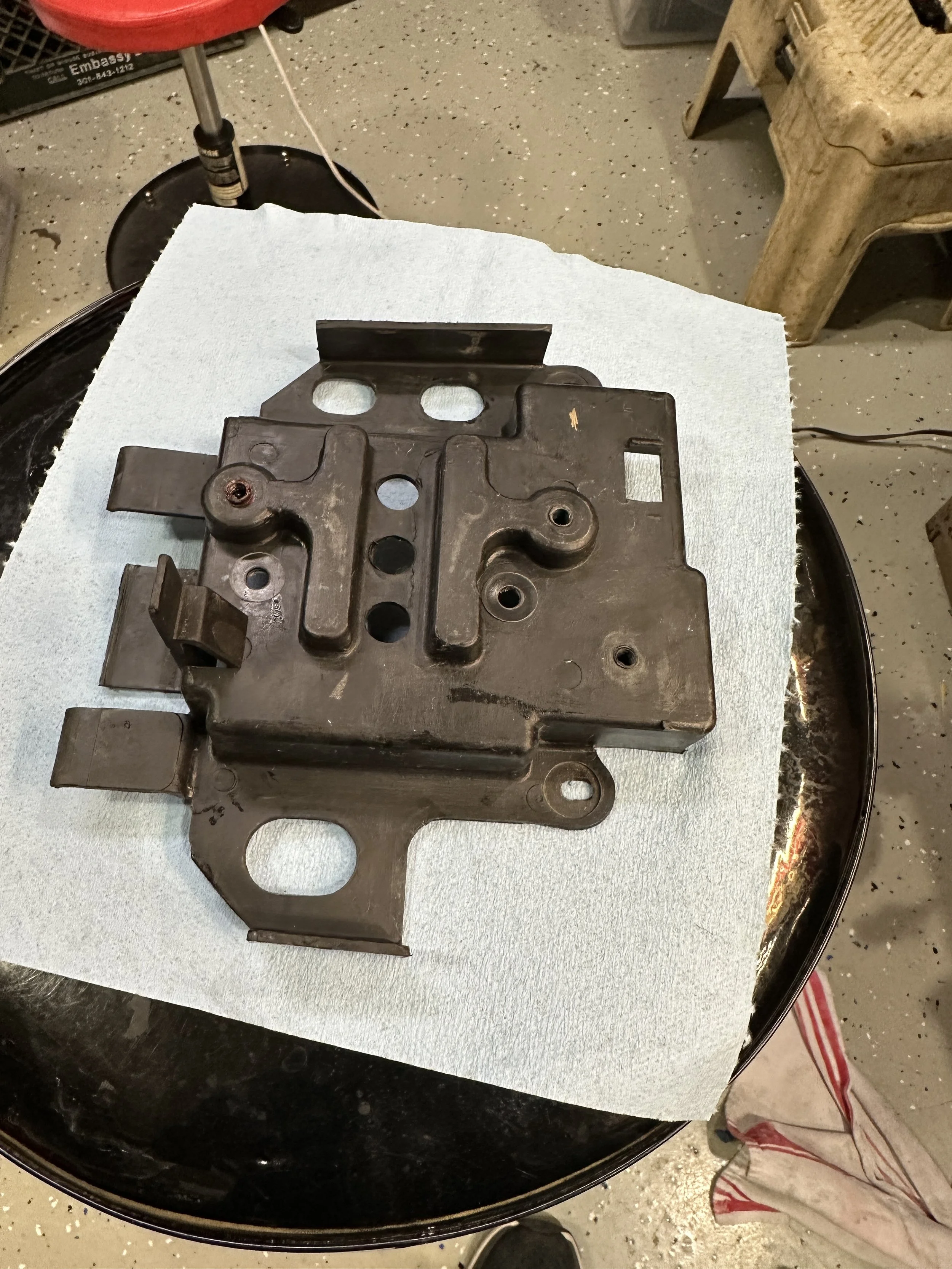

Air/Battery Box

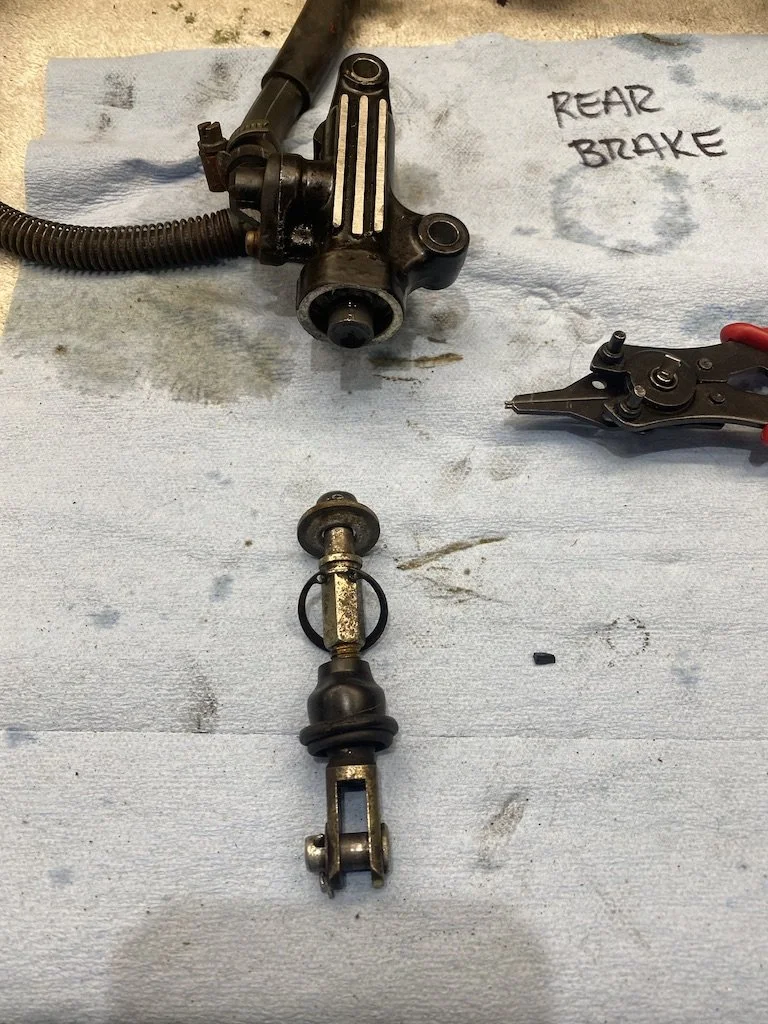

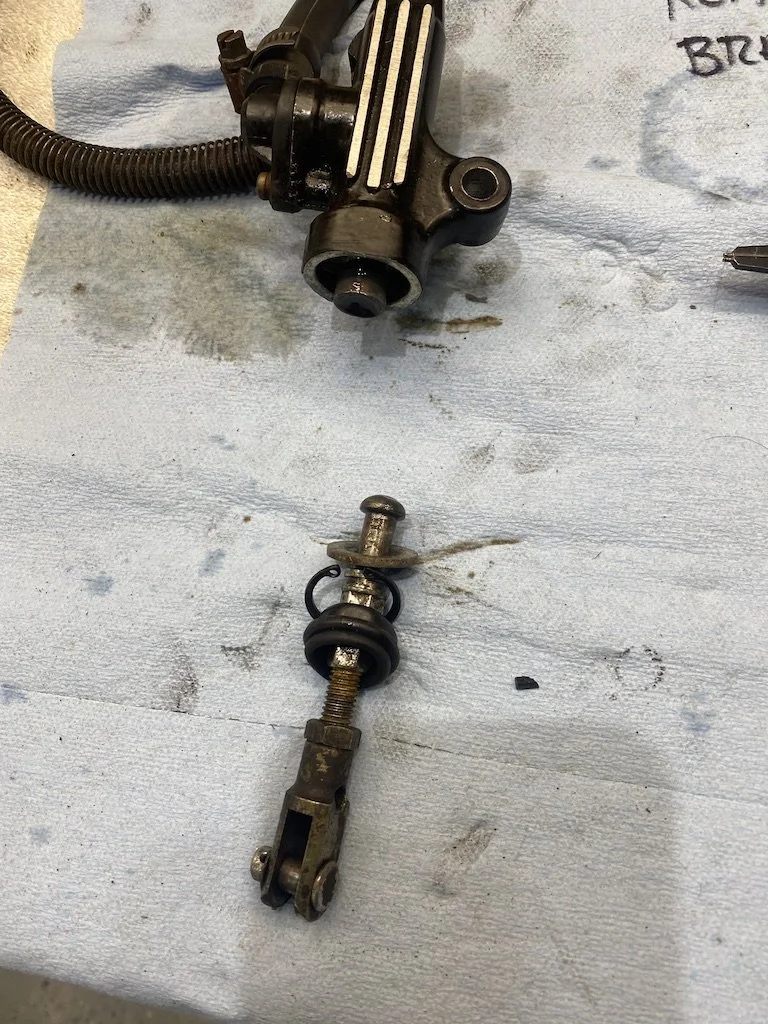

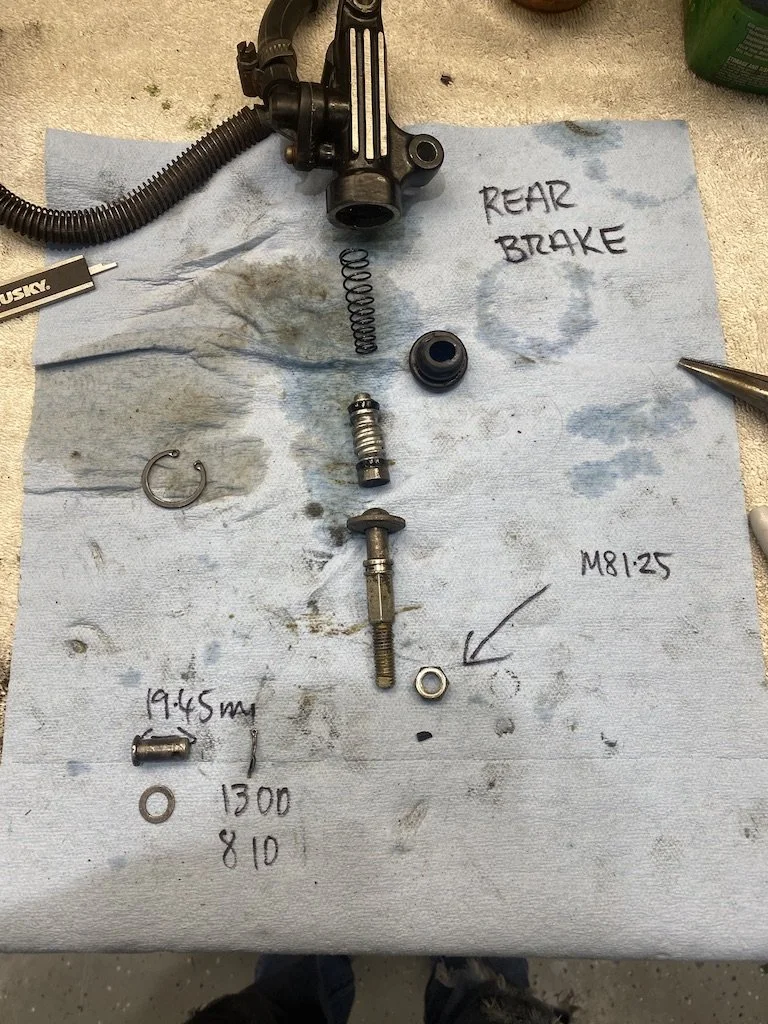

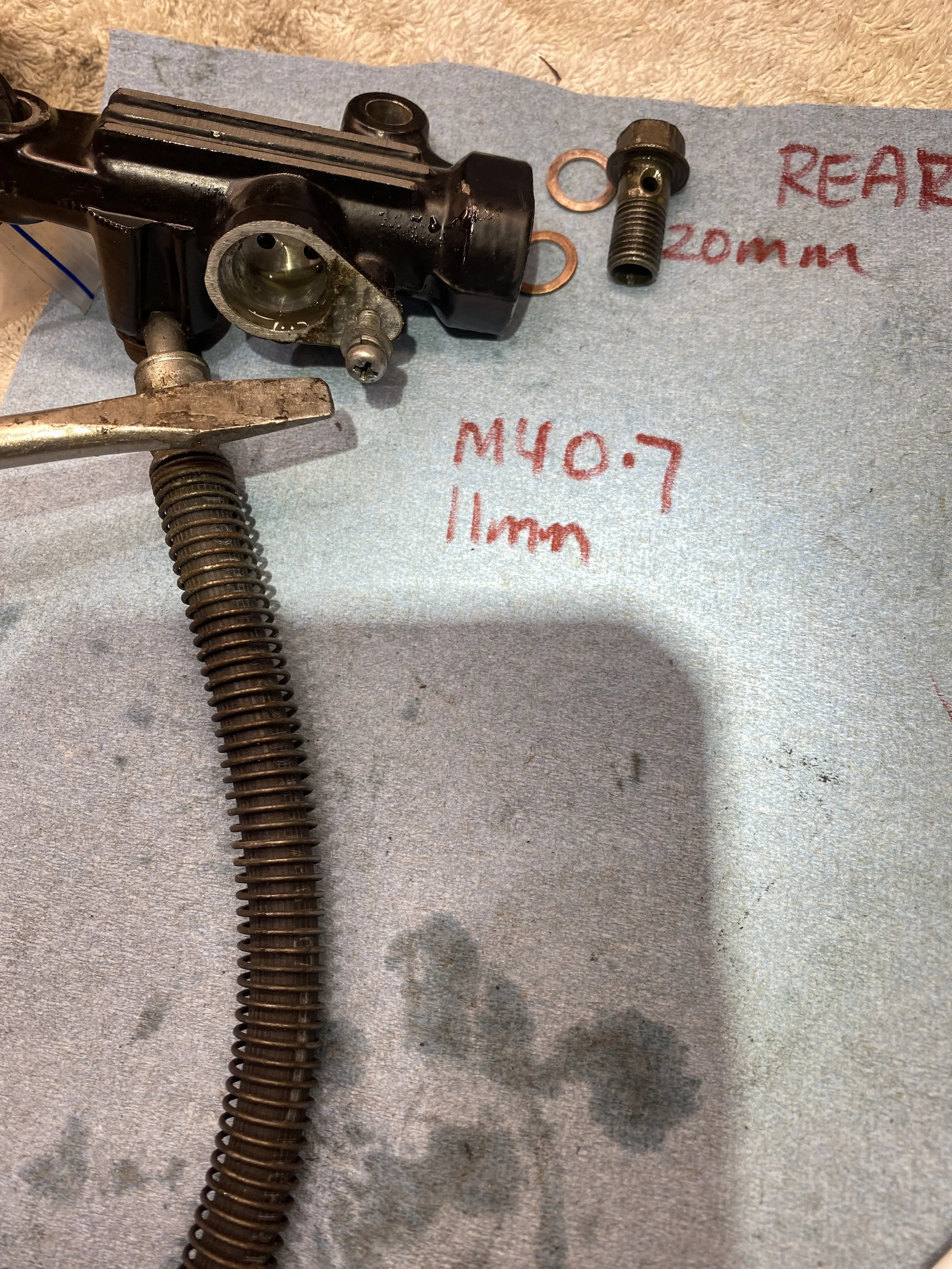

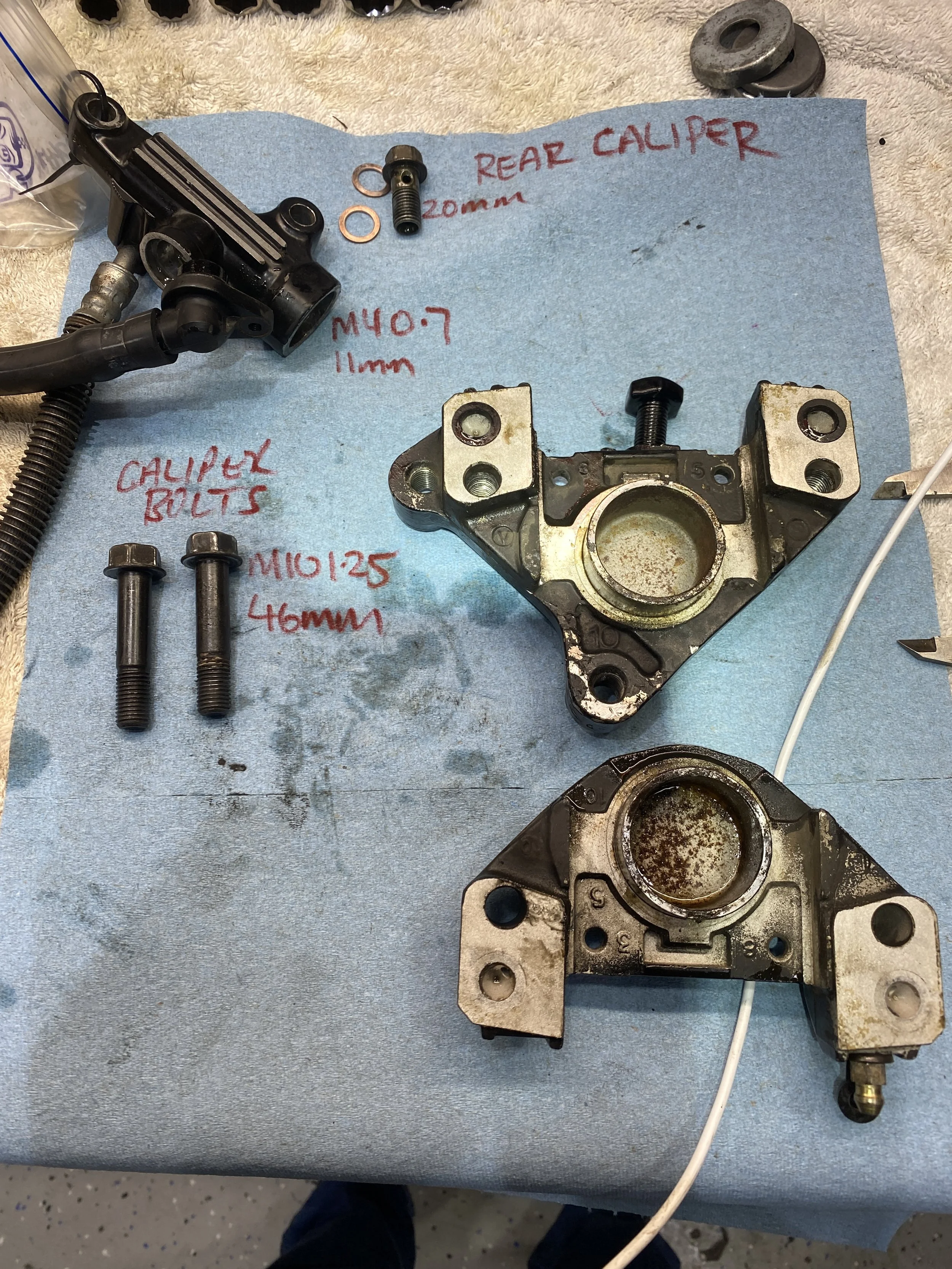

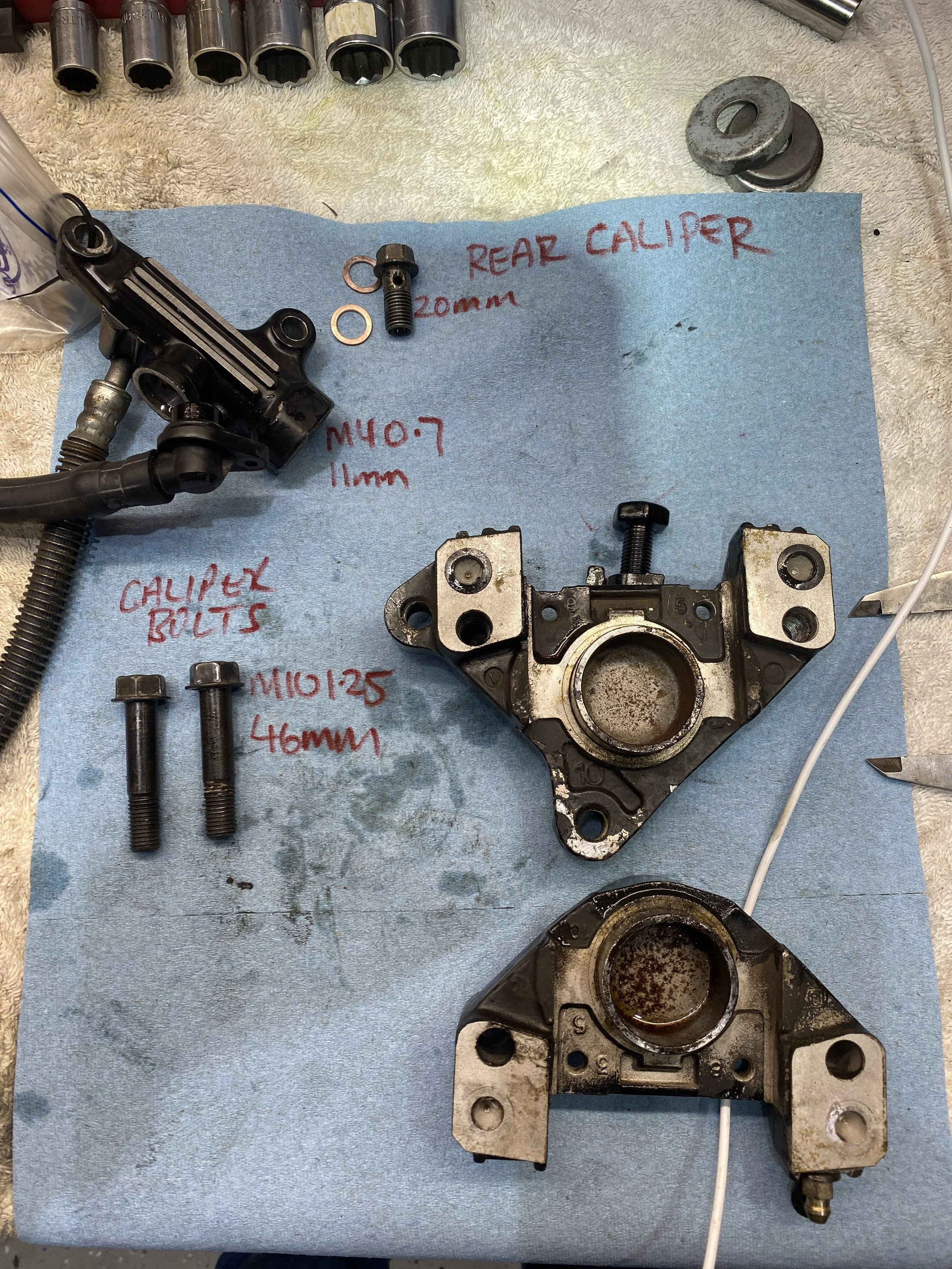

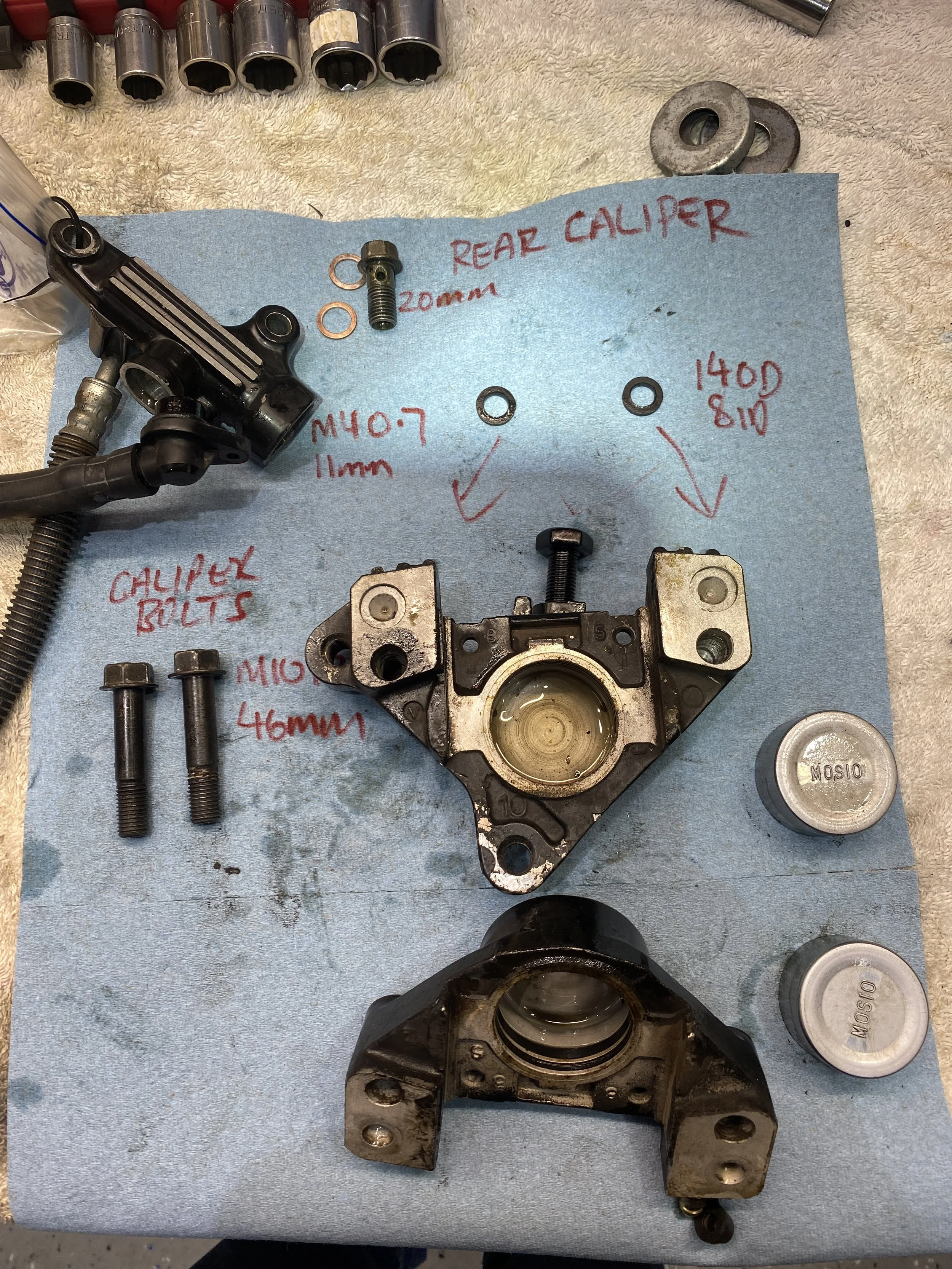

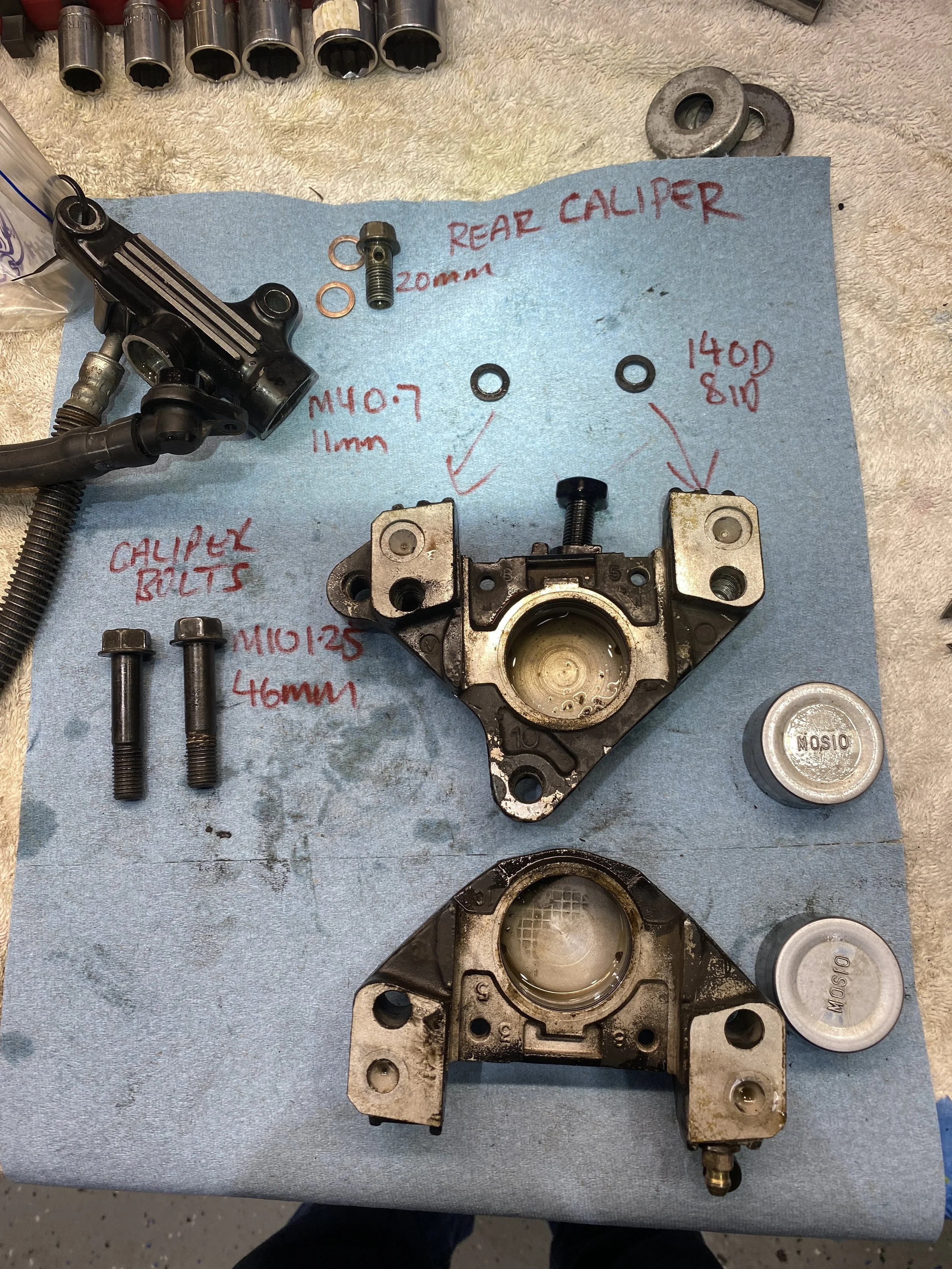

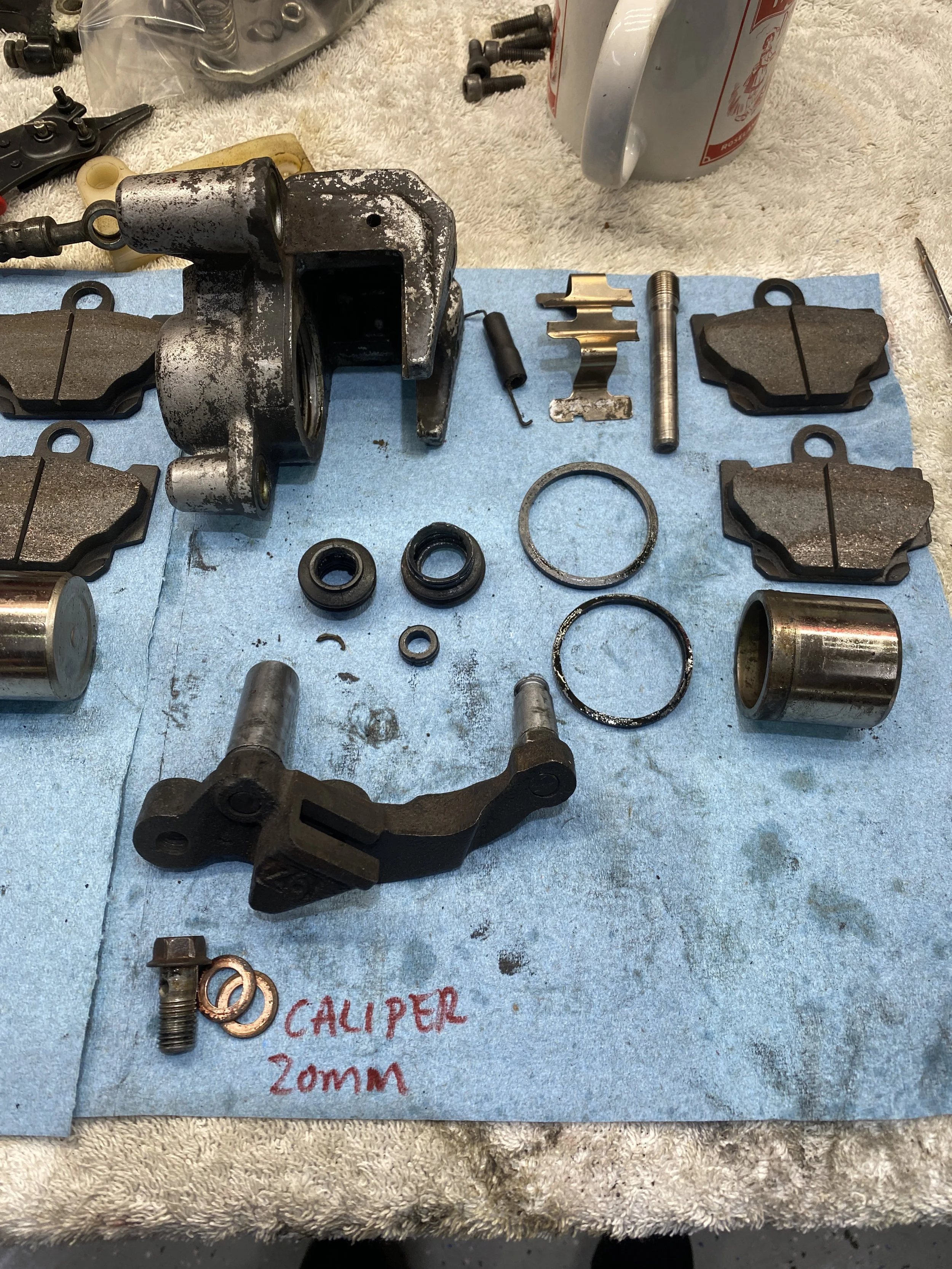

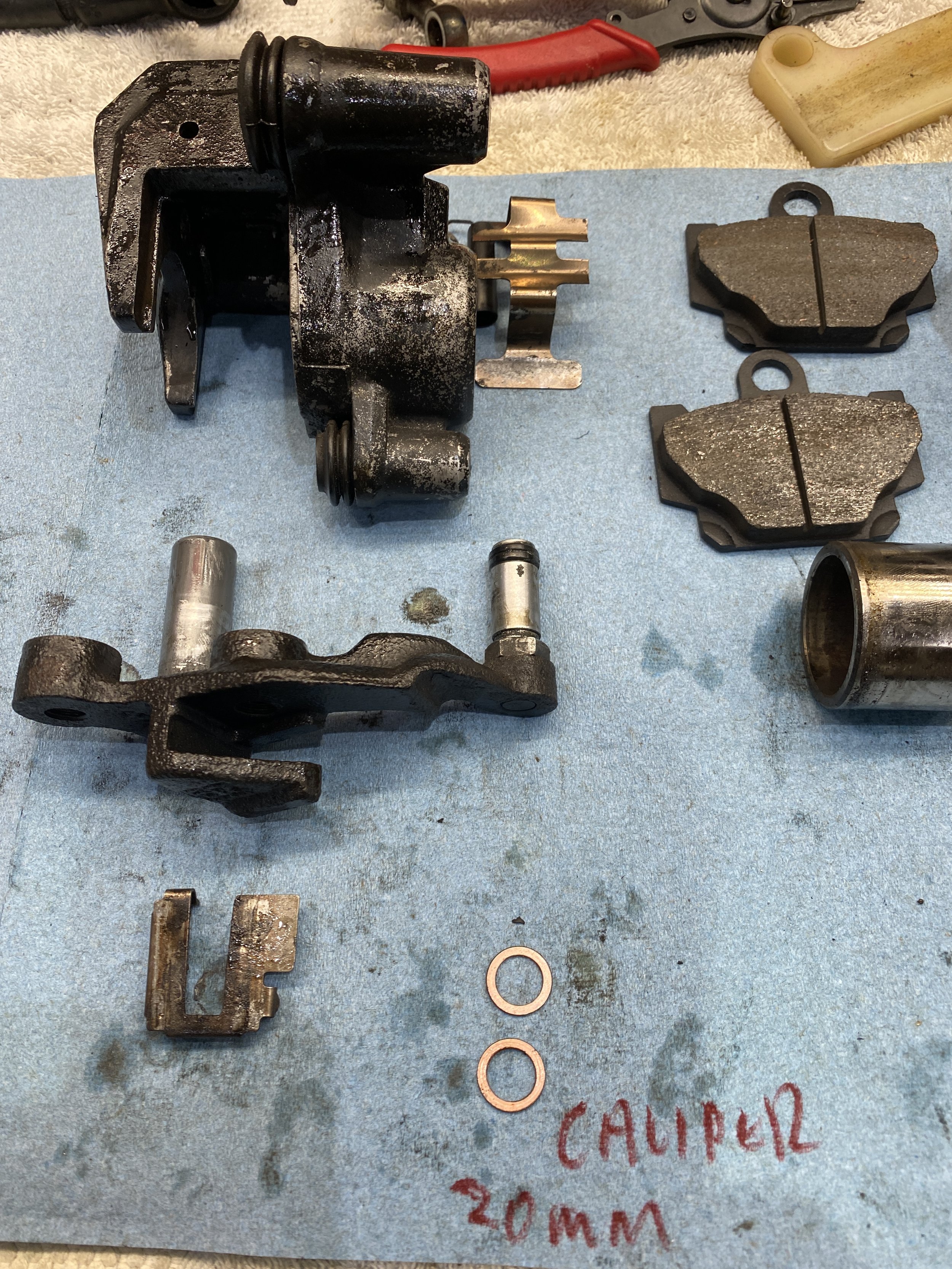

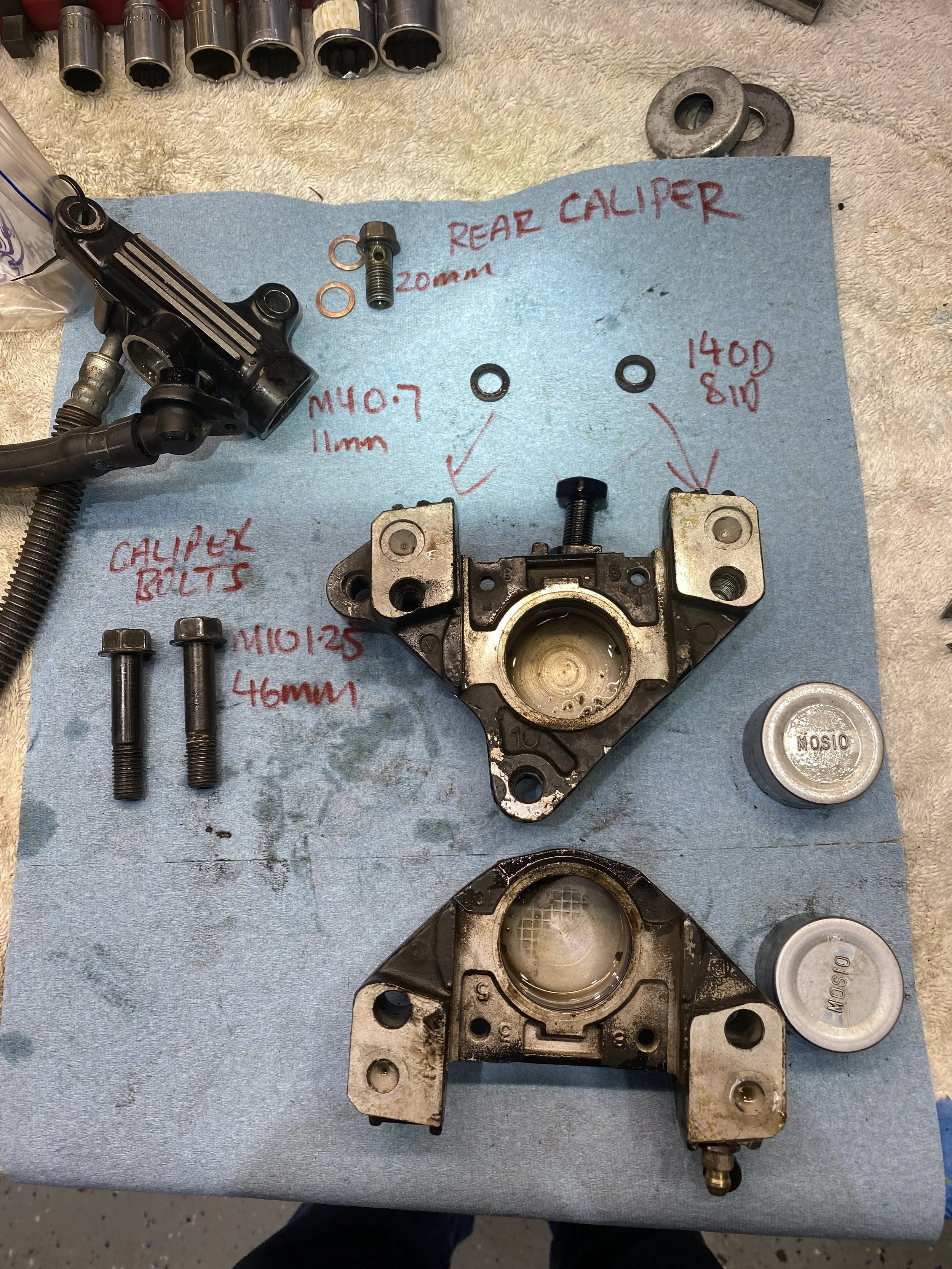

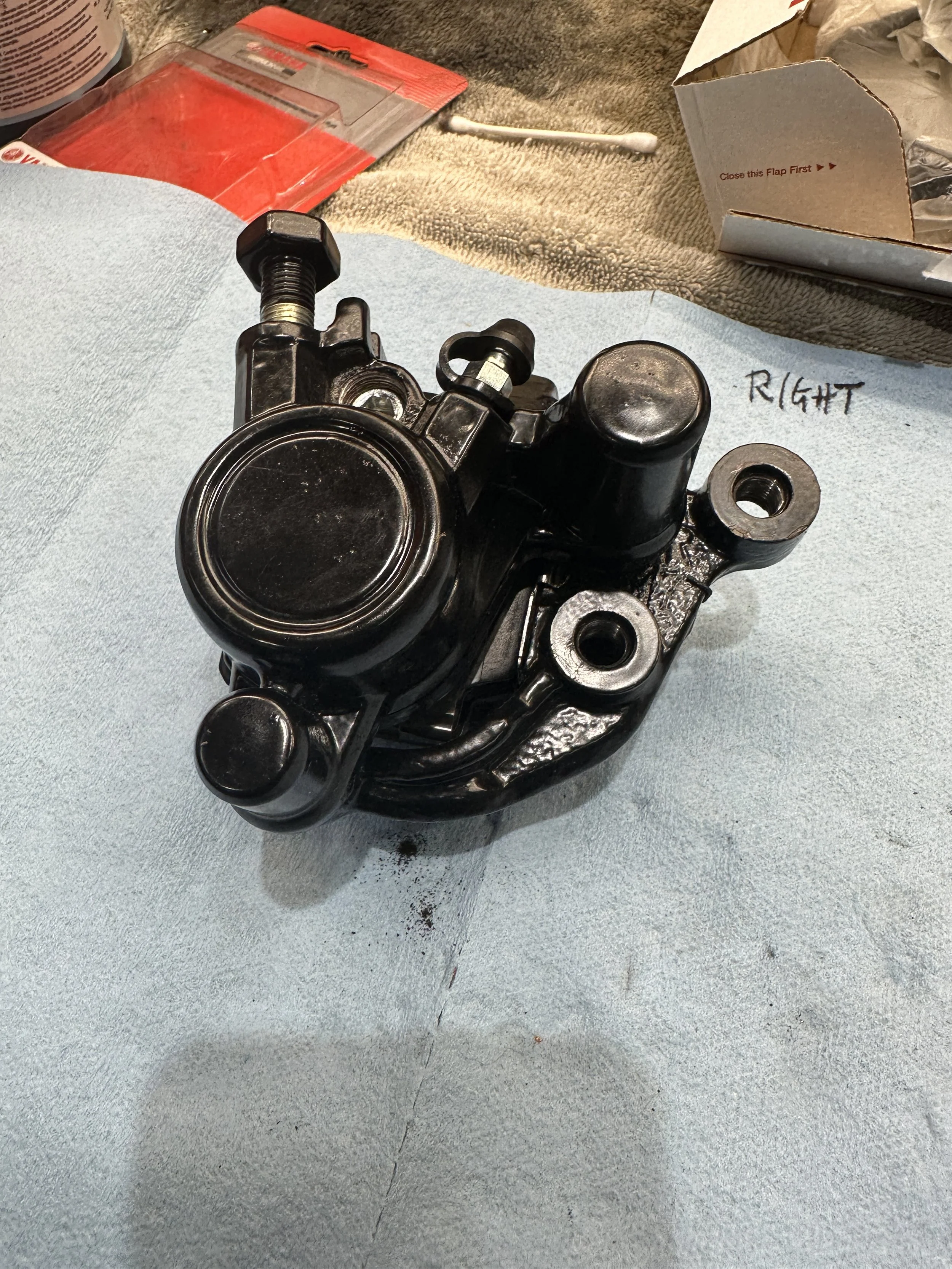

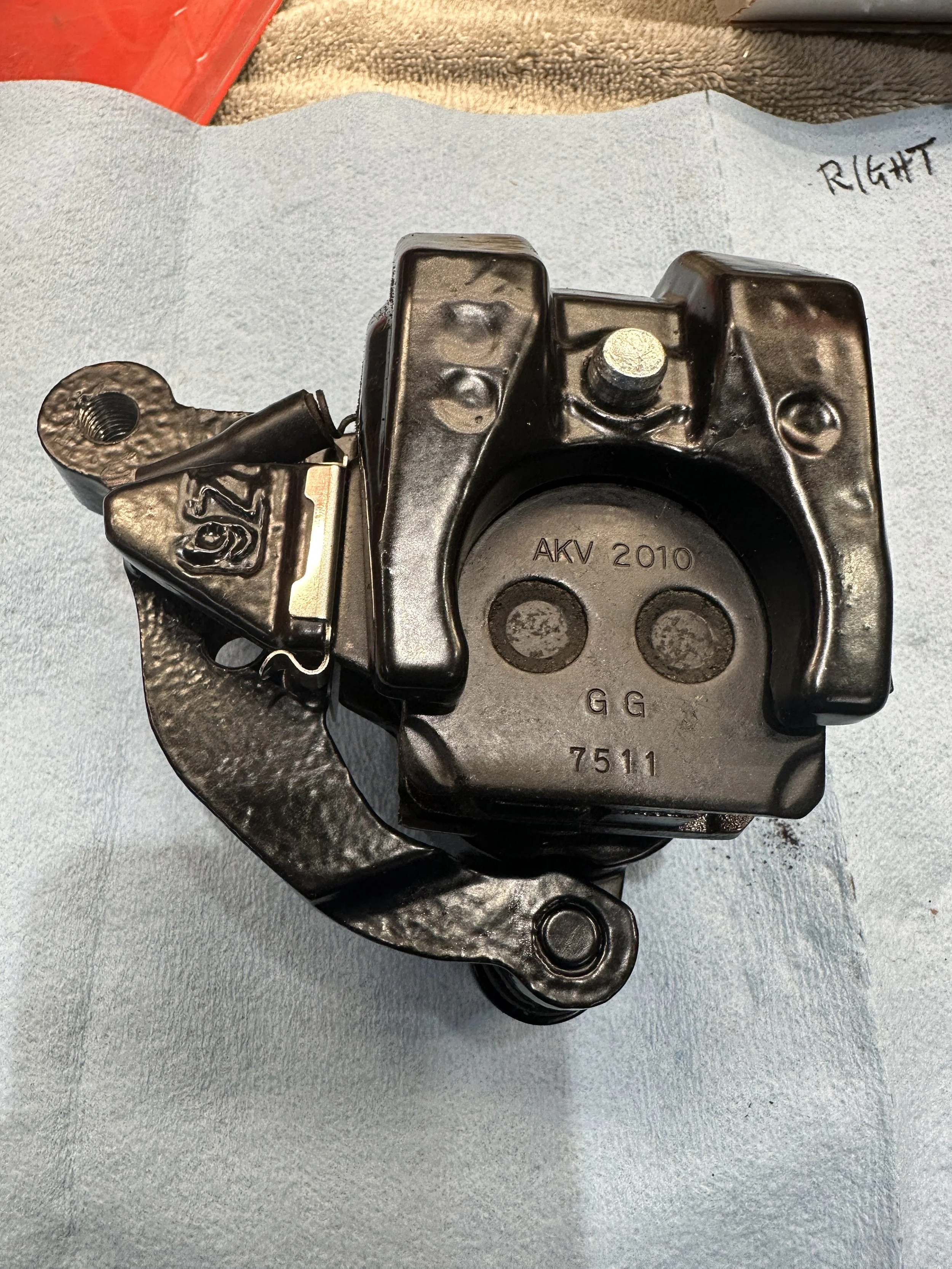

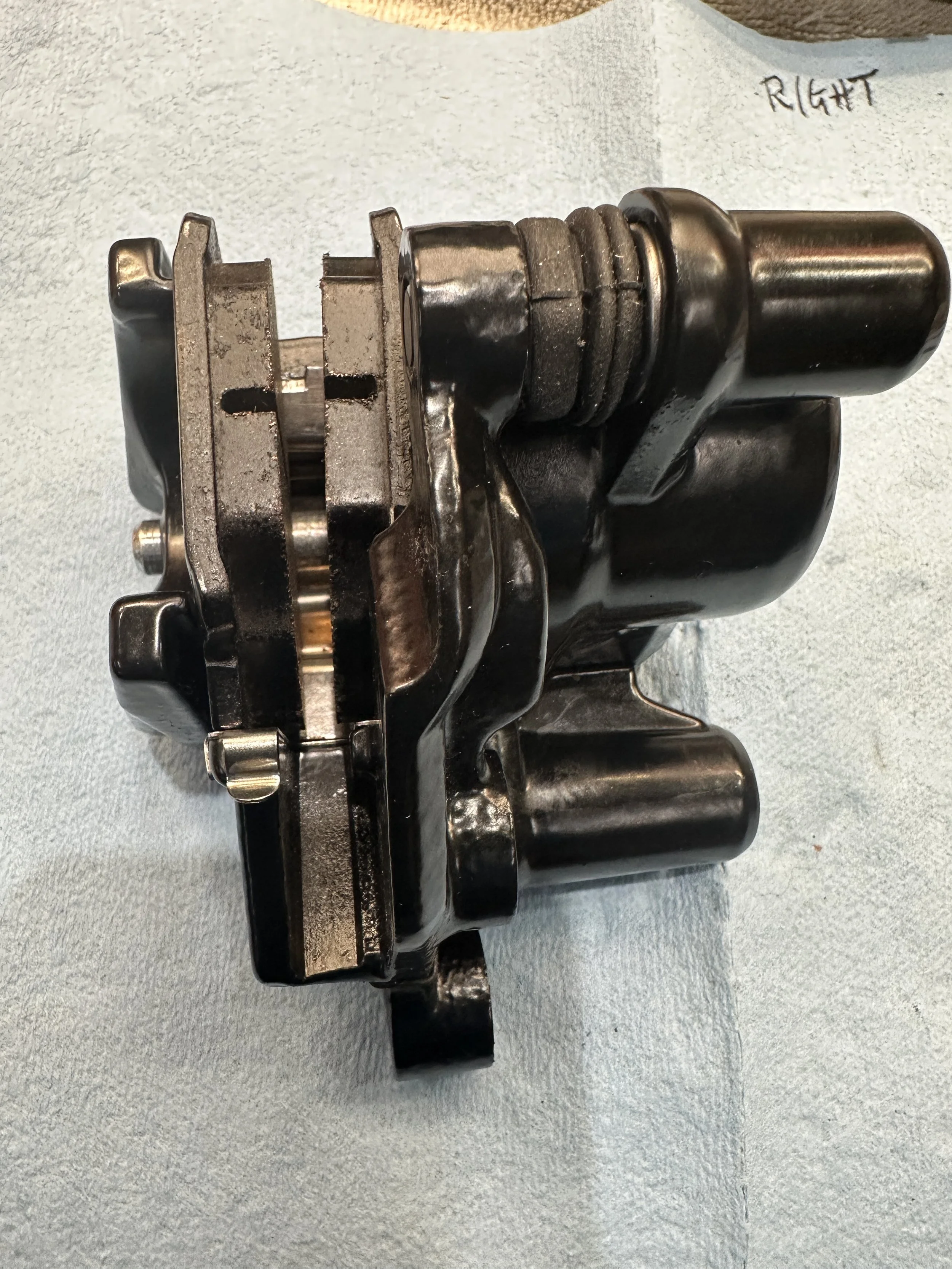

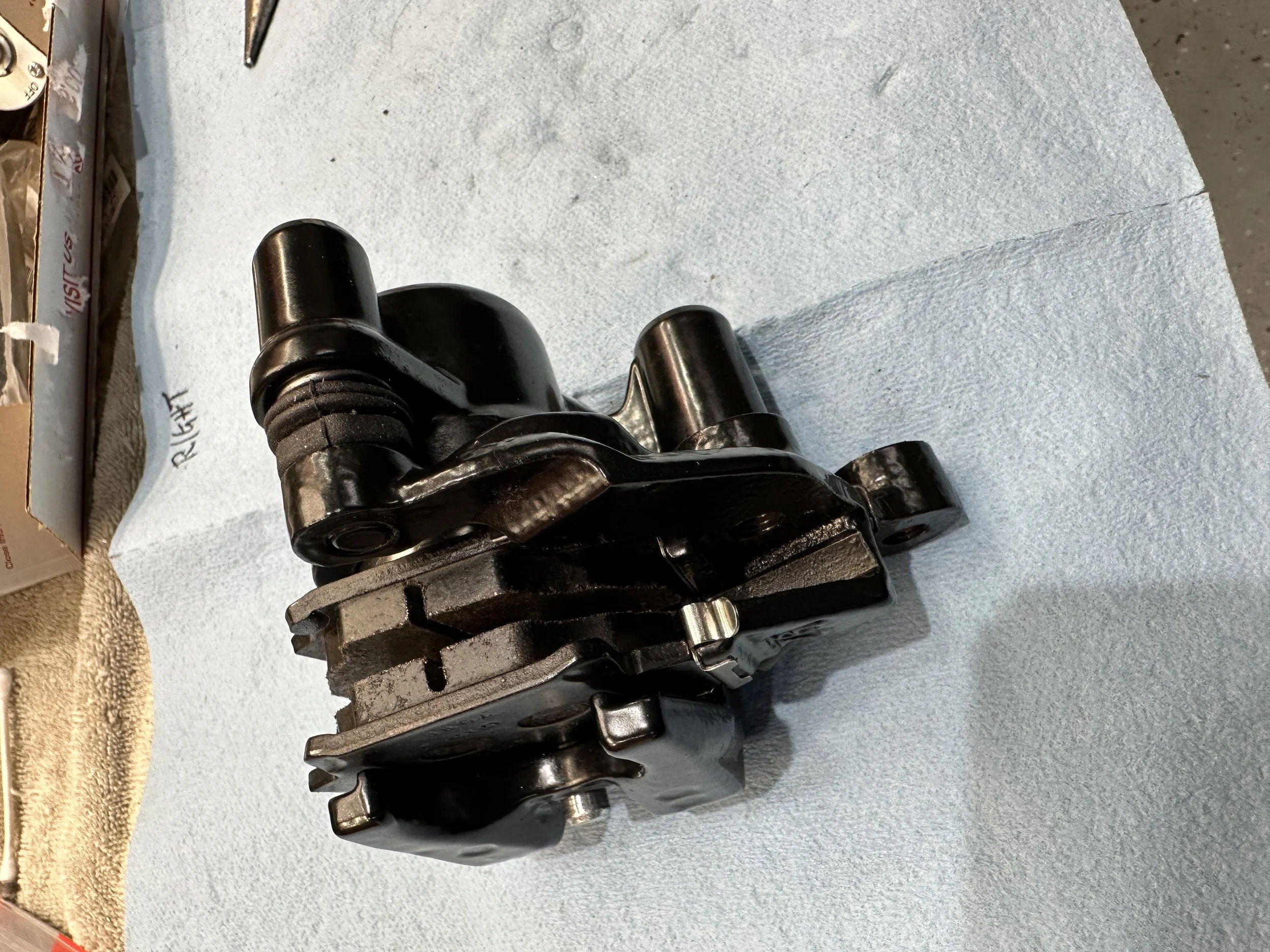

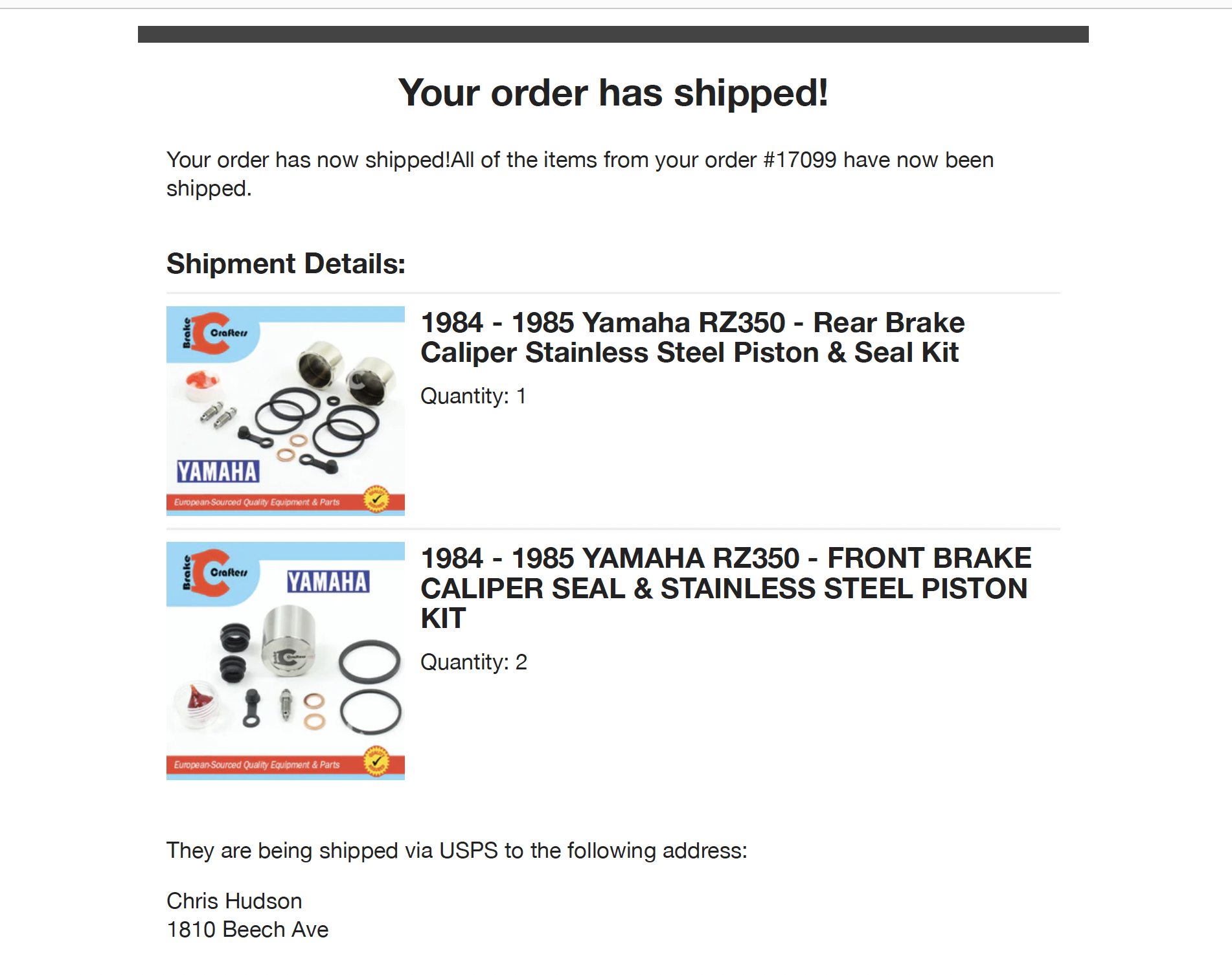

Brakes Disassembly

after much cleaning and stripping attempts- dropped these off to be blasted and powder coated.

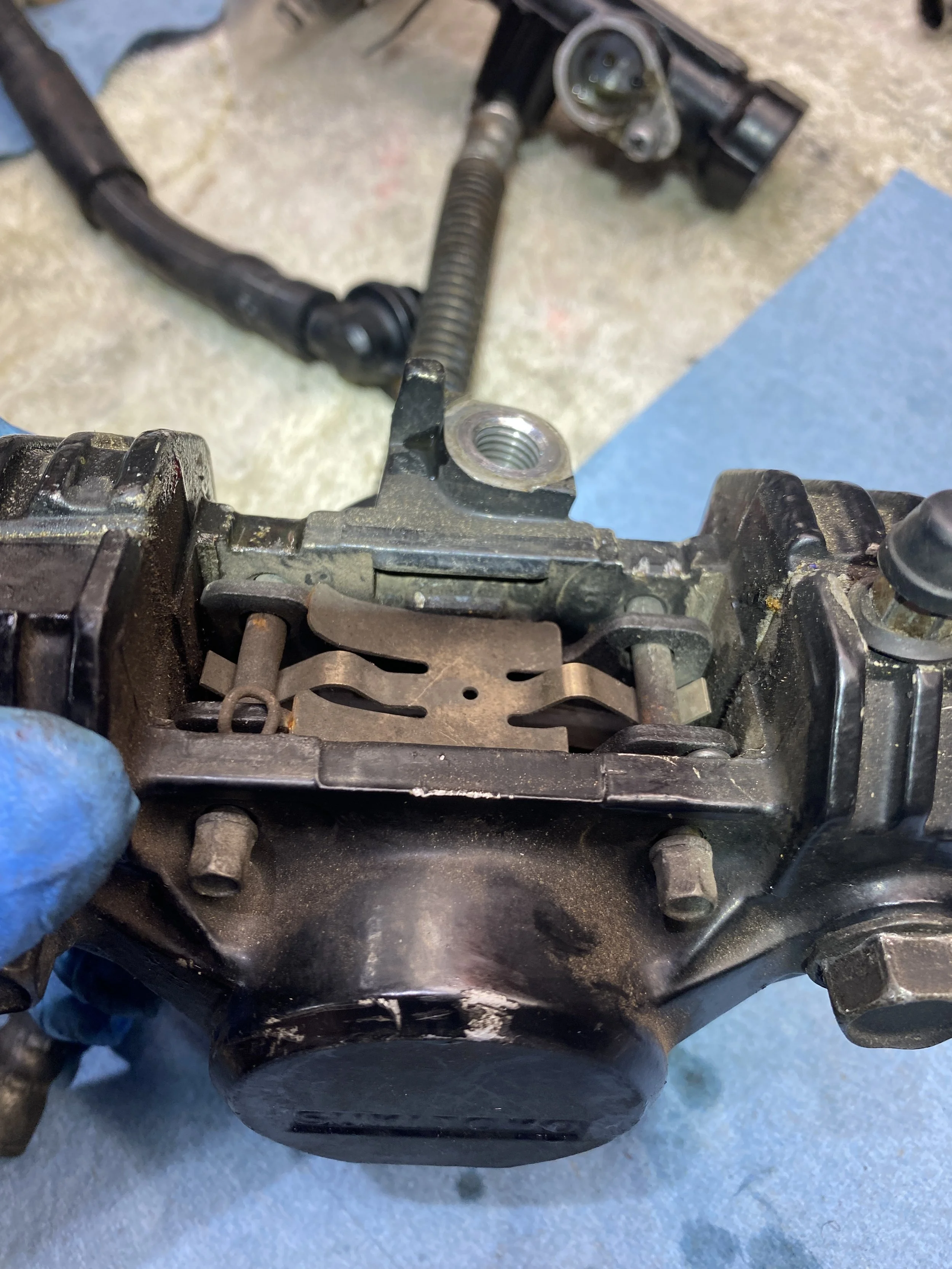

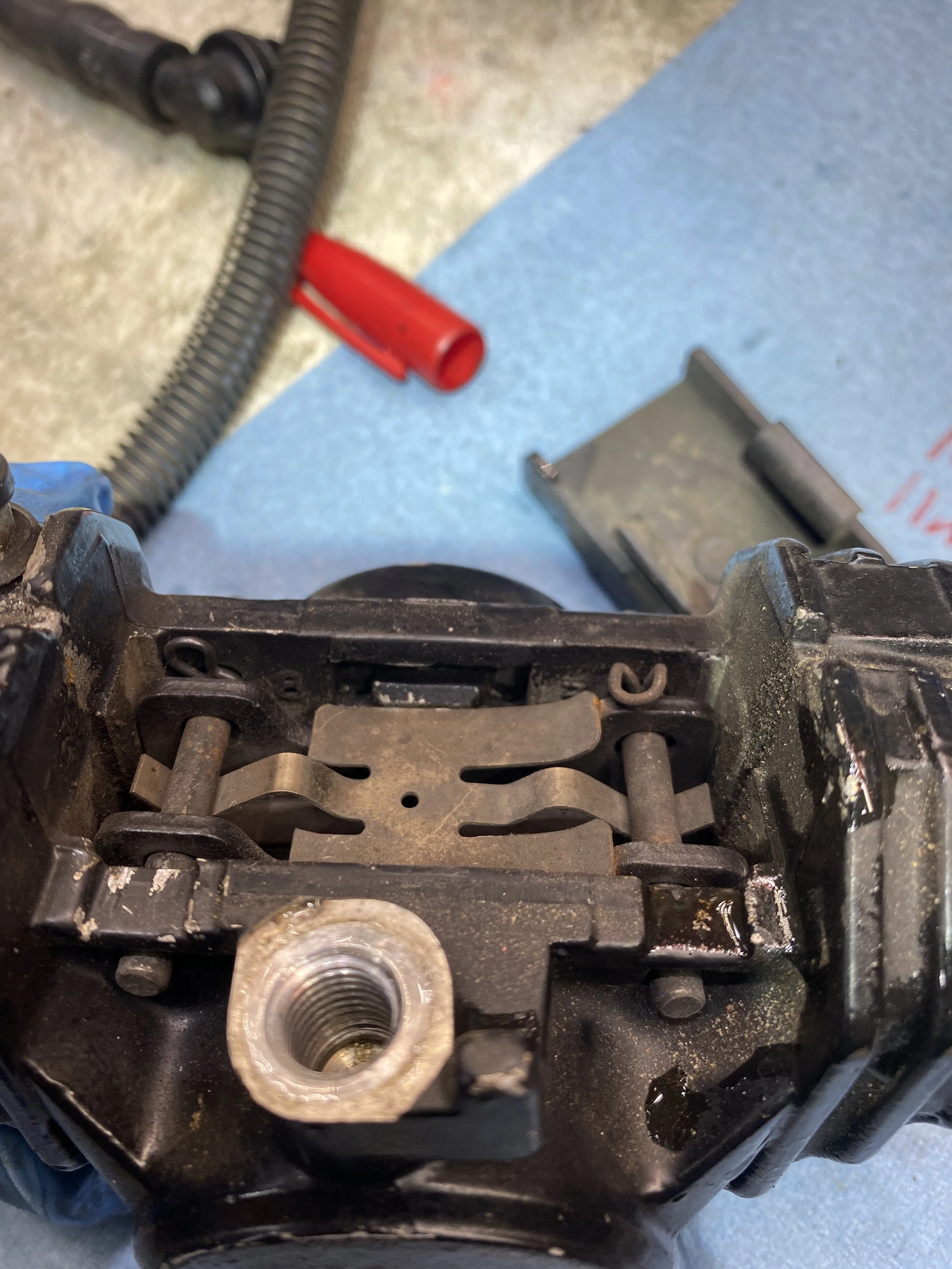

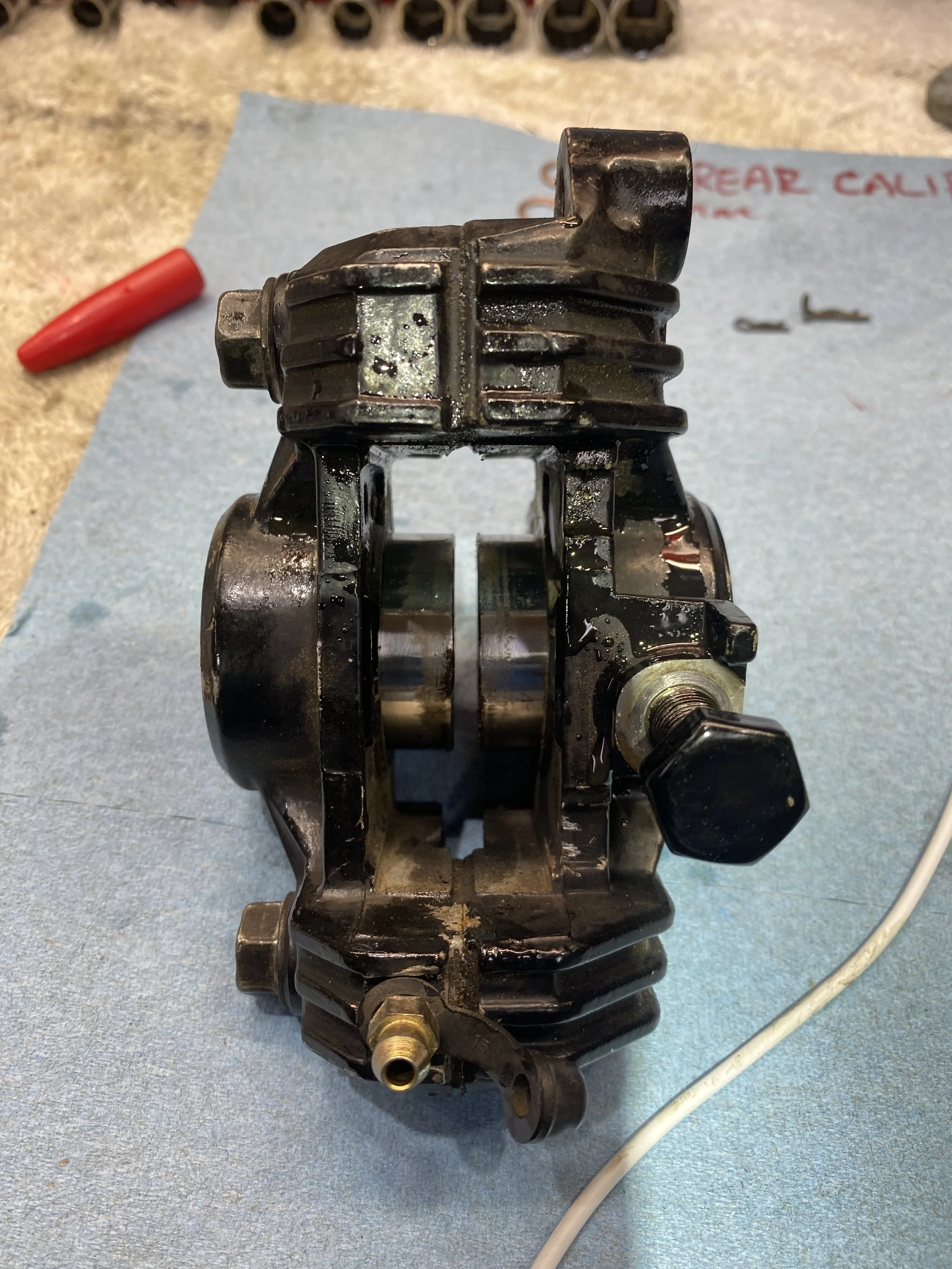

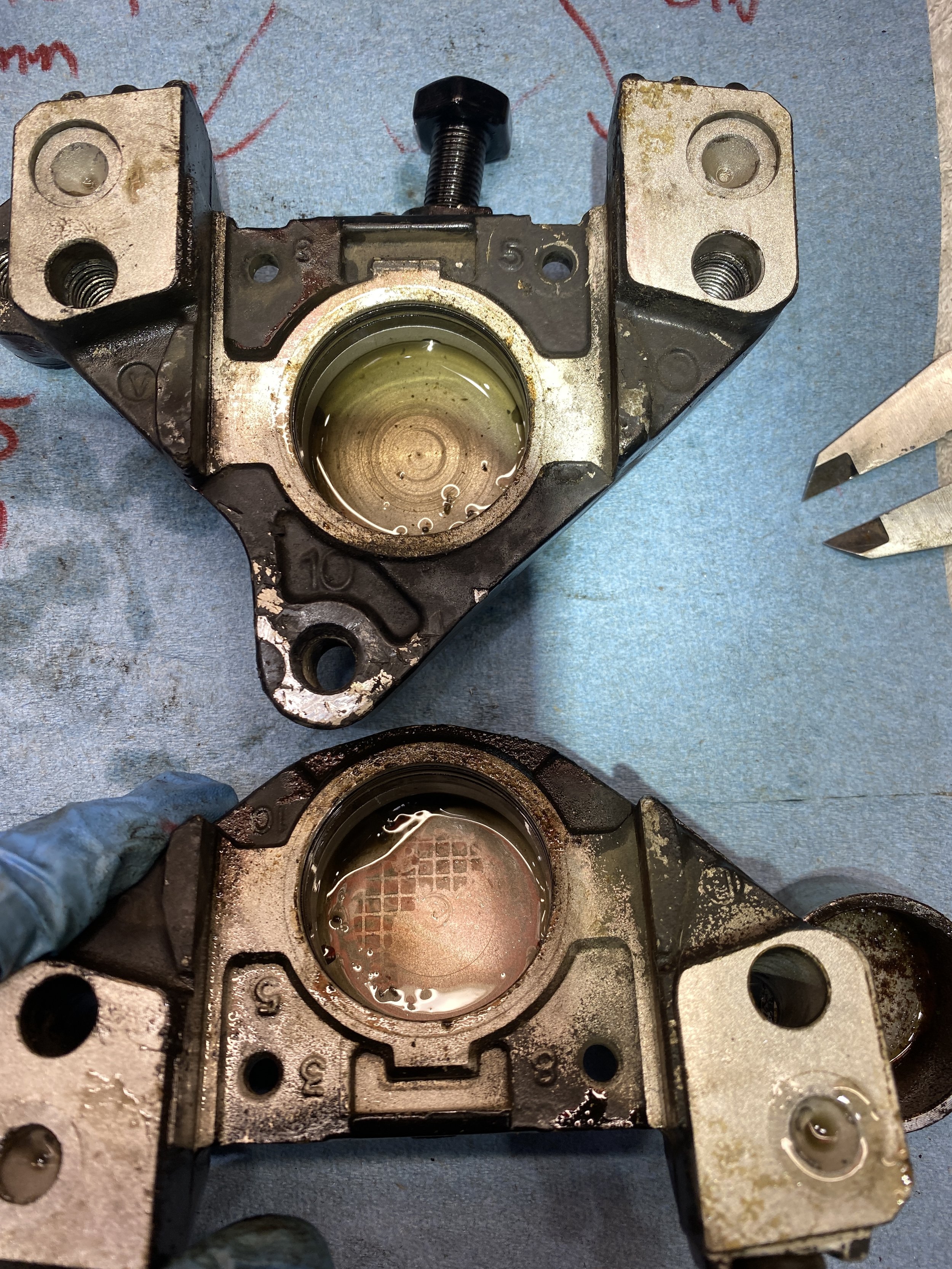

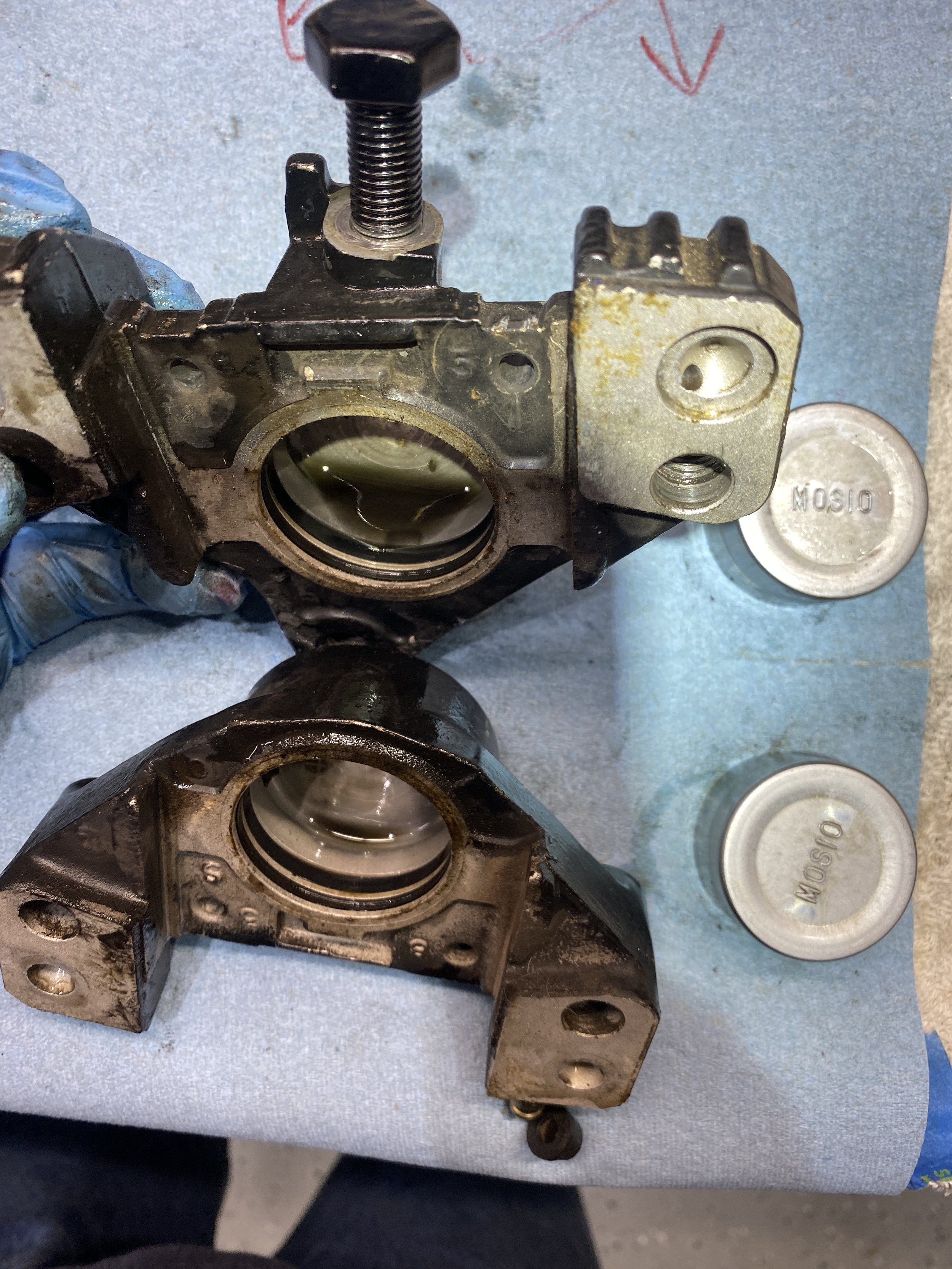

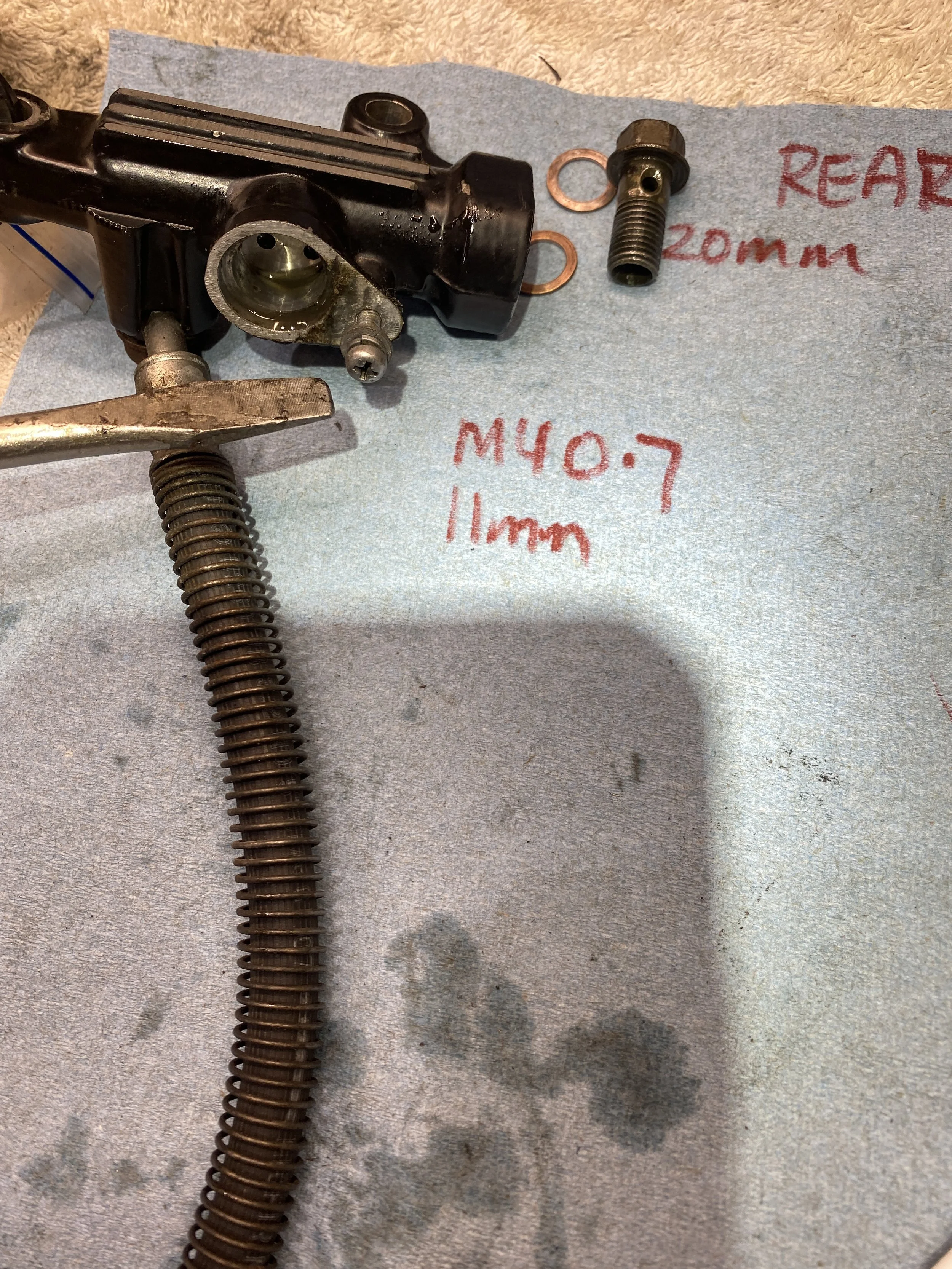

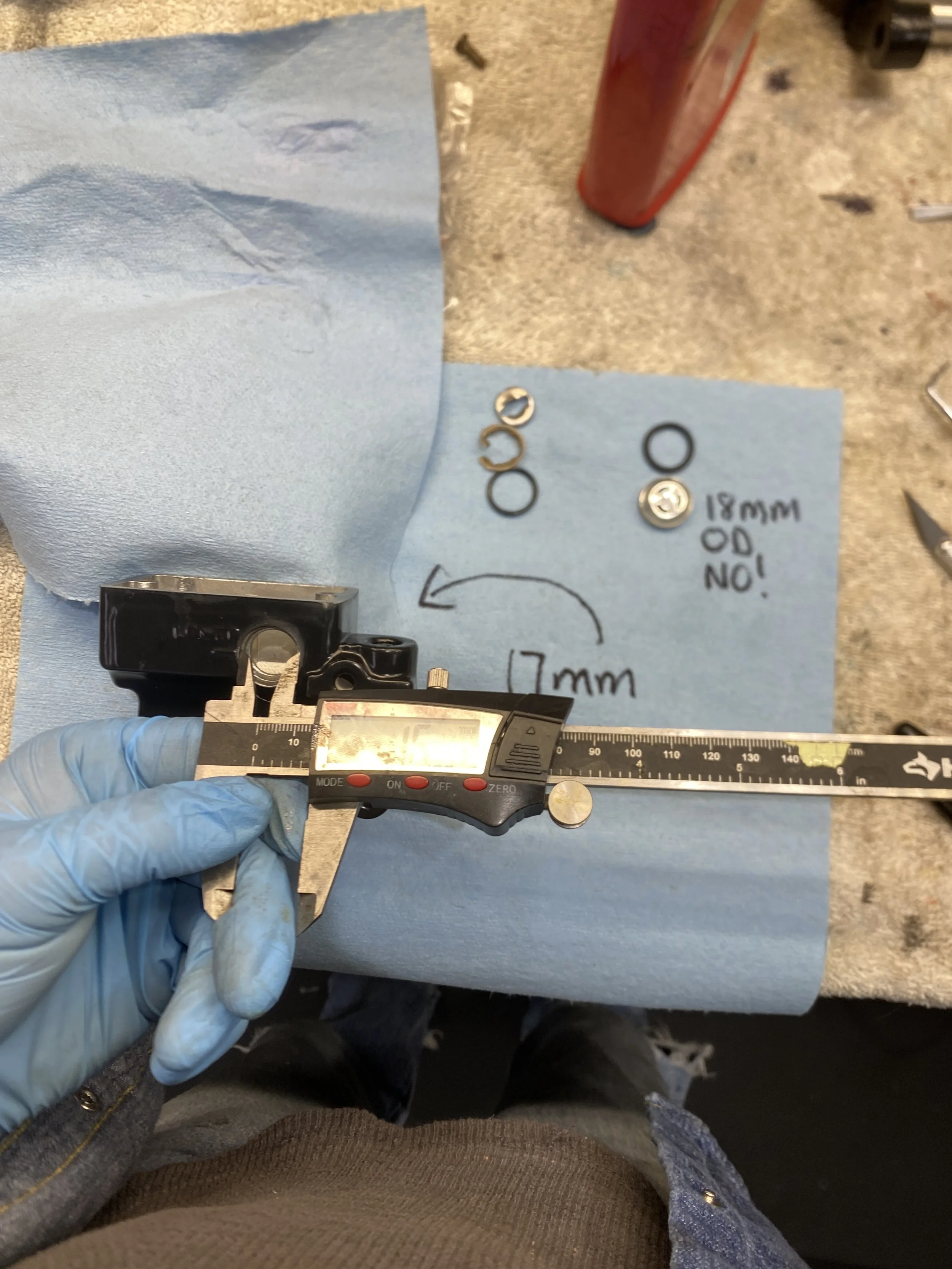

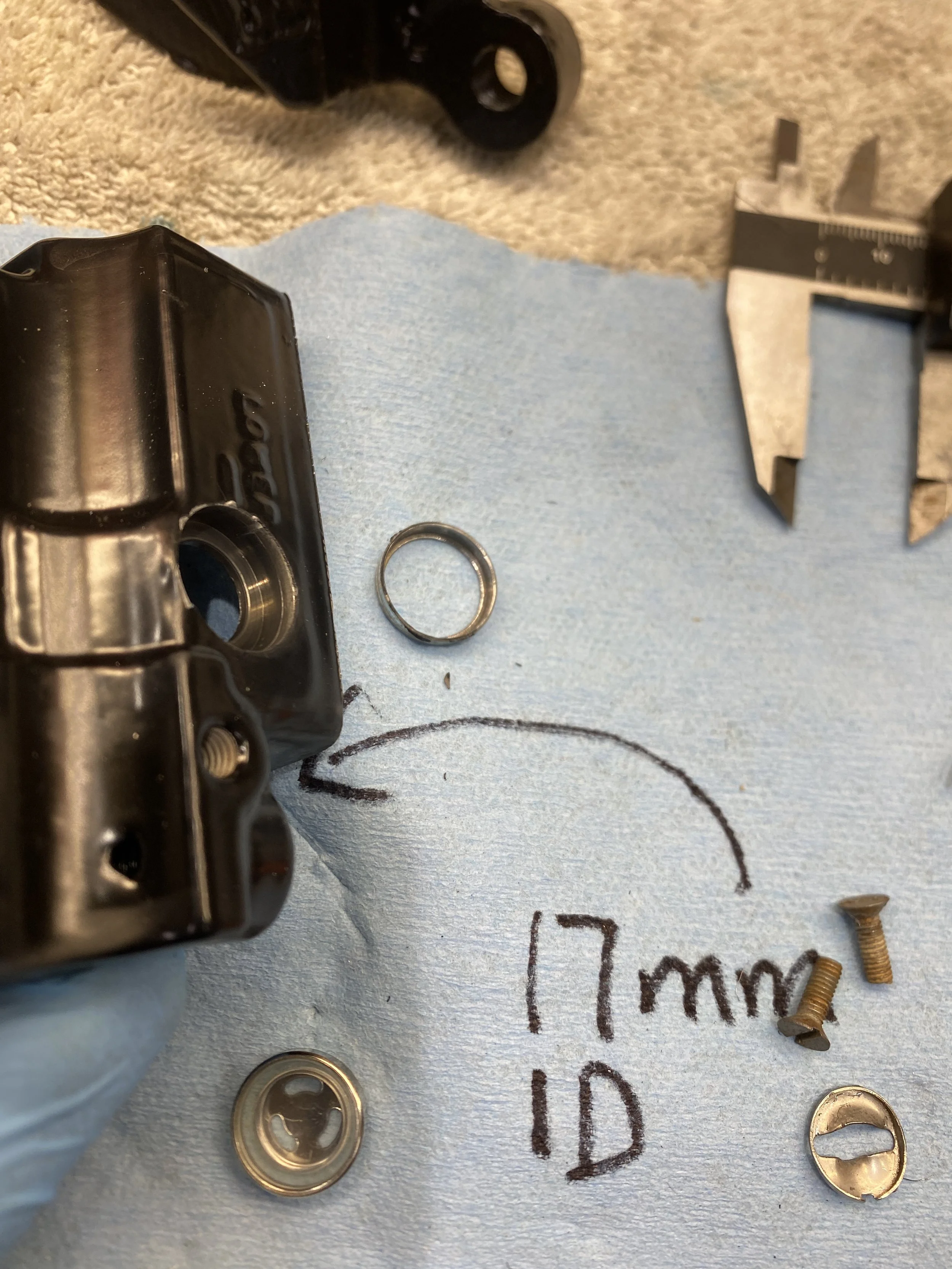

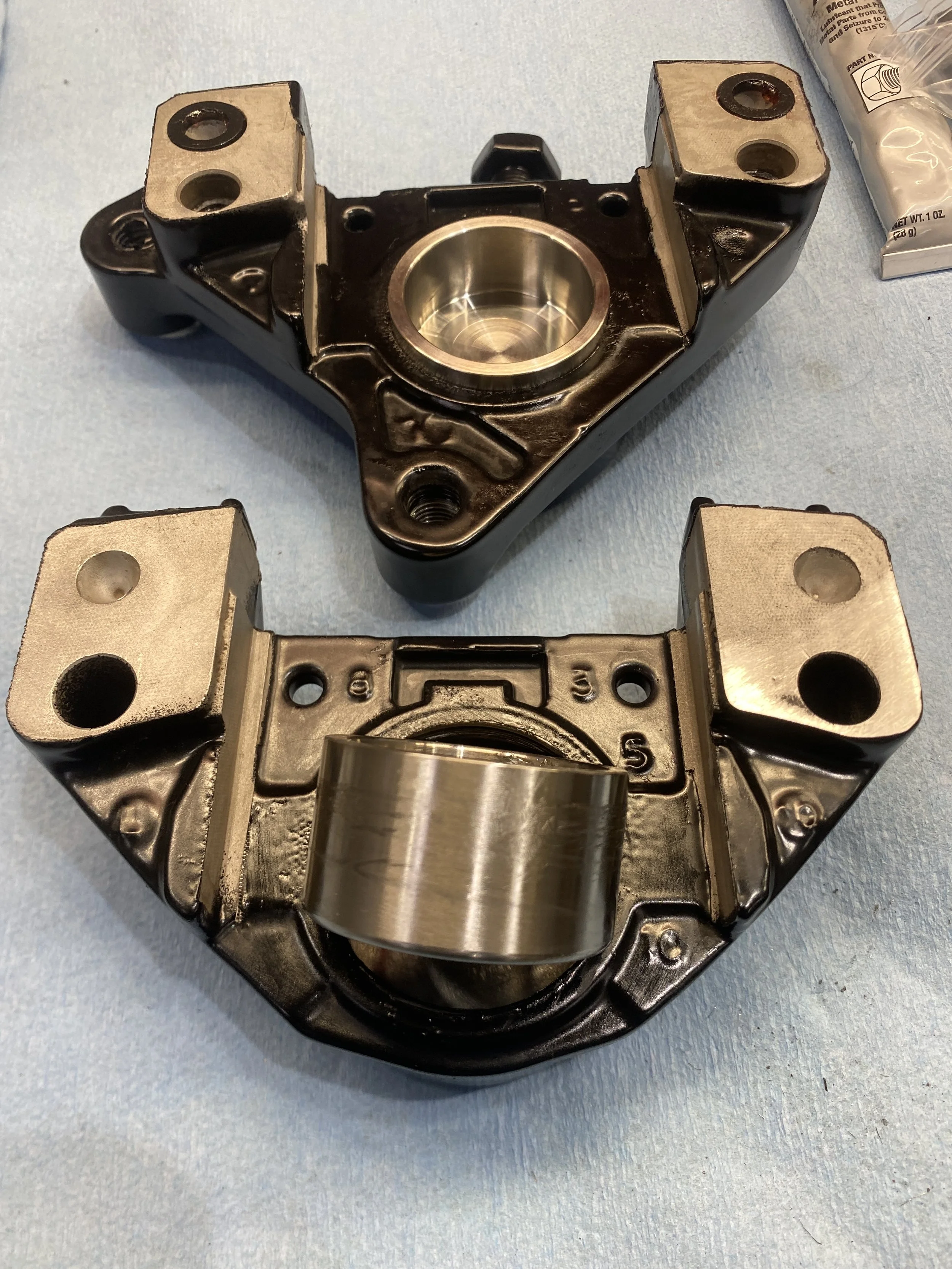

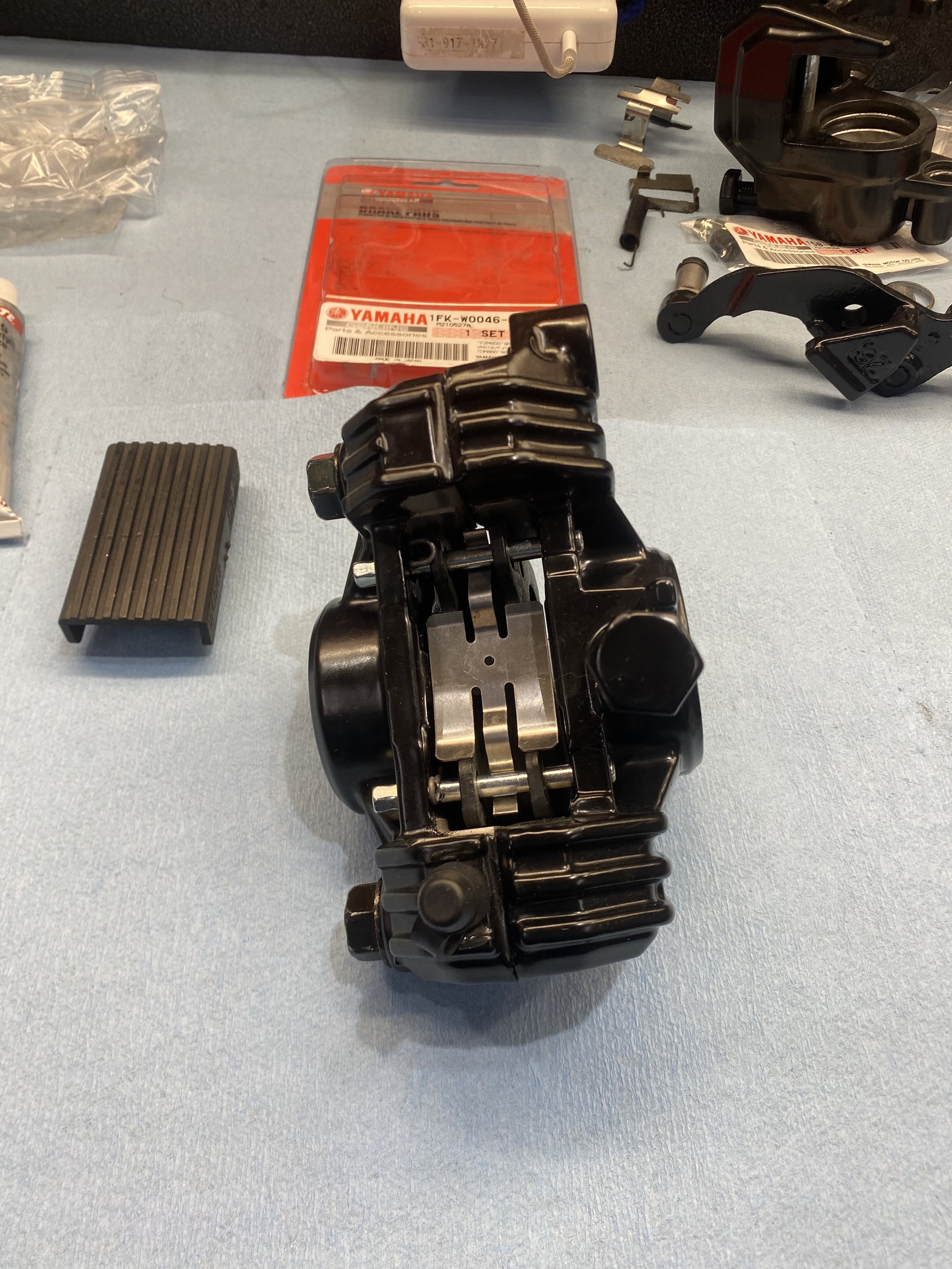

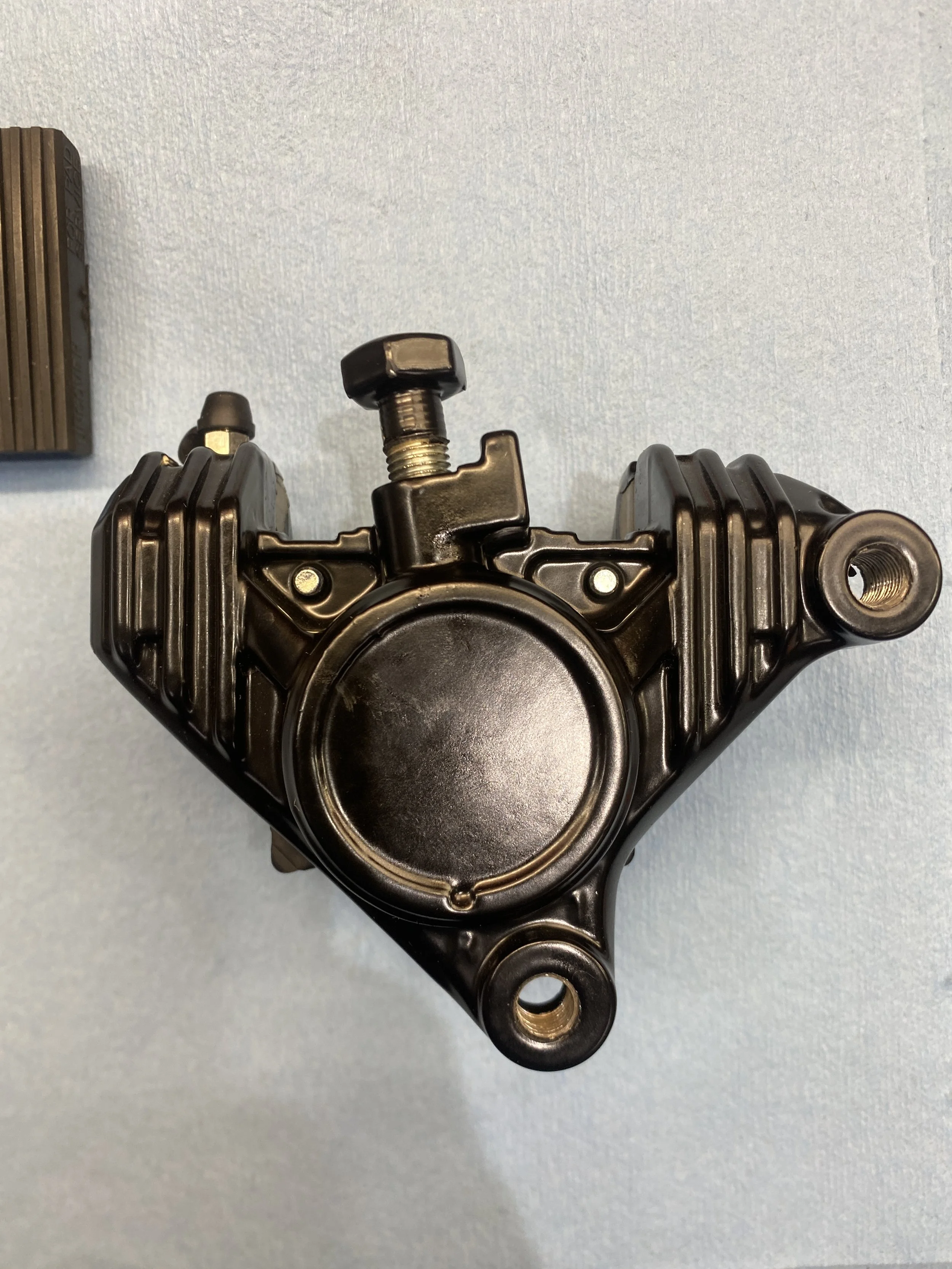

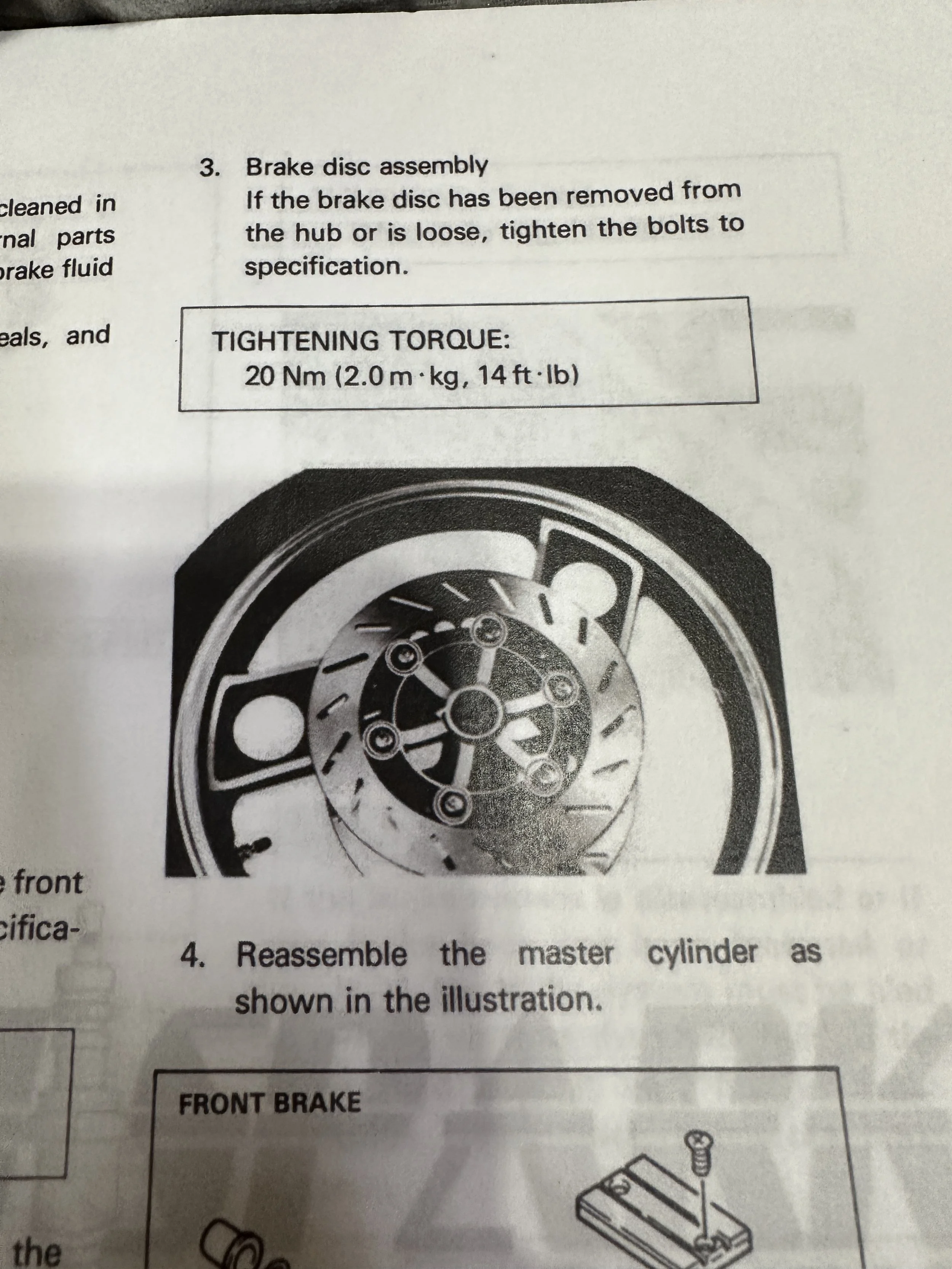

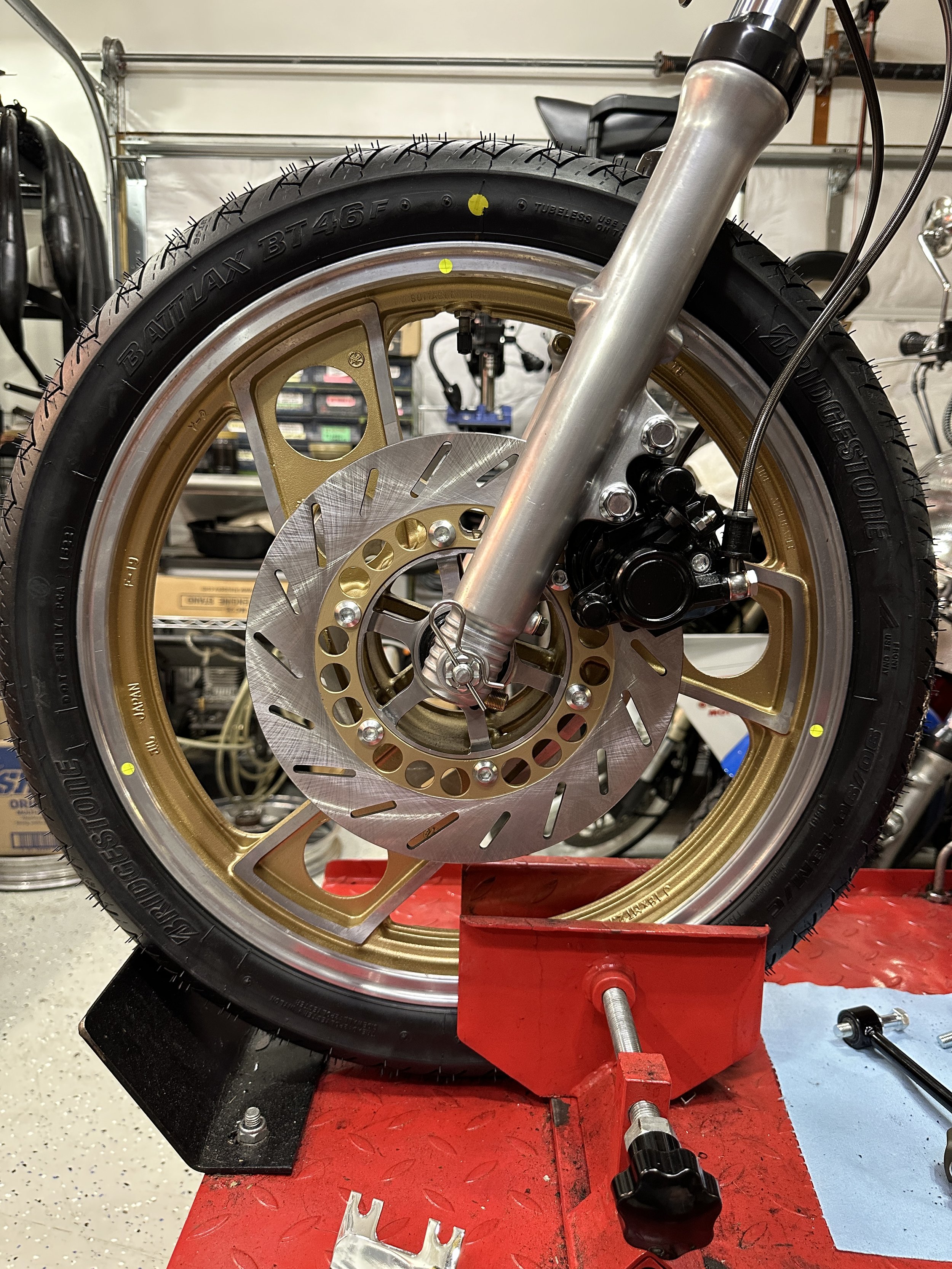

......Rebuilding Brakes.....

......Rebuilding Brakes.....

I didn't pop out the sightglass before it went to powder coating- mainly becuase it was already beyond saving....practically fell out when I looked at it...

Was happy to find a replacement on Ebay. https://www.ebay.com/itm/263817079333,

.....but was frustrated to find it was too big....

.....until I contacted the seller and they told me there was likely another ring still installed...i found it and popped it out...

....and hey presto it fit perfectly.....

Powder coated OEM master cylinder top.....

....just needed a little coating remvoved....used duct tape to protect the top from errant file strokes....

...which you might see...happened anyway....still looks good though....

..at least compared to the original.

this OEM brake lever came from cmsnl.com. 26 Euros. Nut and bolt are original and replated. Spring had a wee clean.

Cleaning up all the threads....

..beautiful.

Removing the adjuster screw from the brake lever the bike came with. I would have really liked it when I was 18.

Installed.

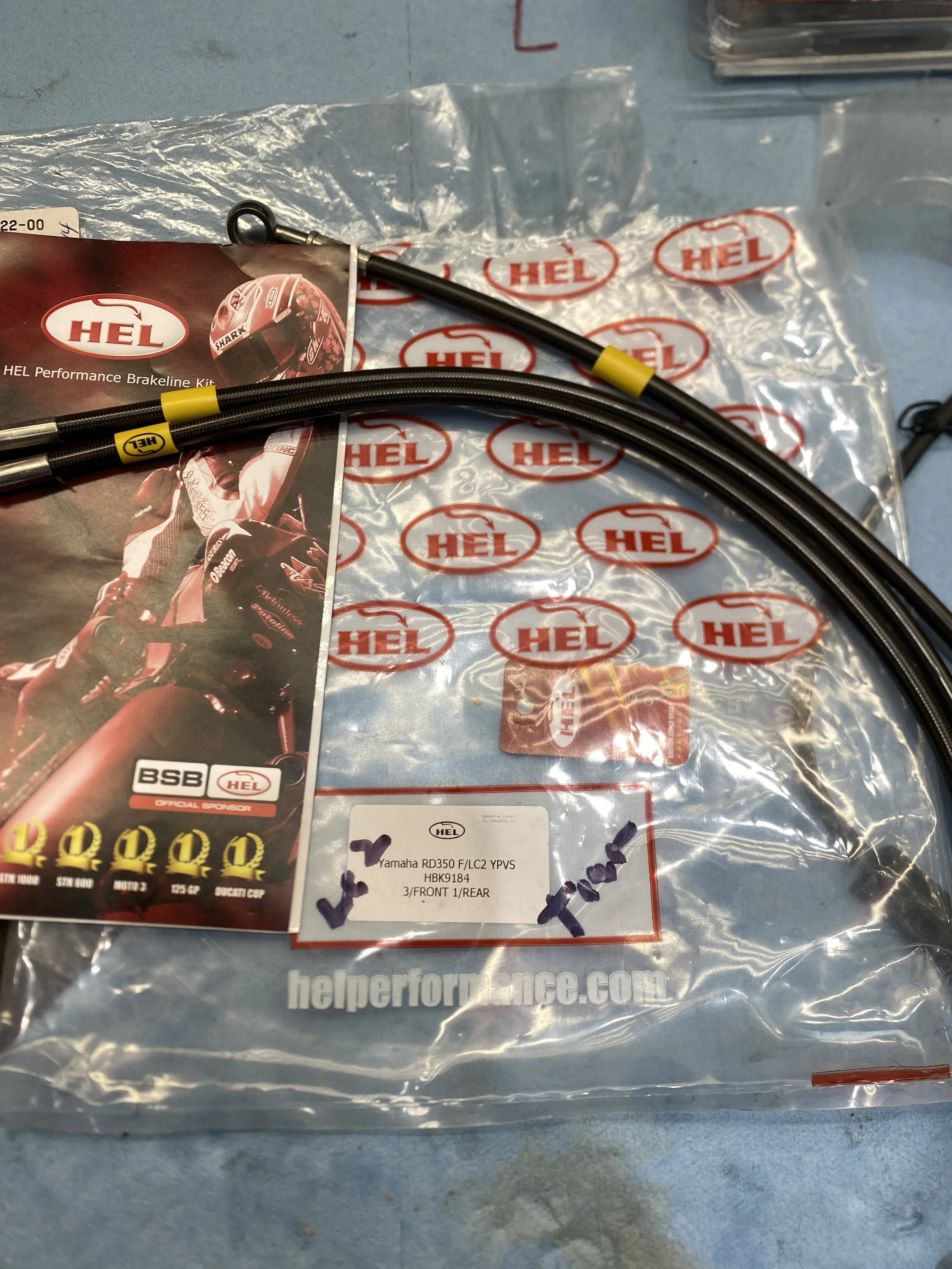

Will be replacing the 40 year old rubber brake lines with the new fangled HEL black braided stainless steel brake lines that came from Norbo...rdlccrazy.com. Full front and back set comes complete with new stainless bolts and washers at about $140 on his YPVS 'trick bits' page. Click on this picture to go there.

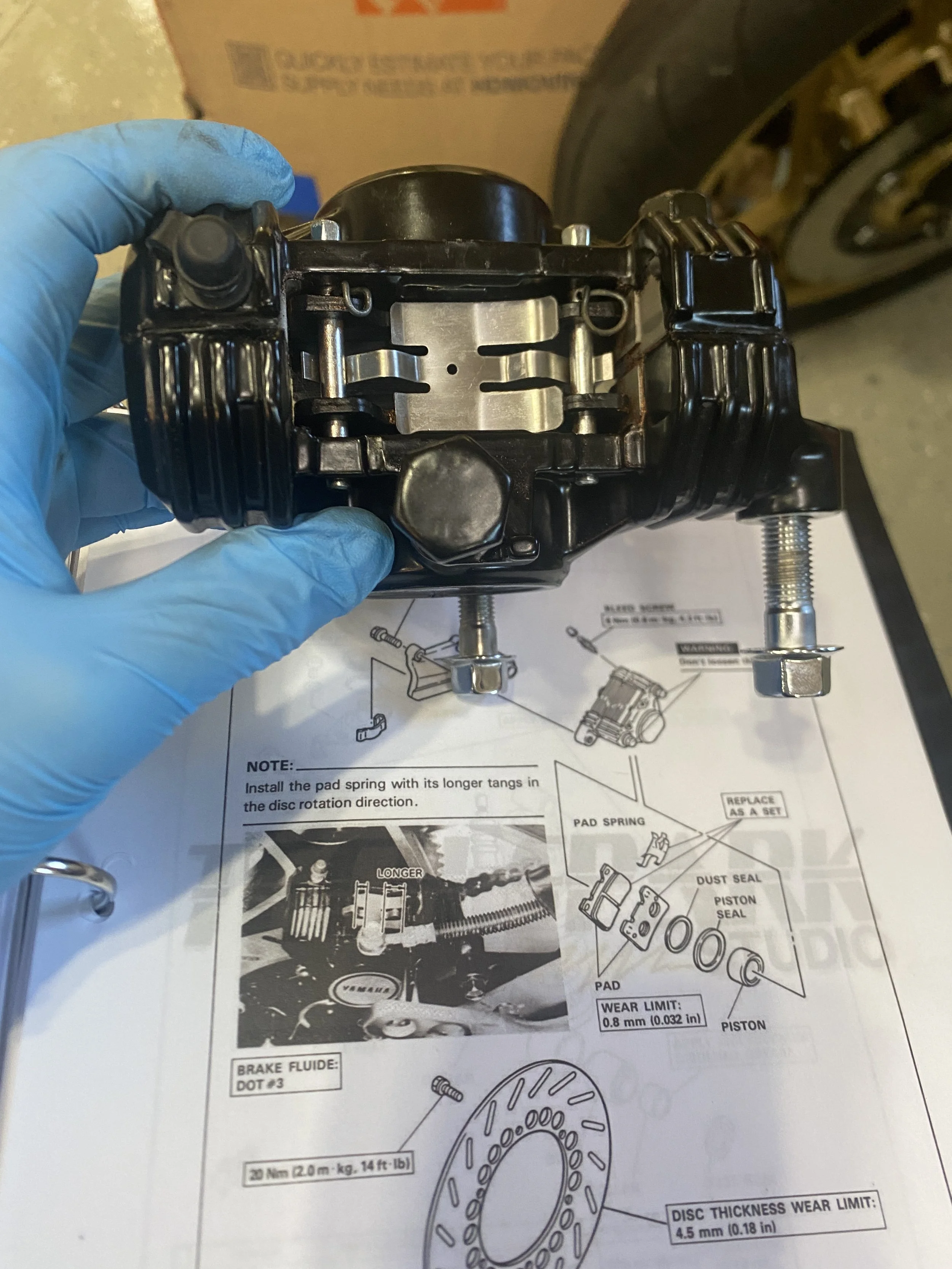

A quick glance at the newly arrived Haynes manual....

.....tells you which way to fit the rear caliper pad spring....longer tangs go in the "...direction of the disc rotation."

I couldn't find OEM replacements either but I think I came up with a sensible alternative to the OEM component. I purchased a box of #83 o-rings from the plumbing section in Home Depot. 1/2" OD, 5/16 ID x 3/32 CS (cross section). They contain Butadiene which is an oil resistant rubber, nevertheless I only used a little red rubber grease. I put 2 o-rings on which satisfied the middle groove around the circumference. For the perpendicular slot that is there to let out air, I heated up a small square edged file and with the o-rings installed, I lay it lightly at right angles and melted a shallow slot. Works a treat. With a bit of the rr grease in there it slides back and forth smoothly and you can hear the air hiss out. This'll work if I strike out getting something better.

And now to the Rear Master Cylinder...

Cleaning up the threads on the master cylinder mounting bolts.....

....methinks the cerakote is a couple of microns thicker than your average olive drab plating.

Always good to ensure the corresponding threads are equally clean and ready to receive...

Assembly of the assembly....

...complete.

Installed.....

...here it is without the distractions...RGV is second next project.

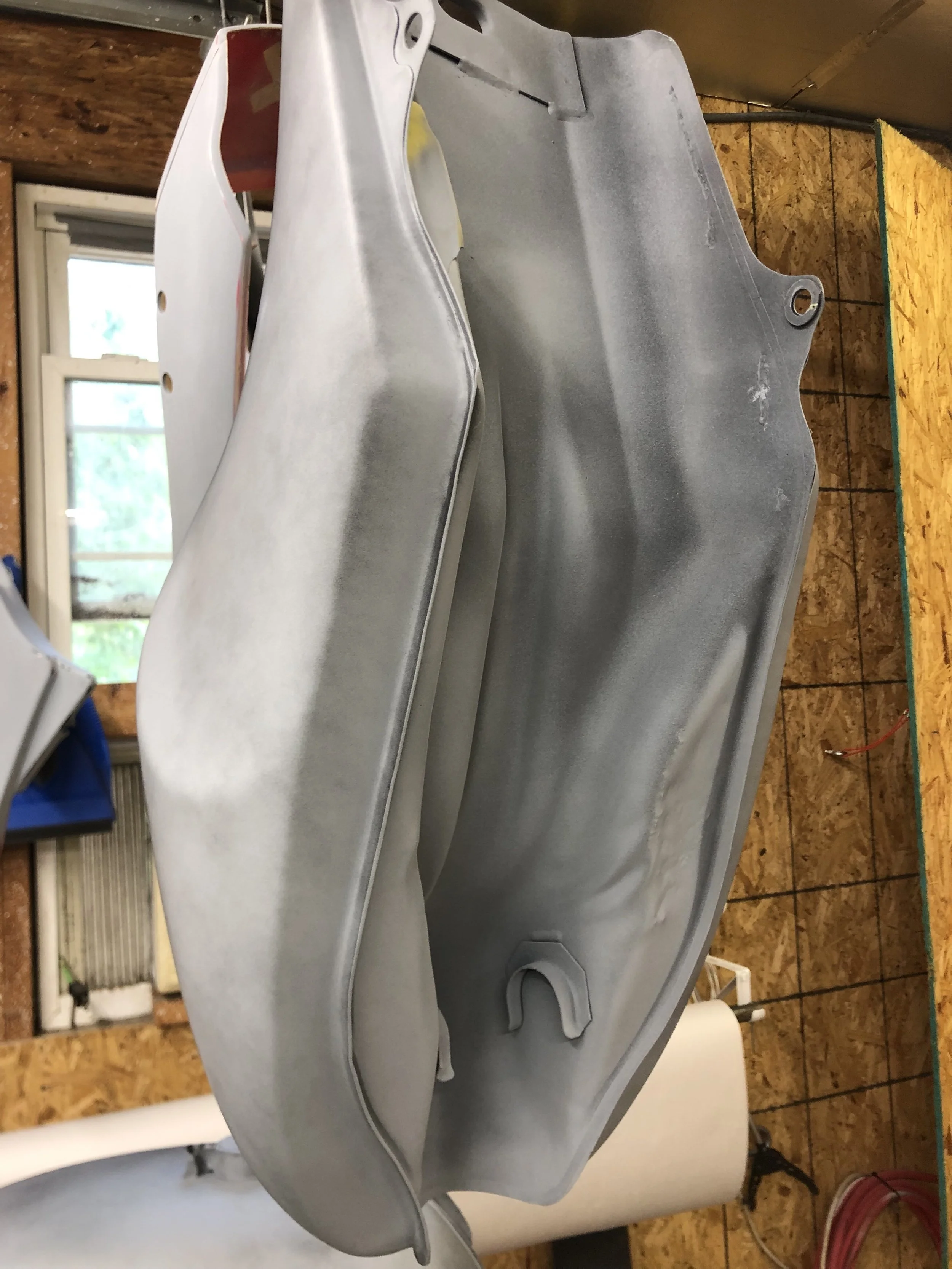

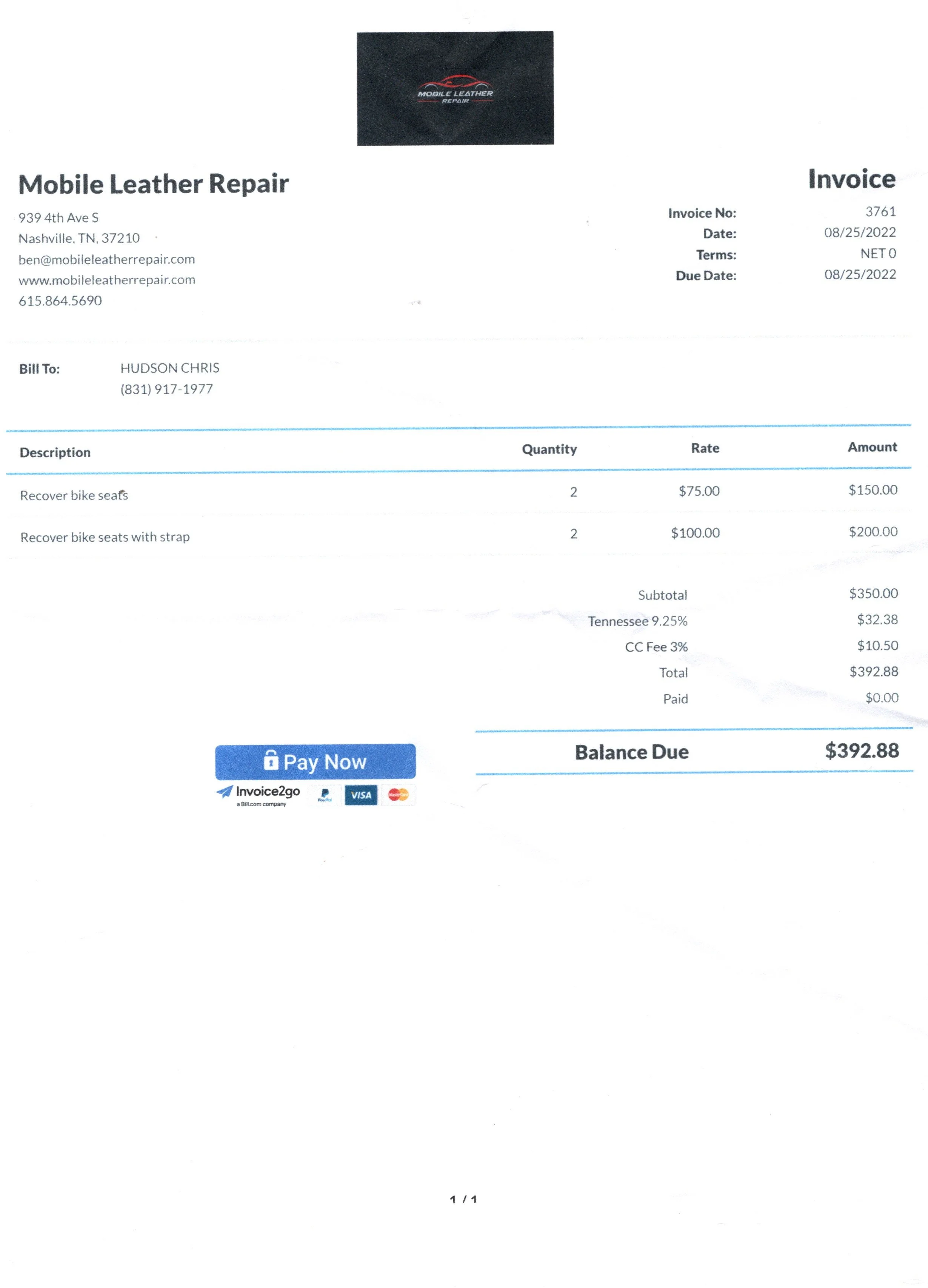

Bodywork

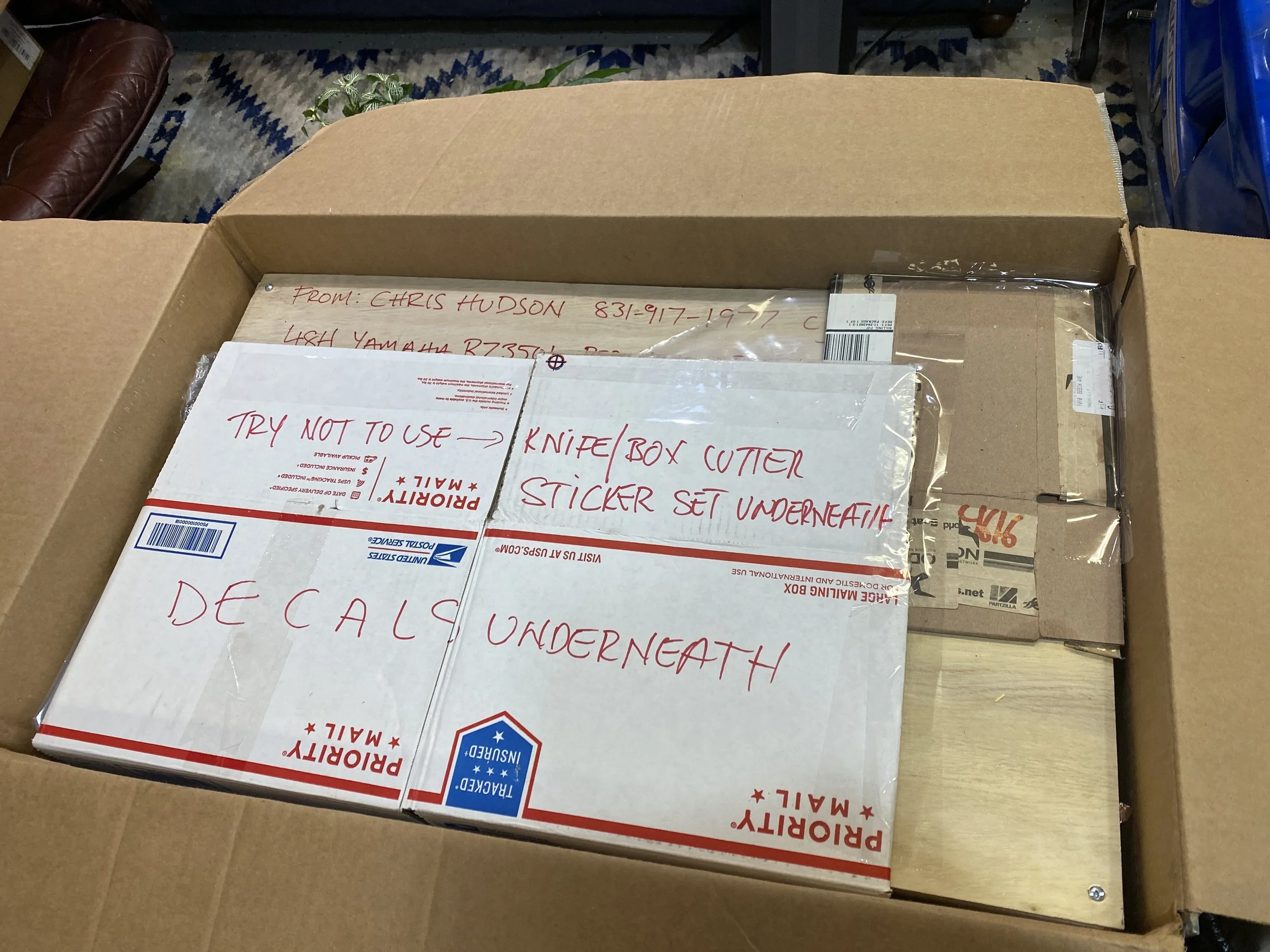

10/27/21 Deposit Sent 06/29/2022 Received and unboxed by BD Cycles 10/13/2022 Received back 106 days for the job and it's incredible $2350 plus shipping.

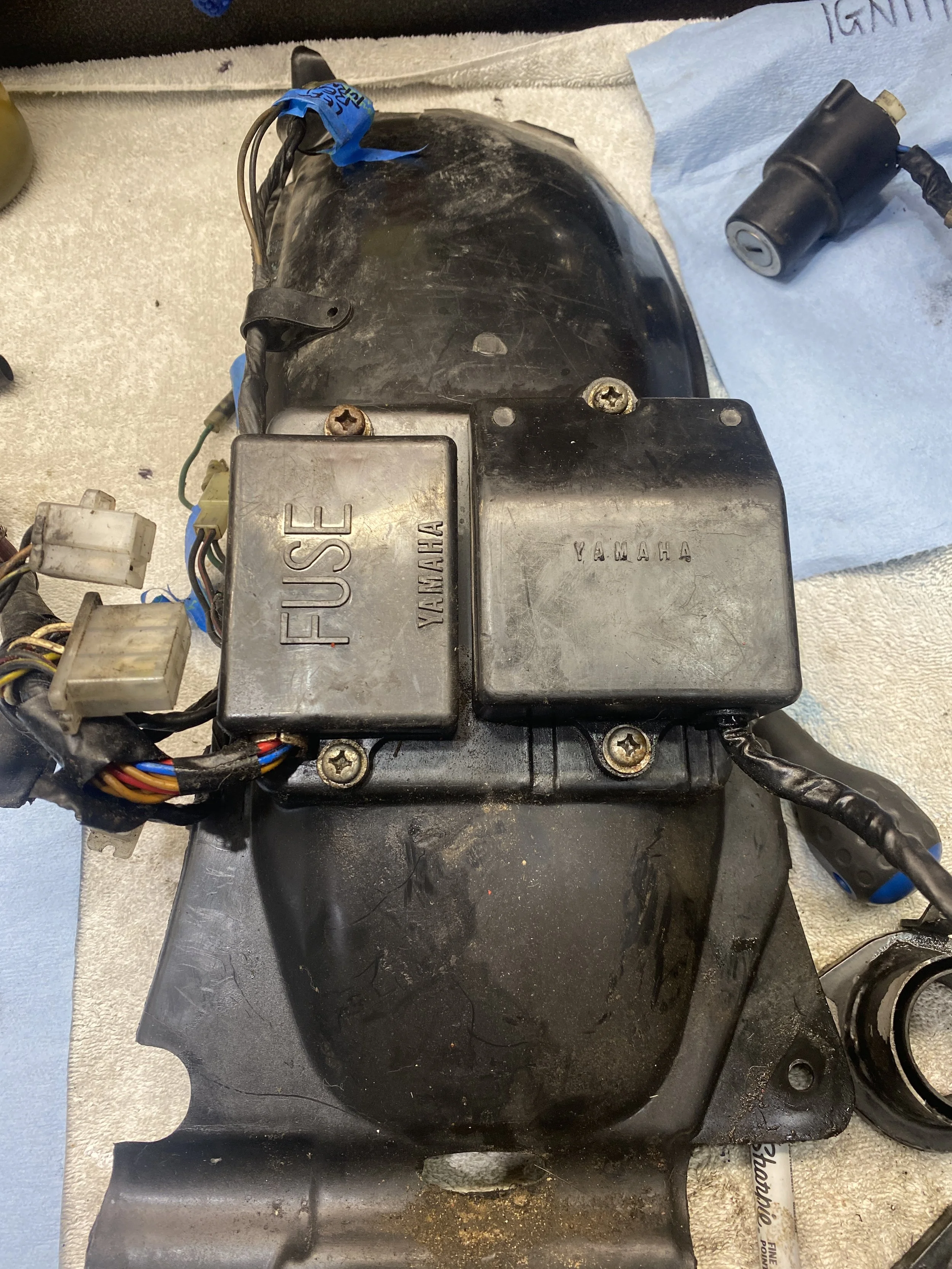

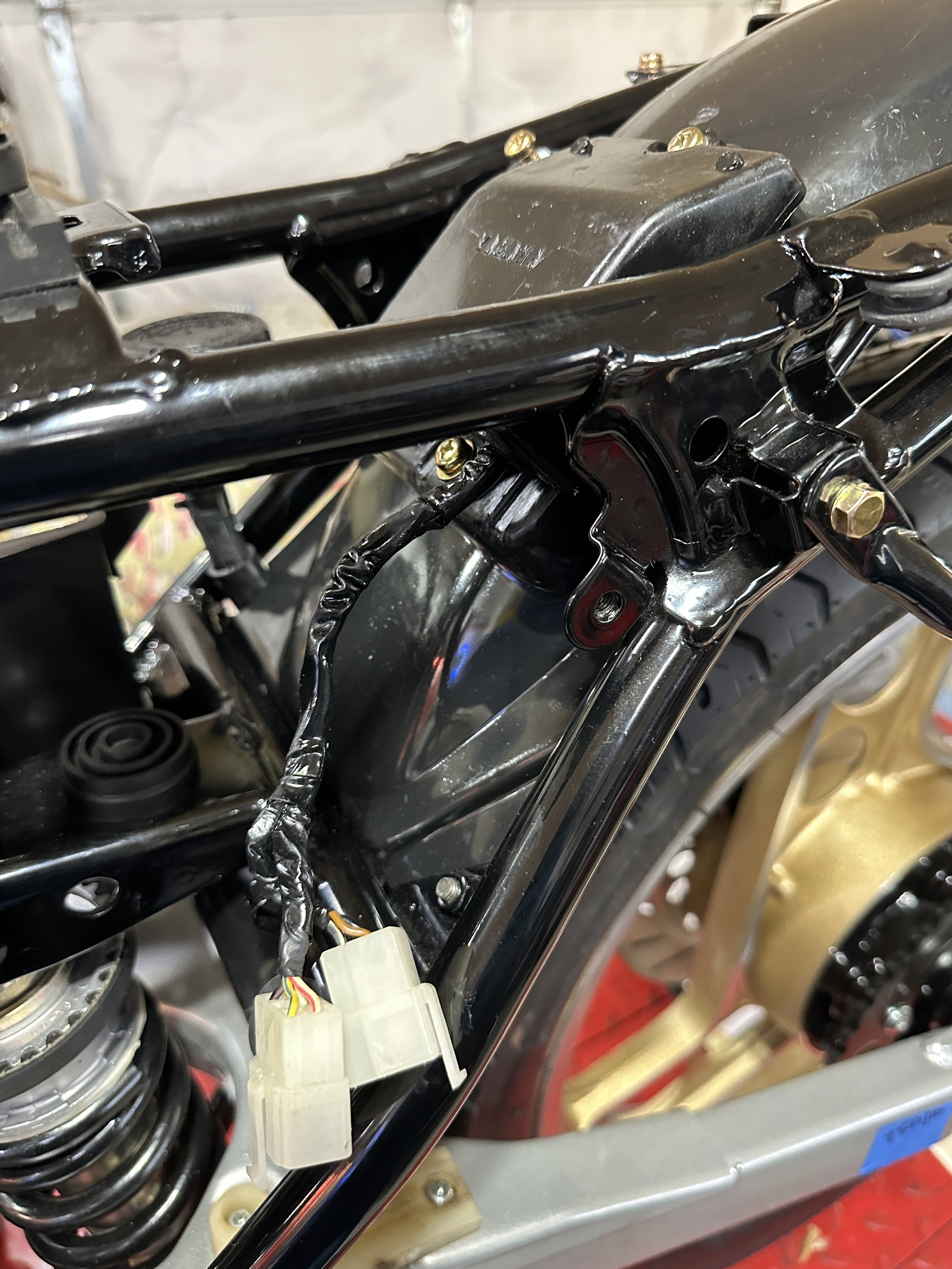

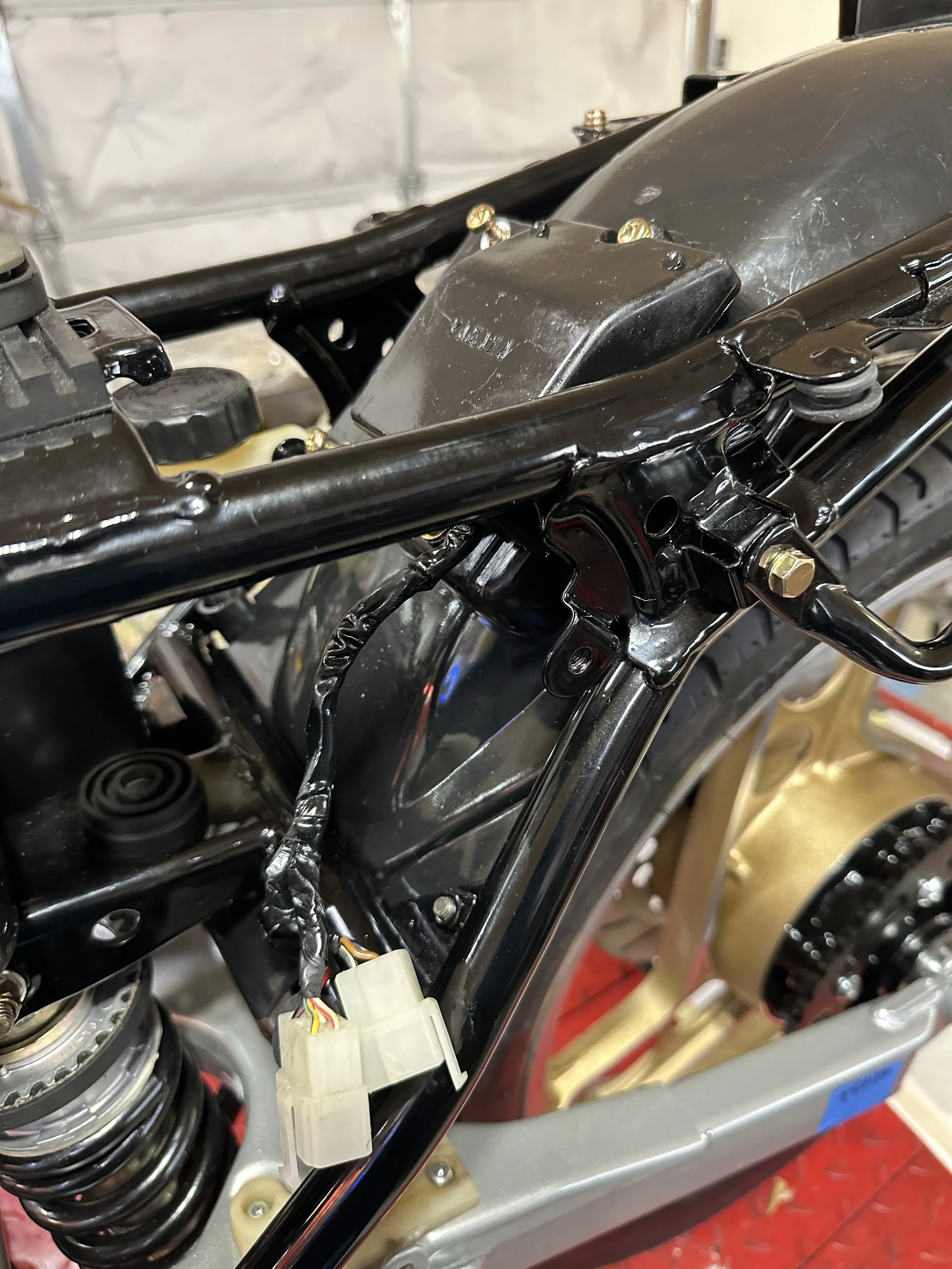

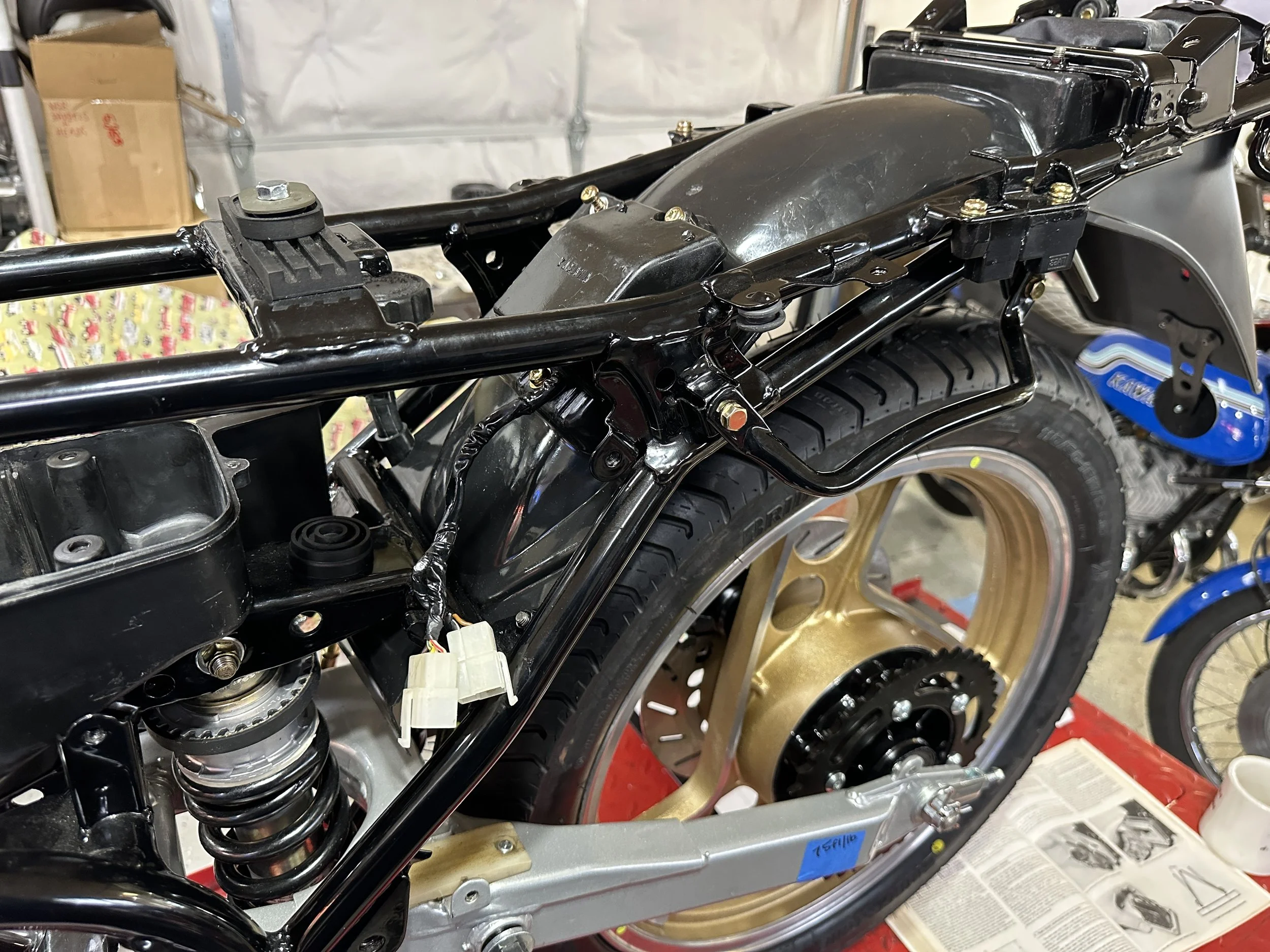

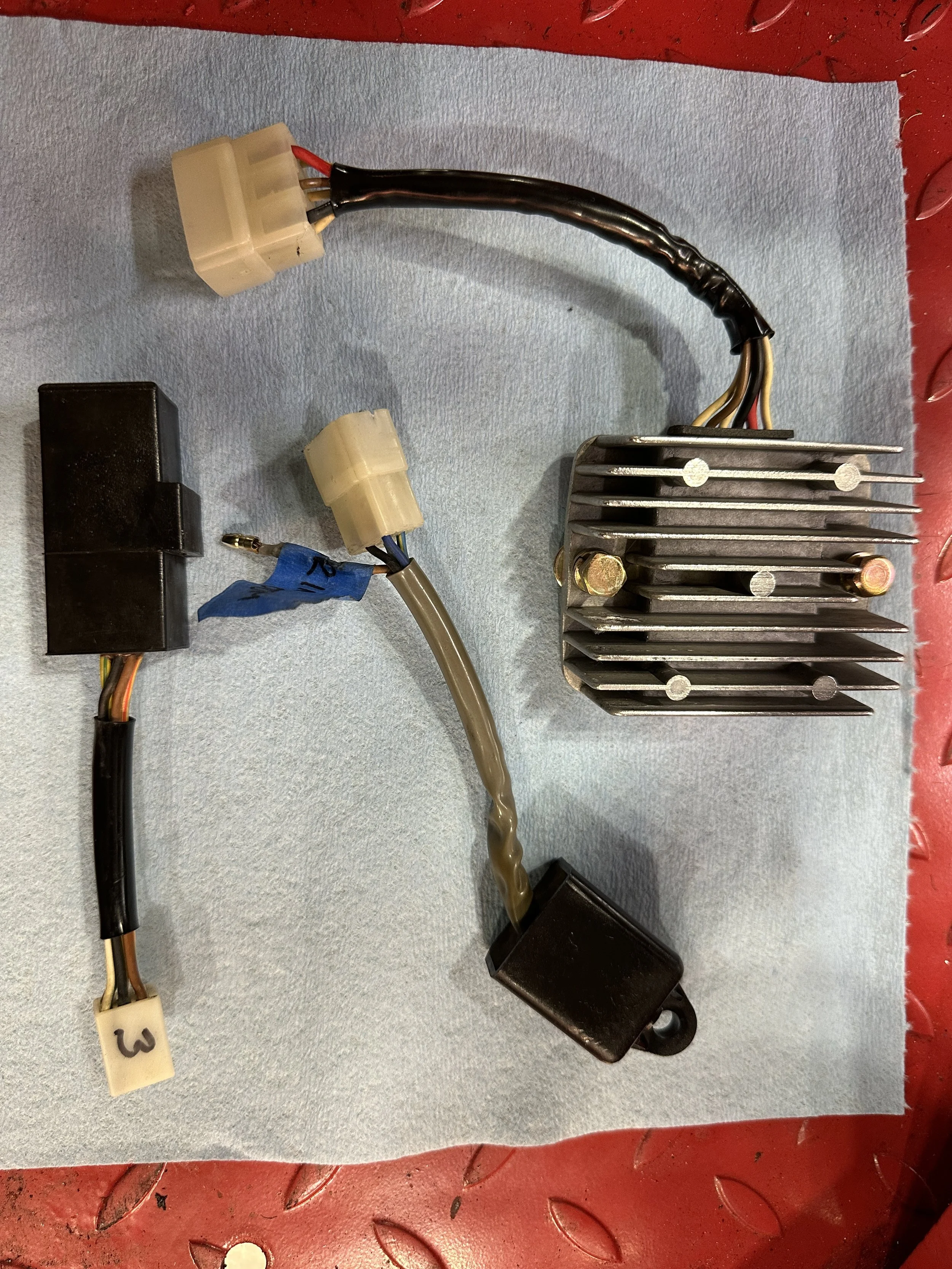

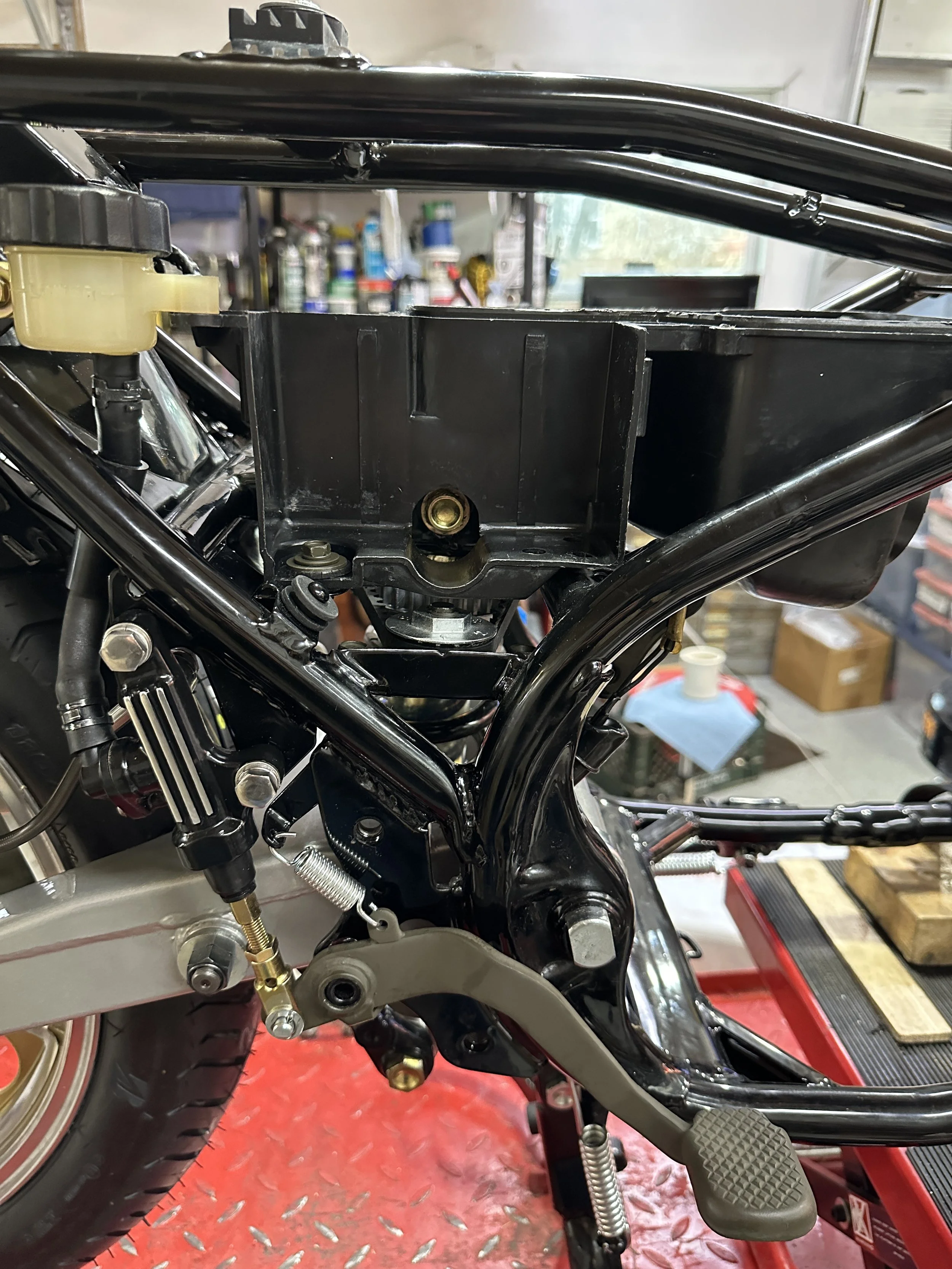

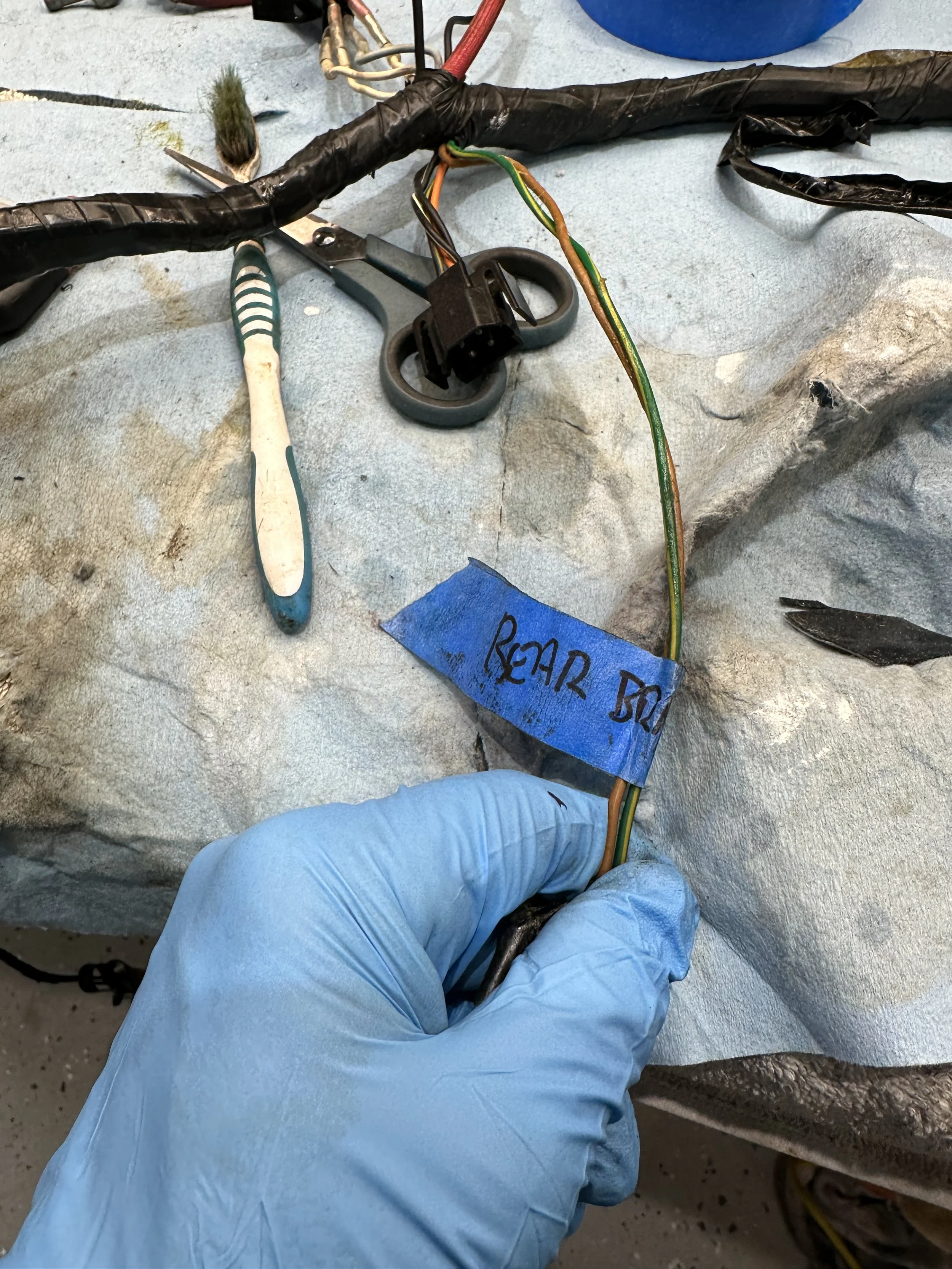

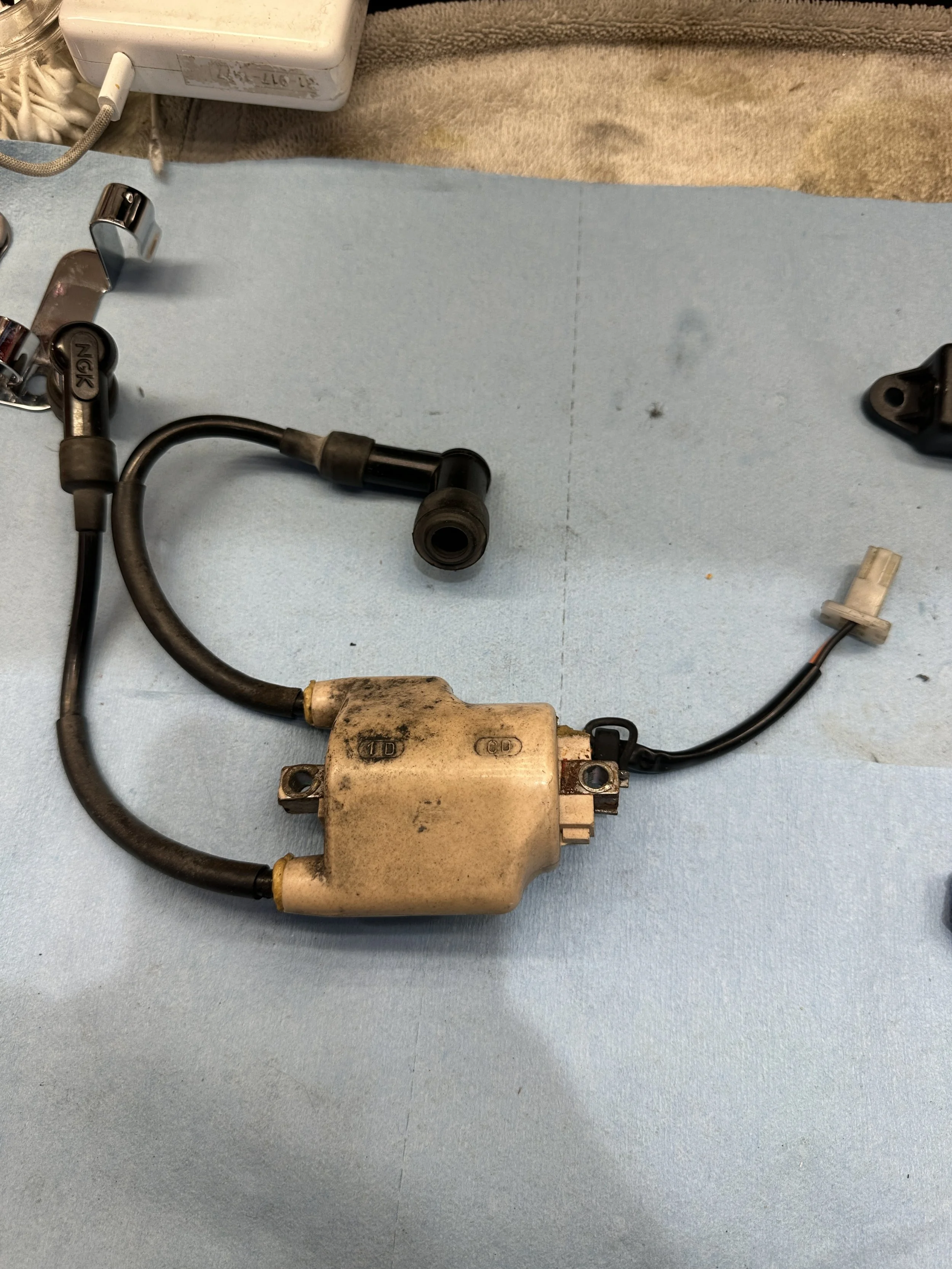

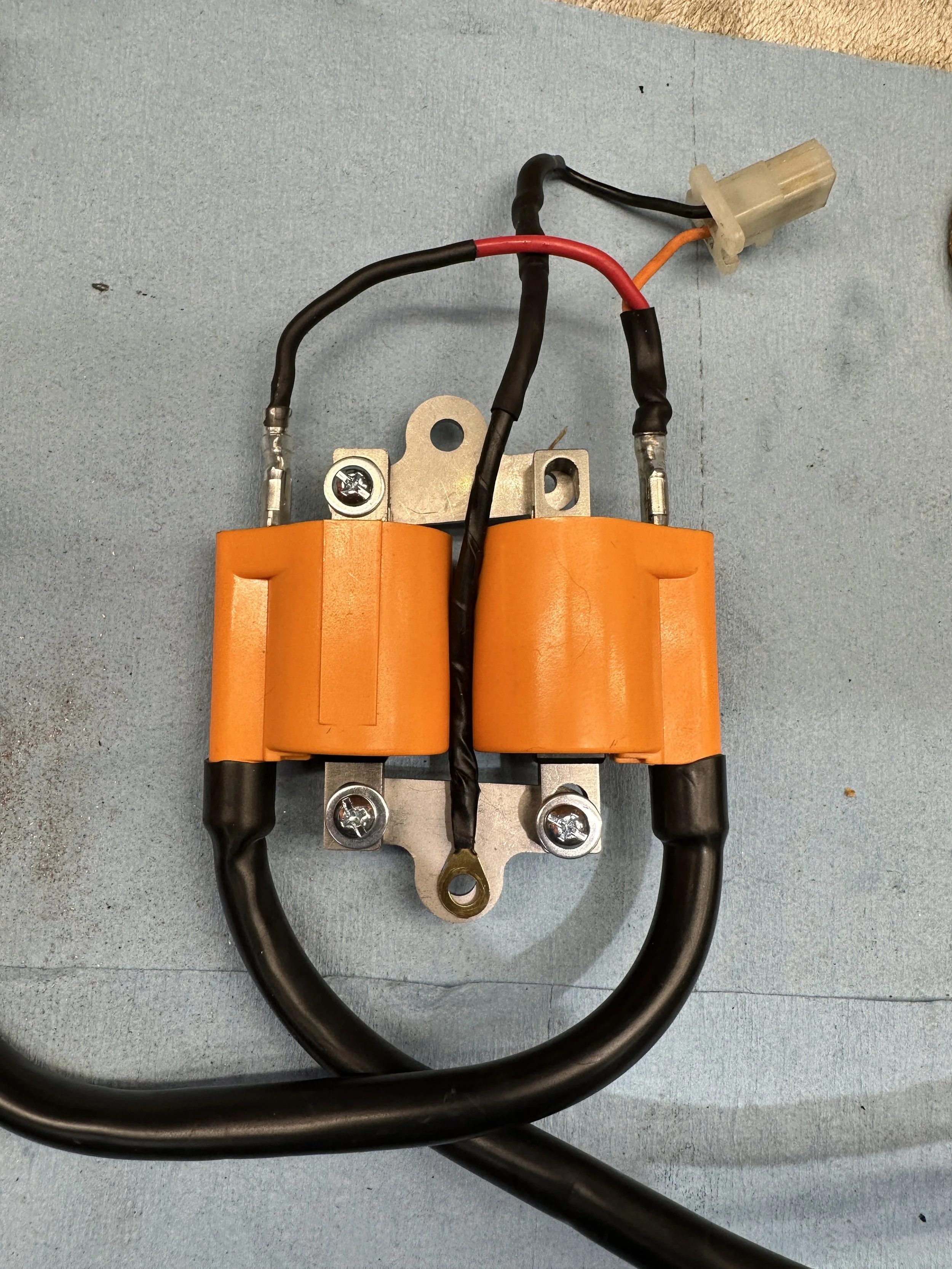

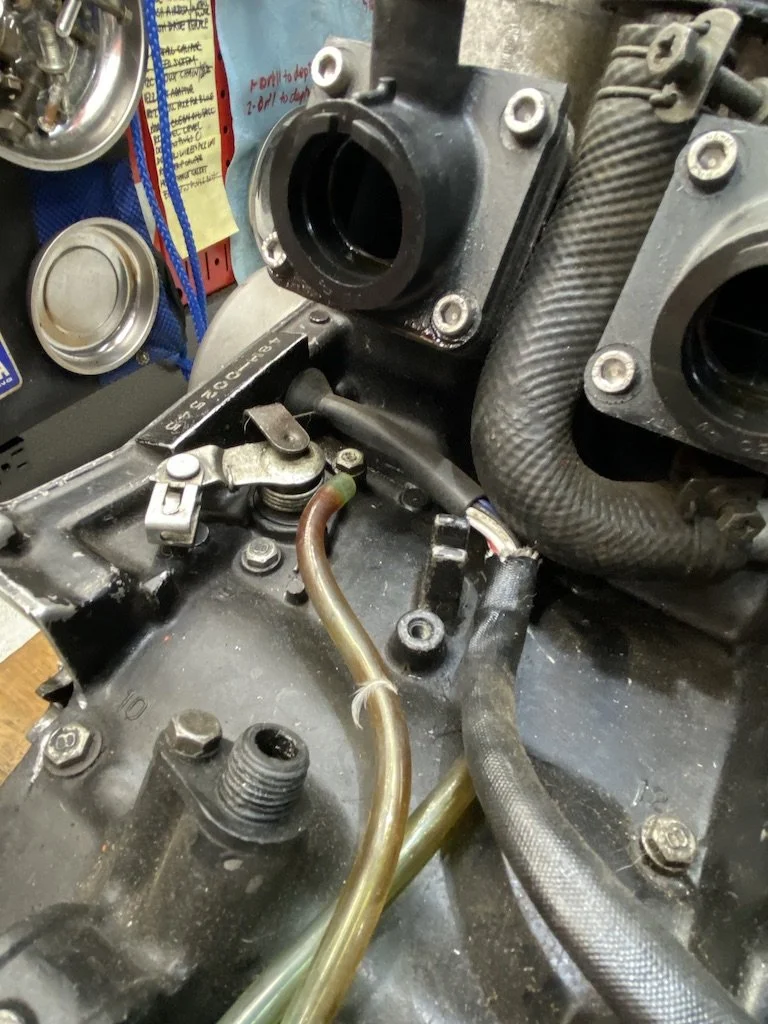

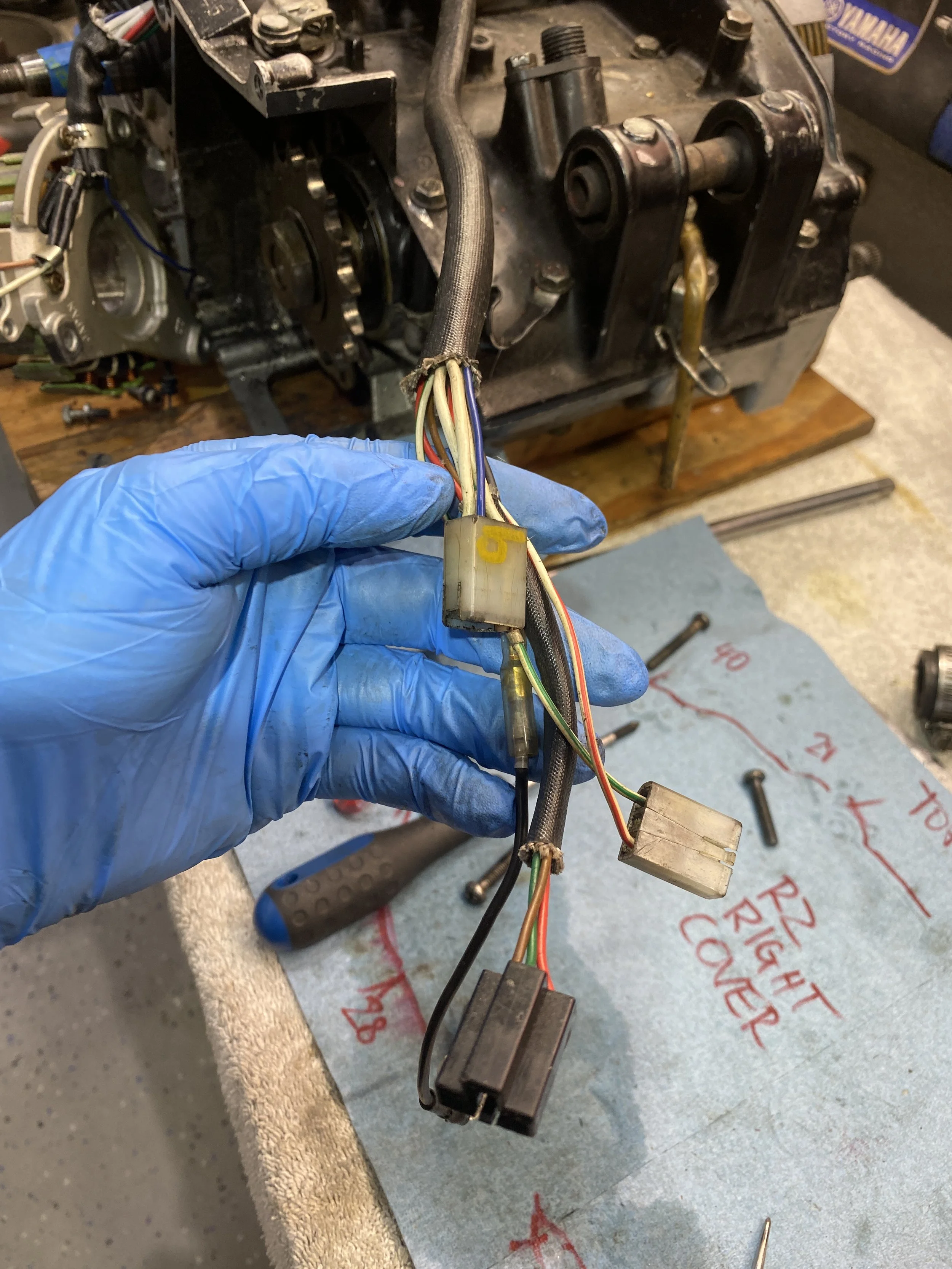

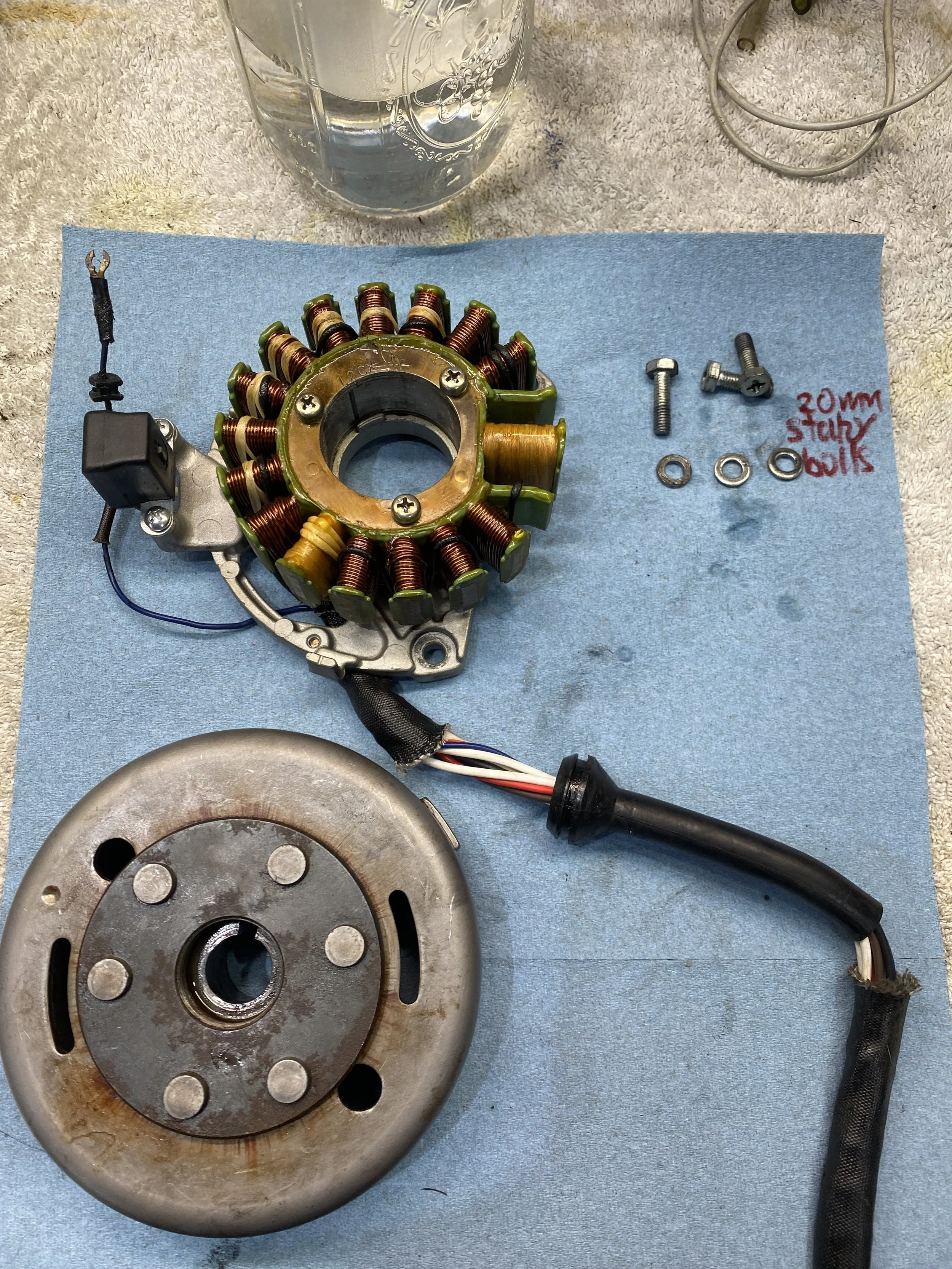

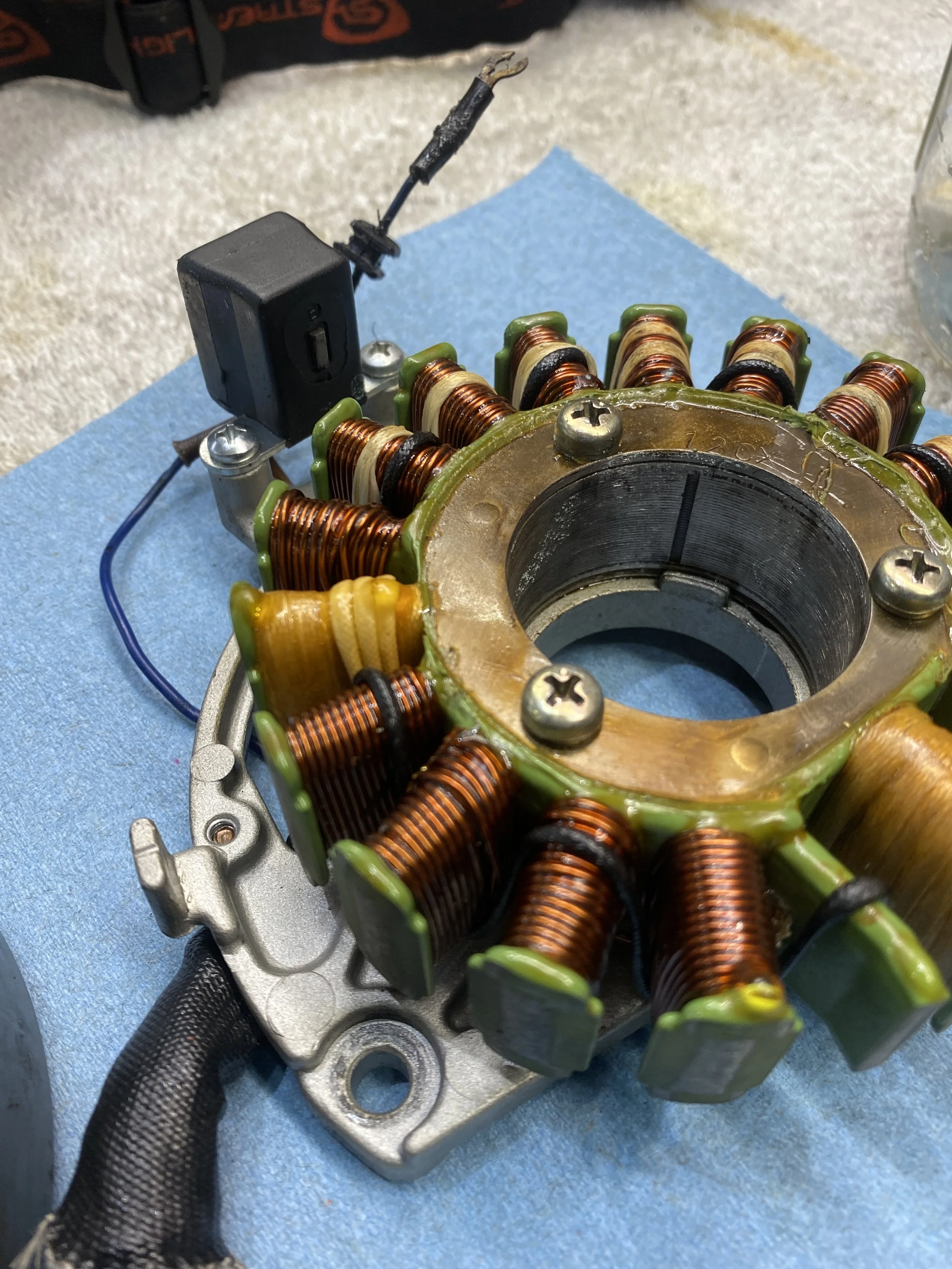

Electronics

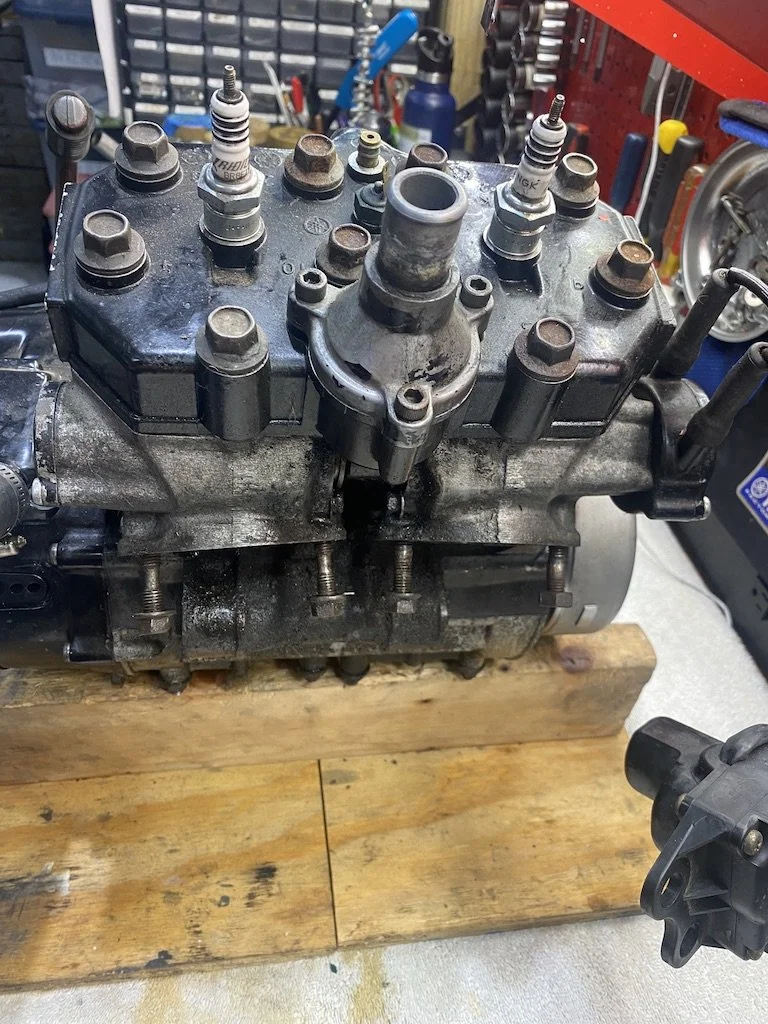

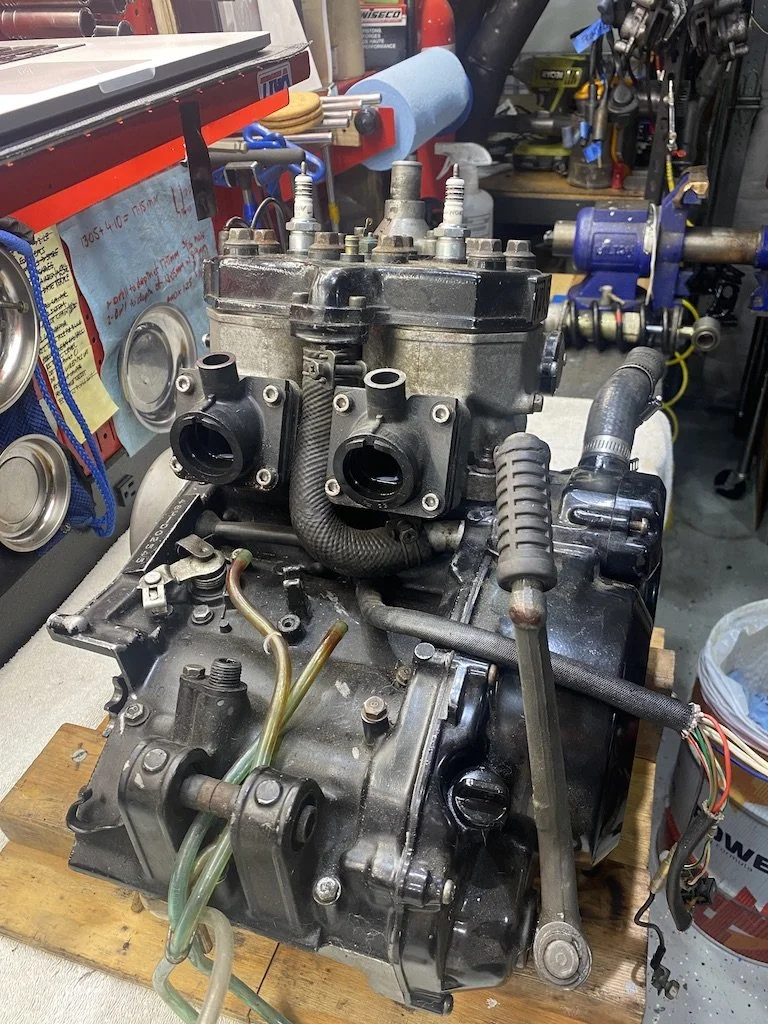

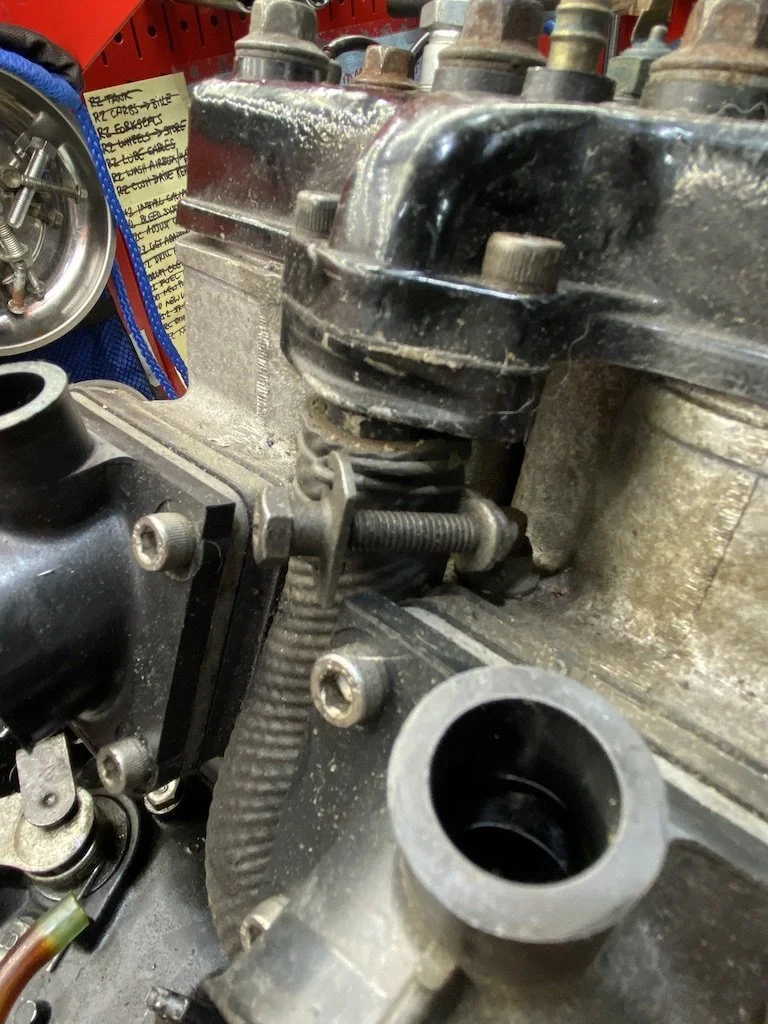

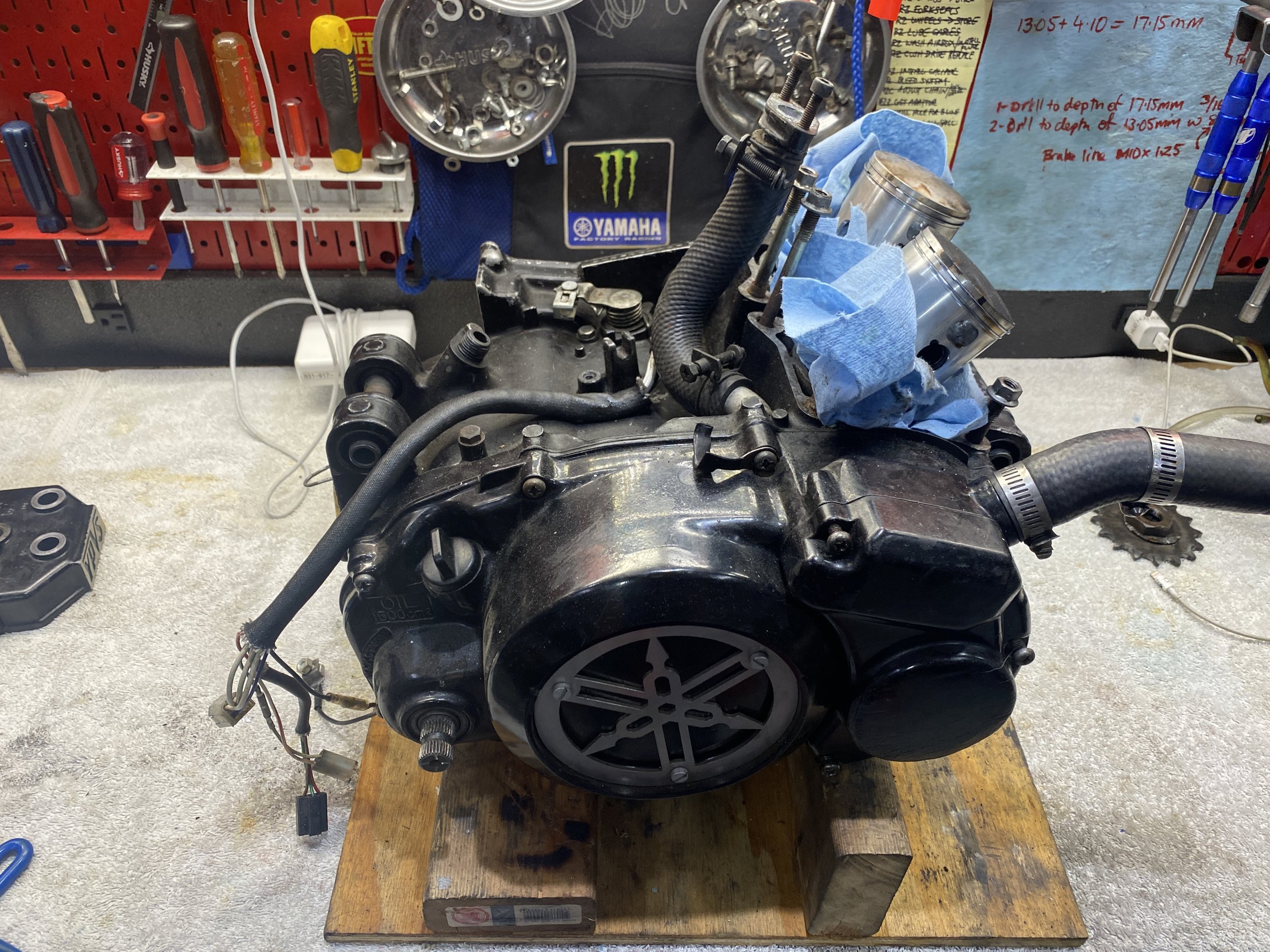

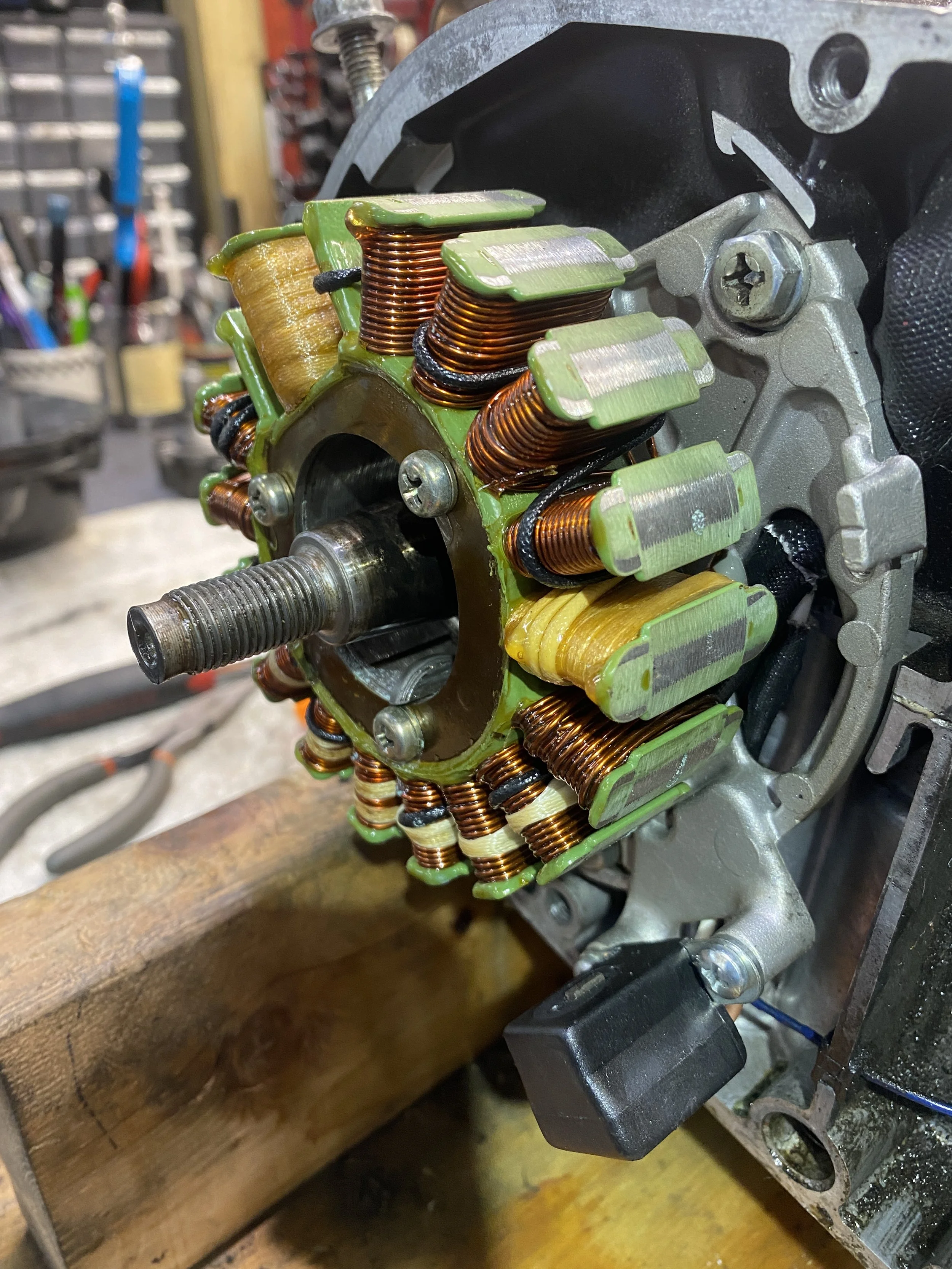

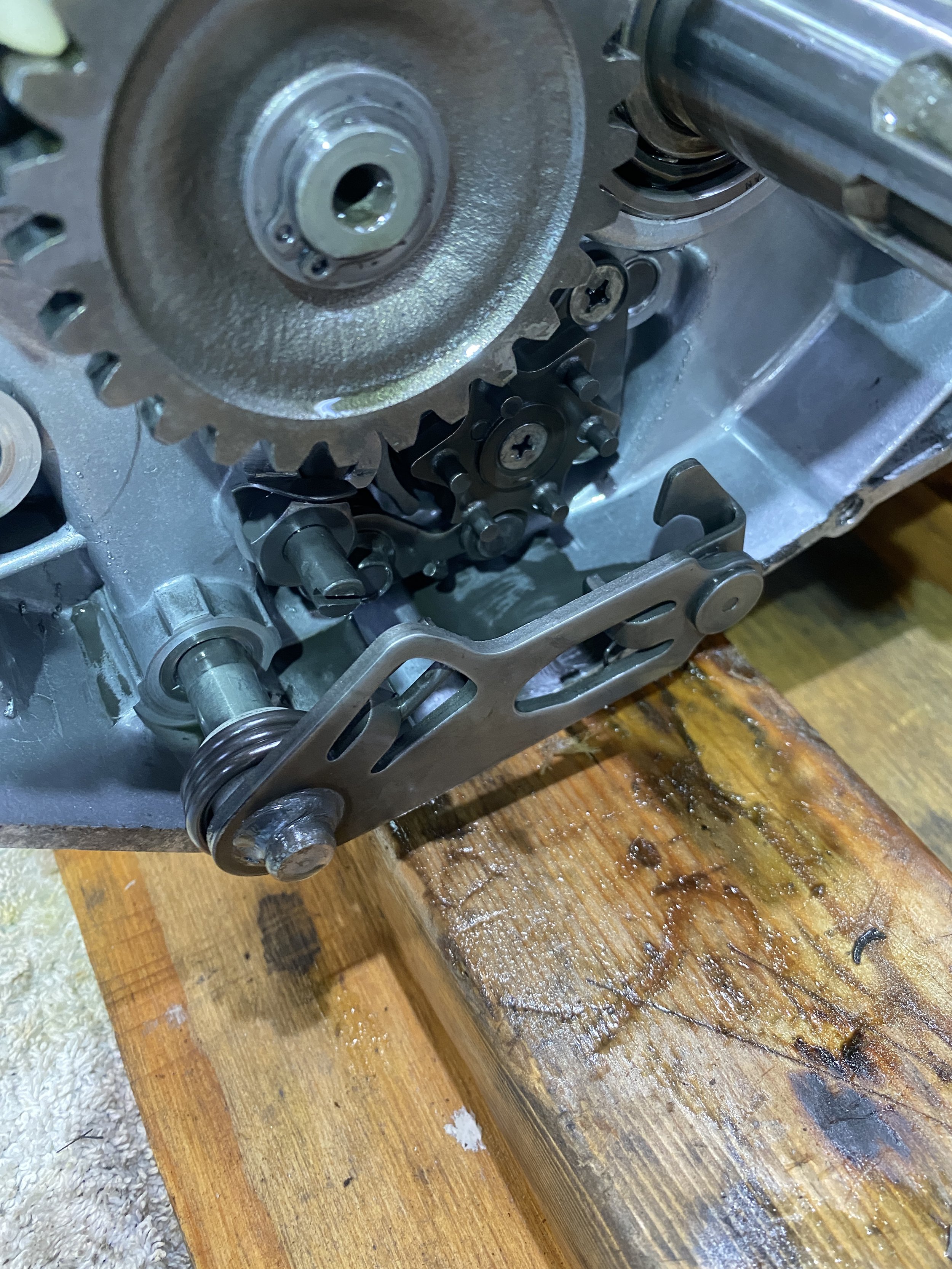

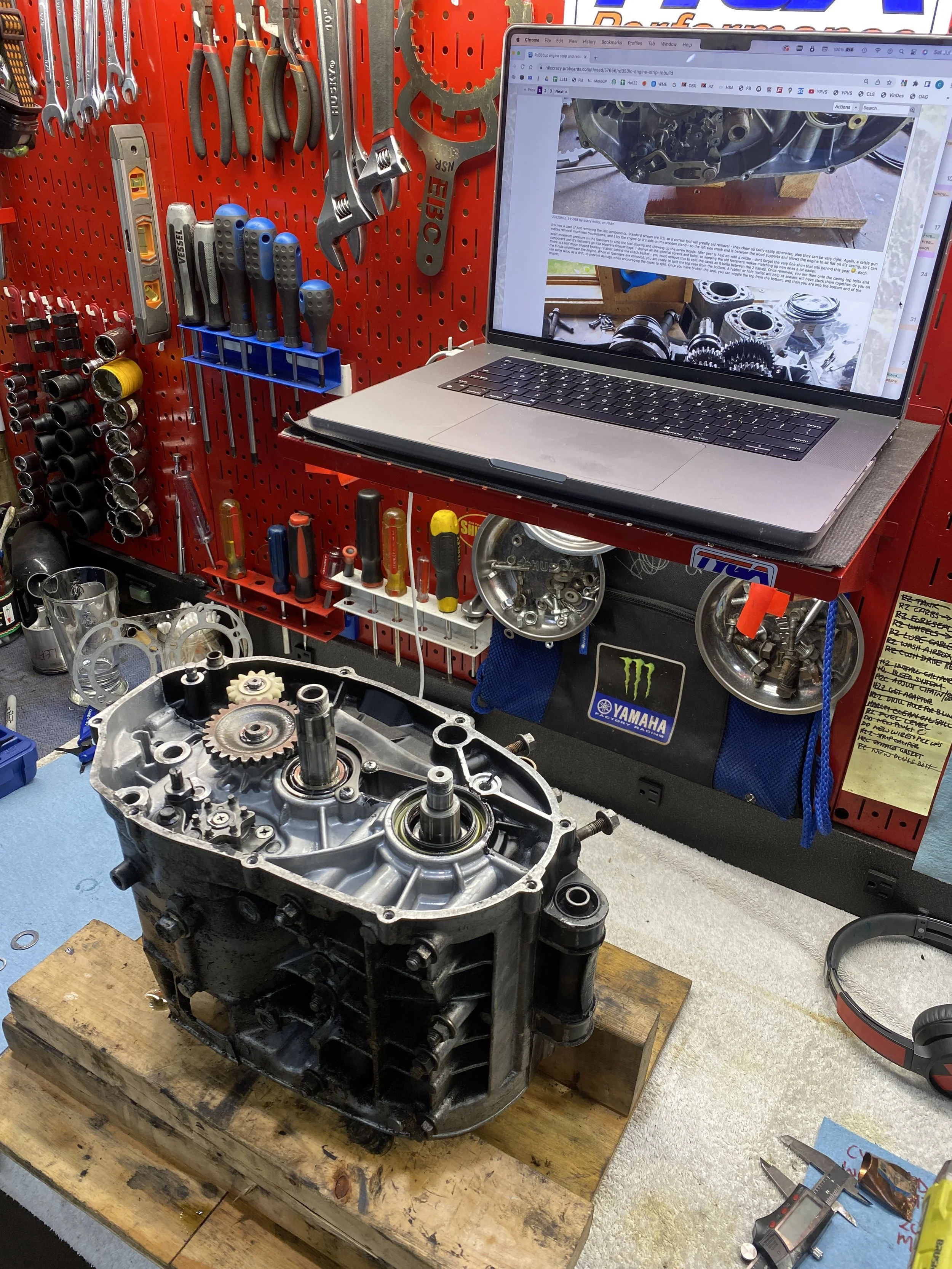

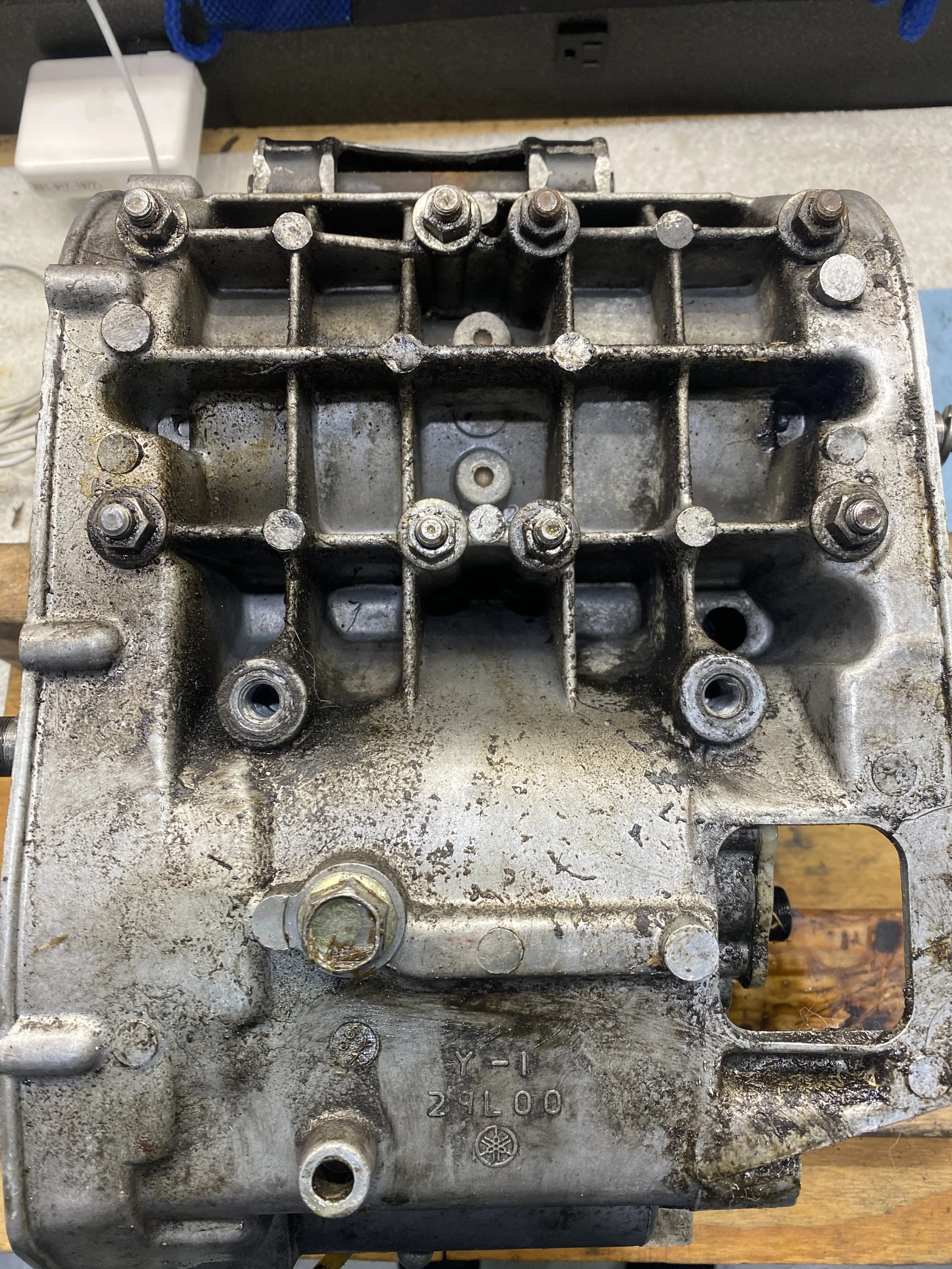

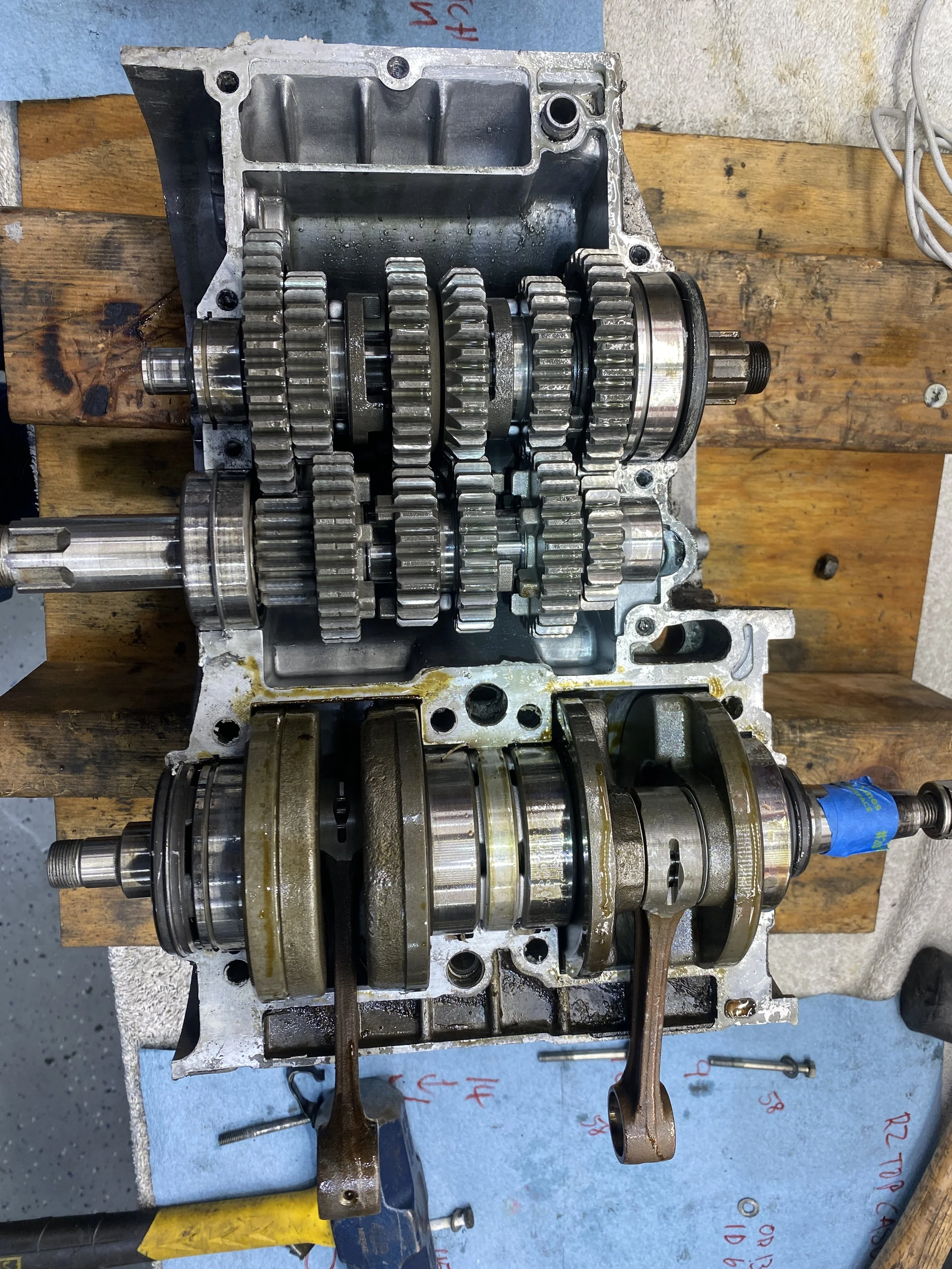

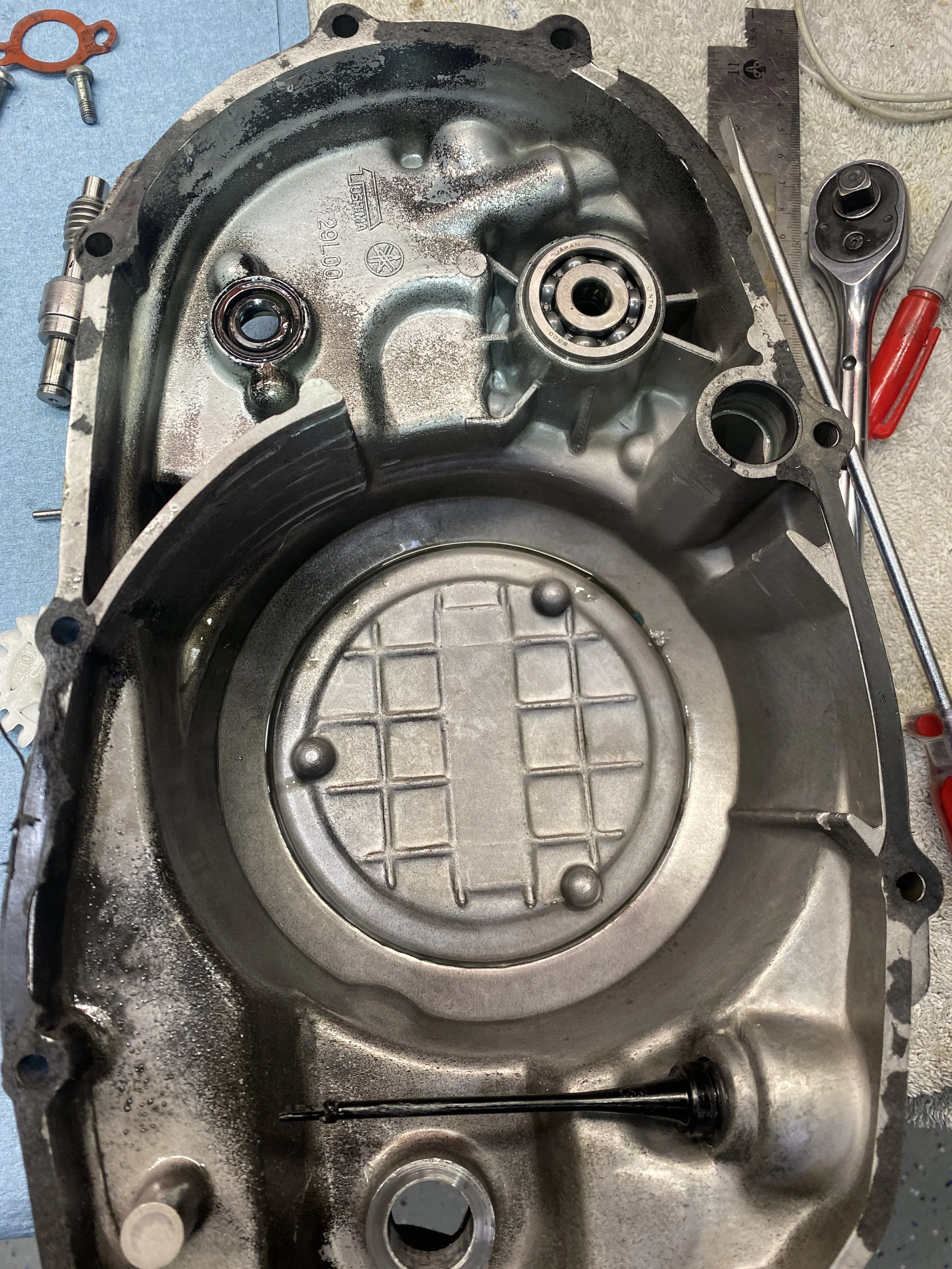

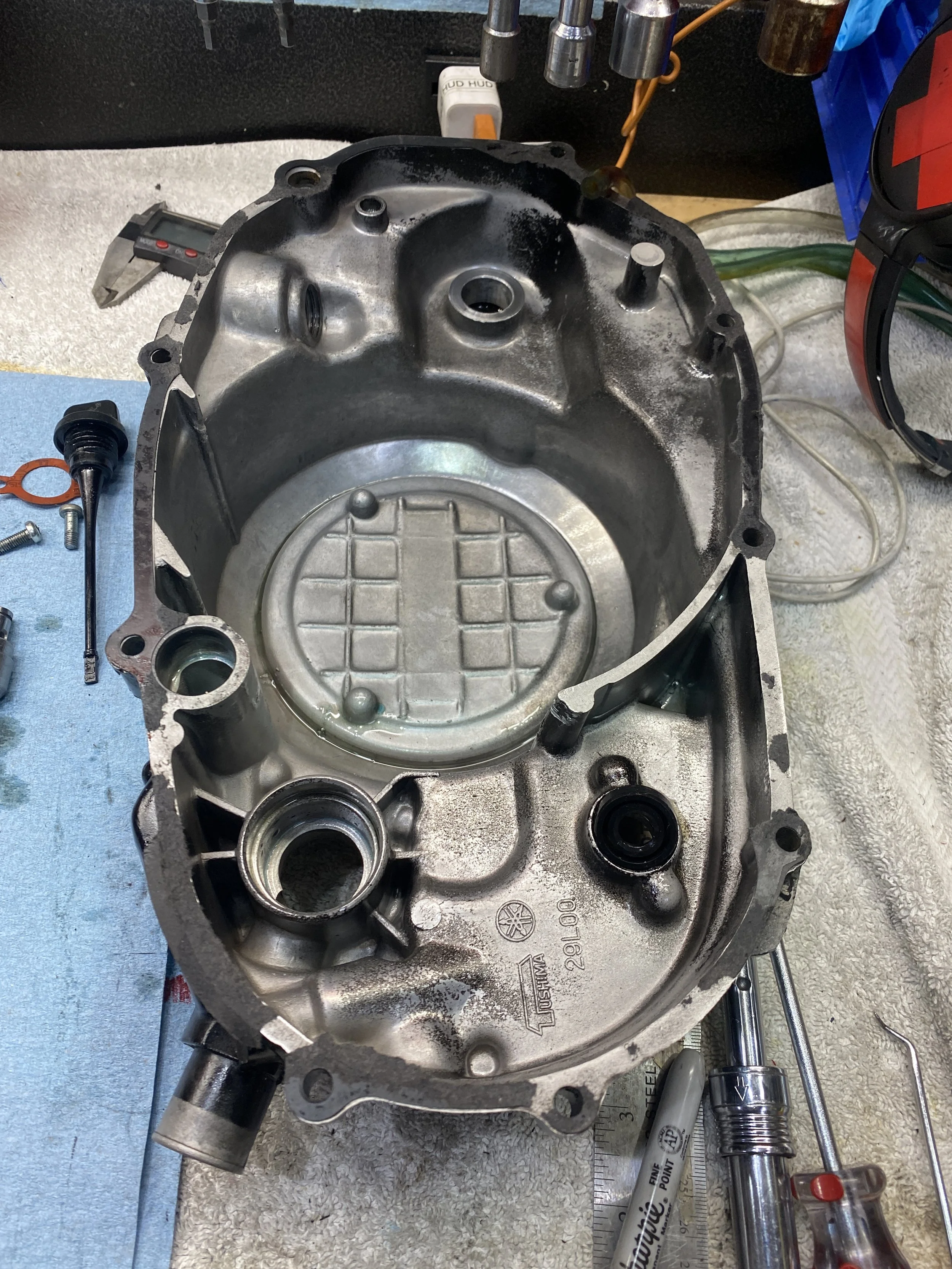

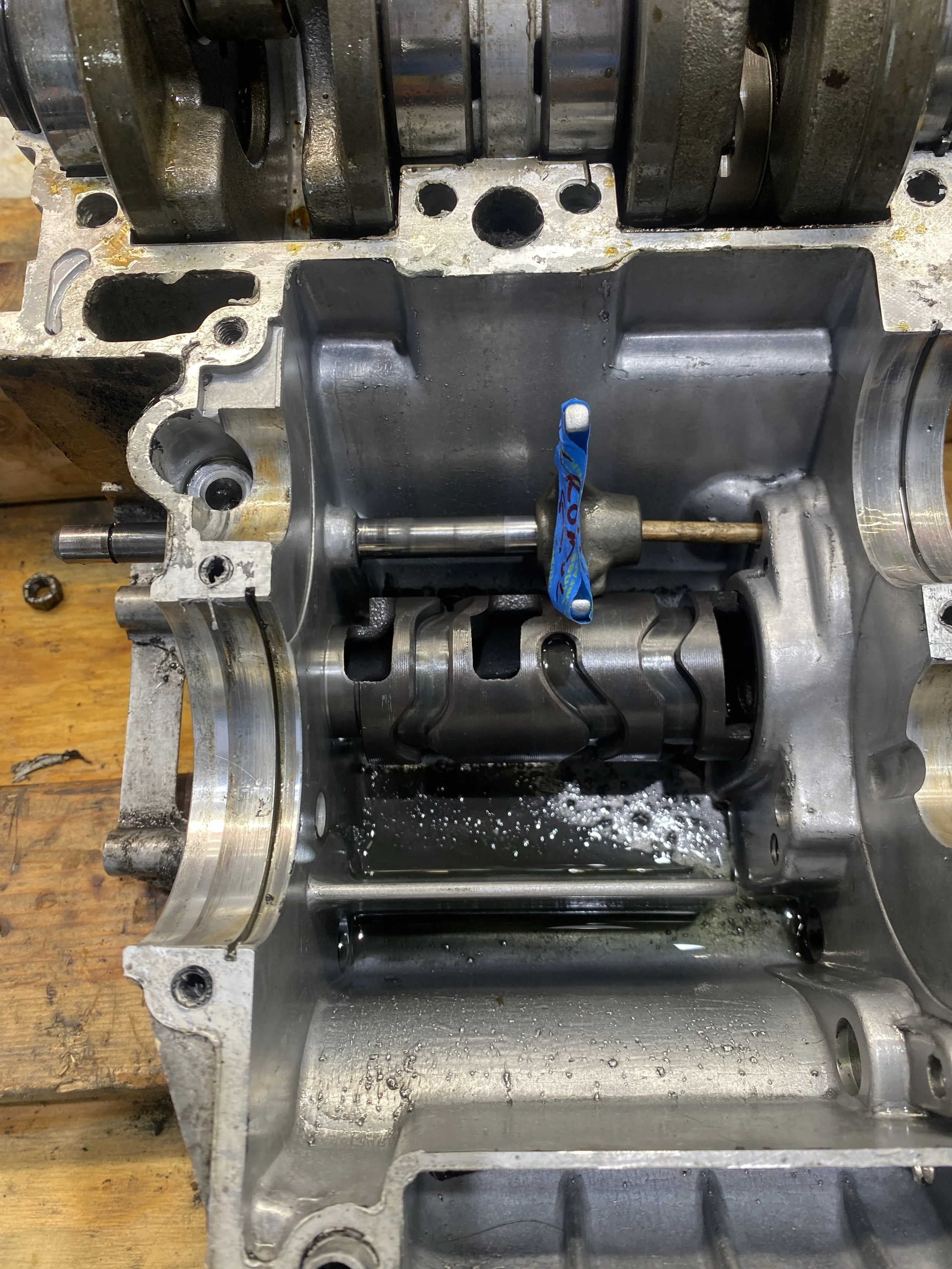

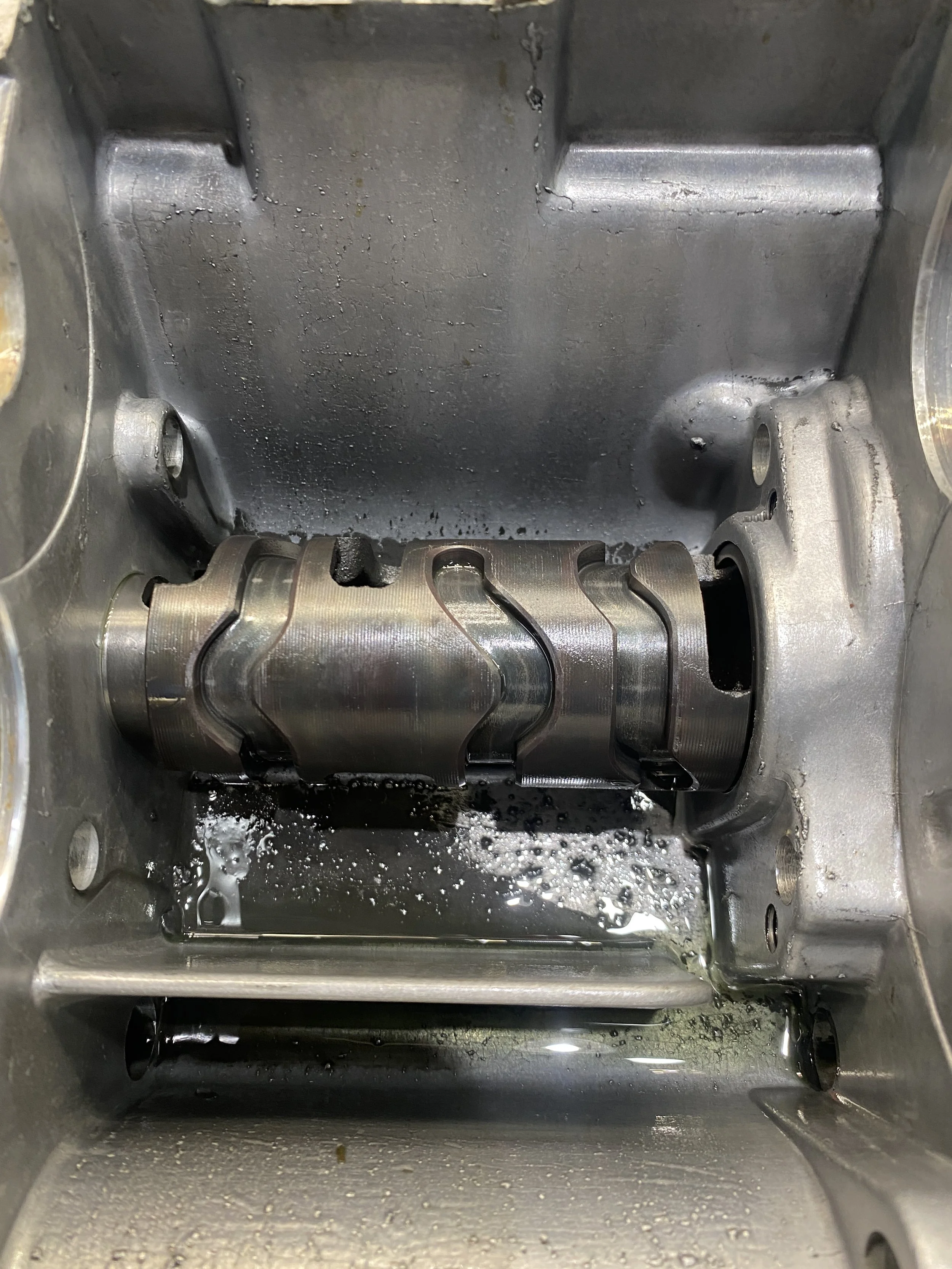

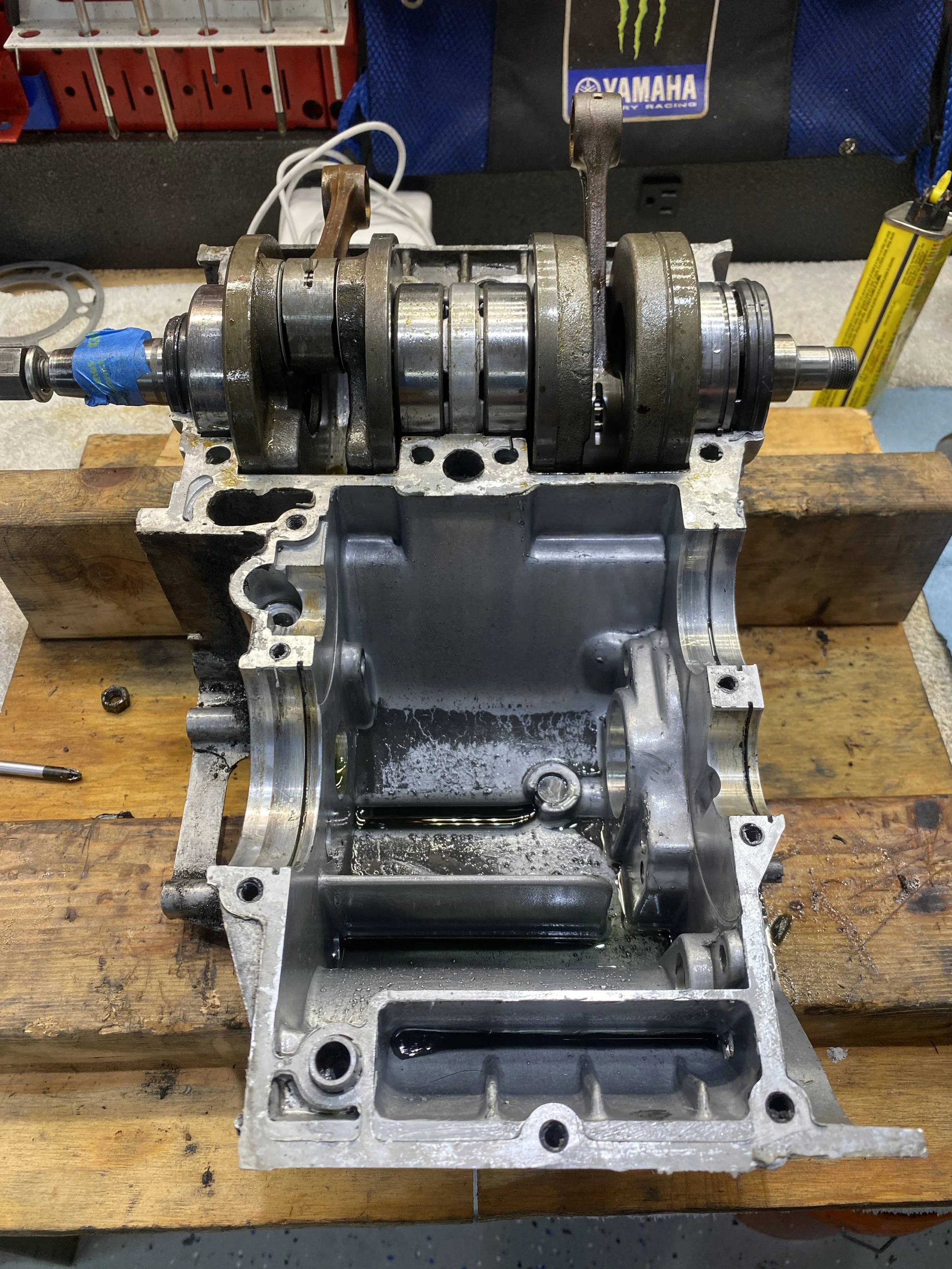

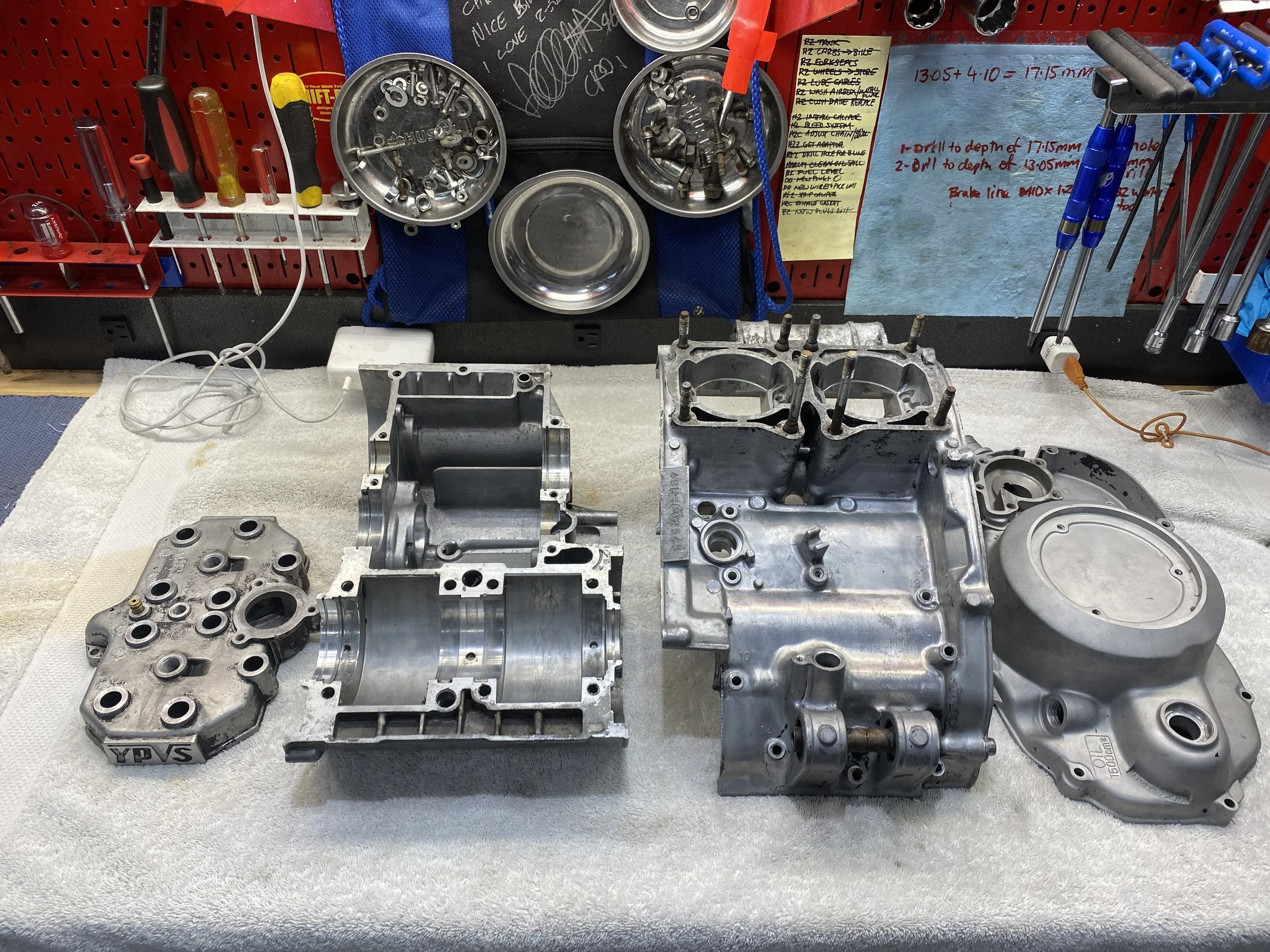

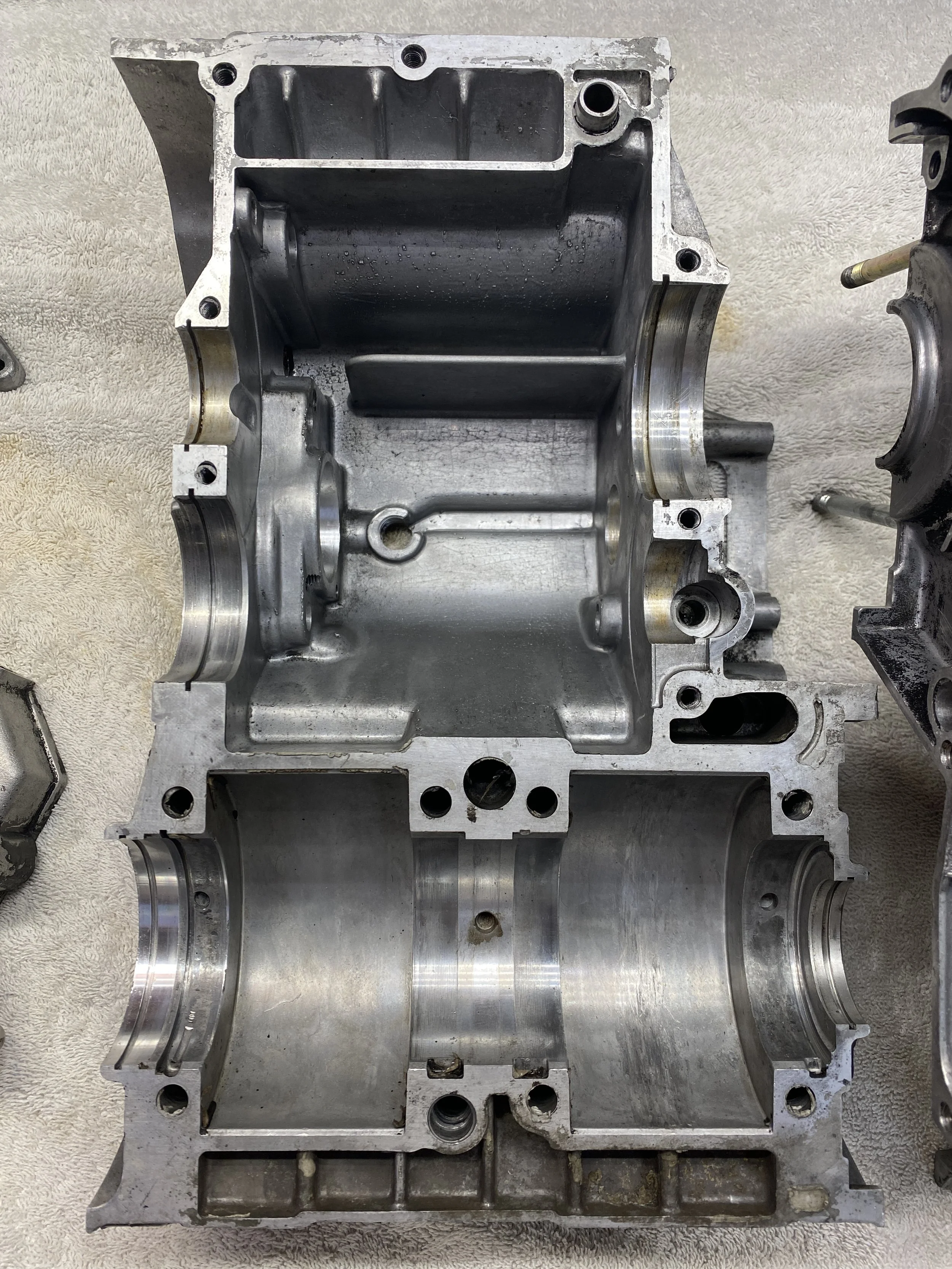

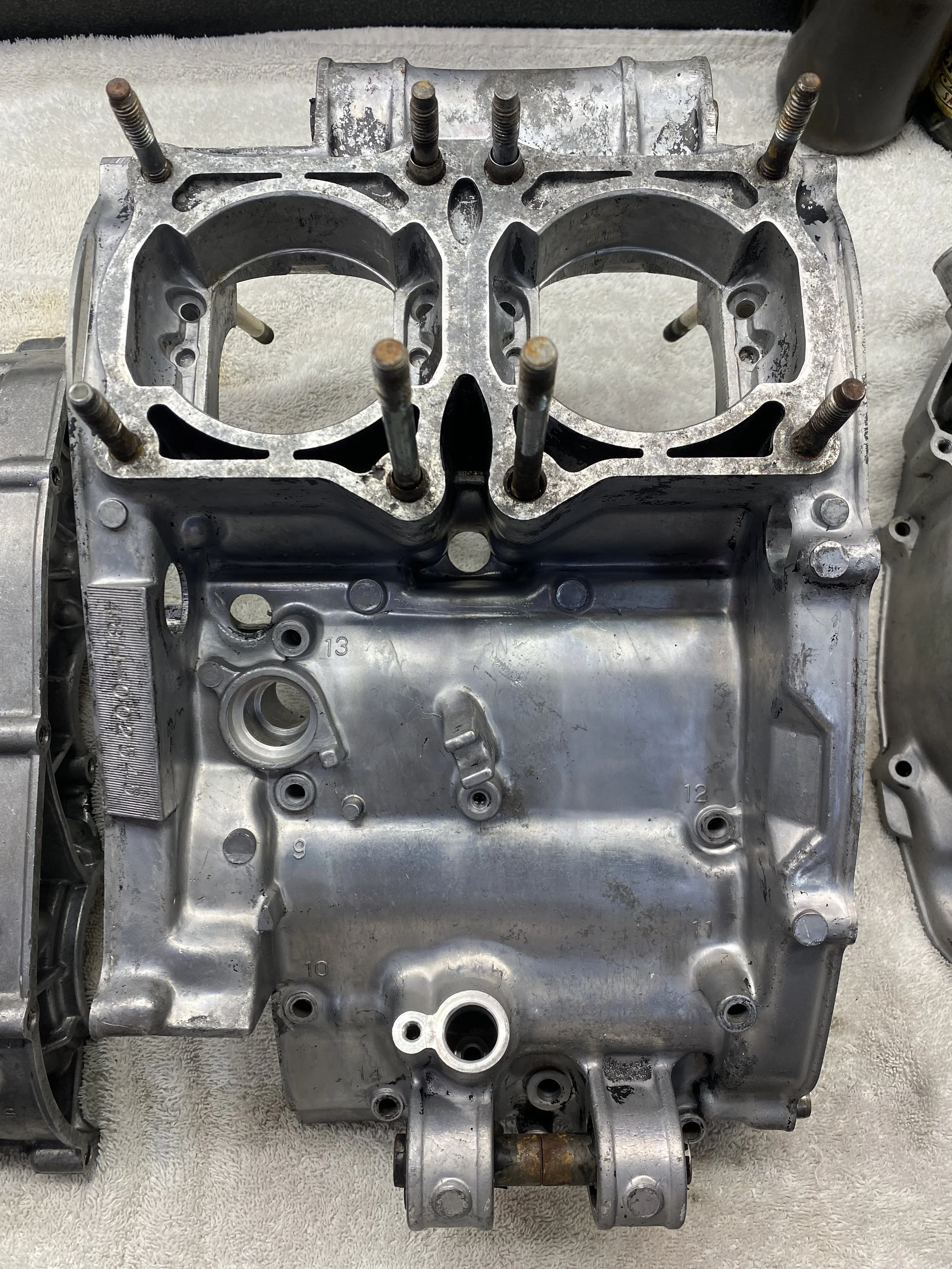

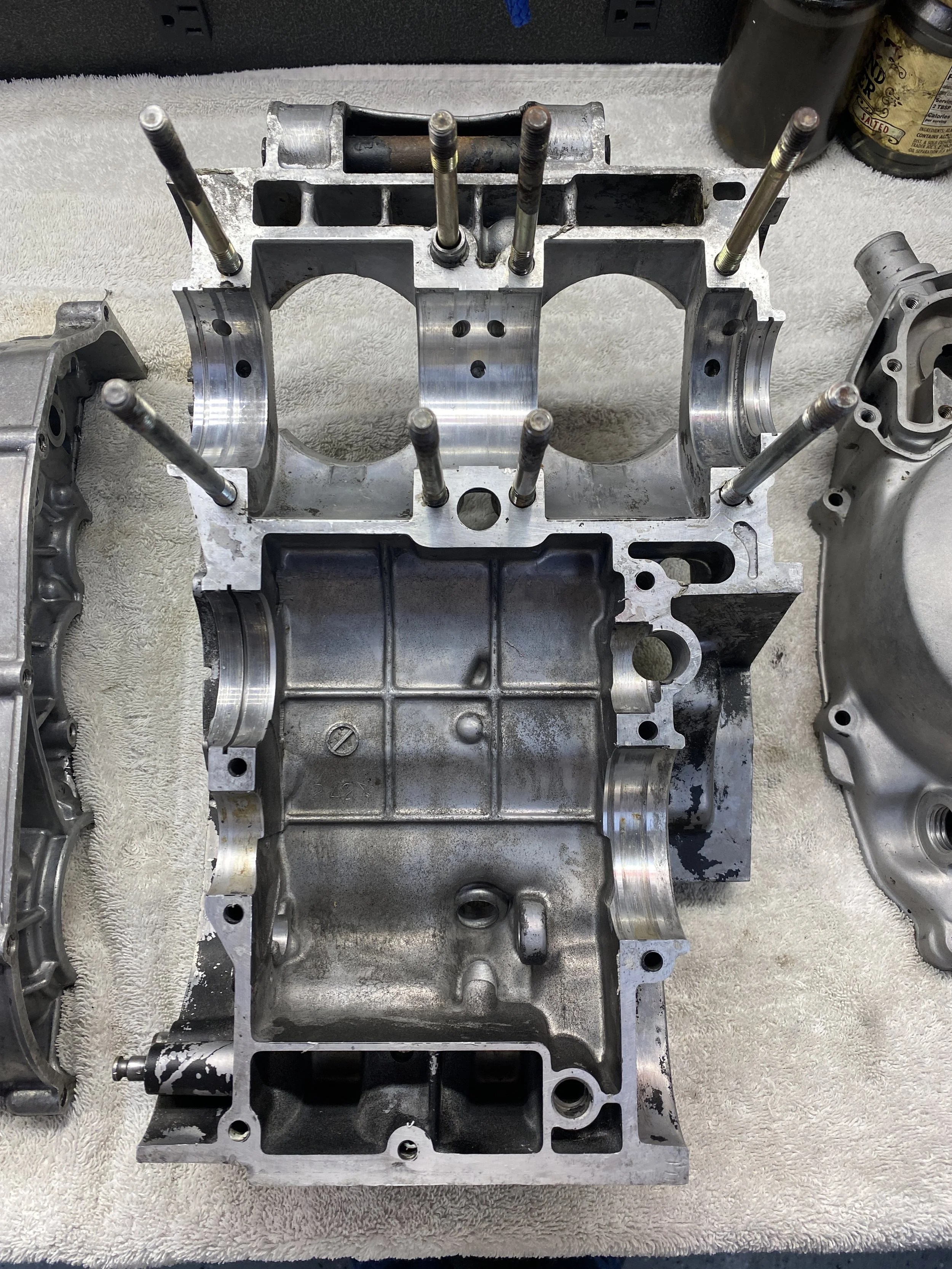

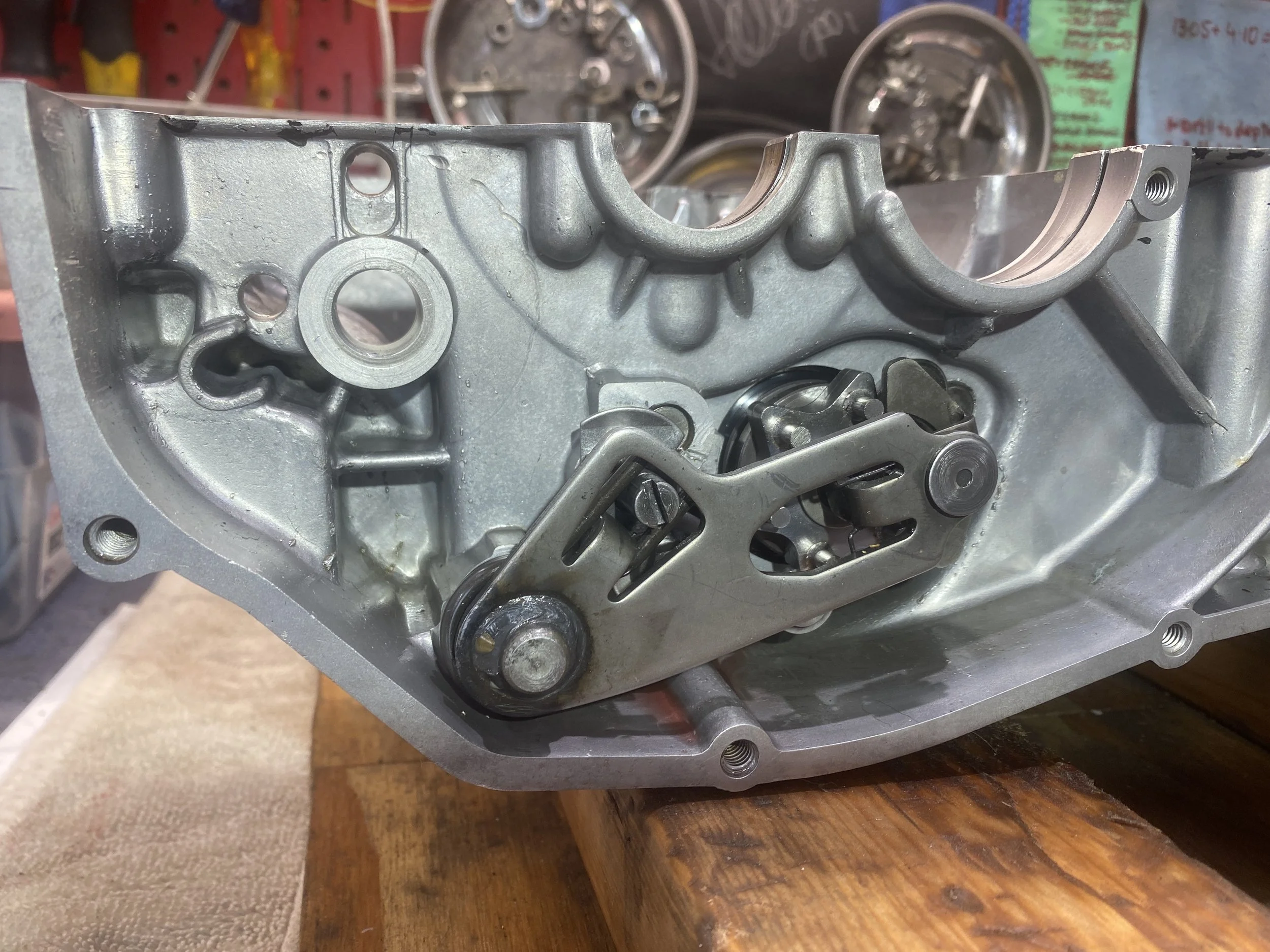

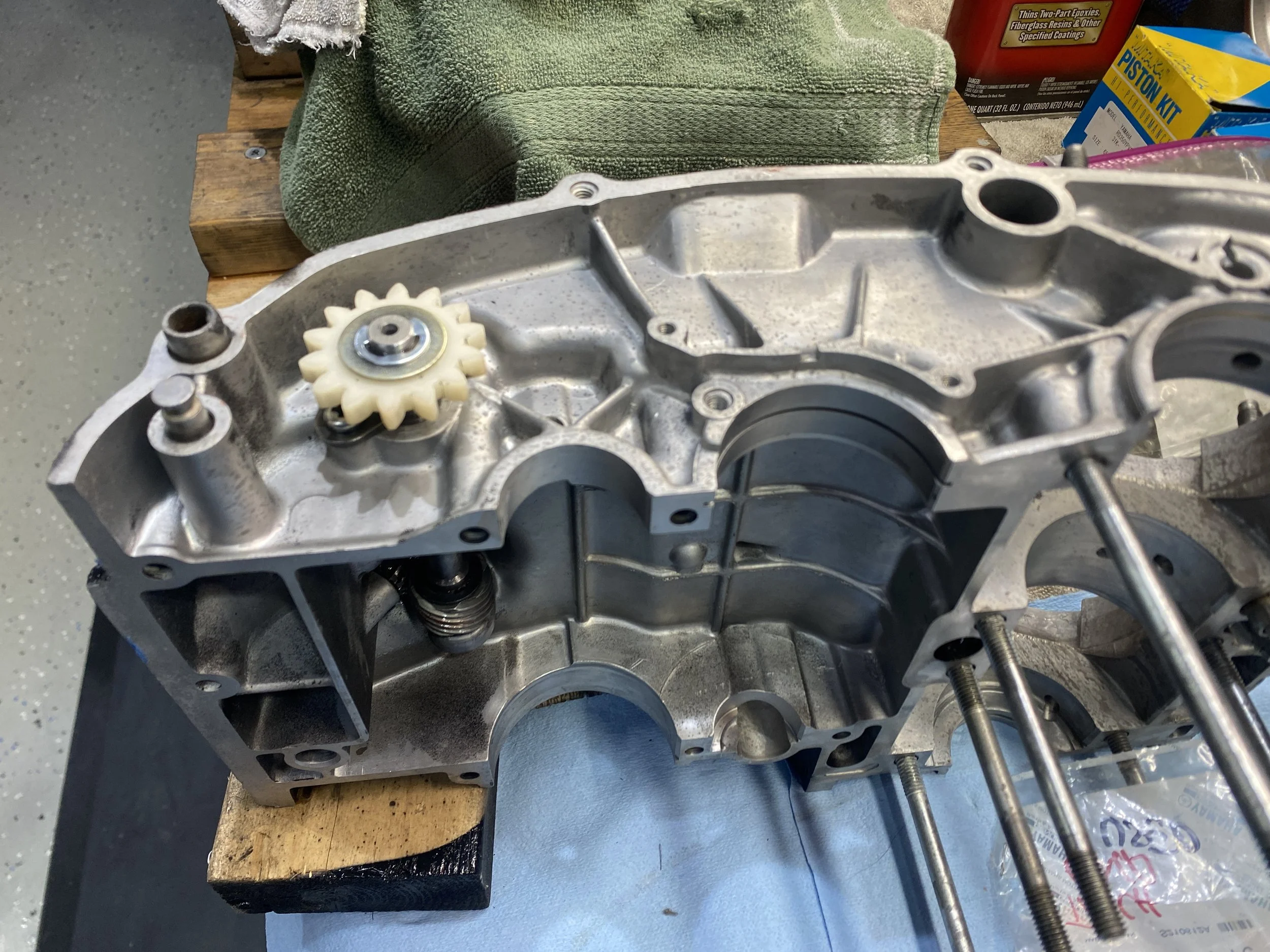

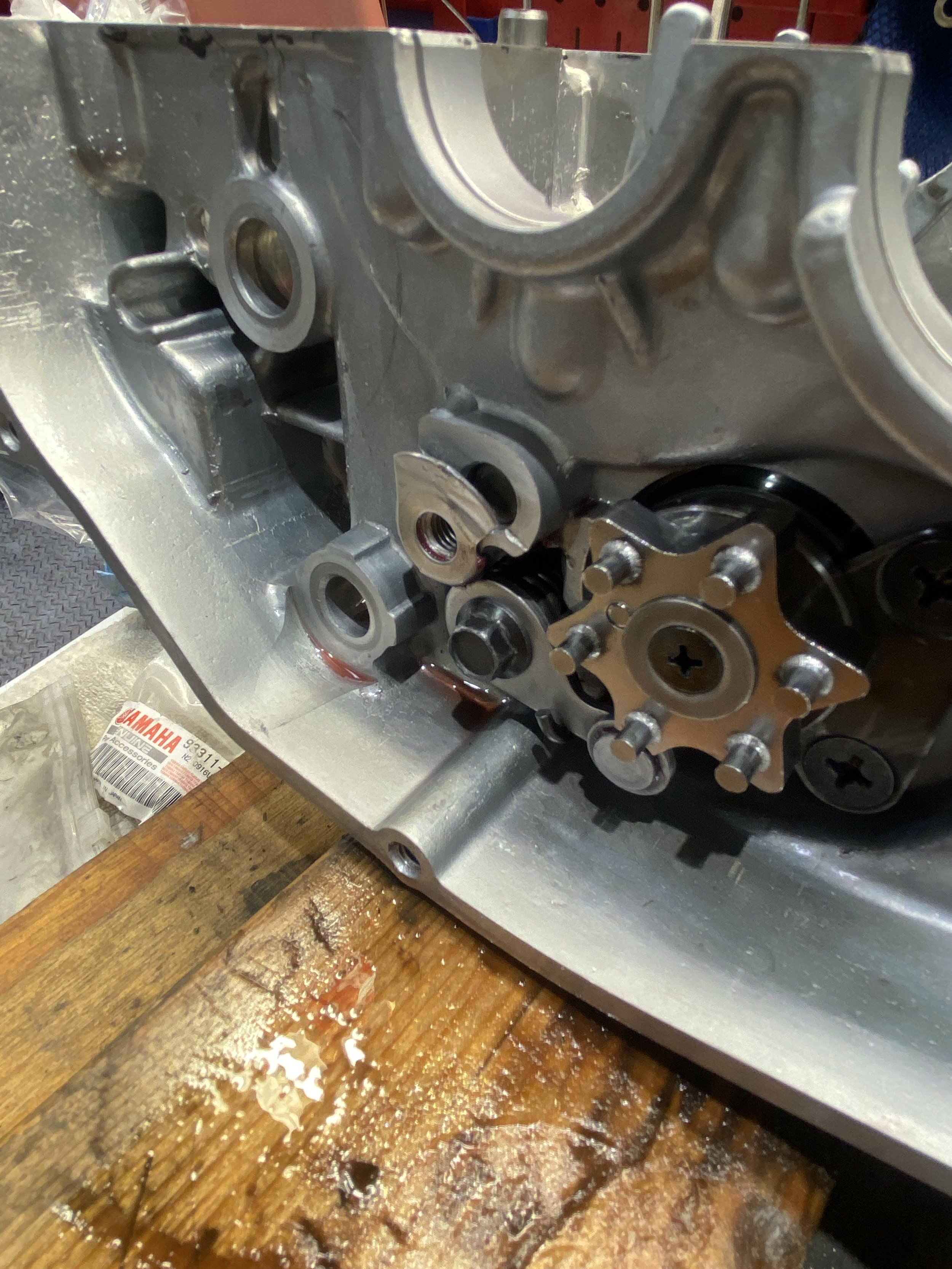

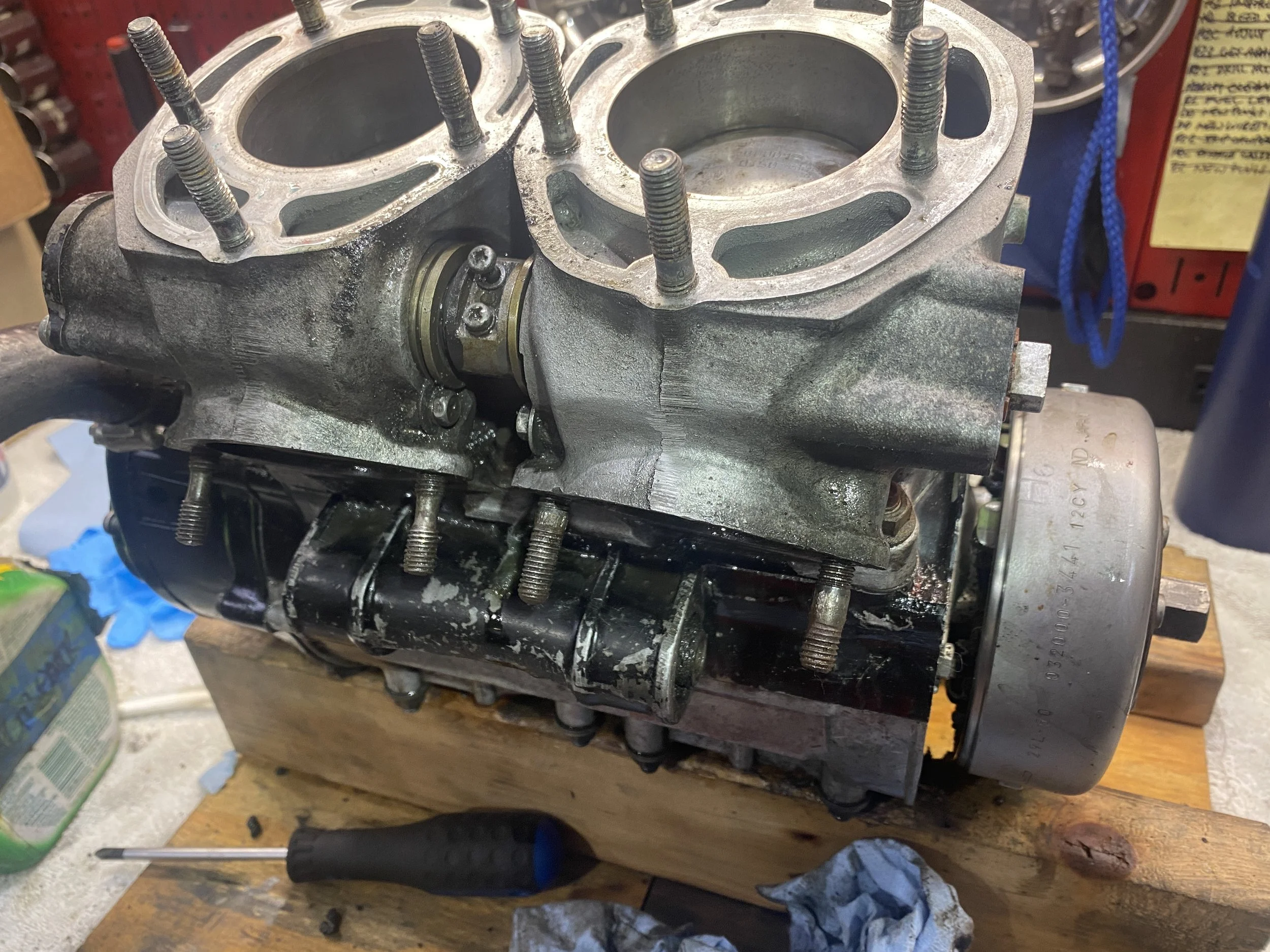

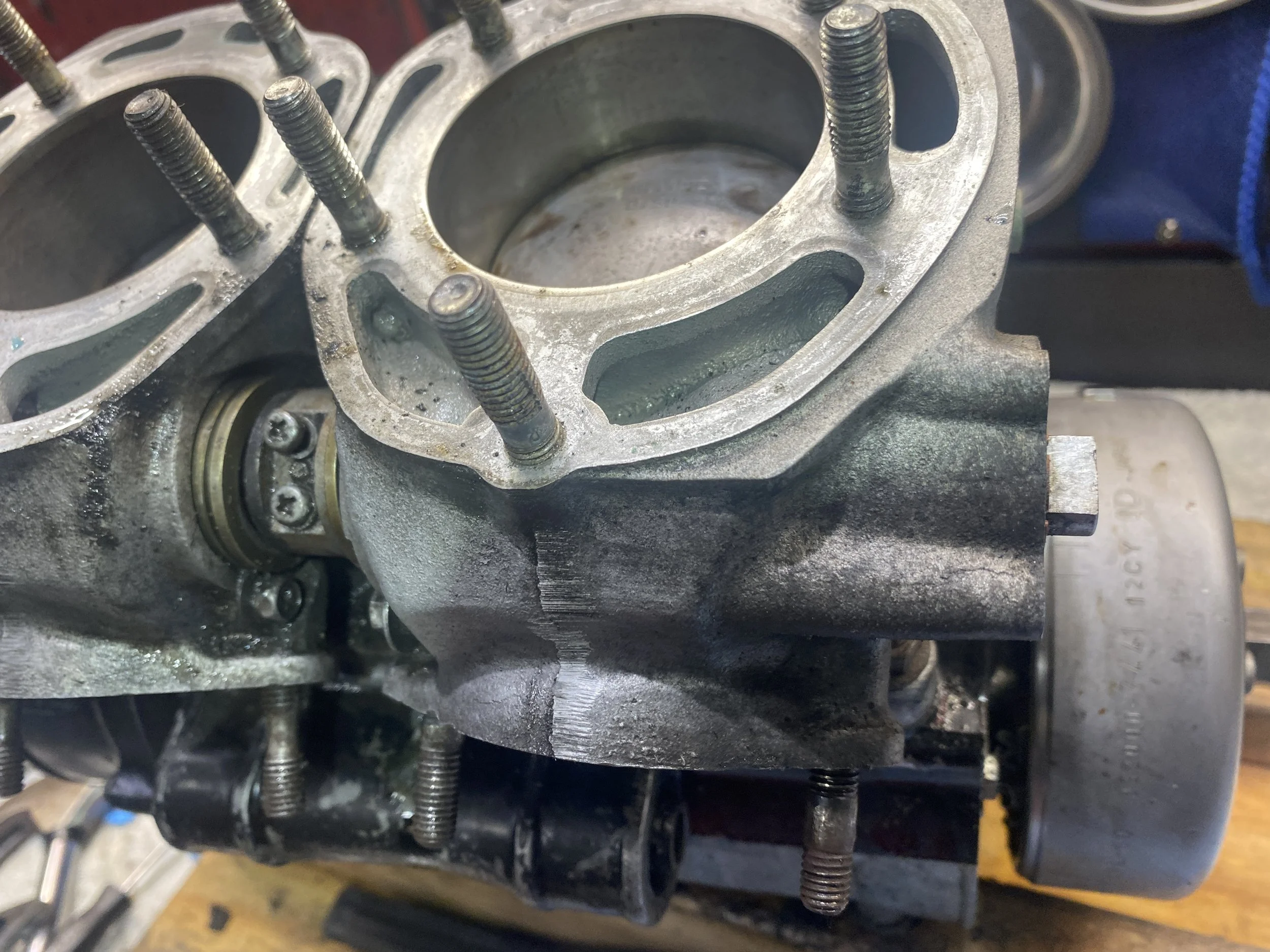

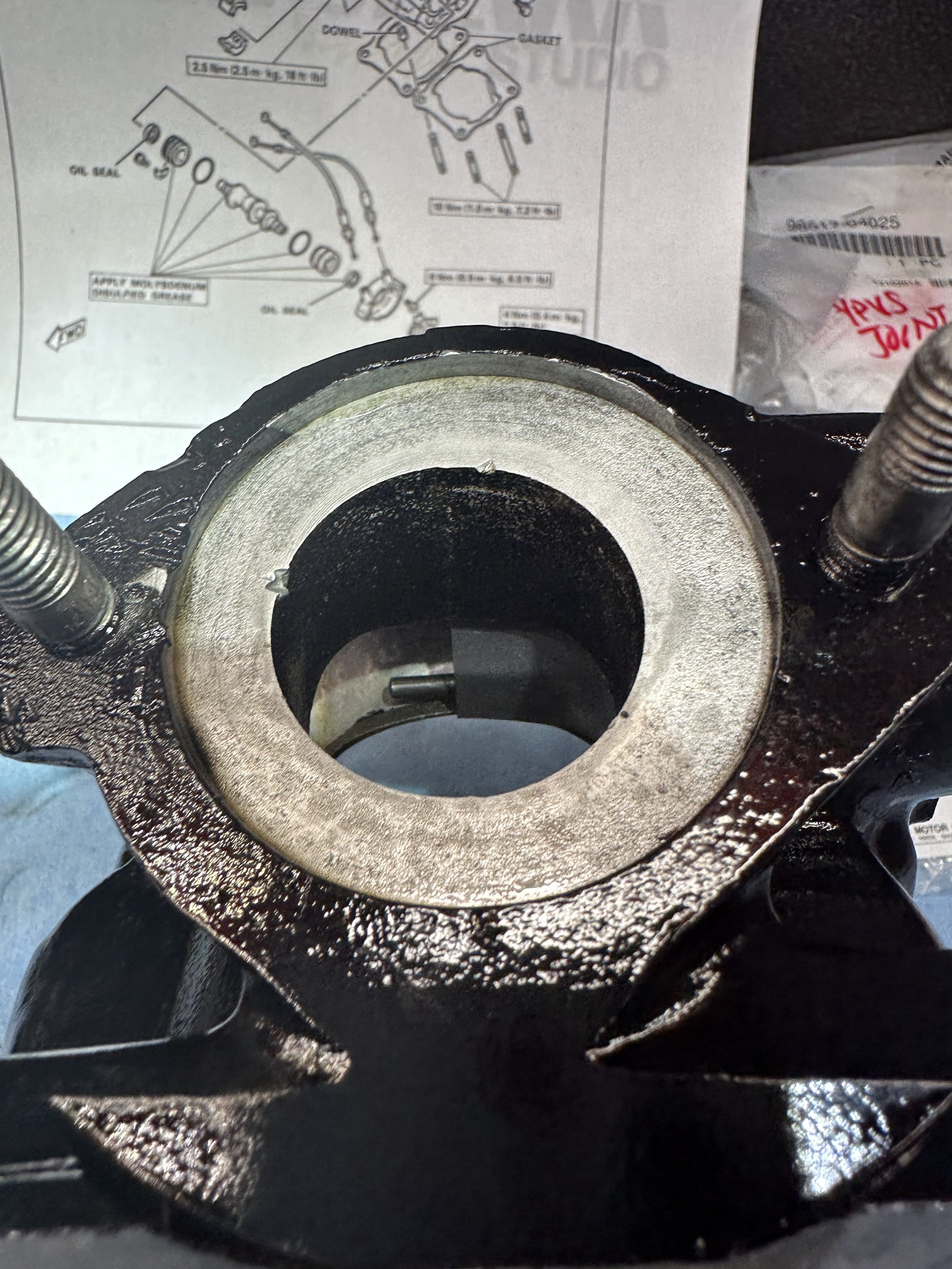

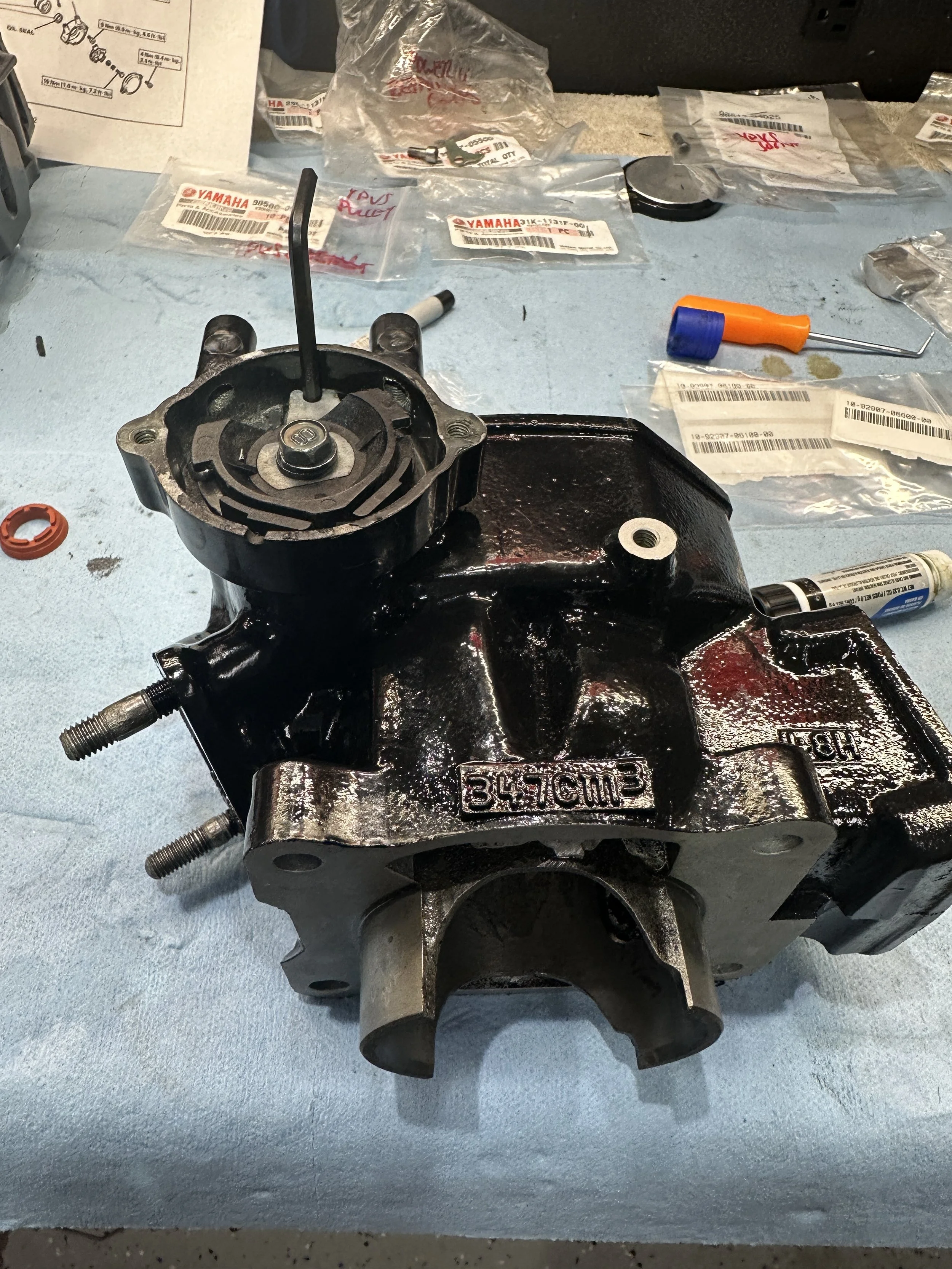

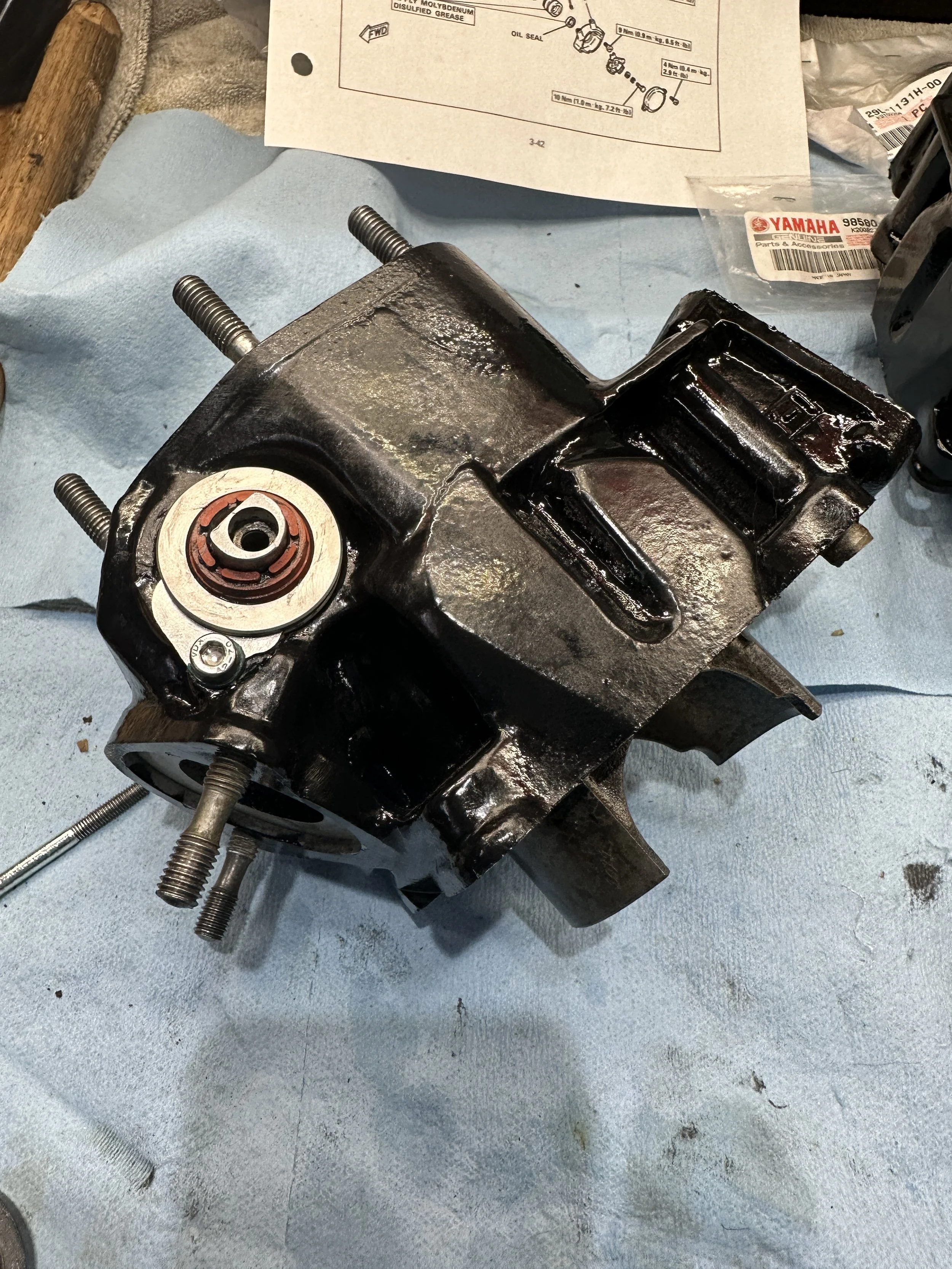

Engine Disassembly

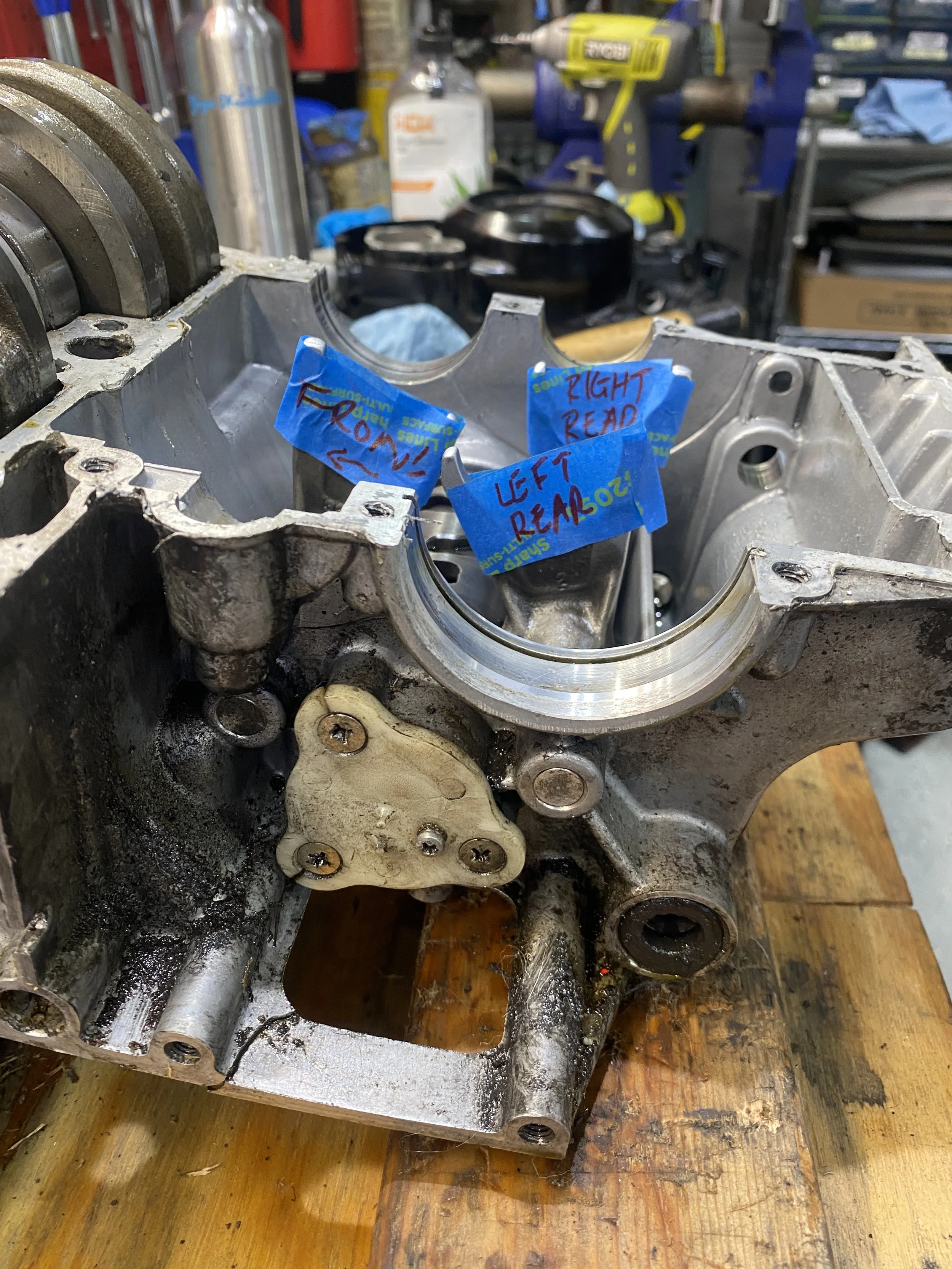

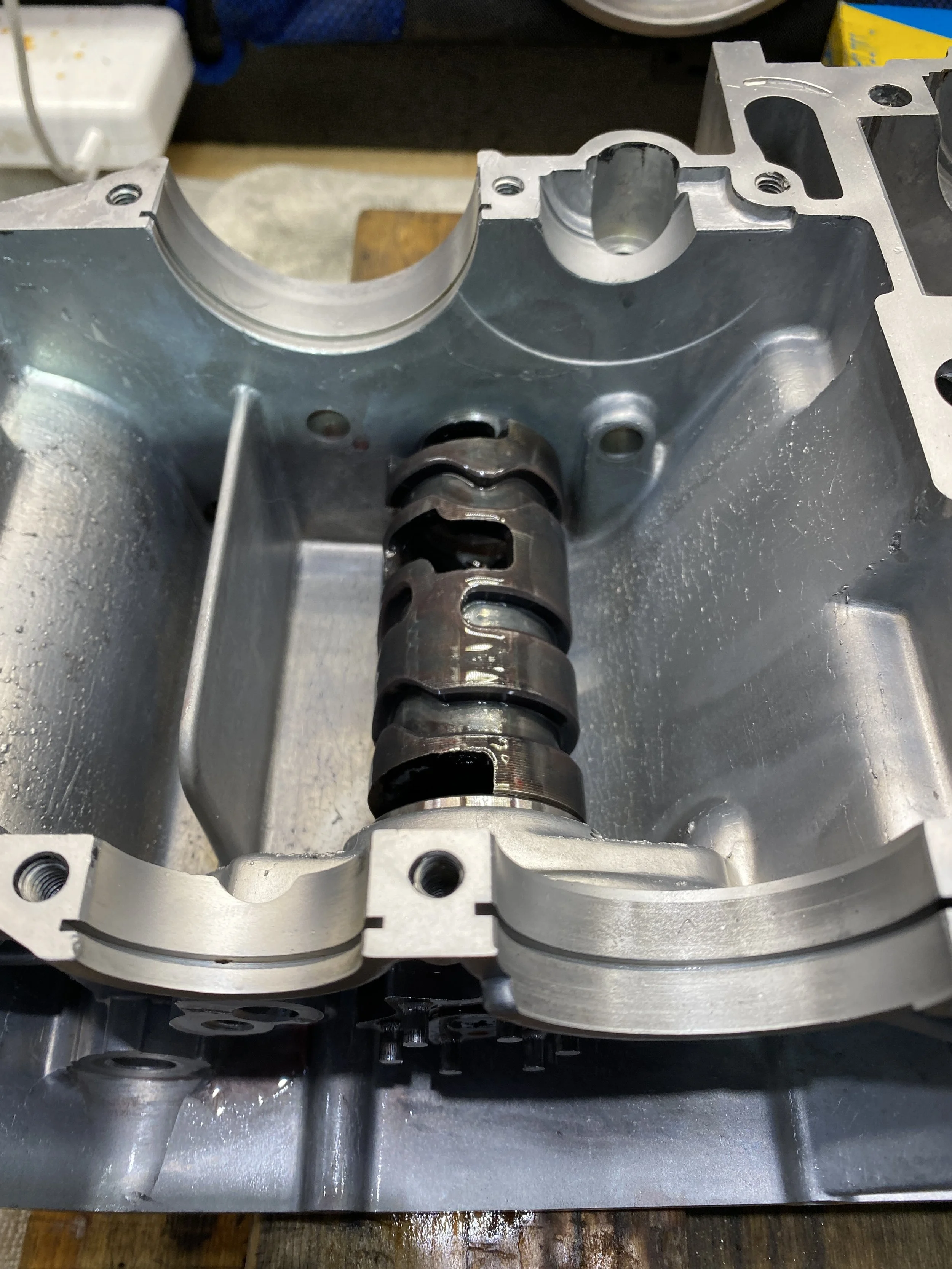

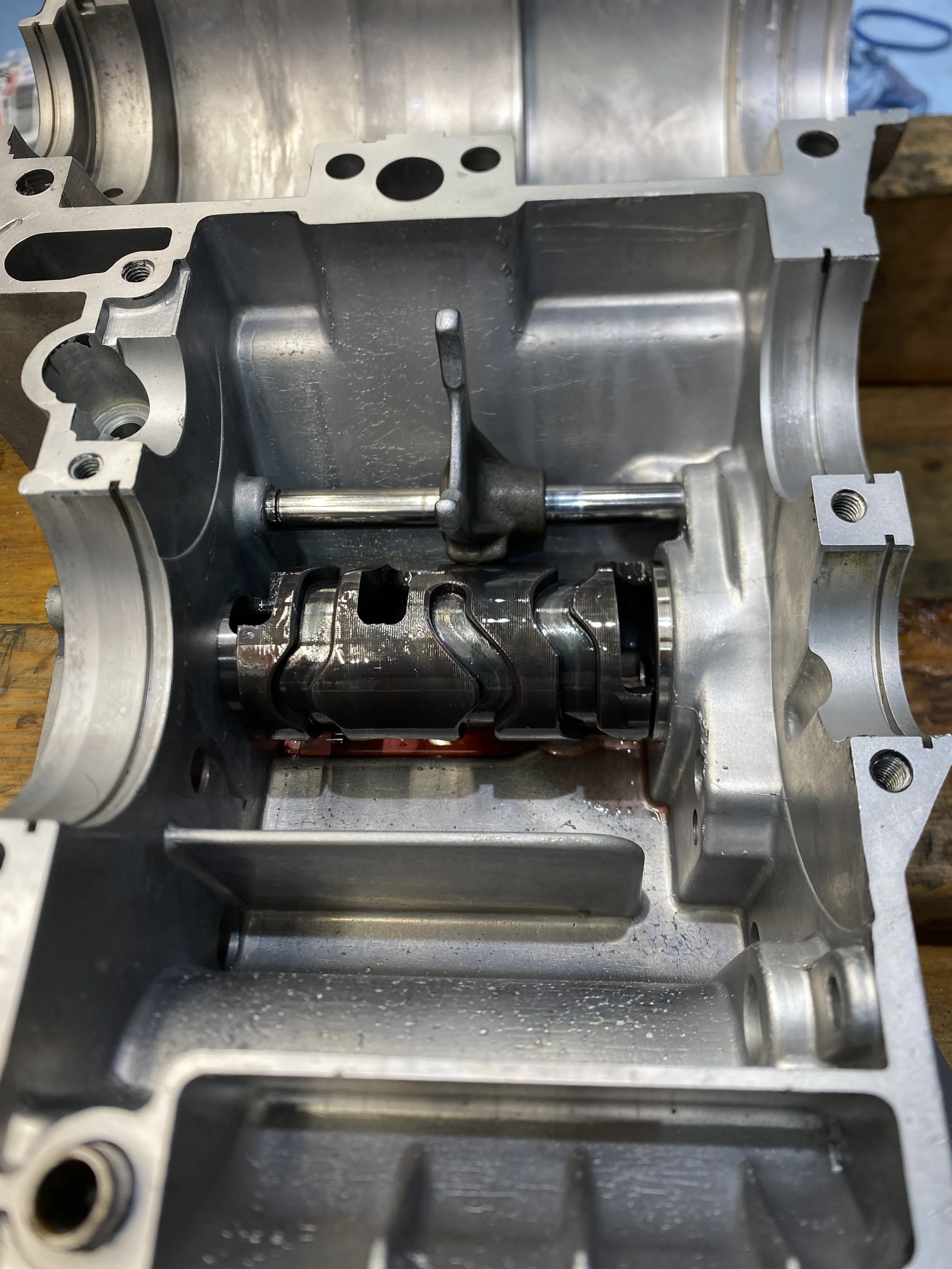

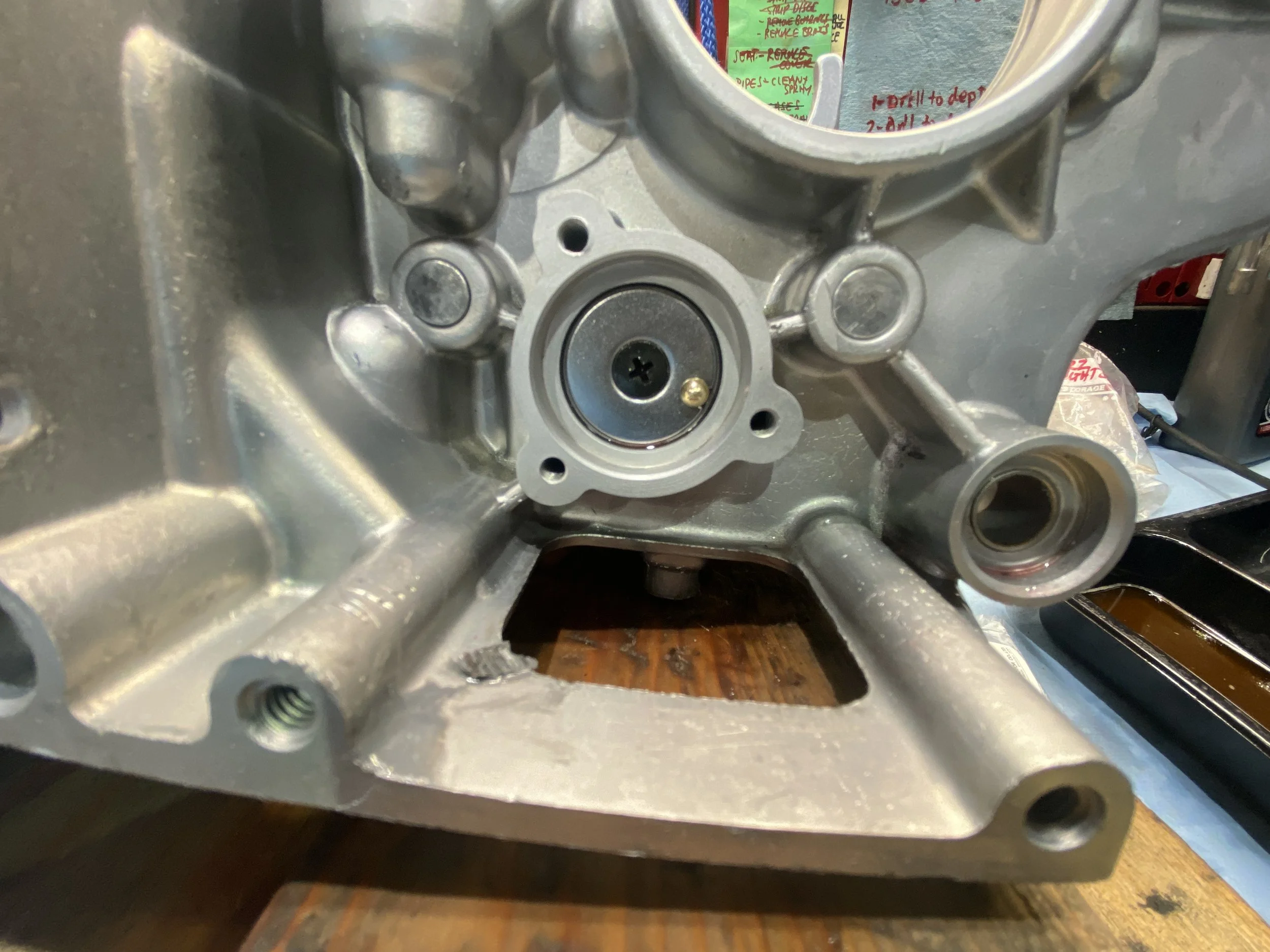

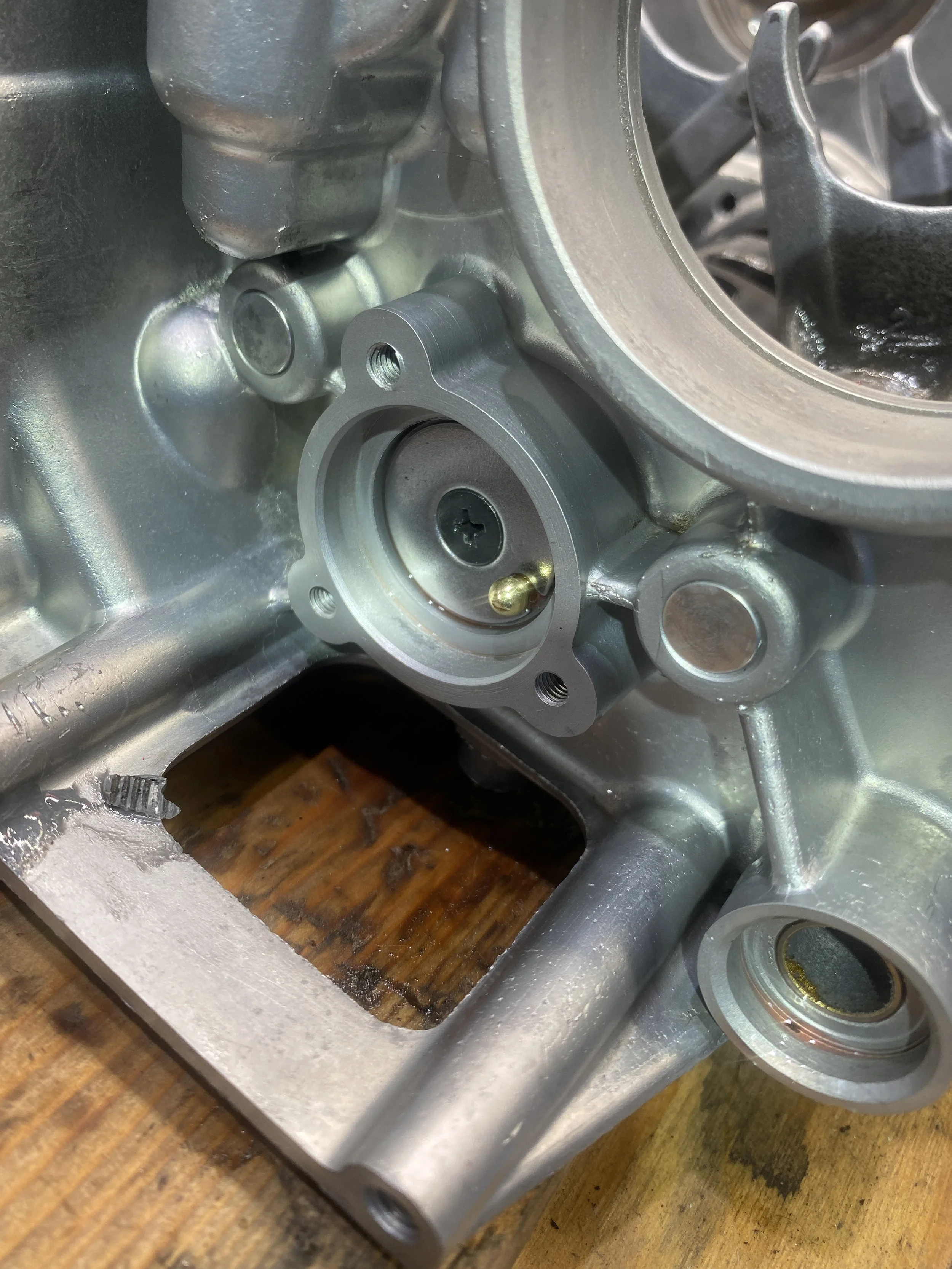

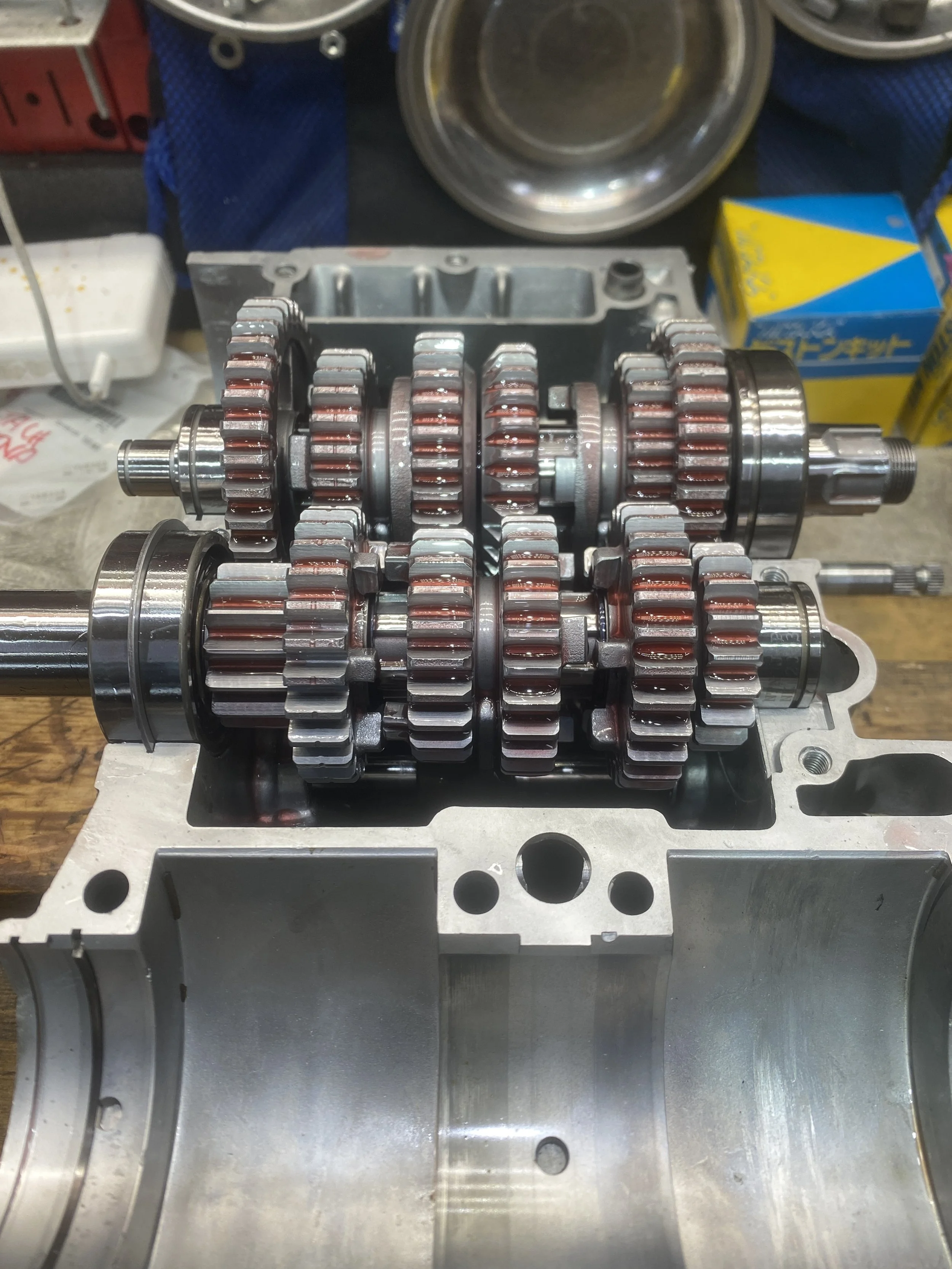

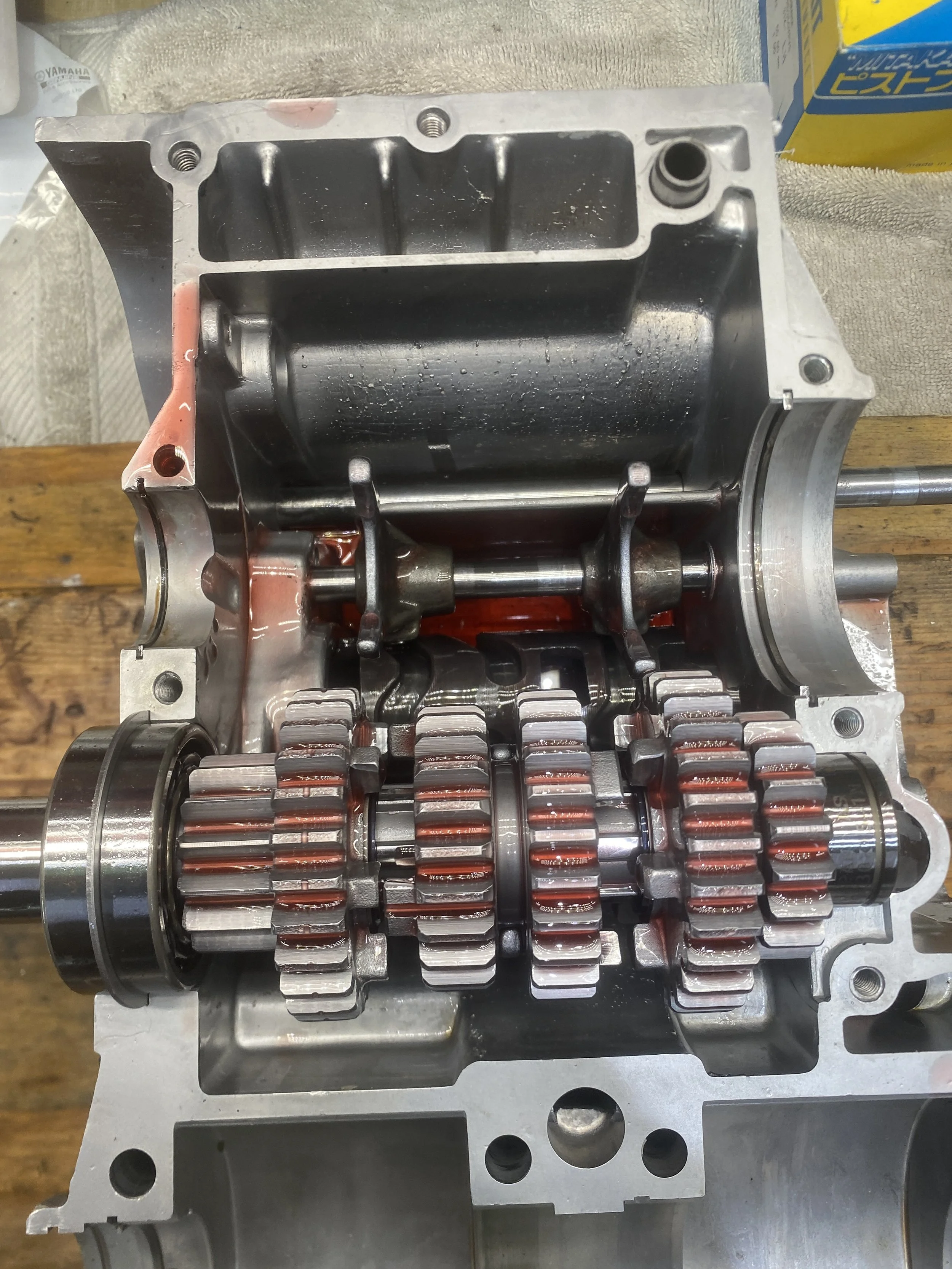

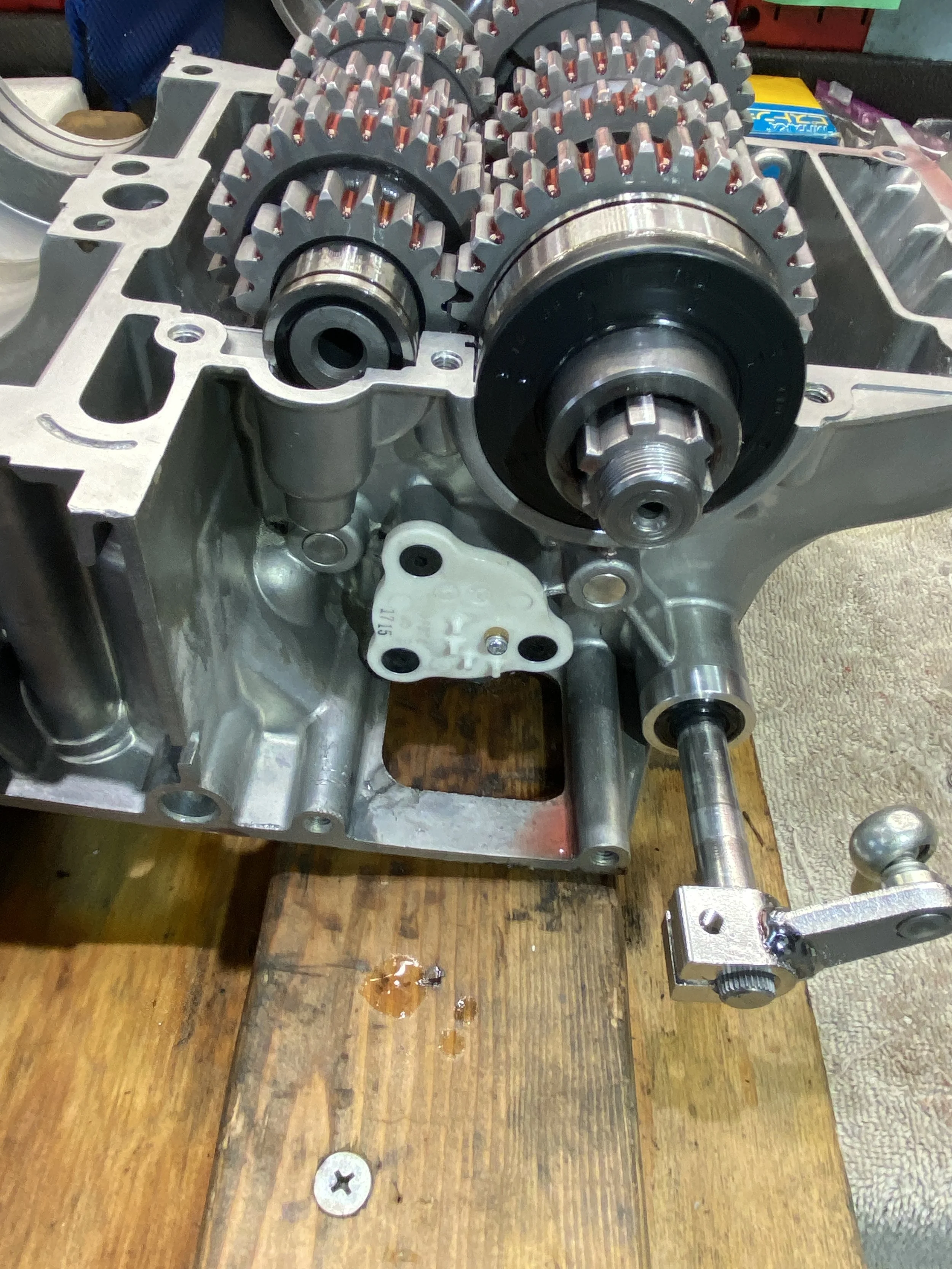

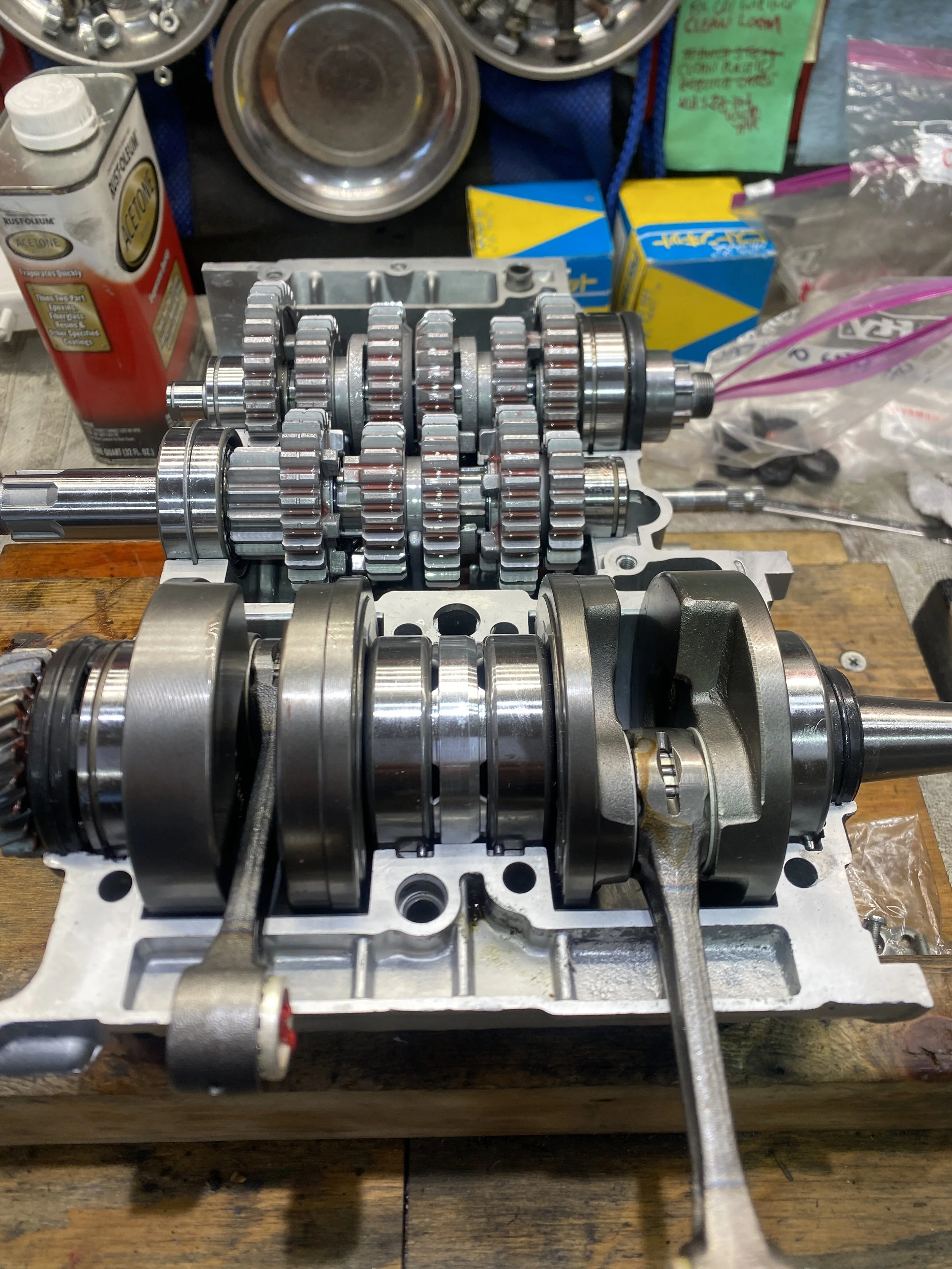

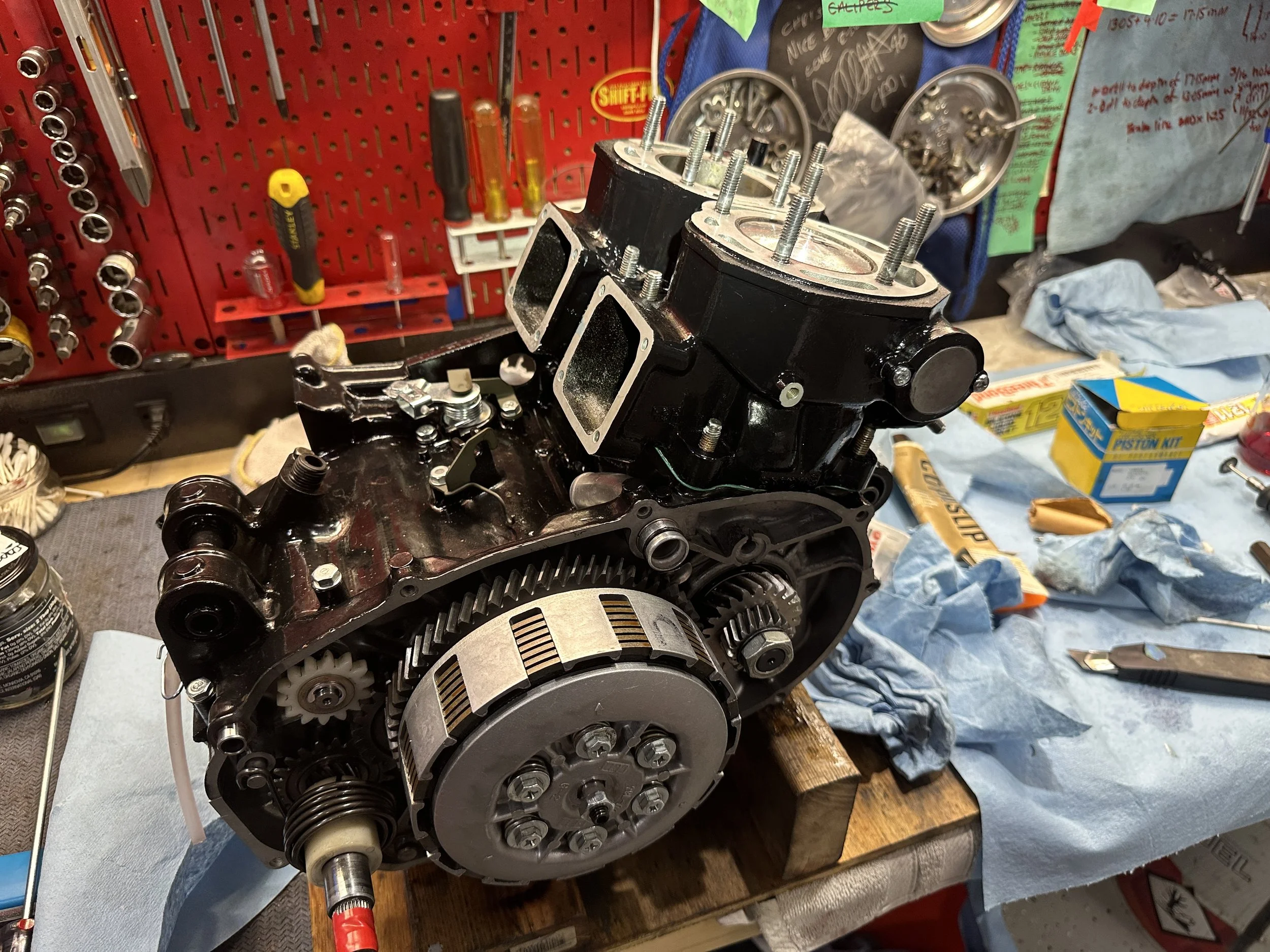

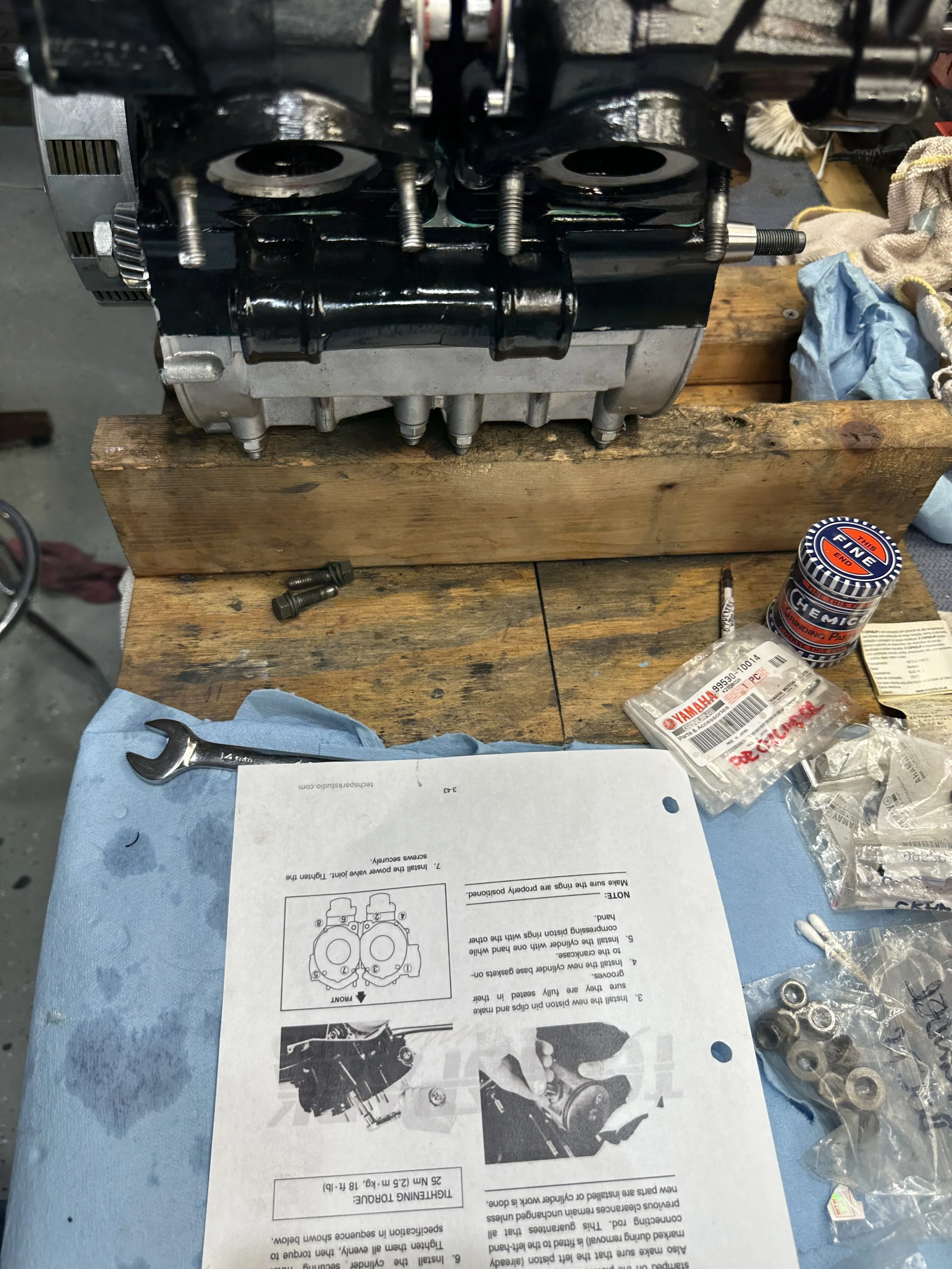

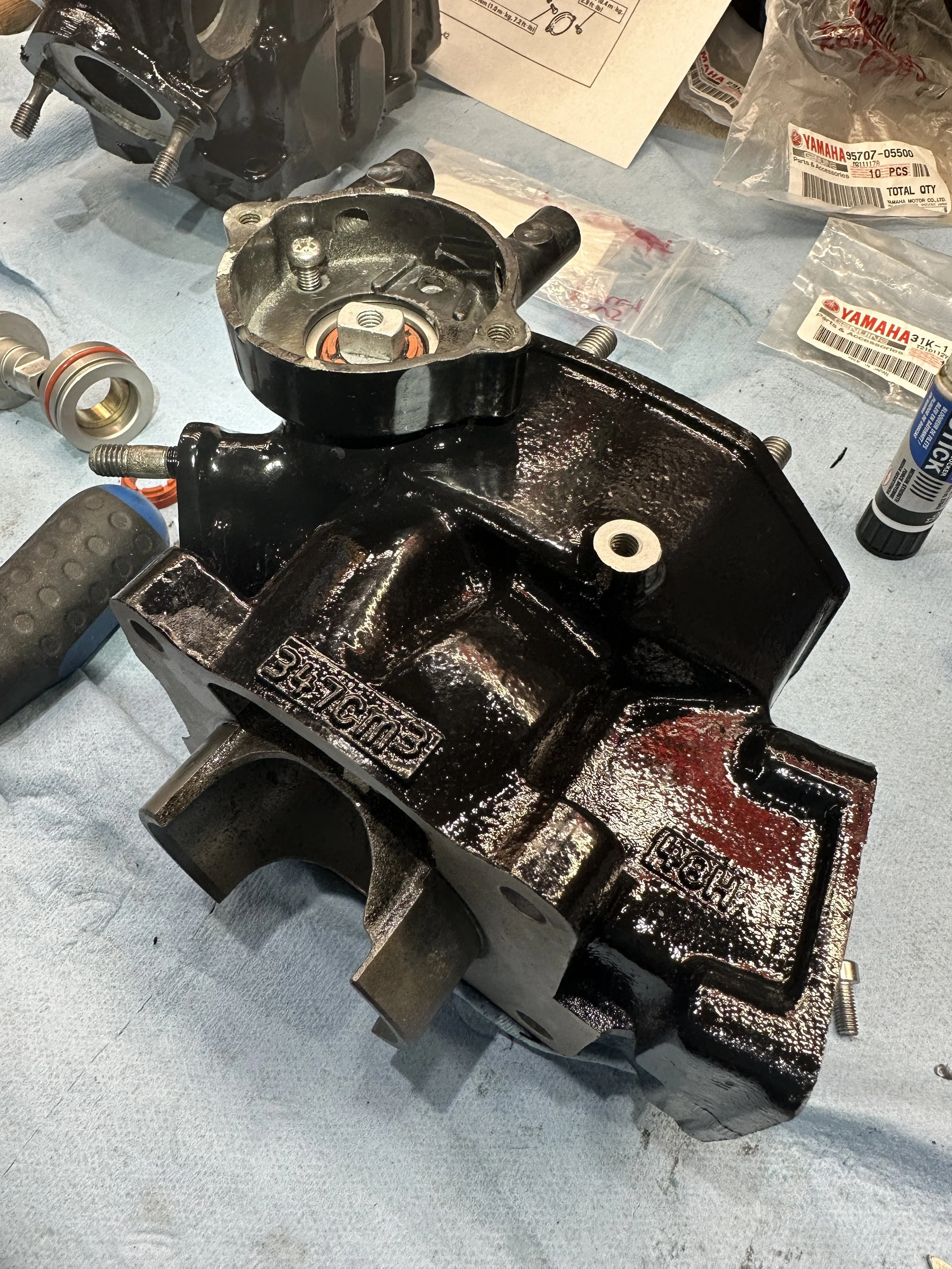

Engine : Reassembly.

Engine : Reassembly.

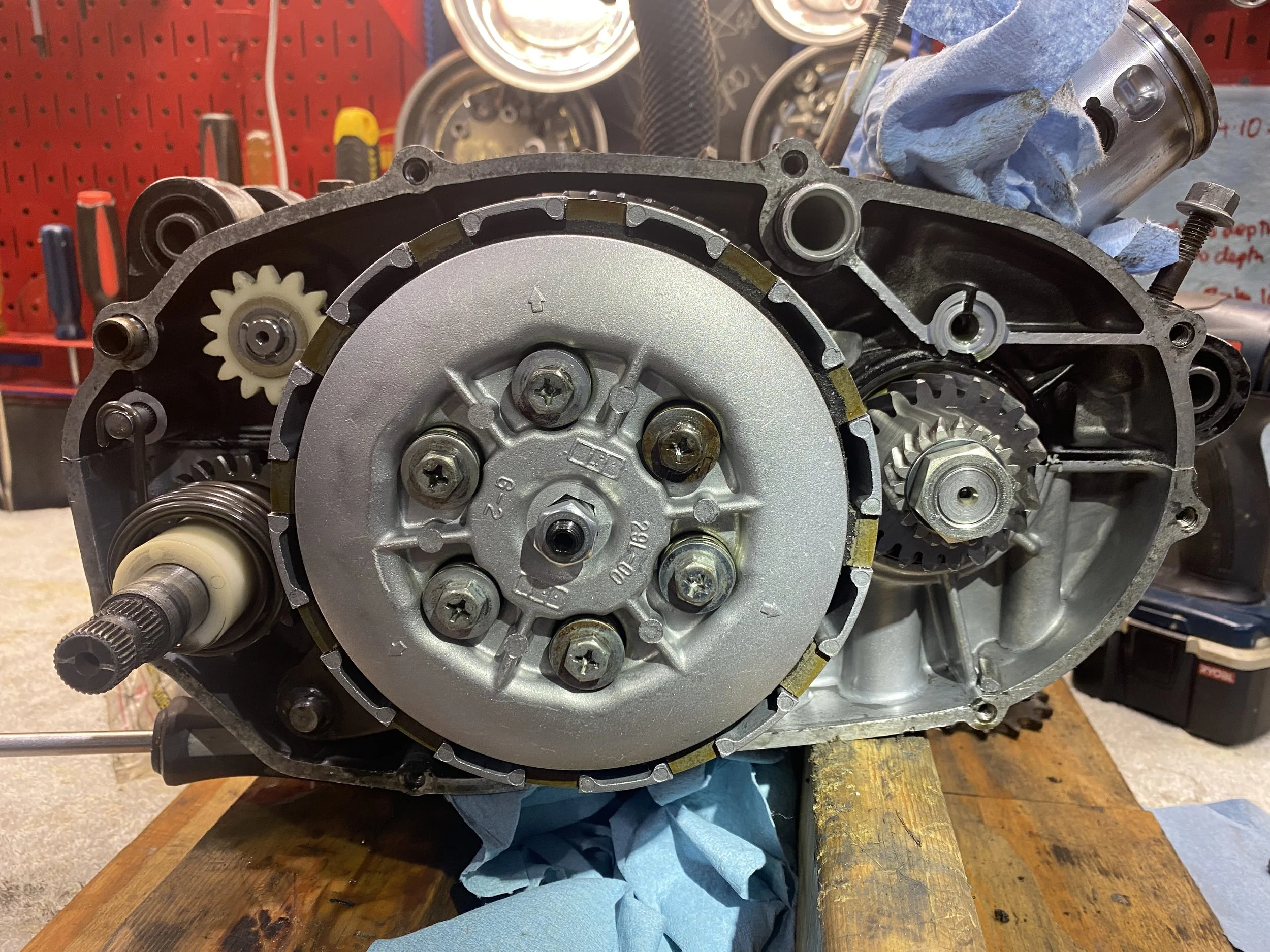

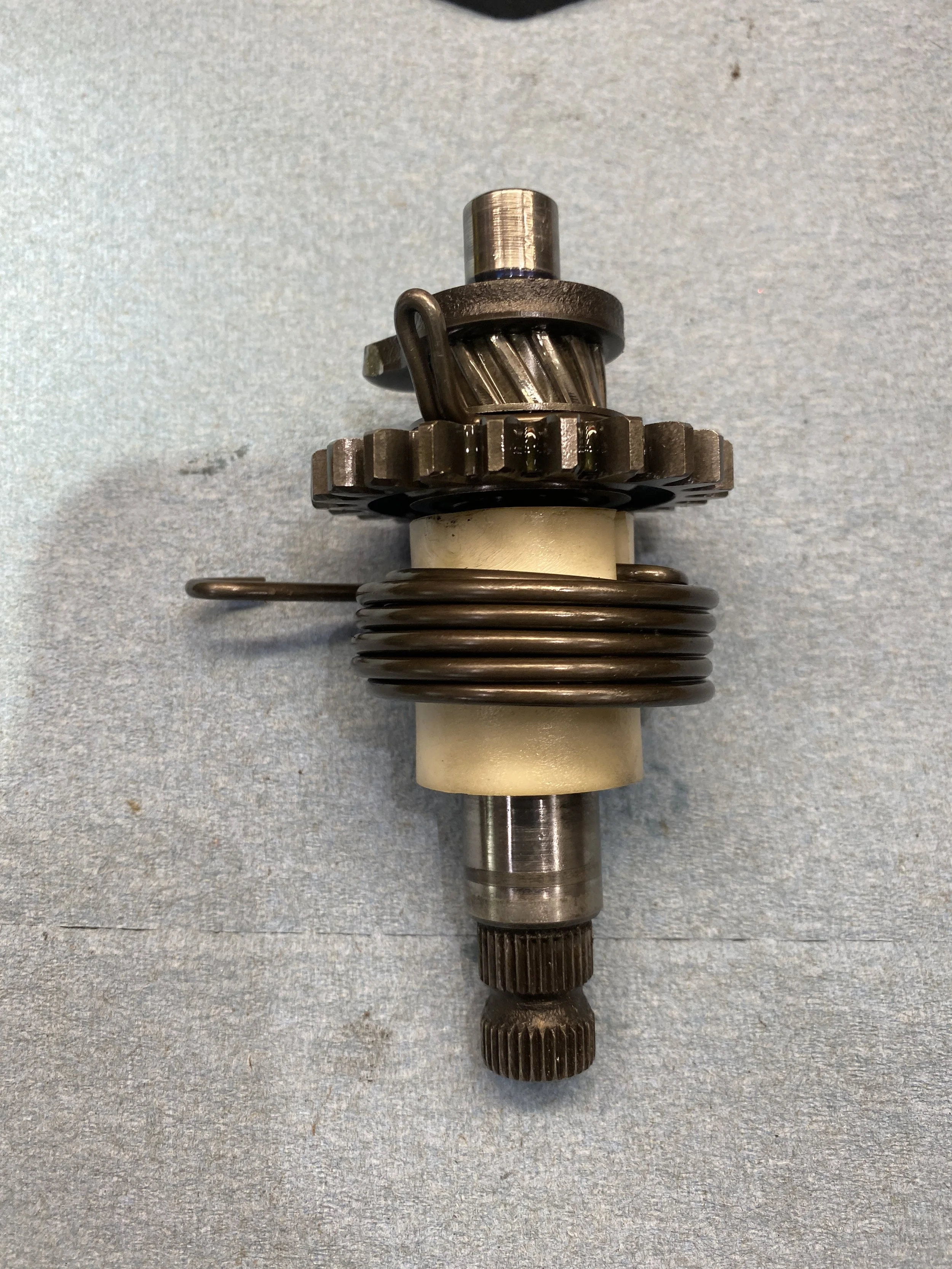

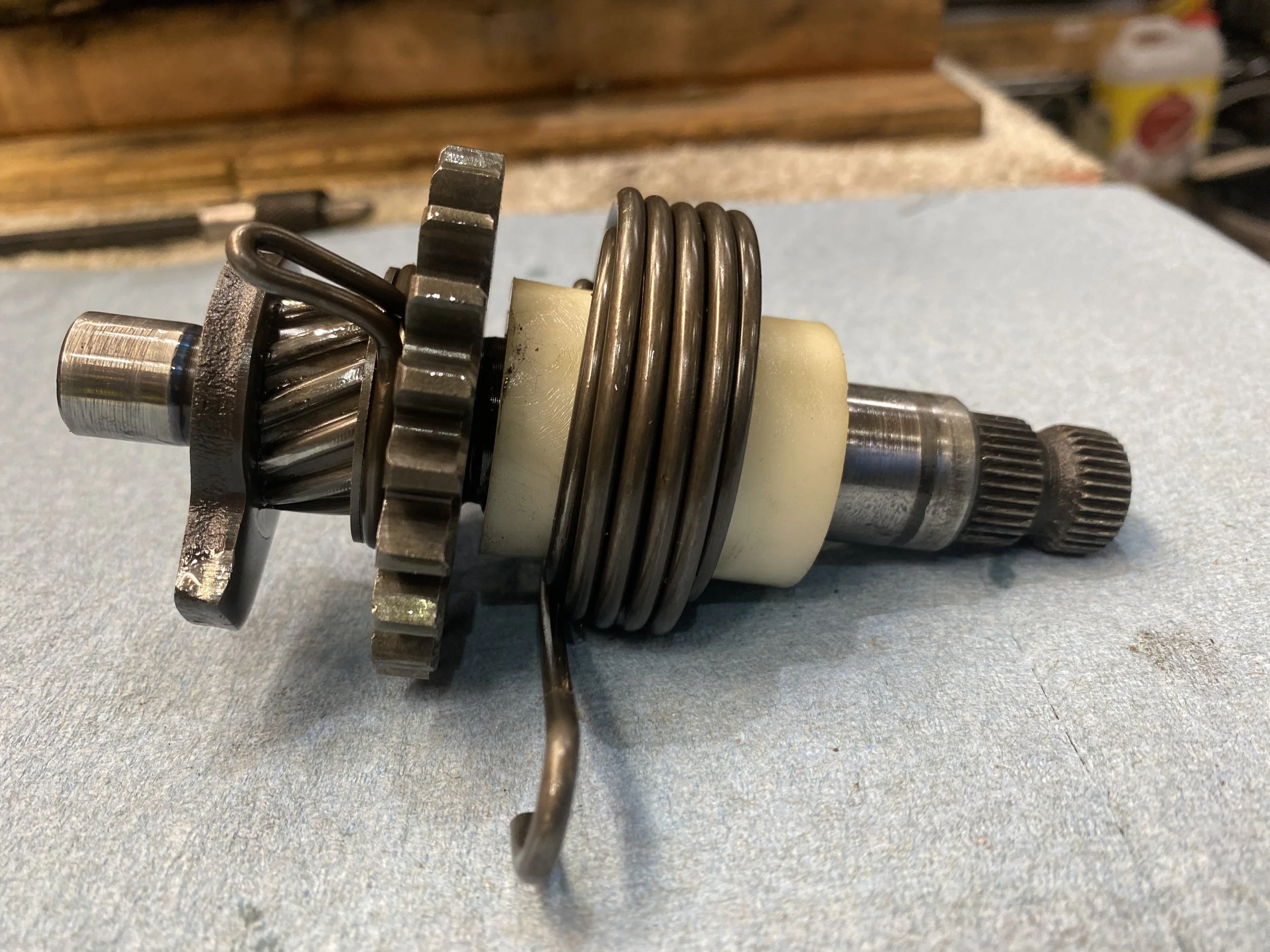

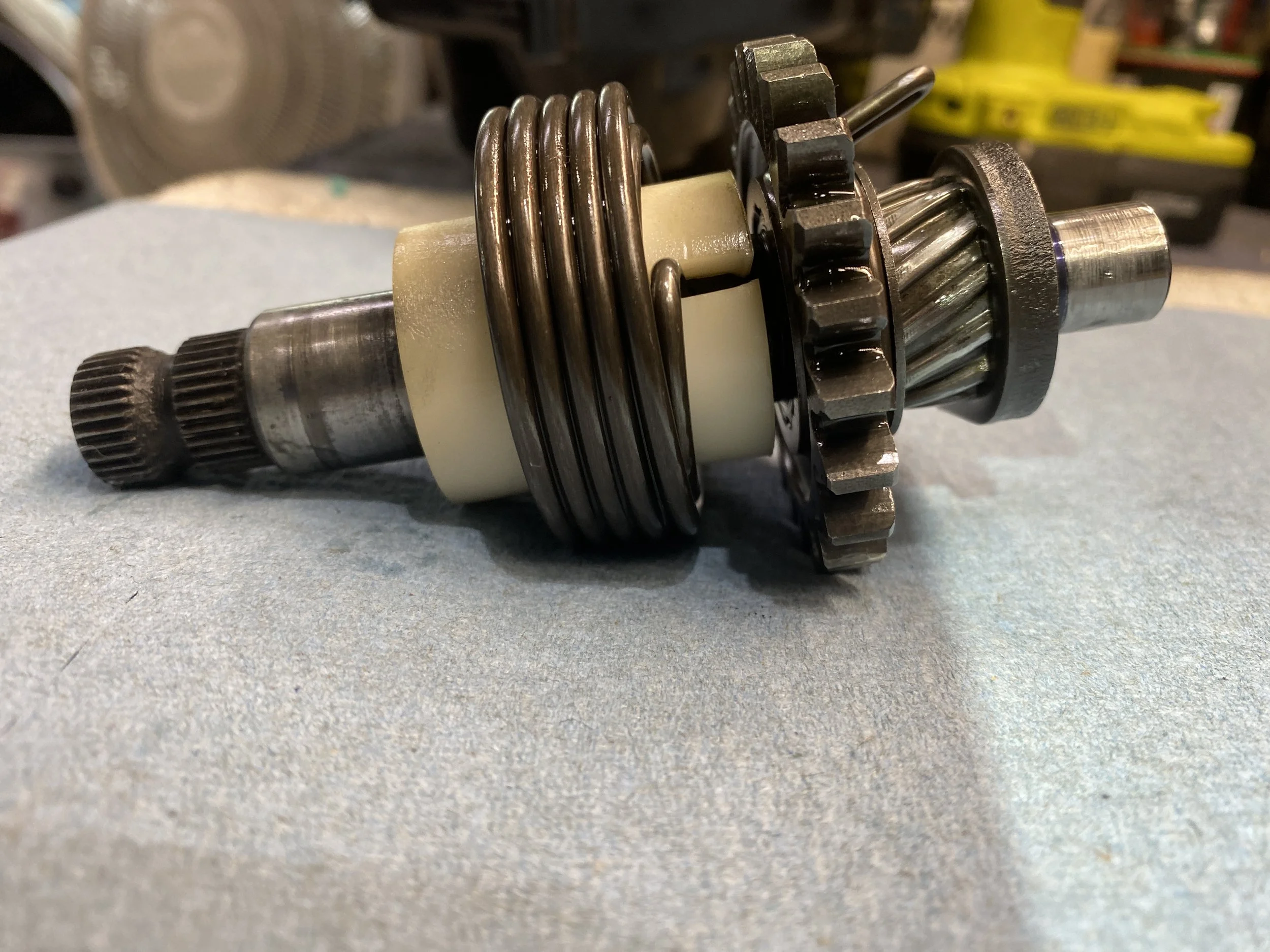

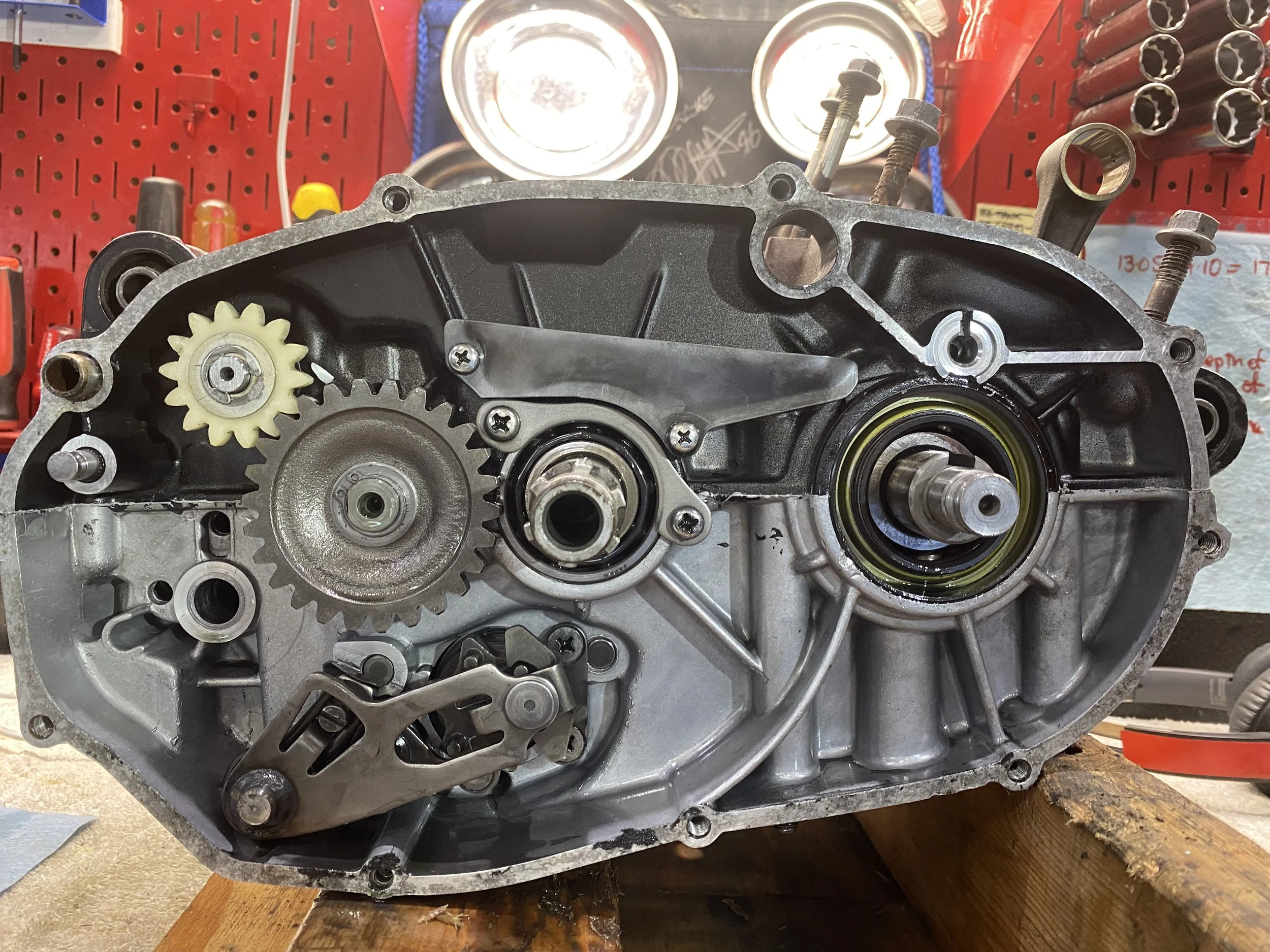

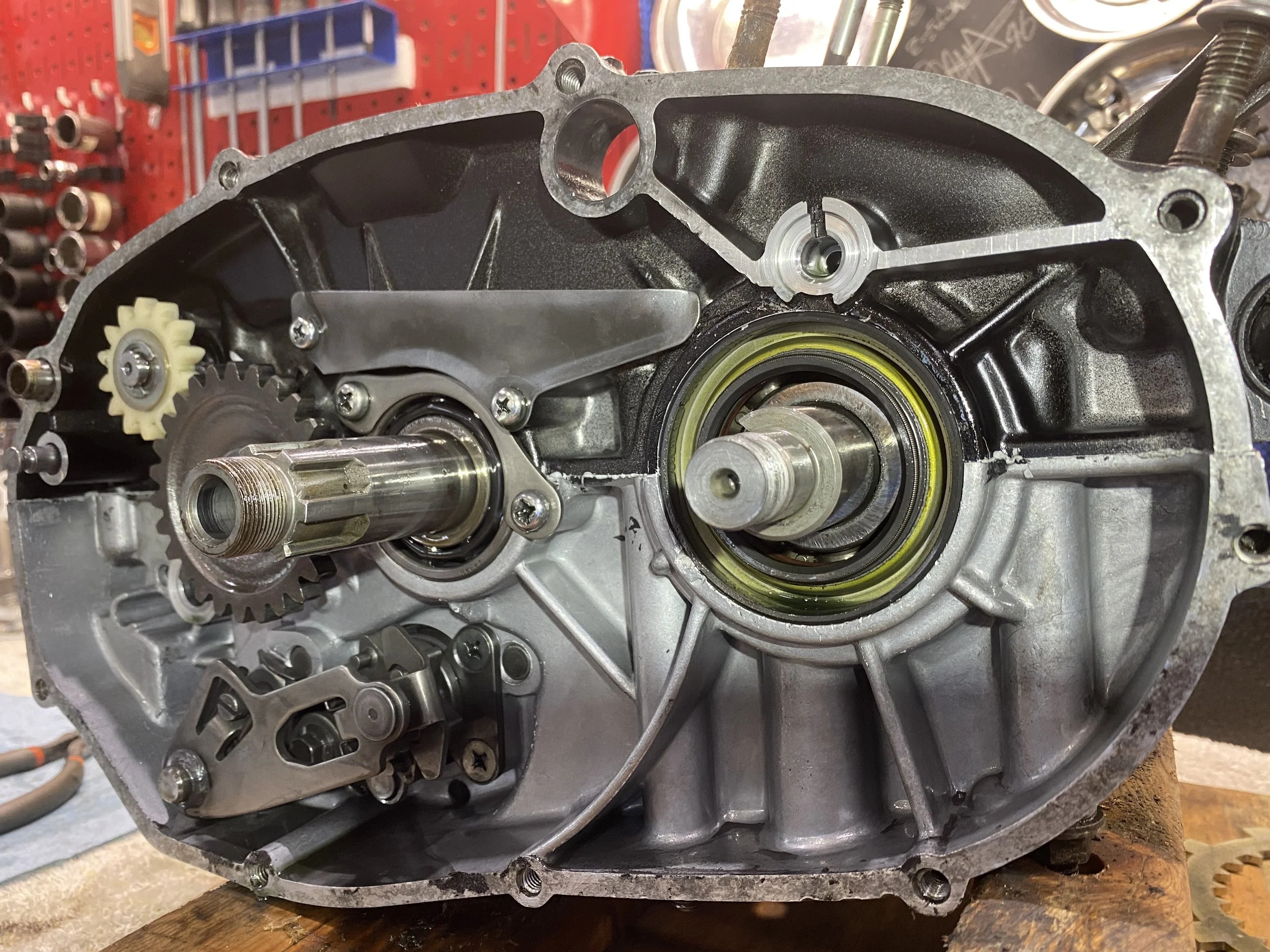

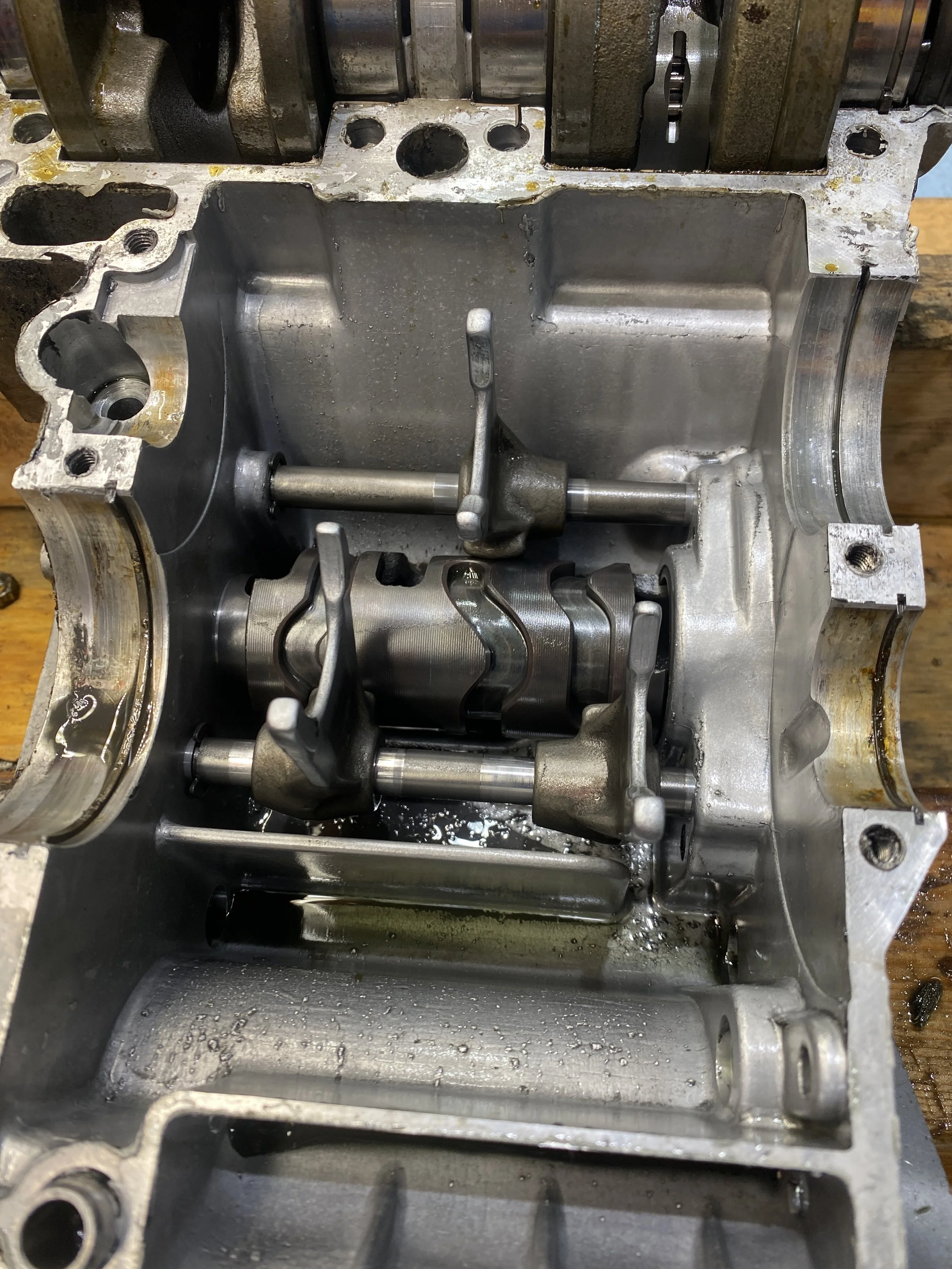

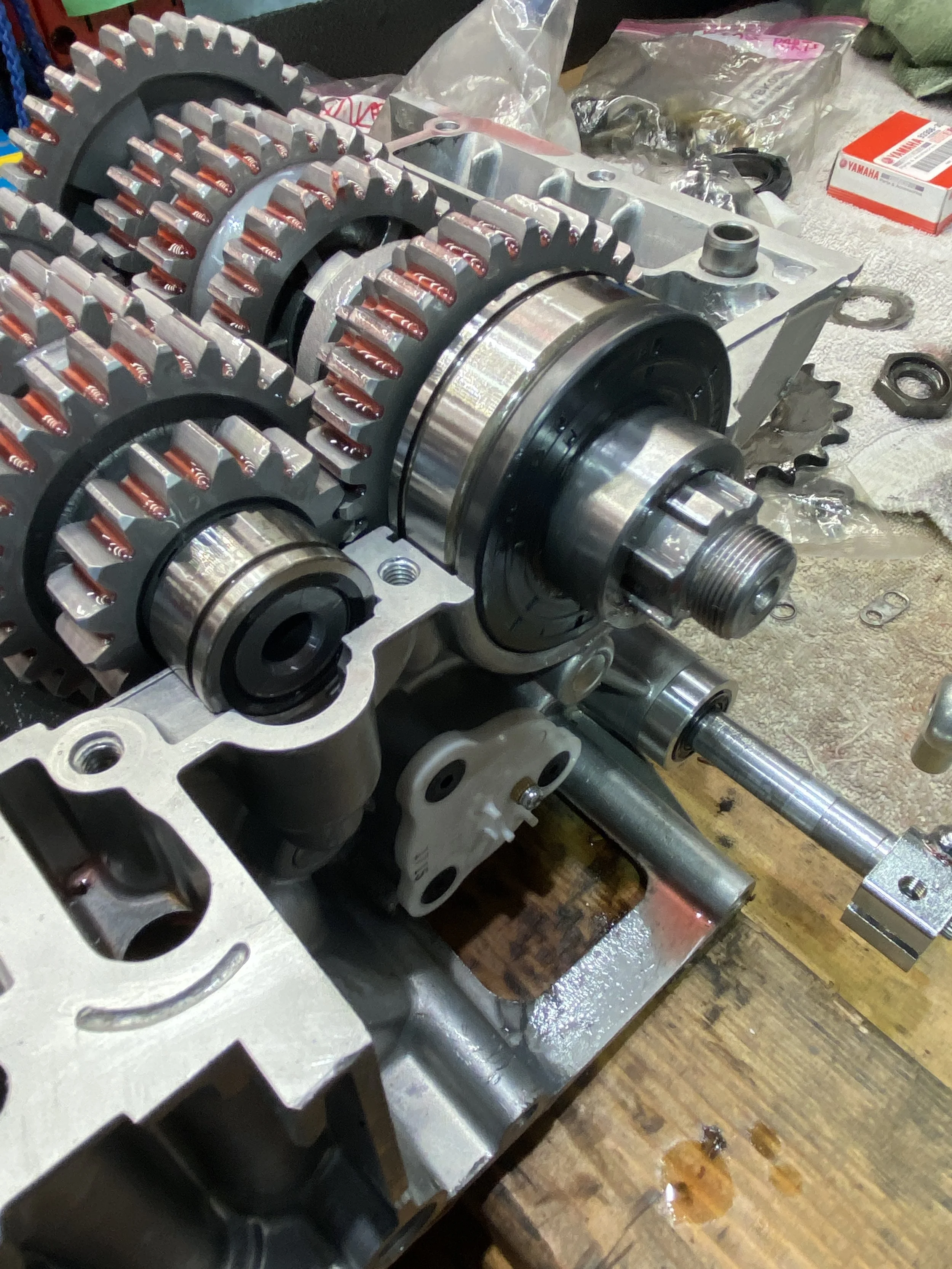

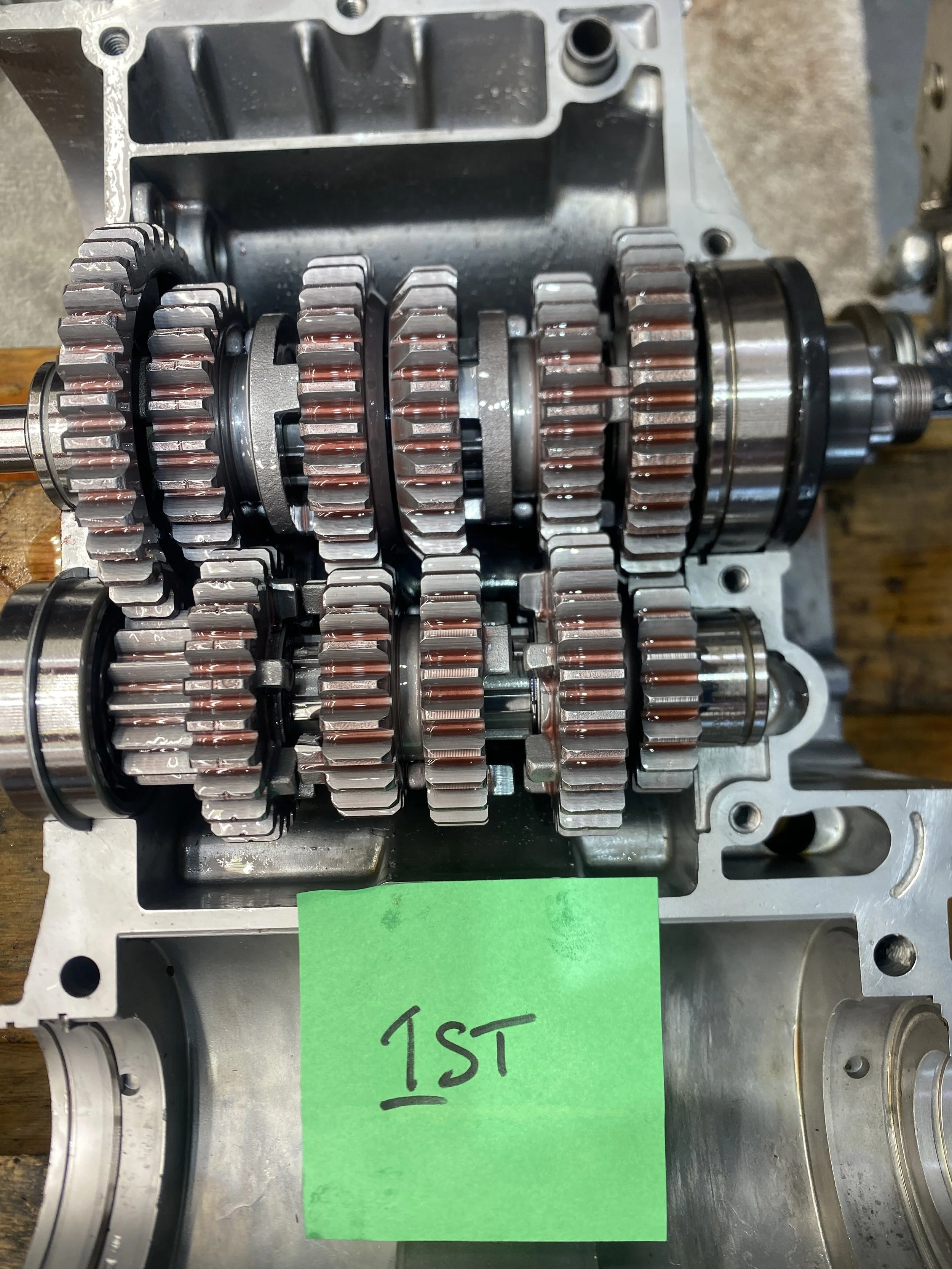

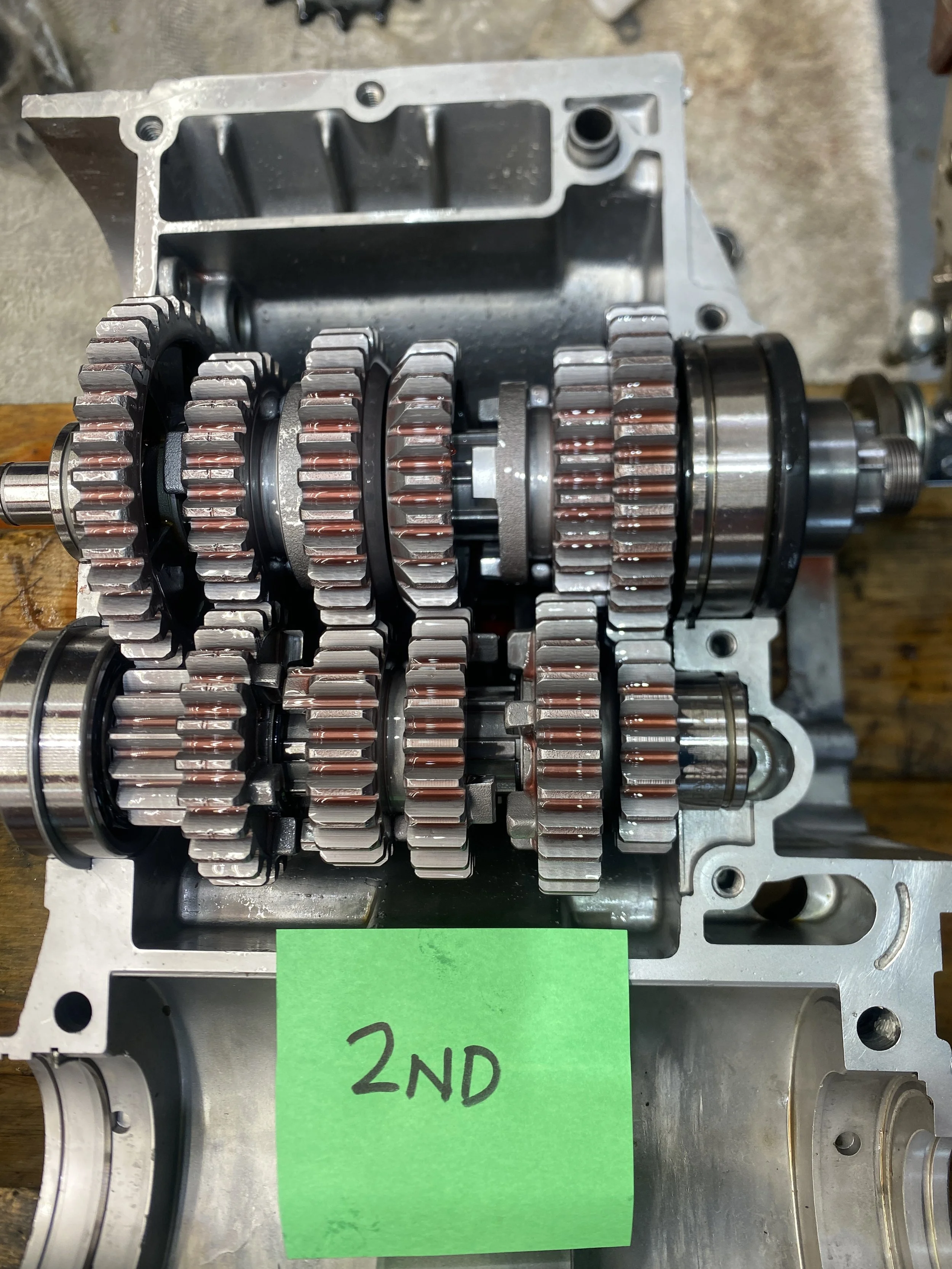

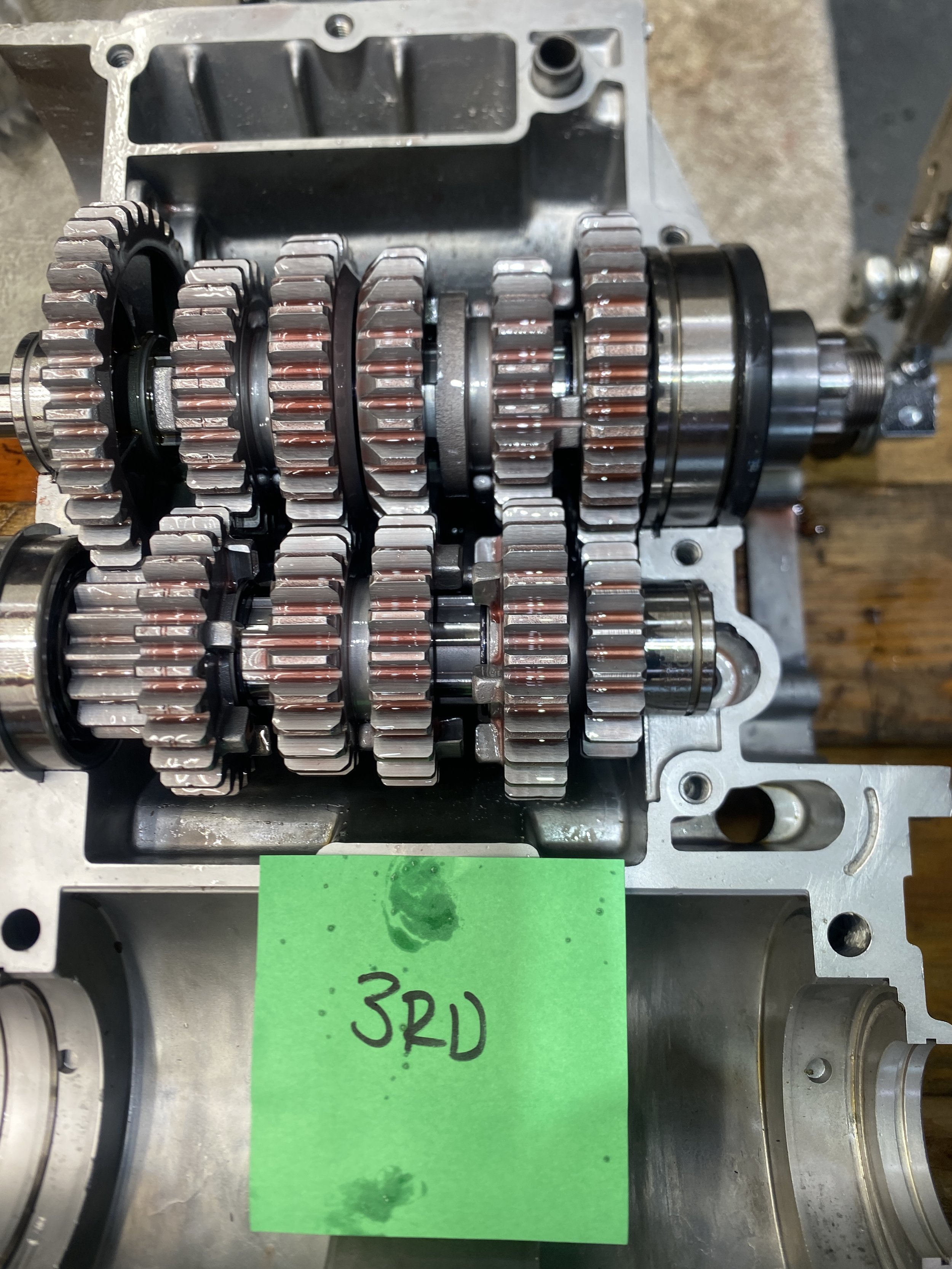

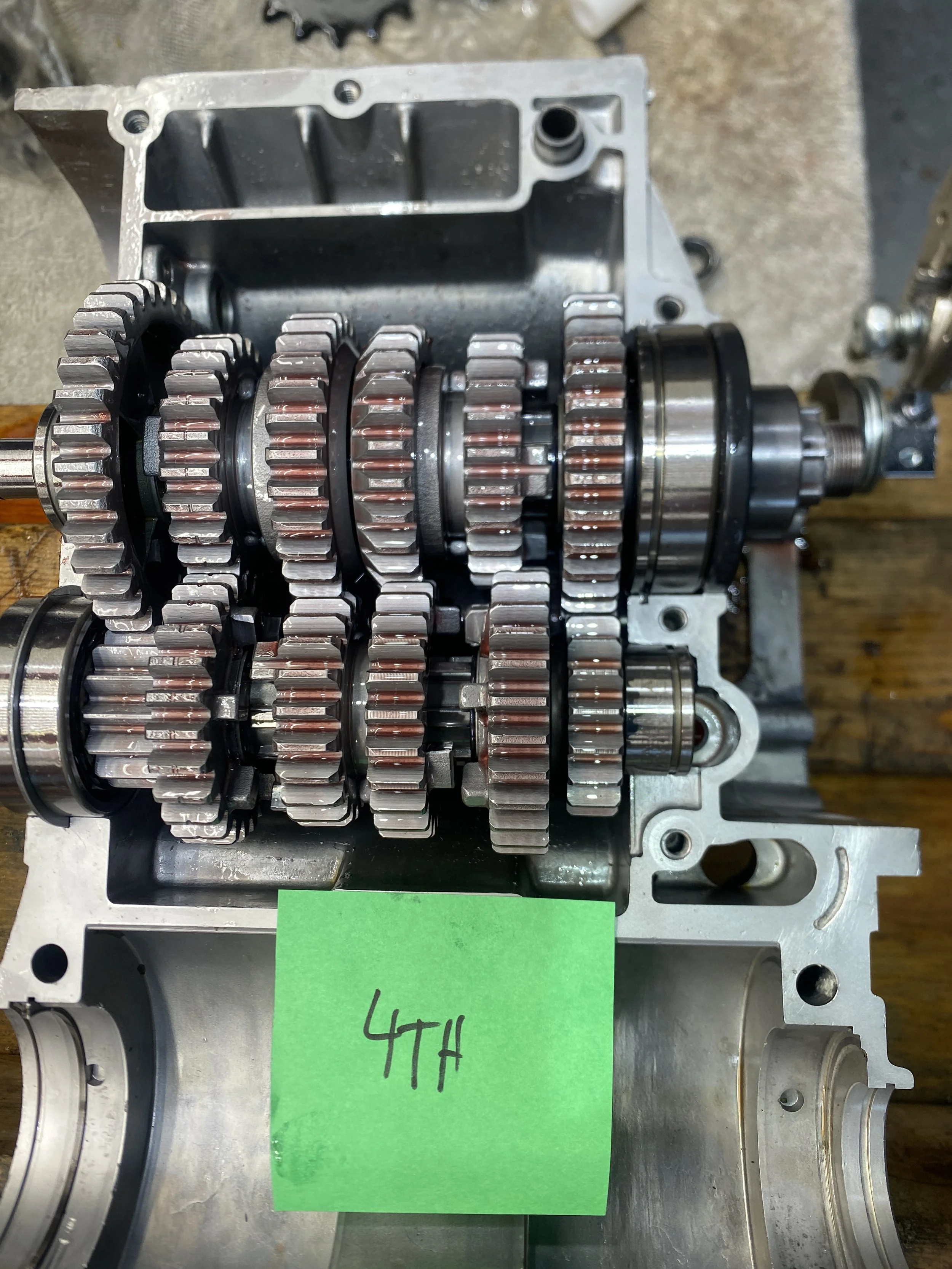

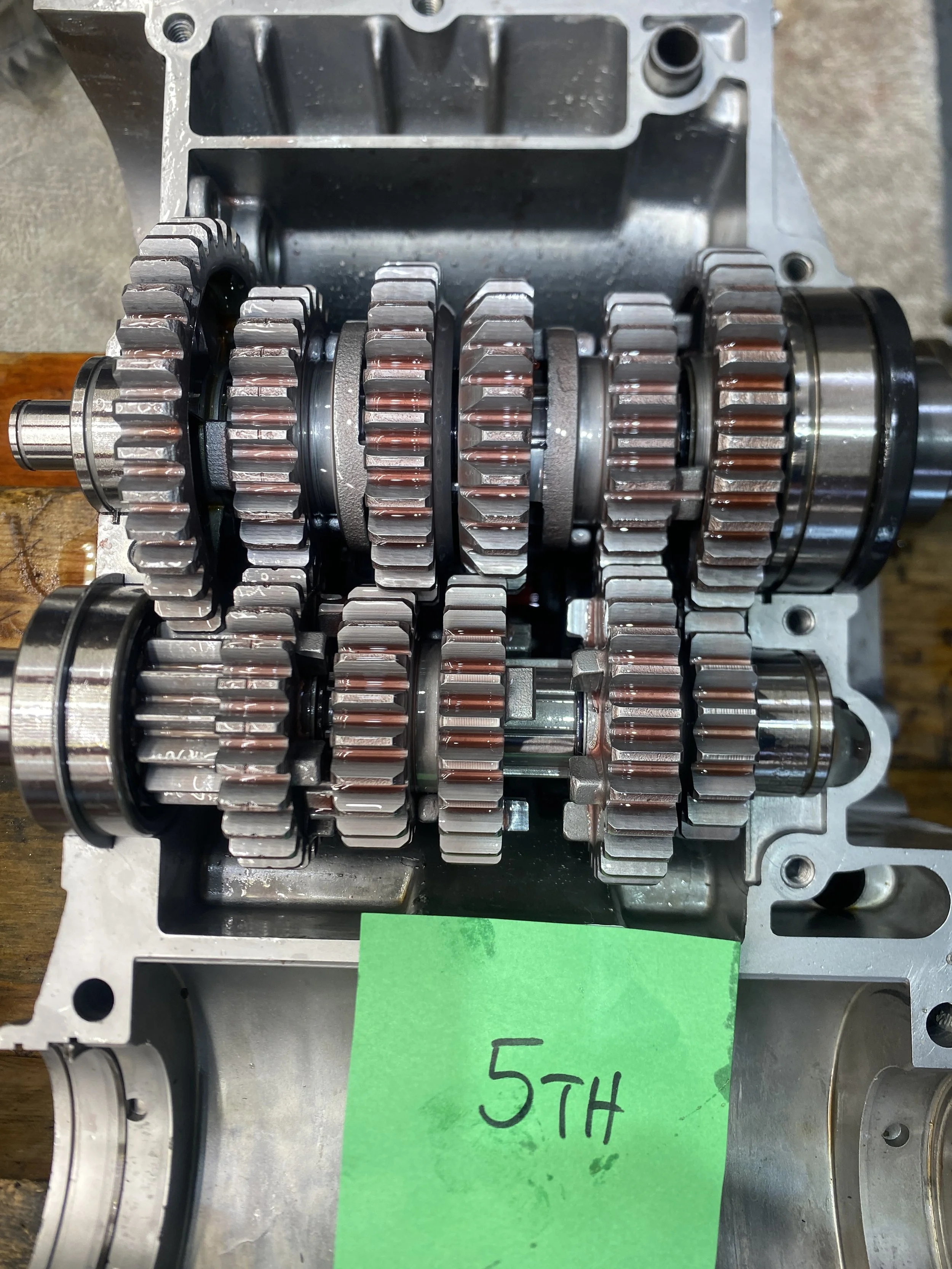

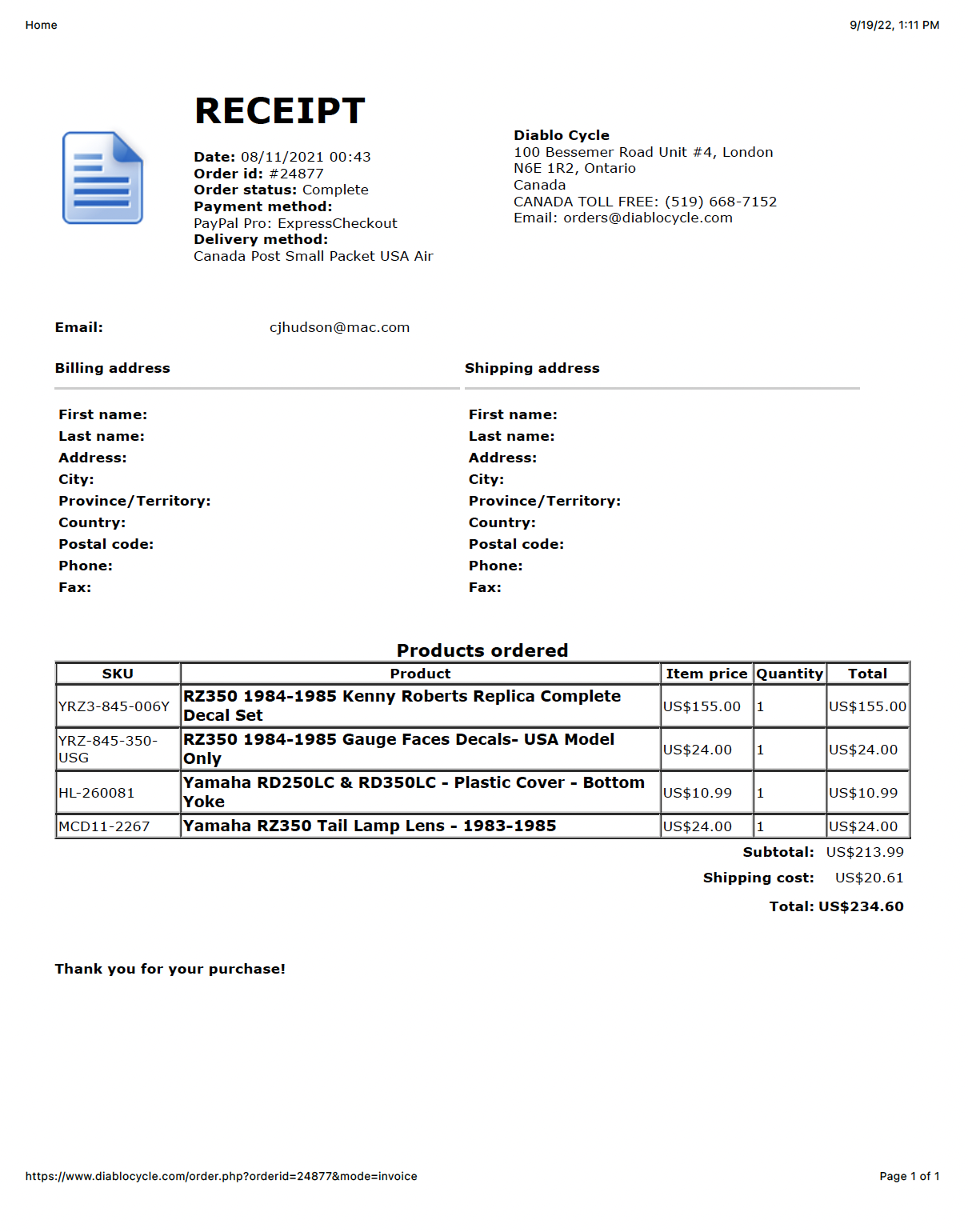

As Of 10/30/22 with the arrival of the refurbished and race-cut transmission from Mark Doucette…..all the pieces are ready to be assembled

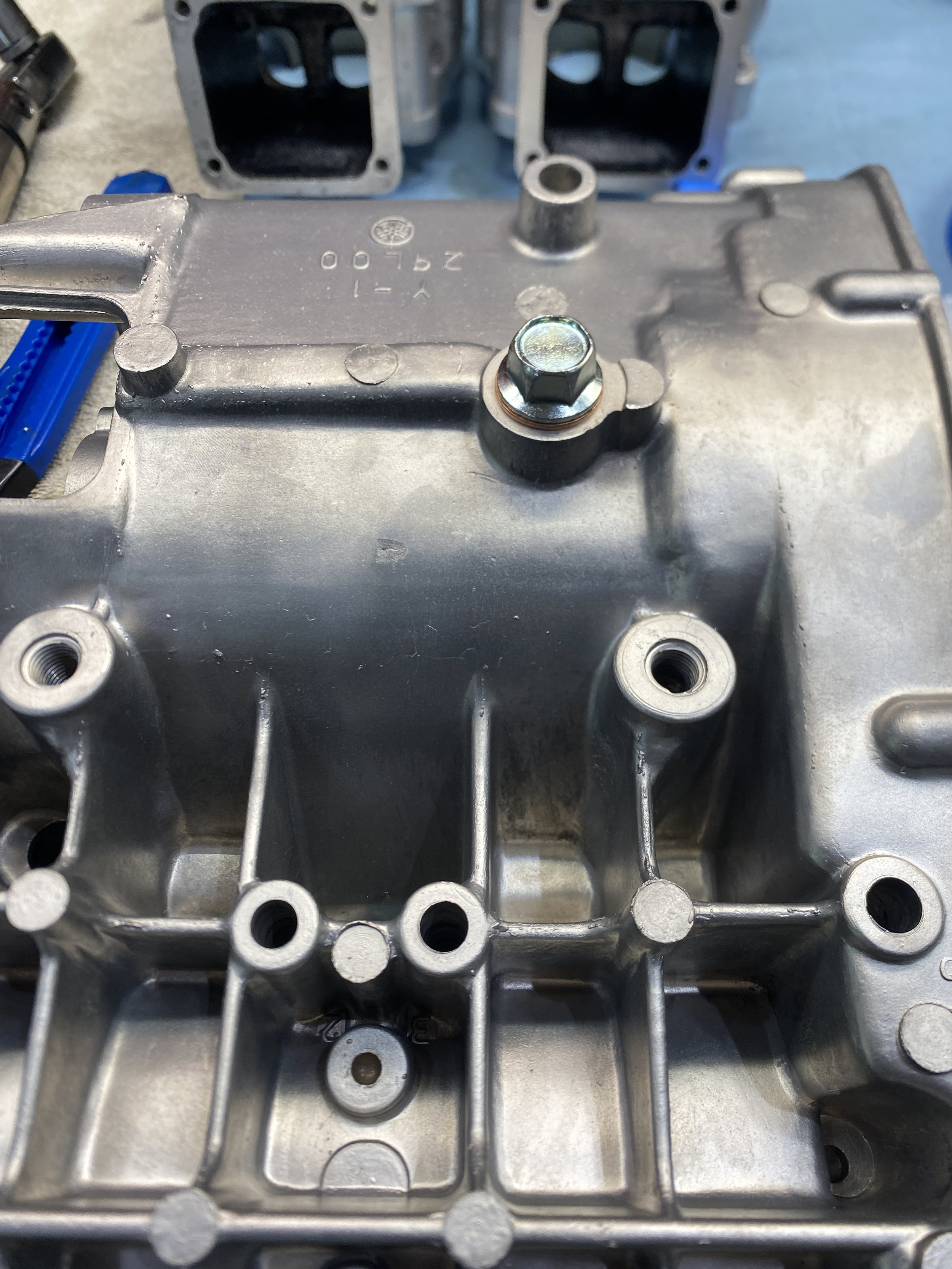

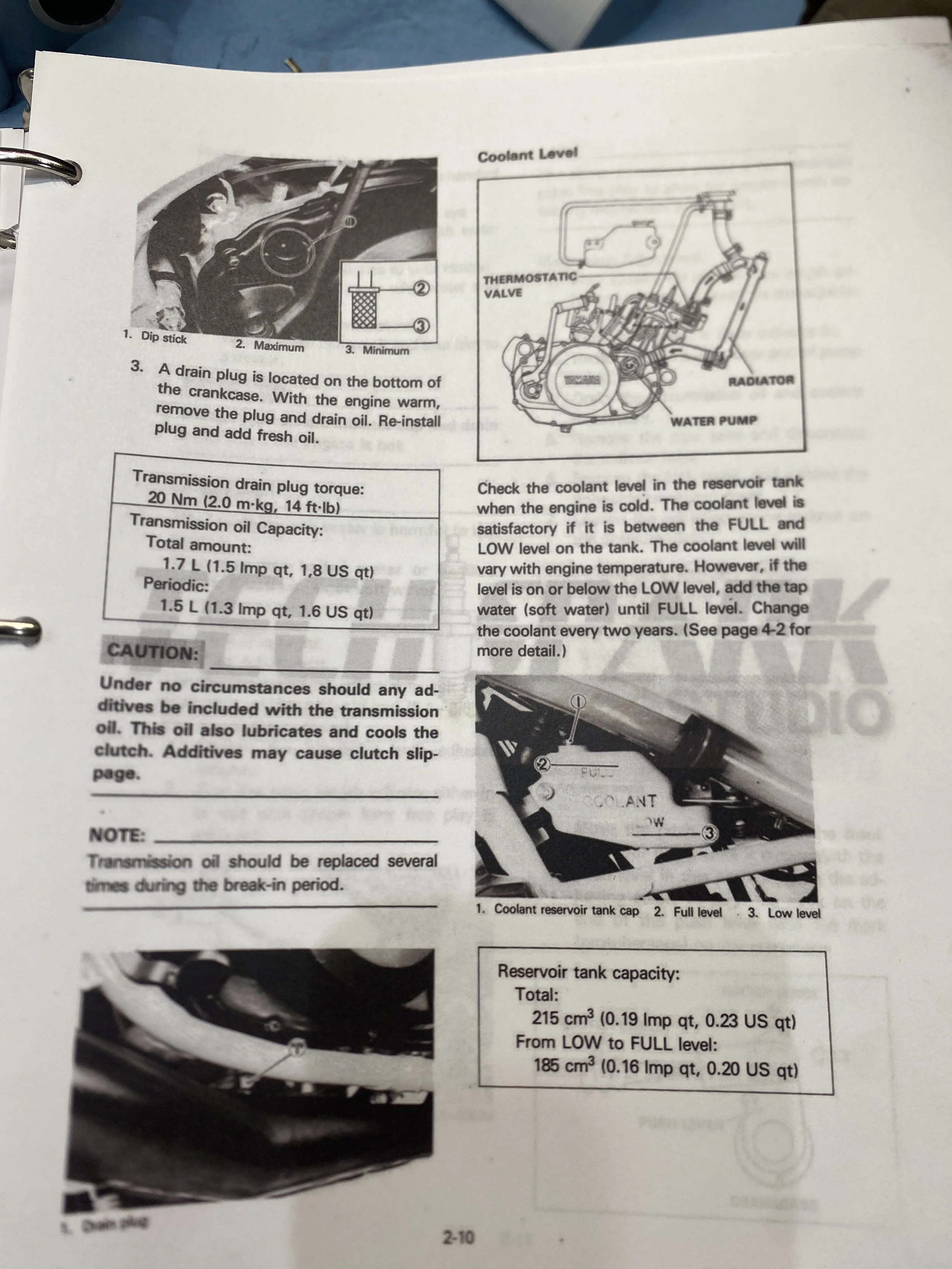

The very first thing to put together. Sump plug with a new washer. 90109-14385-00 SUMP BOLT #10 ON CRANKCASE PAGE 4F4-14766-00-00 SUMP BOLT WASHER #11 ON CRANKCASE PAGE https://www.partzilla.com/catalog/yamaha/motorcycle/1984/rz350l/crankcase

.....and torque to 14 ft/lb. Doesn't seem that much. but will be fine as long as your copper washer is brand new new.

Rare view from the inside of the sump bolt in place.

Time to dig out the trusty Dusty Miller budget engine stand.

Don't tighten it too much.....

....or this is what typically happens.

Clutch

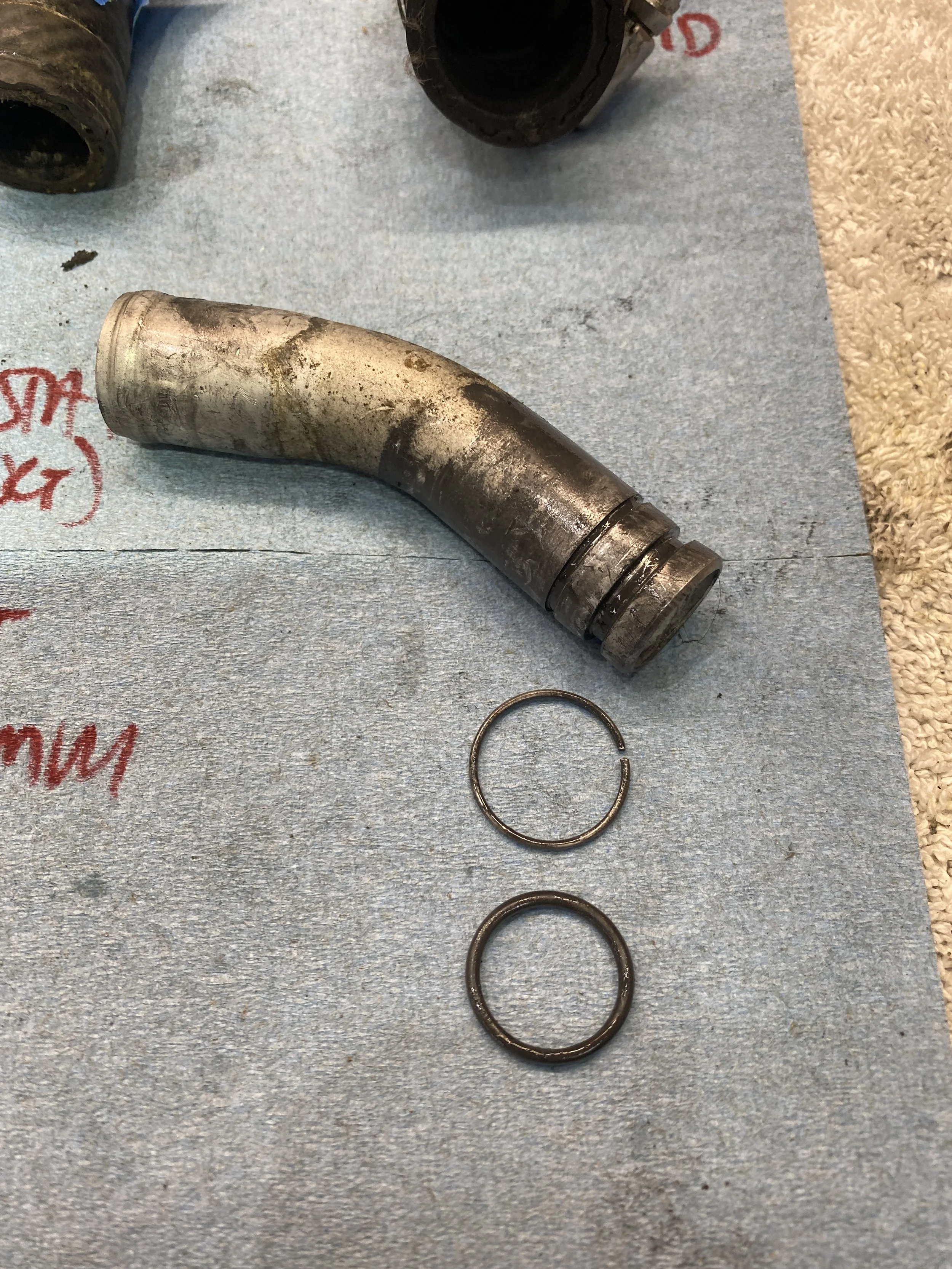

Exhausts

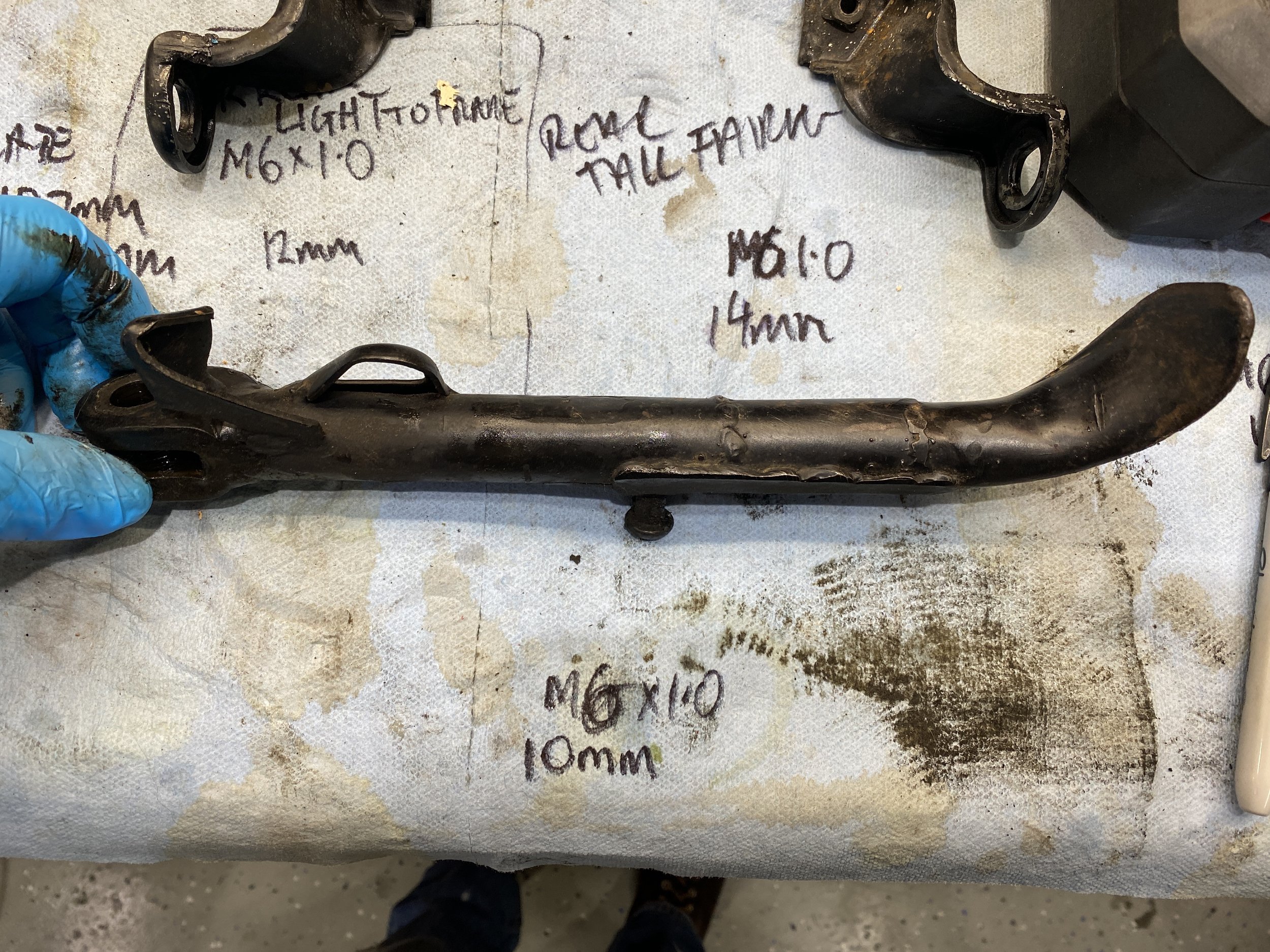

dropped both of these guys off at the sandblasters on 8/18/22. not sure if the Factory's will make it thru a blasting

back from sandblasting. some desparate welds there.

a bit dented but SO light!

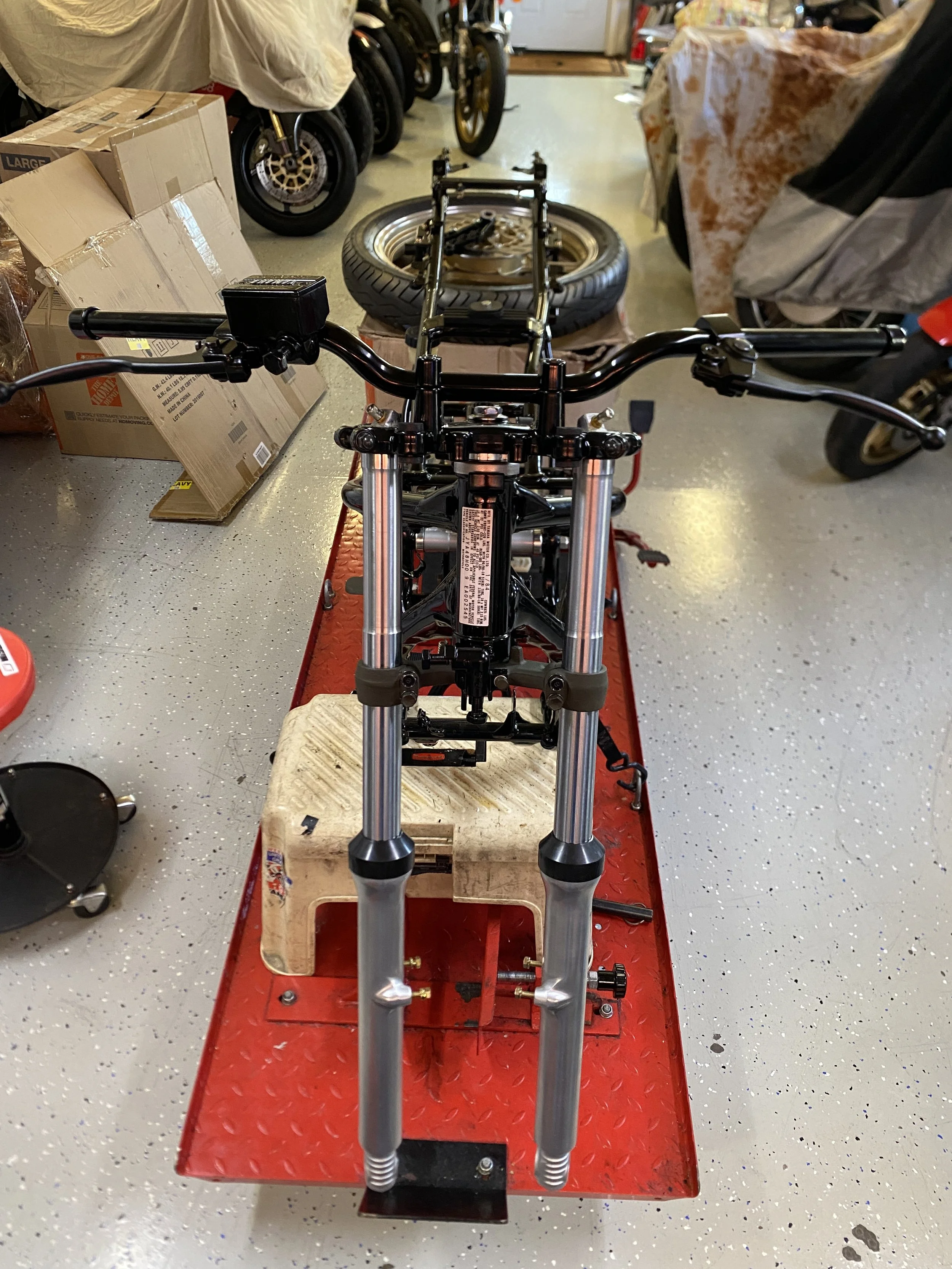

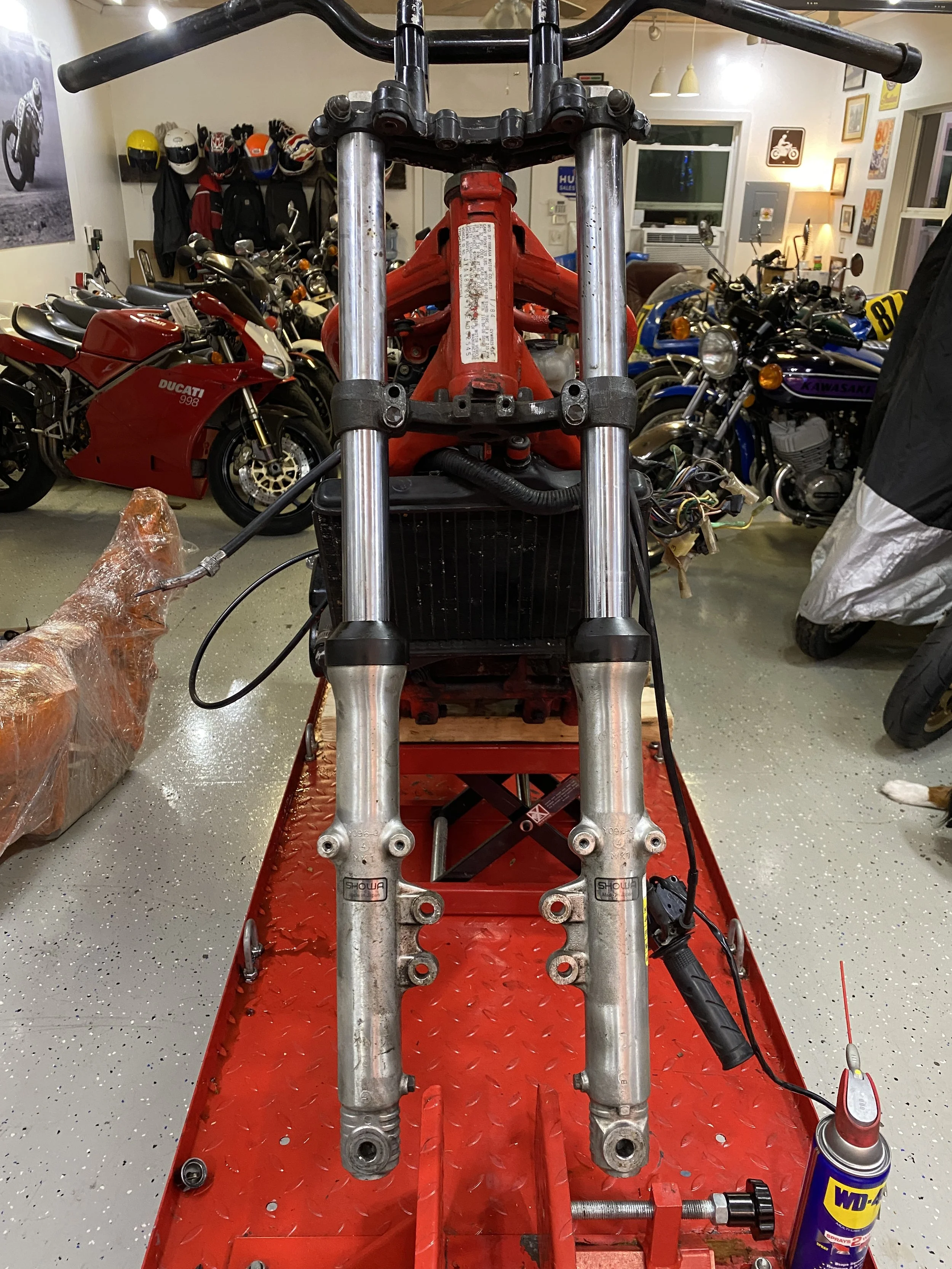

Front Forks

Forks off...

It's sometimes tempting to just polish these up to chrome looking standards, but that wouldn't really be correct. Going for the 'factory finish brushed alloy'

..some evidence of the original finish here...

With the fork bottoms blasted to a uniform finish, started off with 150...

which, as you can see is pretty damn coarse

next stage is 220

both now at 220

on to 400

....800....

and then finally steel wool '0' with WD...i declined to go finer than that as then it's simply polishing...

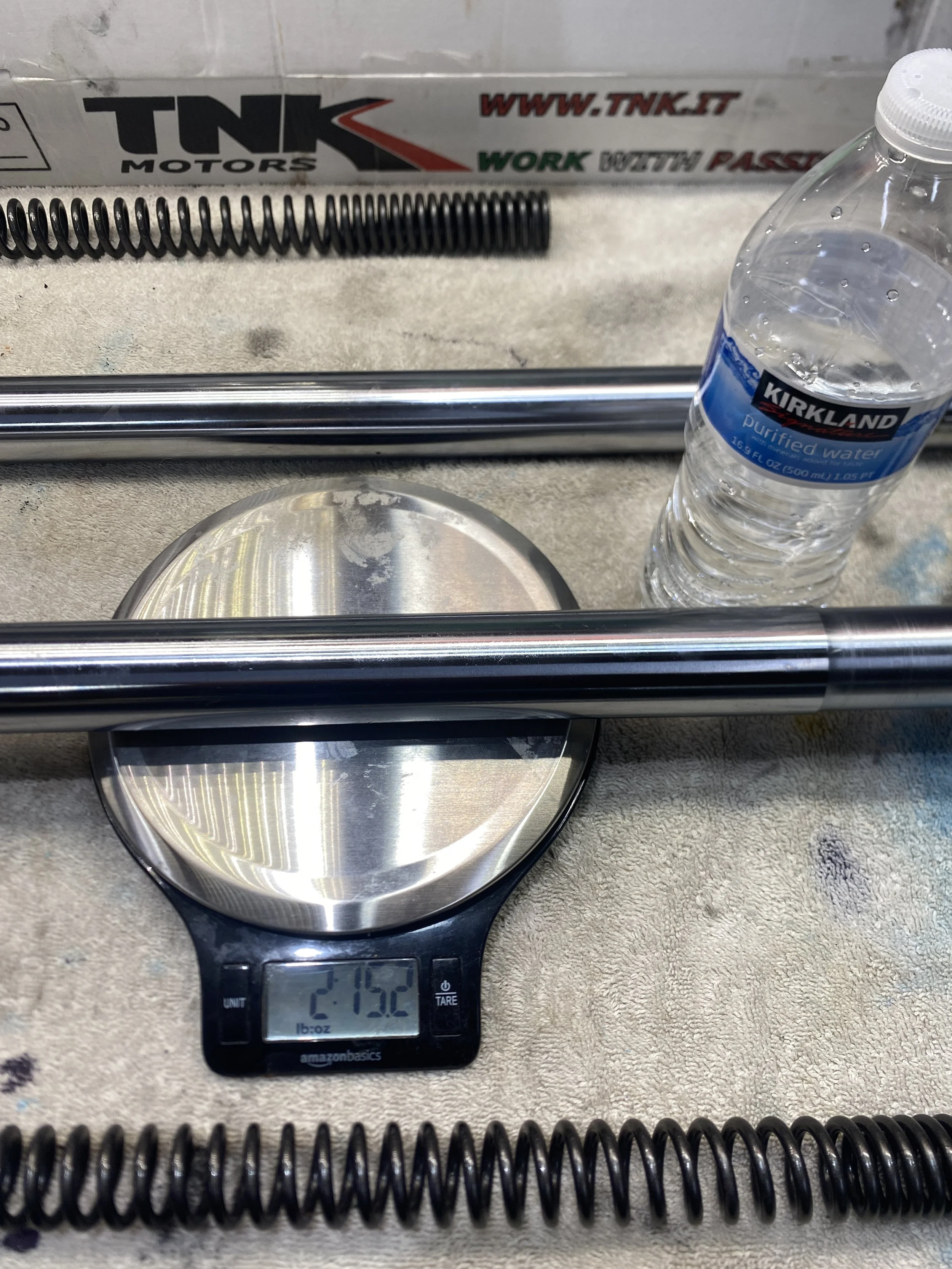

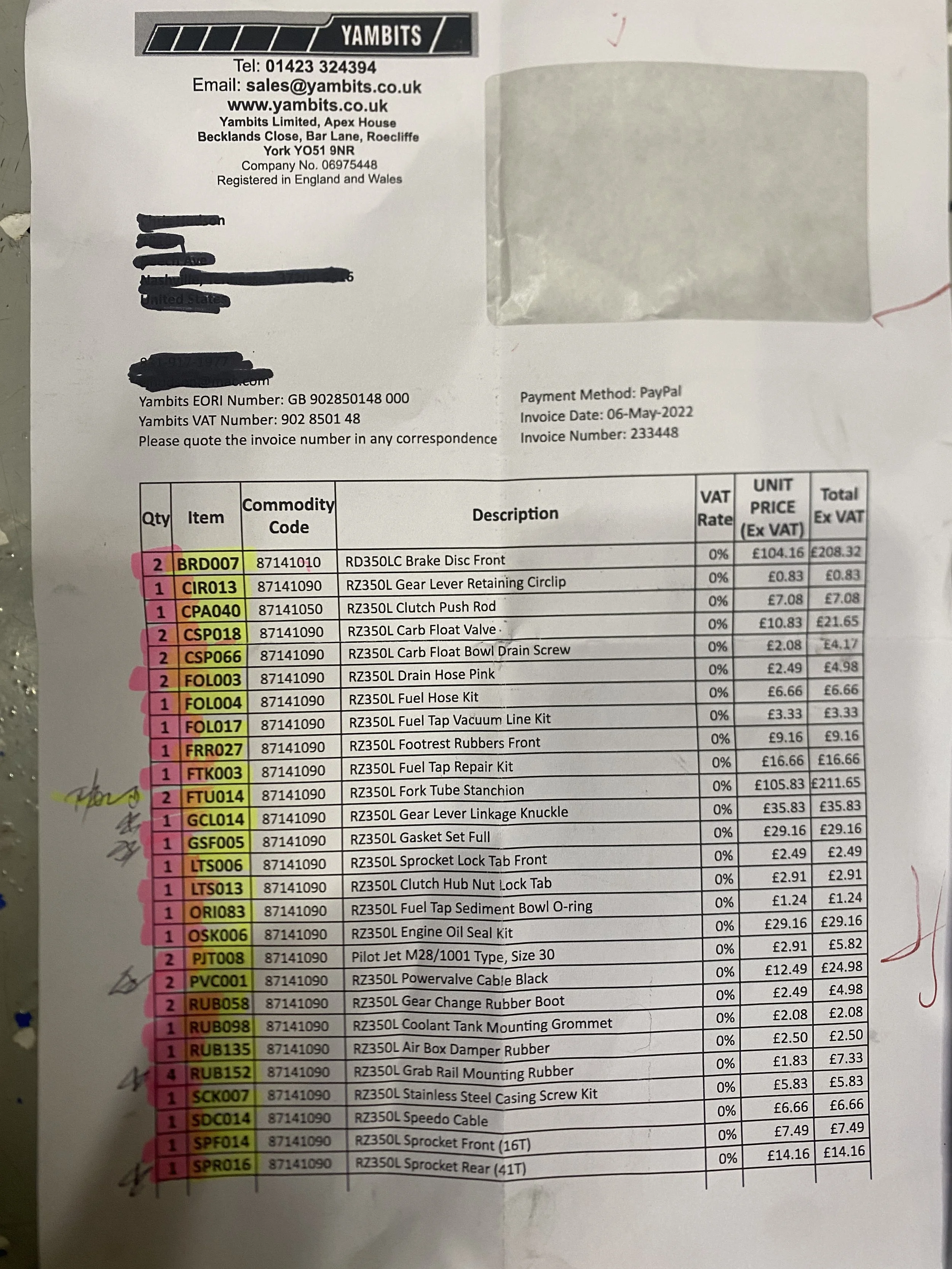

Stanchions from Italy...via Yambits. Springs are progressive so may not be the originals.

Original forks are pitted, in my opinion beyond help, but are heavier (3lb 36oz) than the new ones.

I know there is a place in the UK who can regrind and re-chrome these. Something I might do if the Yambits/Italian forks aren't confidence inspiring.

The new stanchions from are quite a bit lighter (by a little over 1lb) than what was originally on the bike. Concerned? I might be.

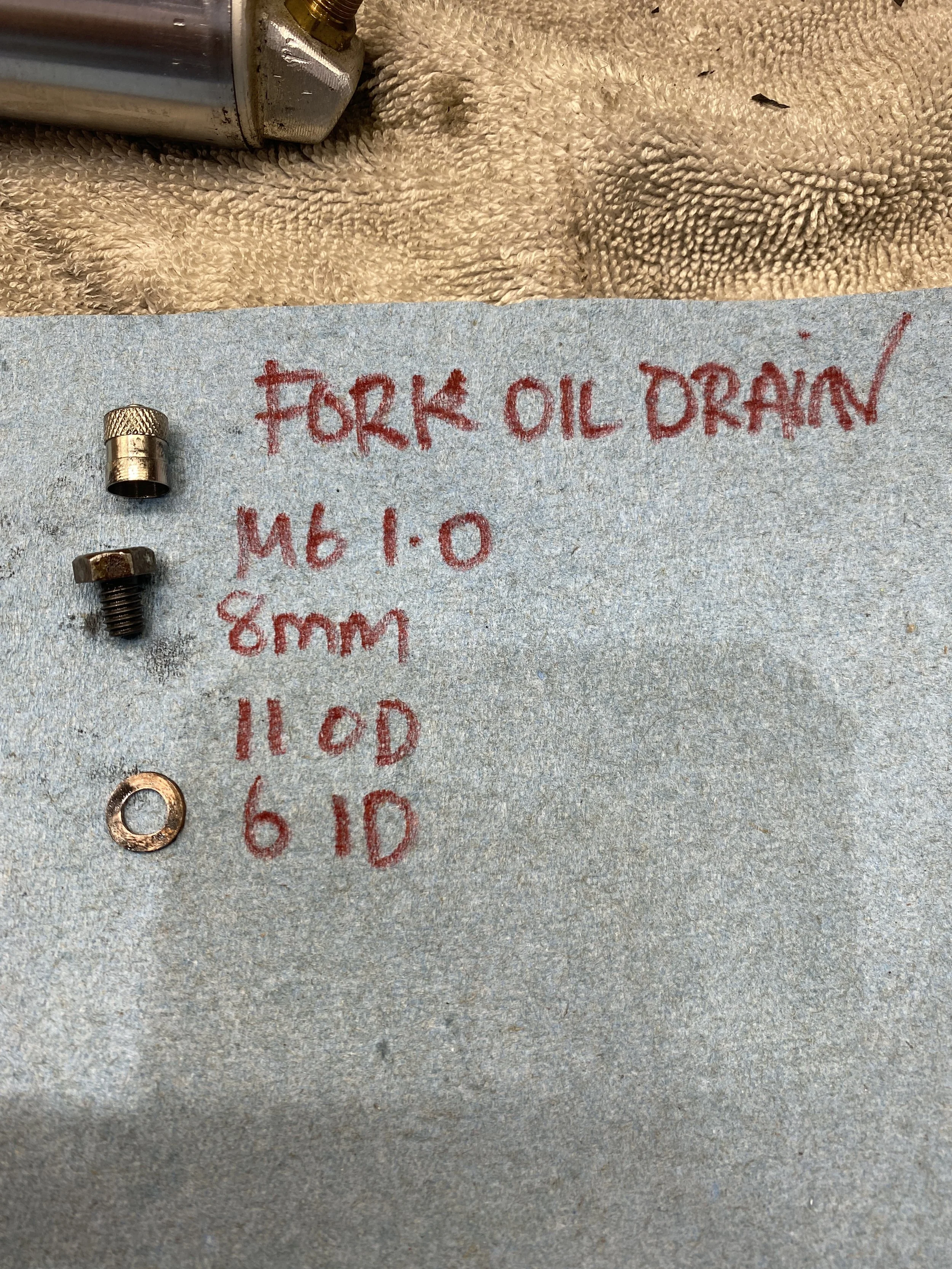

Freshly plated bolts and new copper washers back into the drain holes. Not sure why I thought they should be black but...they are.

The selection of hi kwality parts about to be assembled.

Brand new OEM bushing...

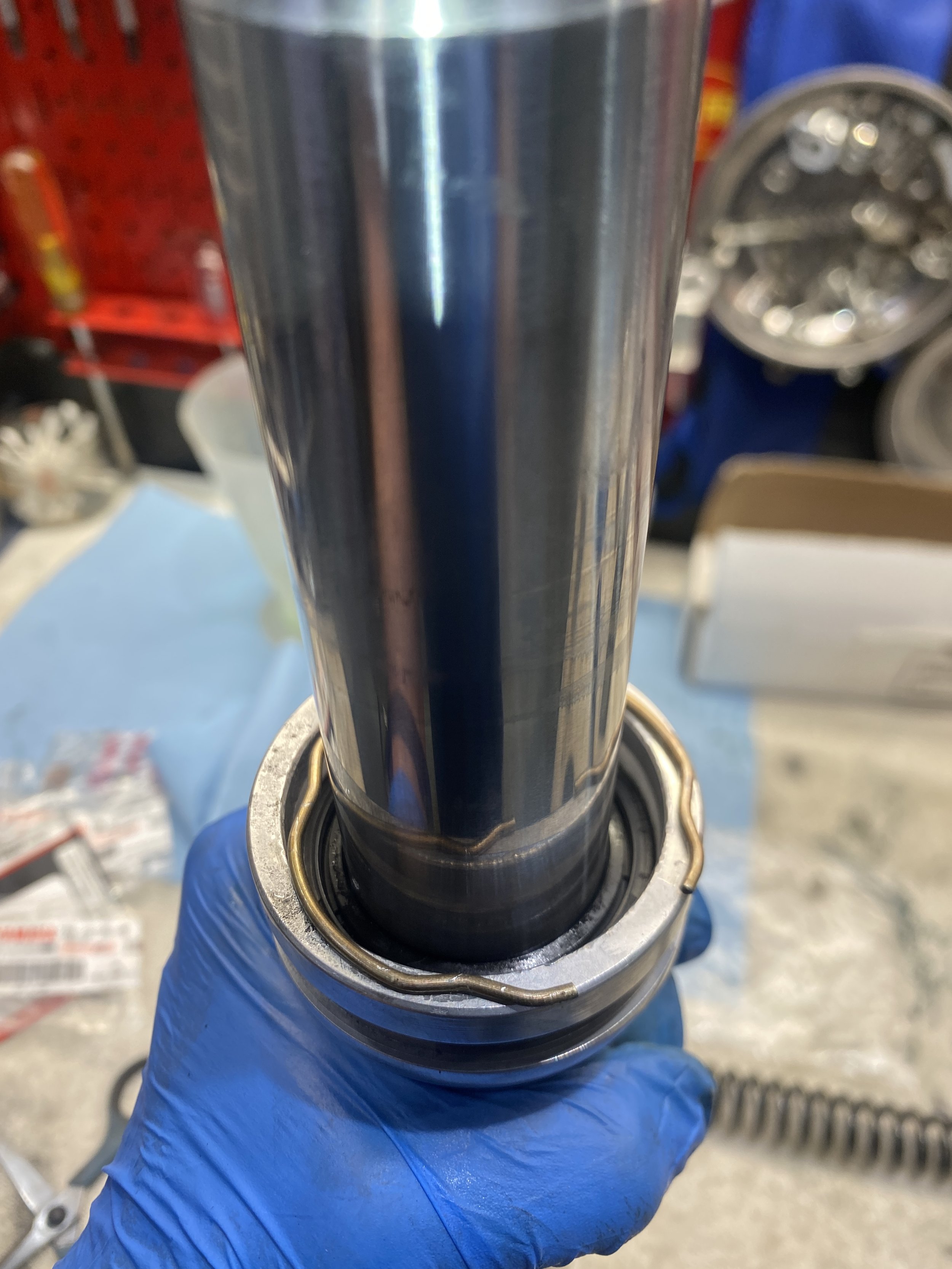

The QR code was more helpful then I thought and led me to a diagram which allowed me to confirm exactly which way you should install the oil seals. It's not completely obvious.

find the double lip and make sure it's that edge that goes towards the oil....

some plastic over the end of the fork will prevent the lips of the seal being torn

All prepped for install. From the left of the pic...oil seal, washer, top 'copper' bushing, bottom 'coated' bushing, oil lock spacer, copper washer and M10 allen head bolt lightly coated with some blue loctite asa recommended in Factory Manual.

with all of that in place and the allen bolt installed and tightened...35-36mm MotionPro oil seal driver ($52.99) comes into play. Alternatively, as Ken of Kens Garage will tell you that 1 1/2 inch Schedule 40 PVC pipe with a male pipe thread adapter on the end will also work. (https://www.youtube.com/watch?v=hKs44zeVVDs)

Easy to fit circlip in place.....

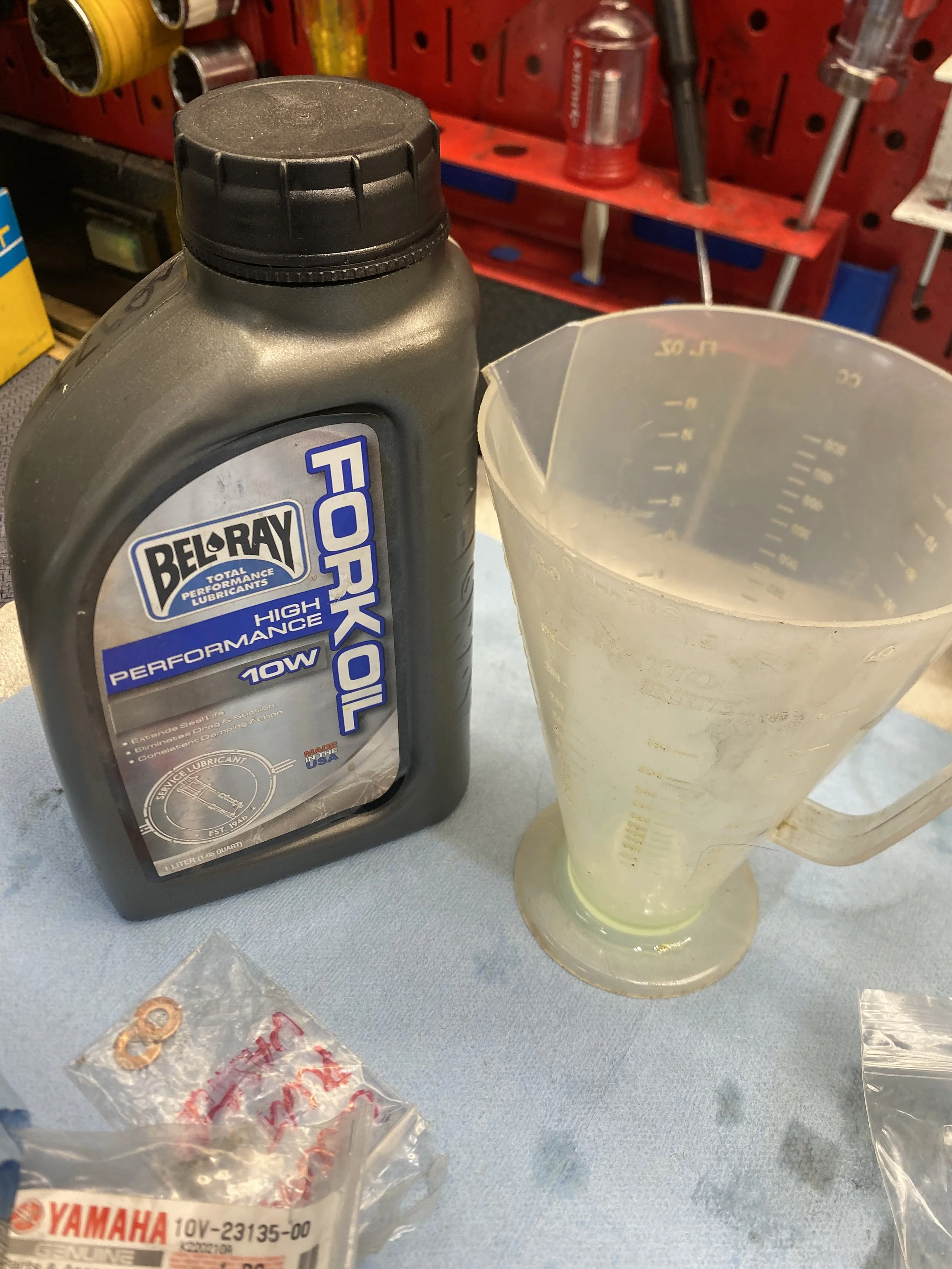

Next up....fill with recommended 250ml or 8.9 US Fluid Oz....

..of Belray 10w Fork Oil.

Motion Pro oil height gadget which allows you to measure the 120mm oil height. Syringe not pictured.

I was excited to slide one on....

and then like a saddo, sat for a while admiring it and listening to tunes. I don't care who knows it....was a great Saturday night. (9/4/22)

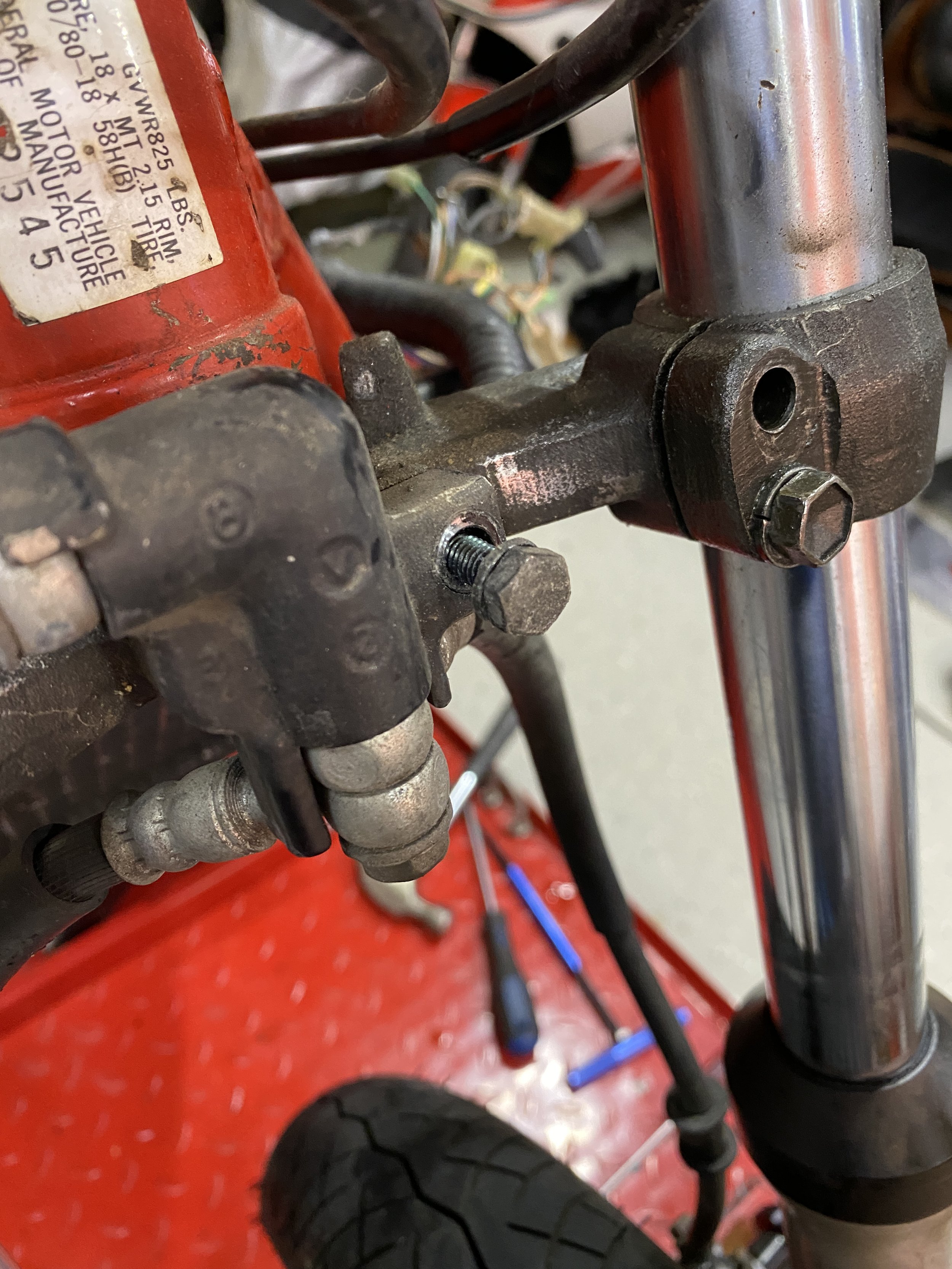

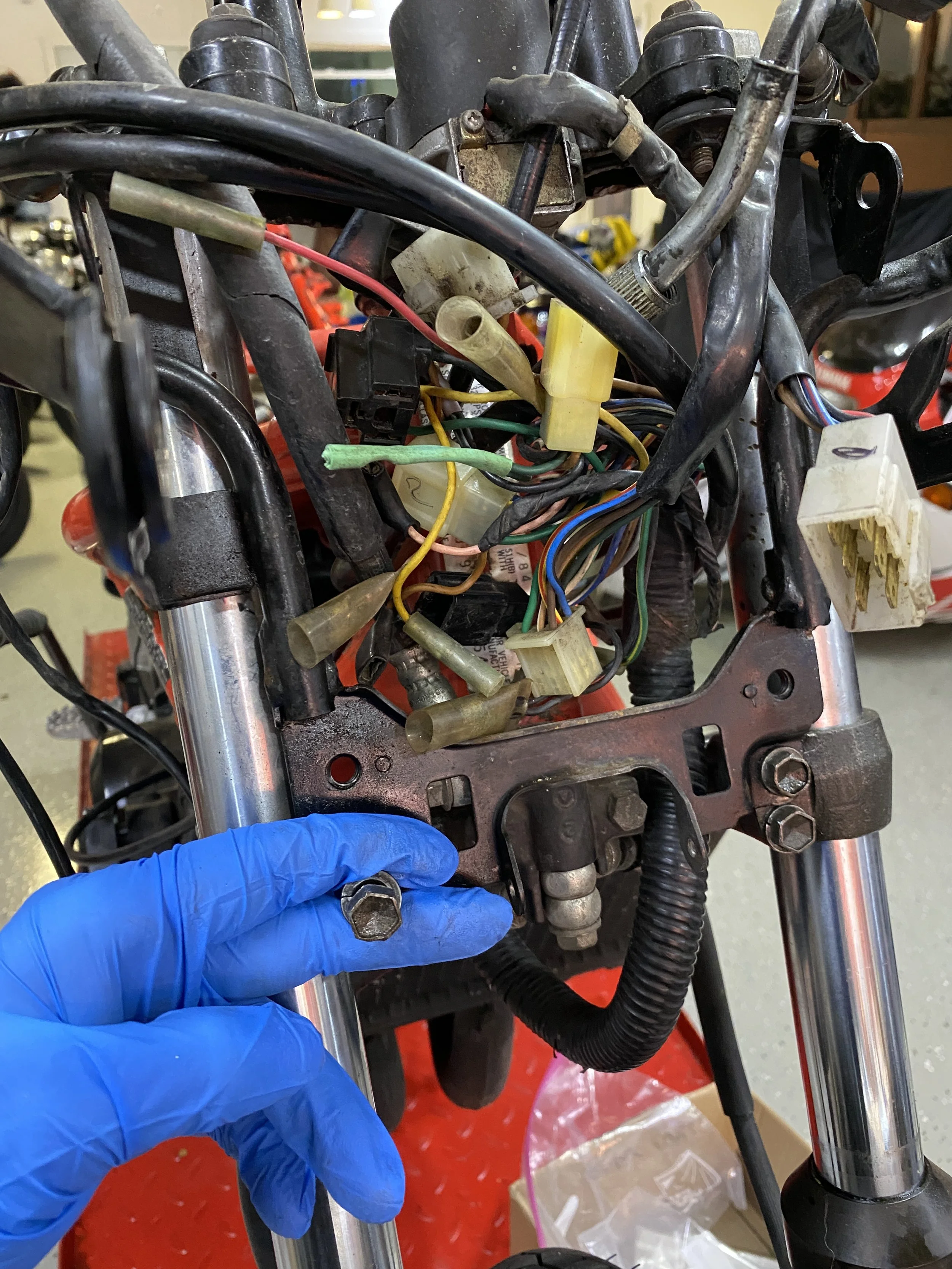

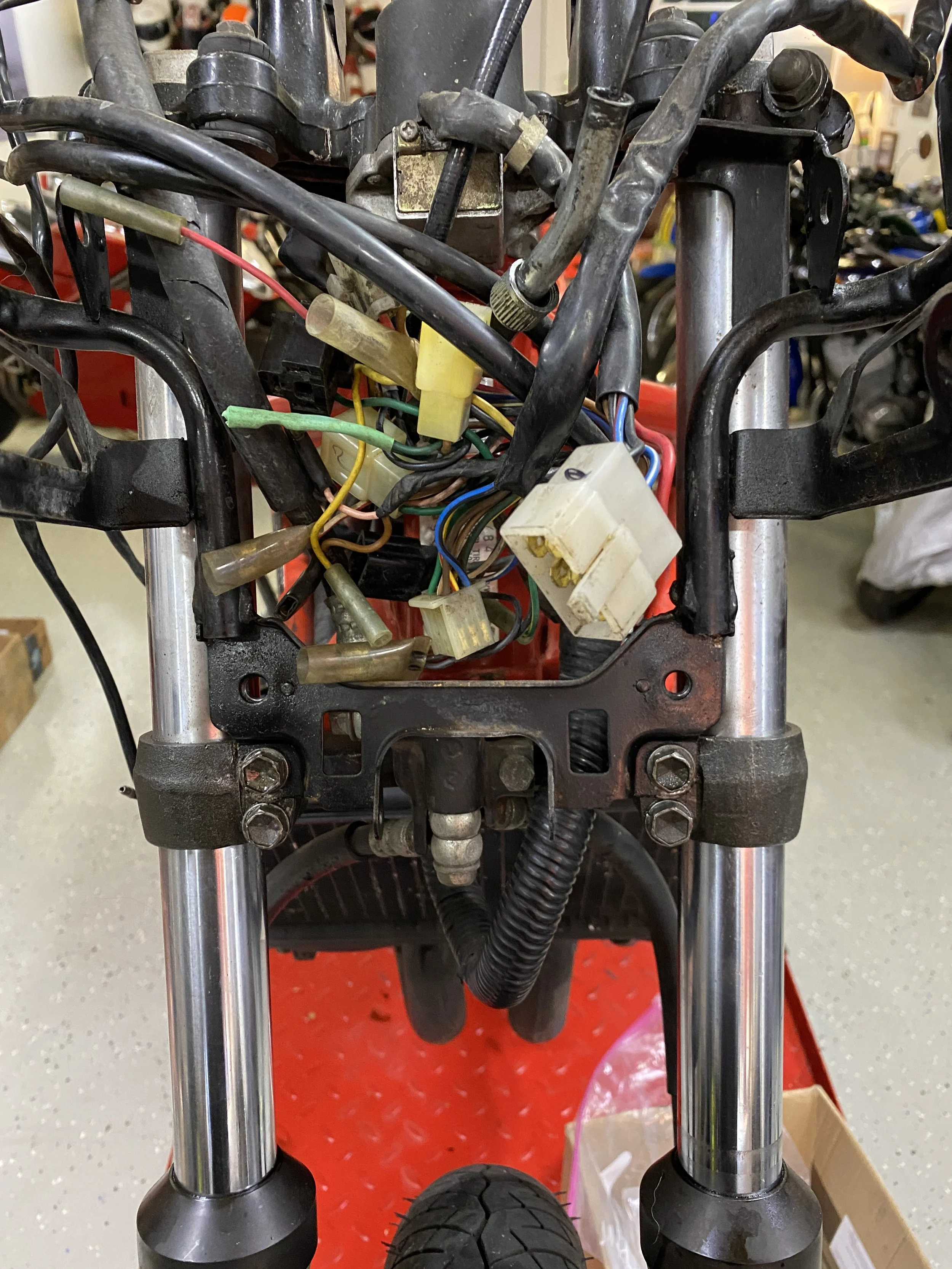

Front End

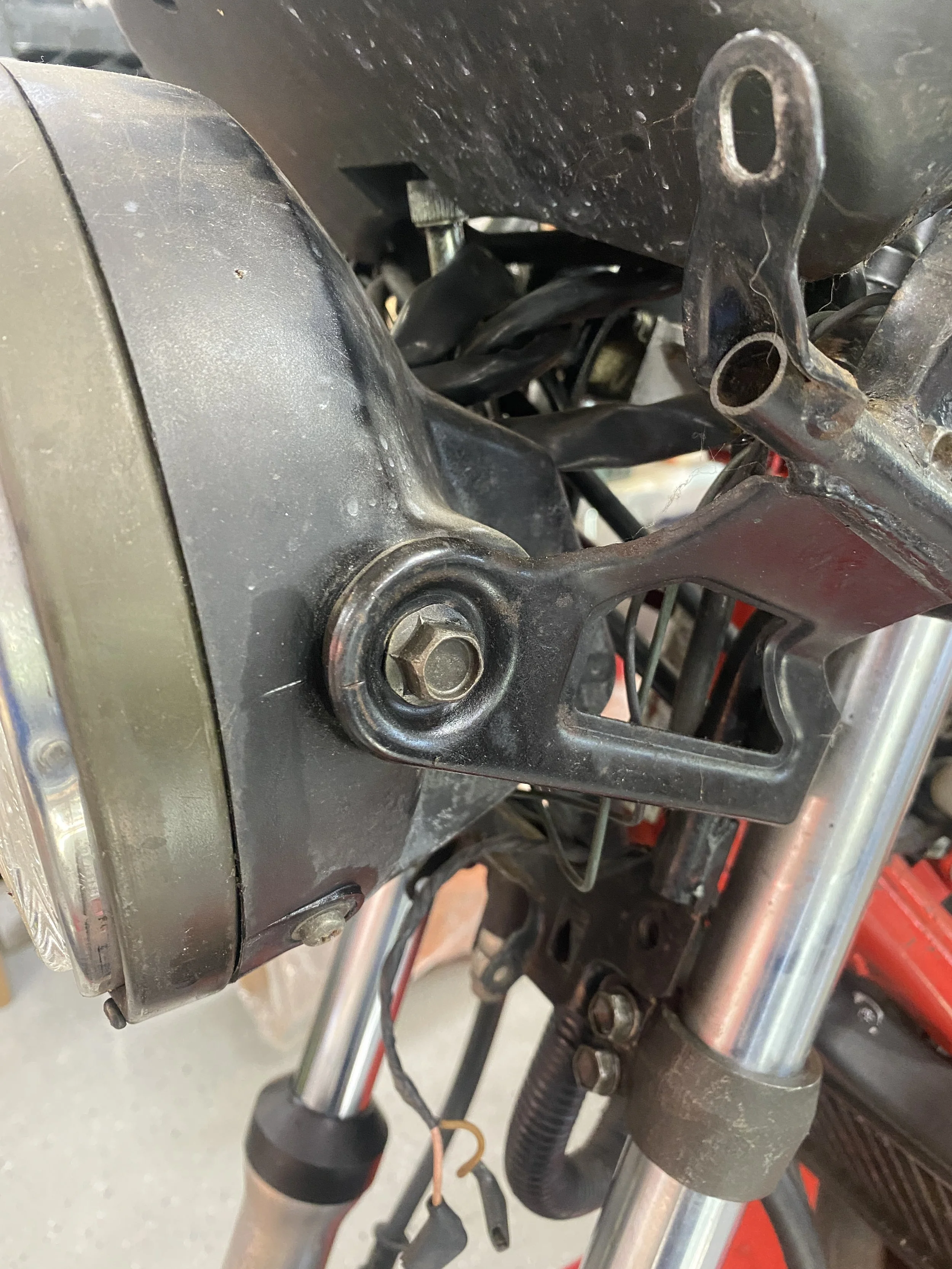

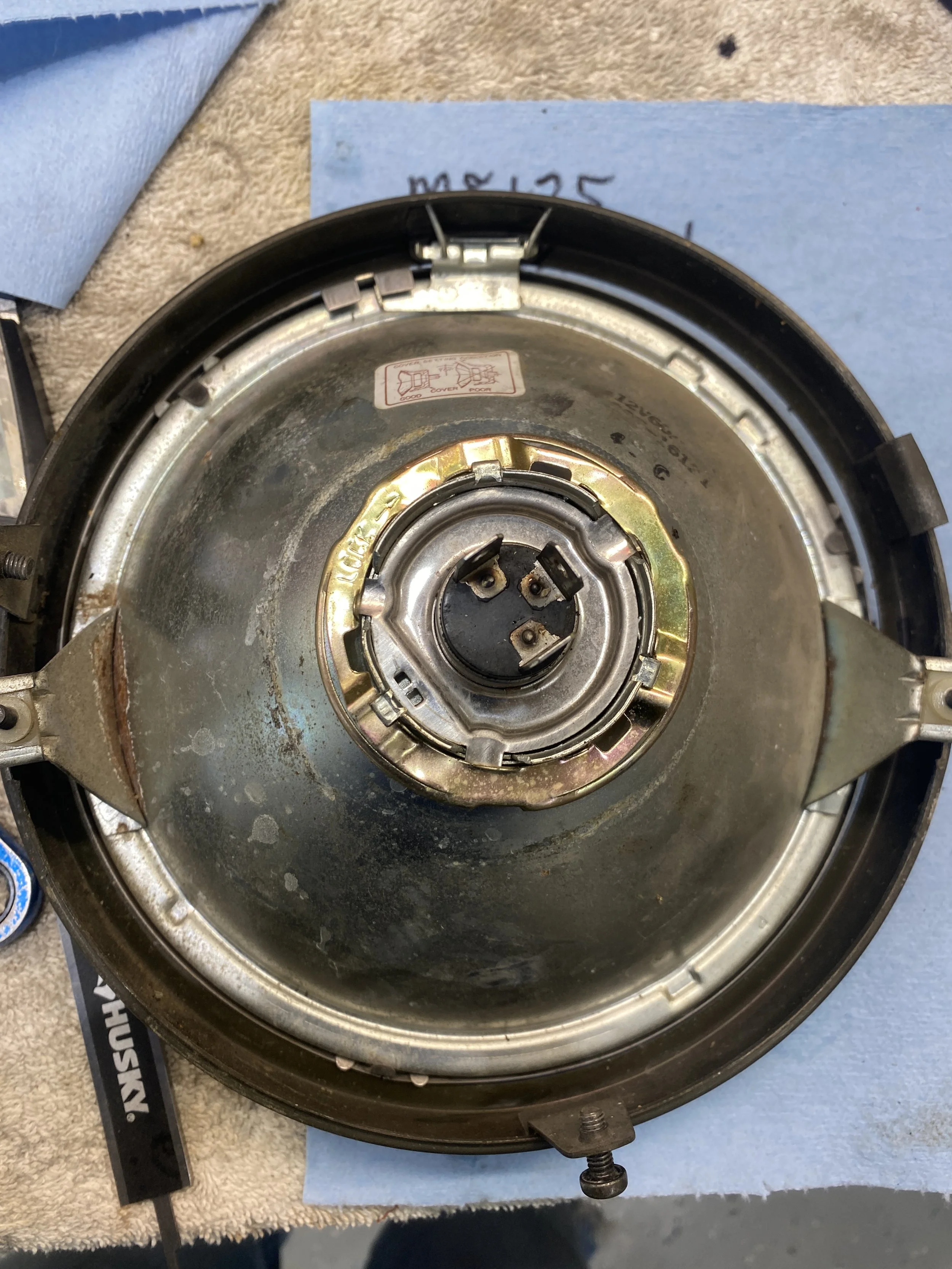

8/21/22. Outer shell cleaned up....mated back with freshly cerakoted headlight rim and newly plated screws....

and springs in place...

as good as it can get.

Helmet & Seat Latches

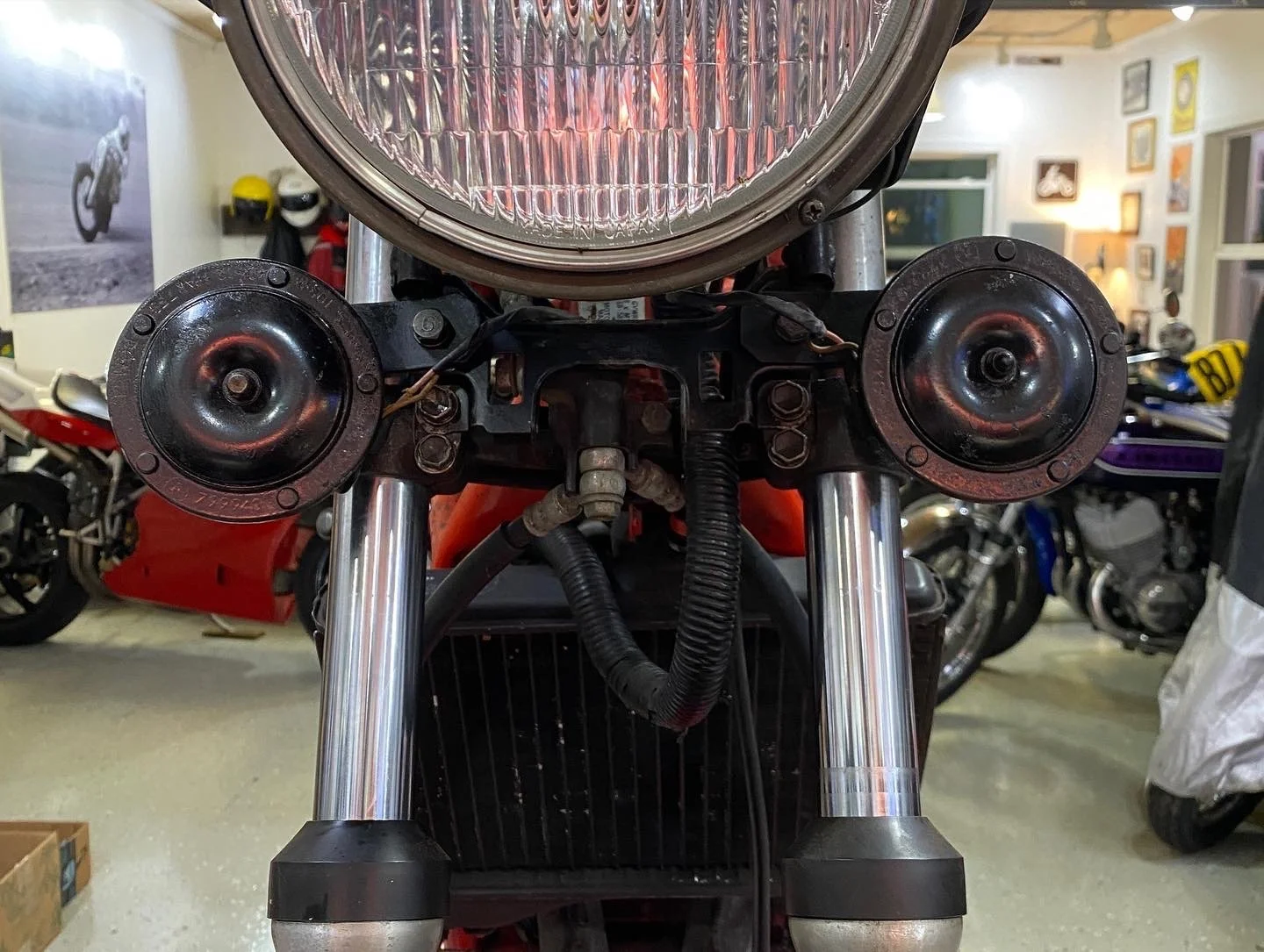

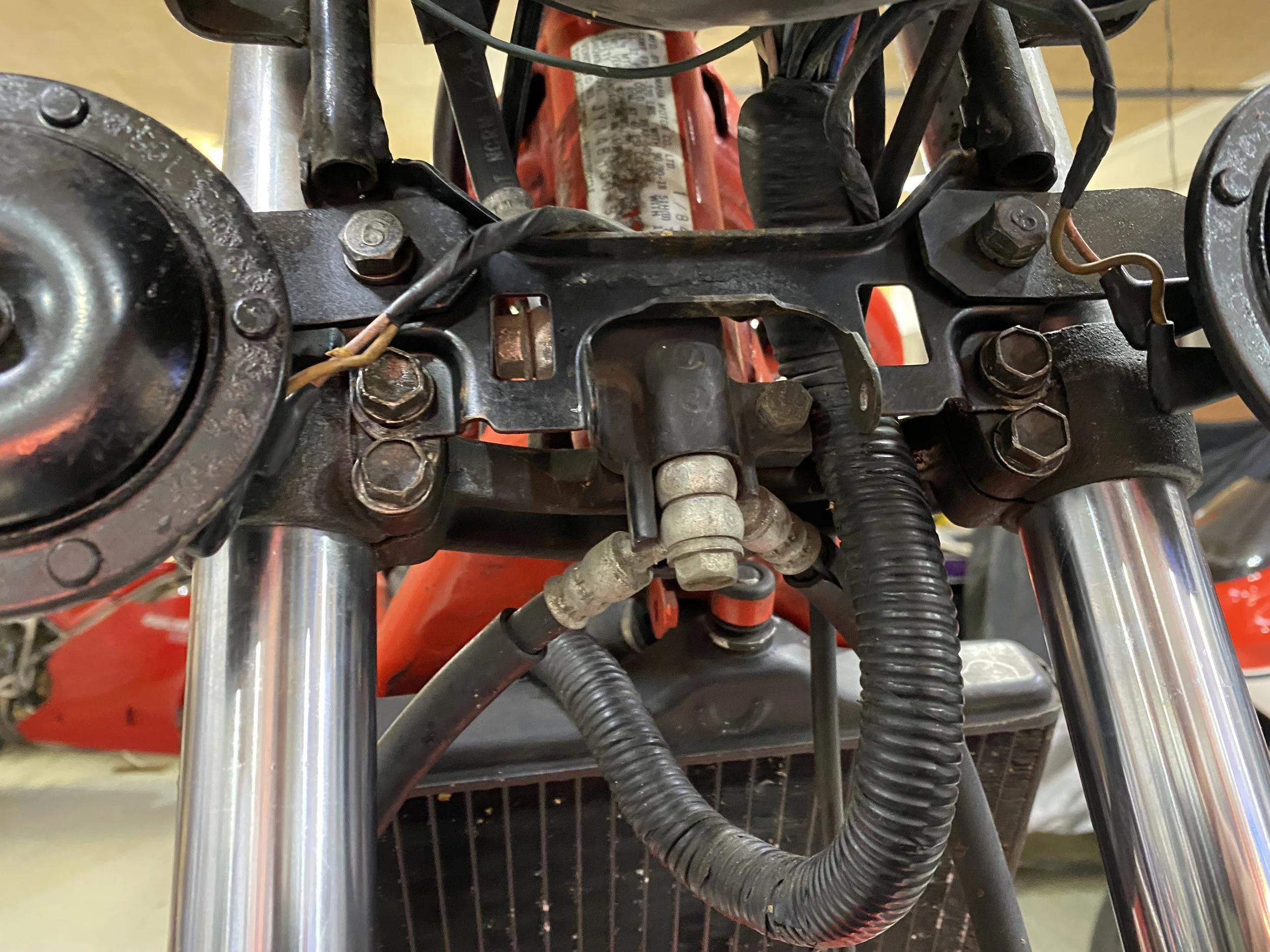

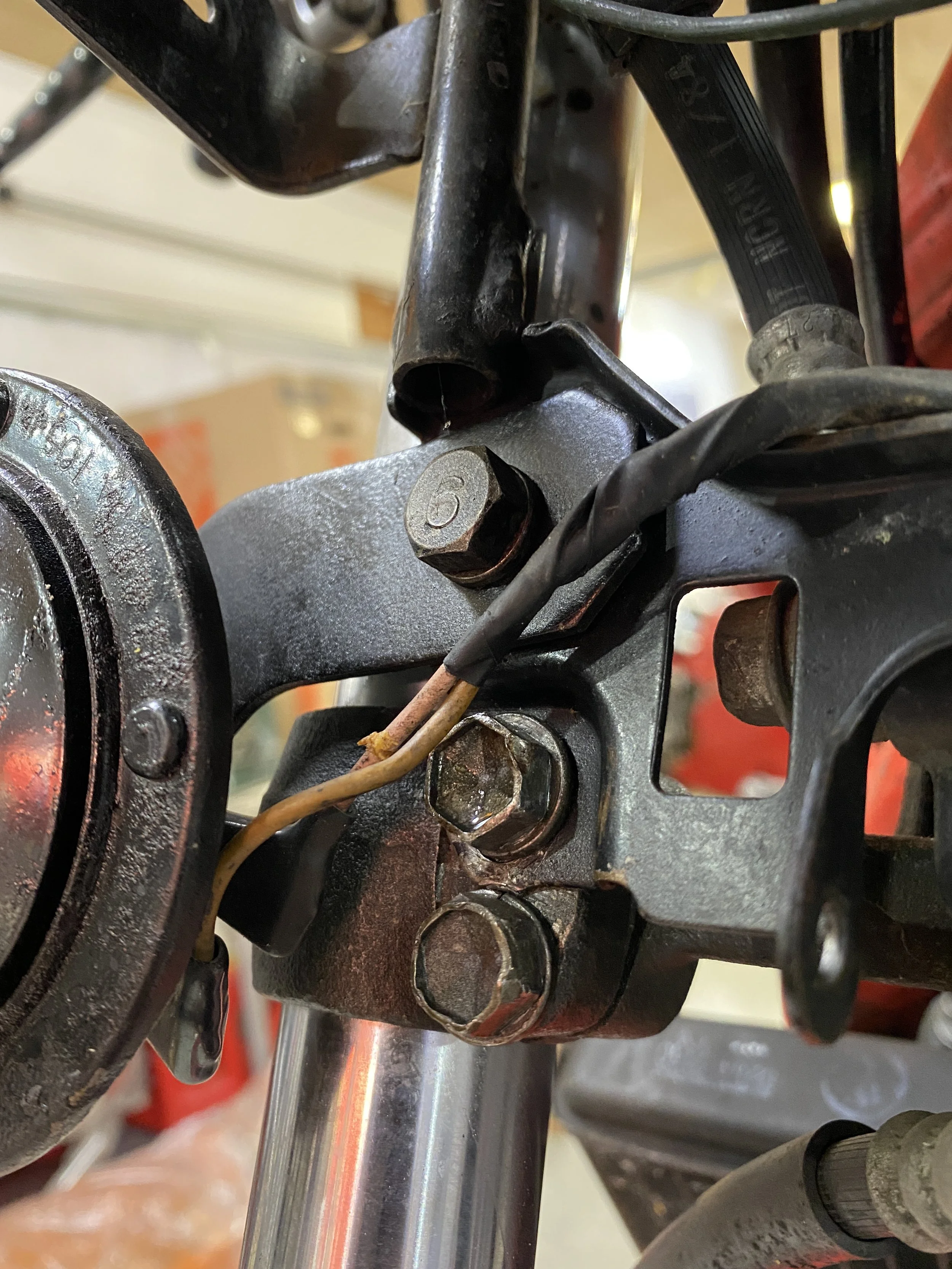

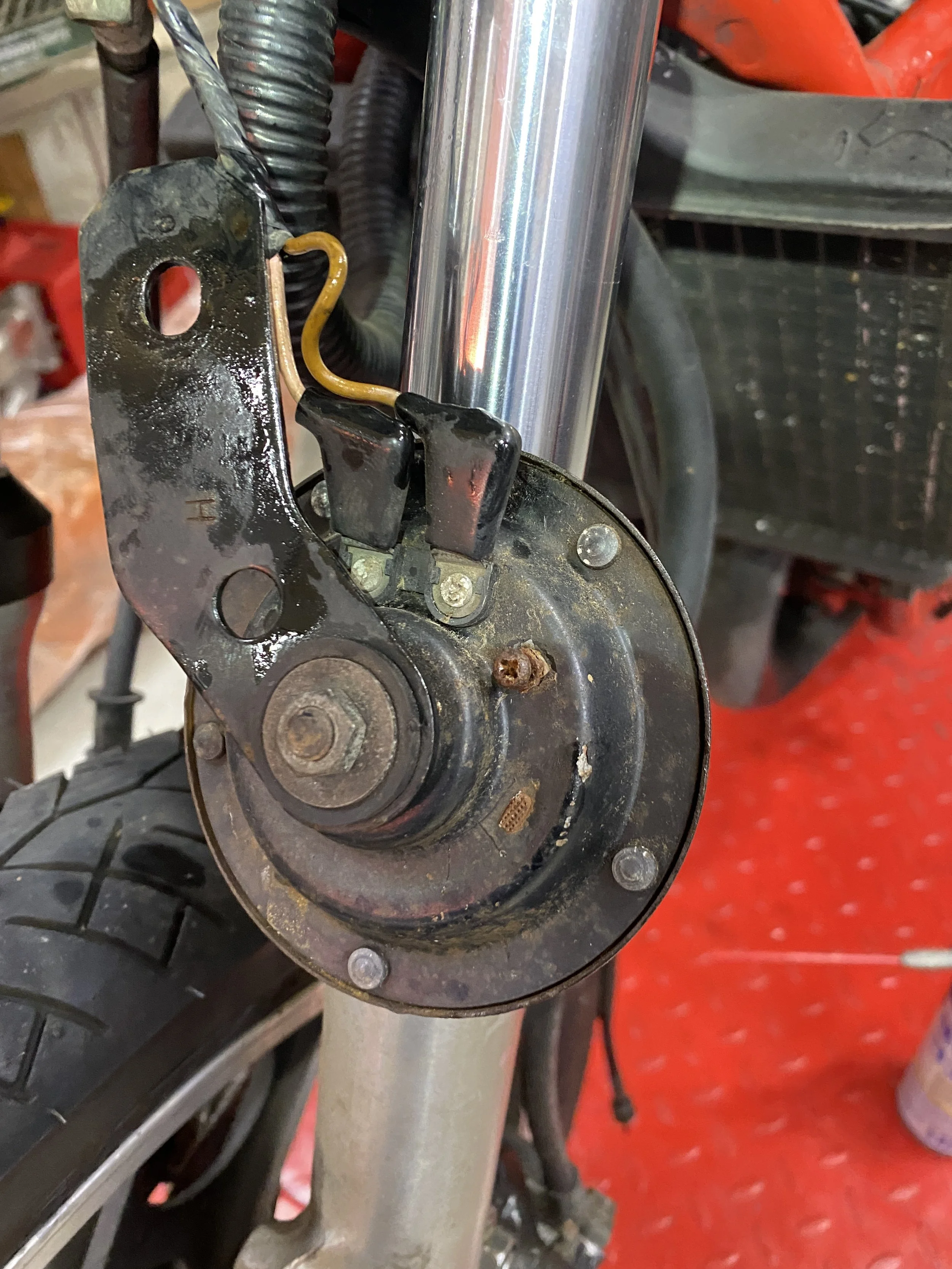

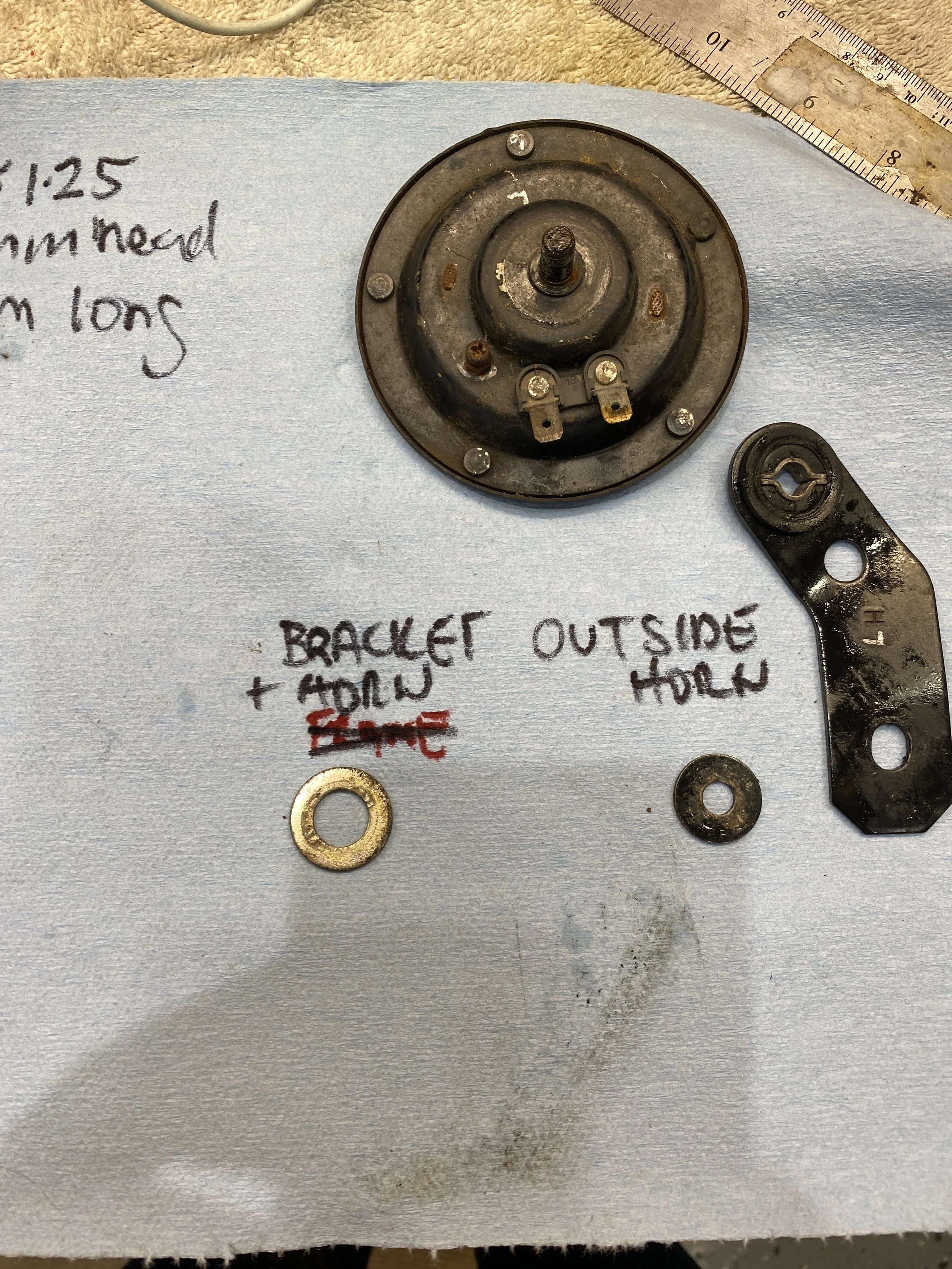

Horns

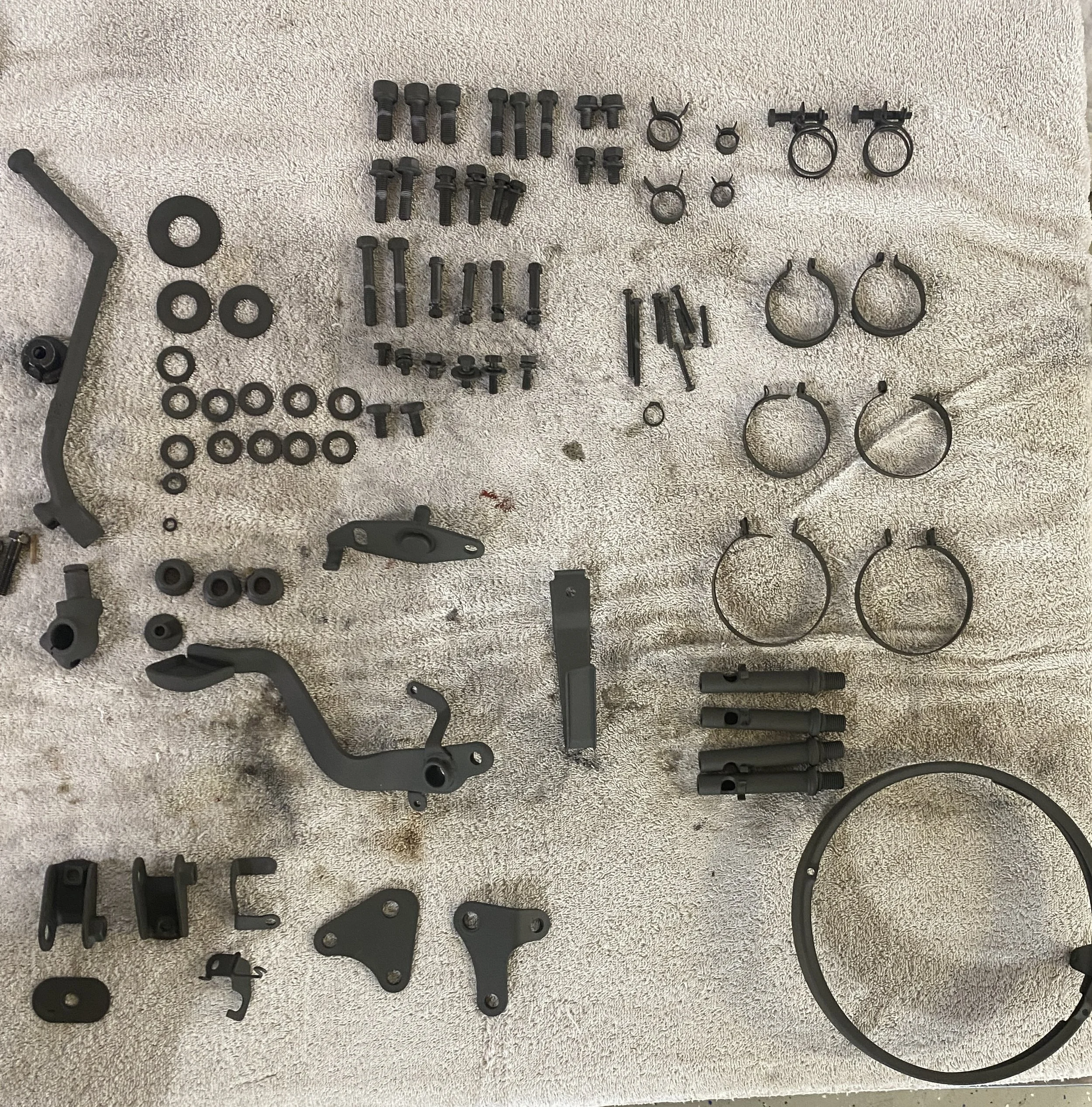

Powder Coating & Plating

Also dropped off the calipers with Brent on Thursday Aug 18th. 8/18/22

and these just to be sandblasted 8/18/22

also dropped these bits at the platers.

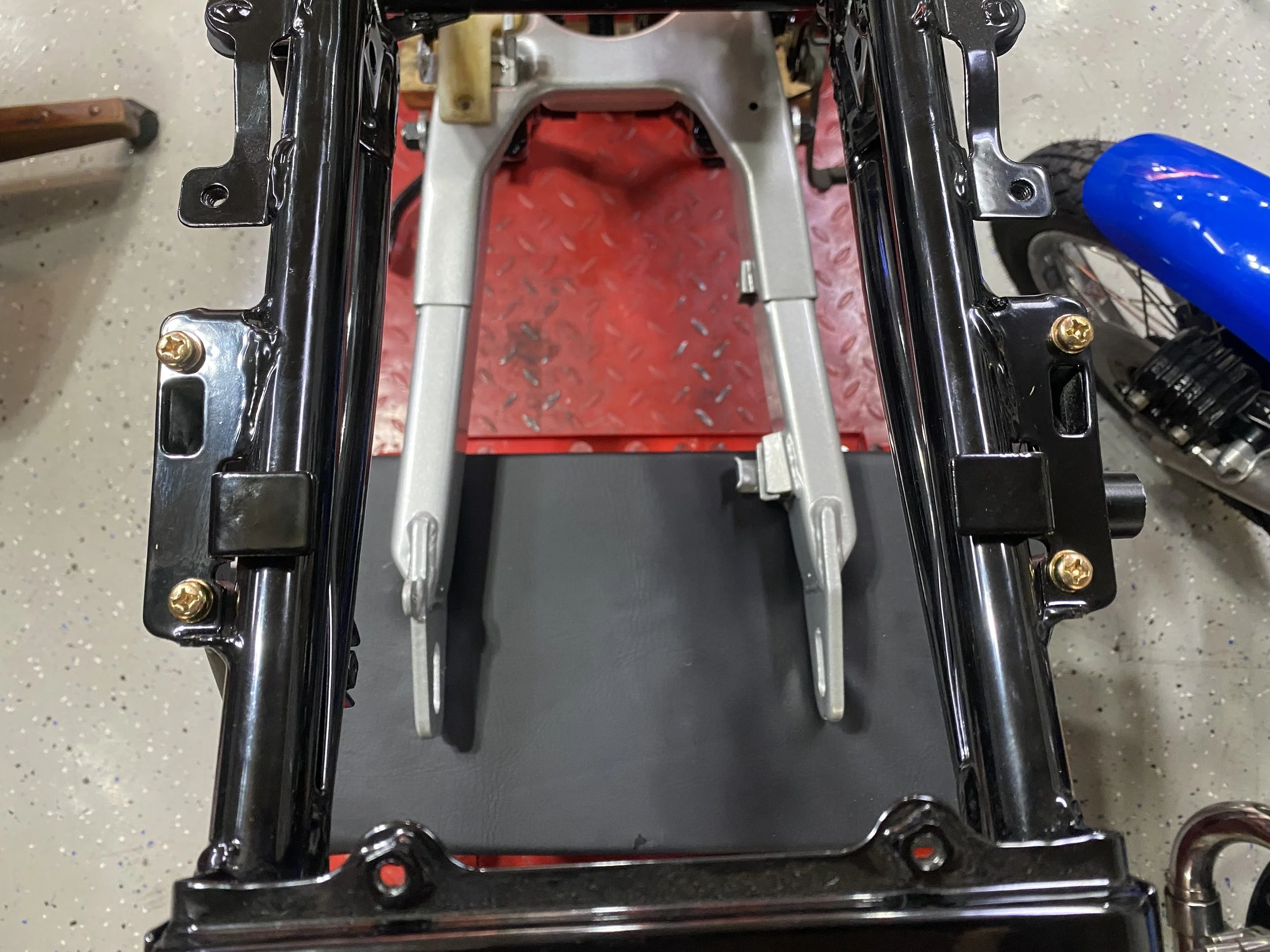

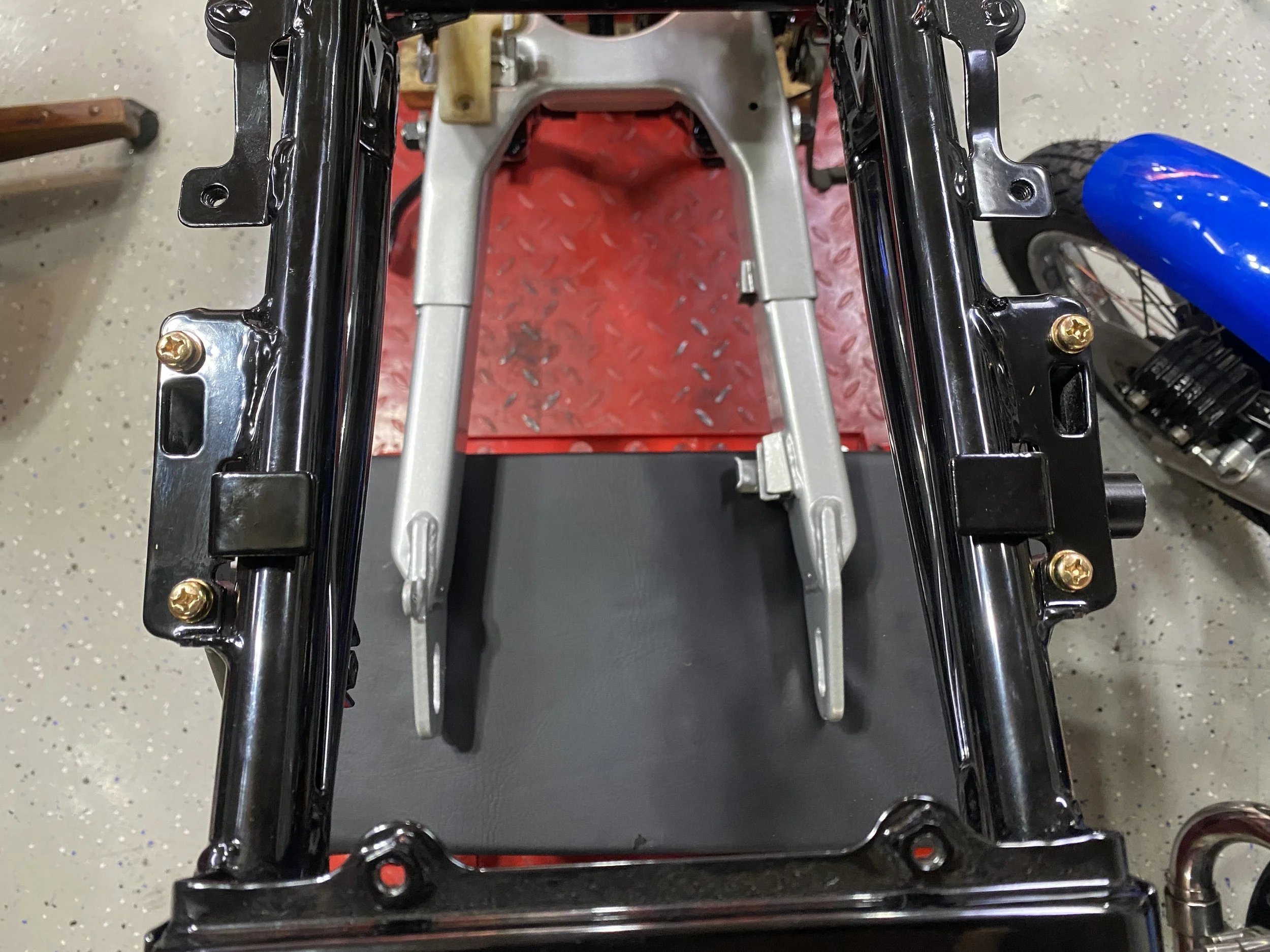

Frame and swingarm back and look amazing.

Factory rubber bung. Best center stand in the garage. So much leverage with that long leg...

triple tree top is gorgeous

side stand and replated spring

dog legs and everything but the shock

Will at https://www.royalrangeusa.com/ did an amazing job of matching the correct shade of olive drab plating but using cerakote. Genius.

pic from our original meeting comparing shades.

Rear Shock and Swingarm

I know I could probably get a YSS shock at a fraction of the price, but it wouldn't be factory. Sent both of these off to www.cycleimprovements.com in Canada to try and make one good one.

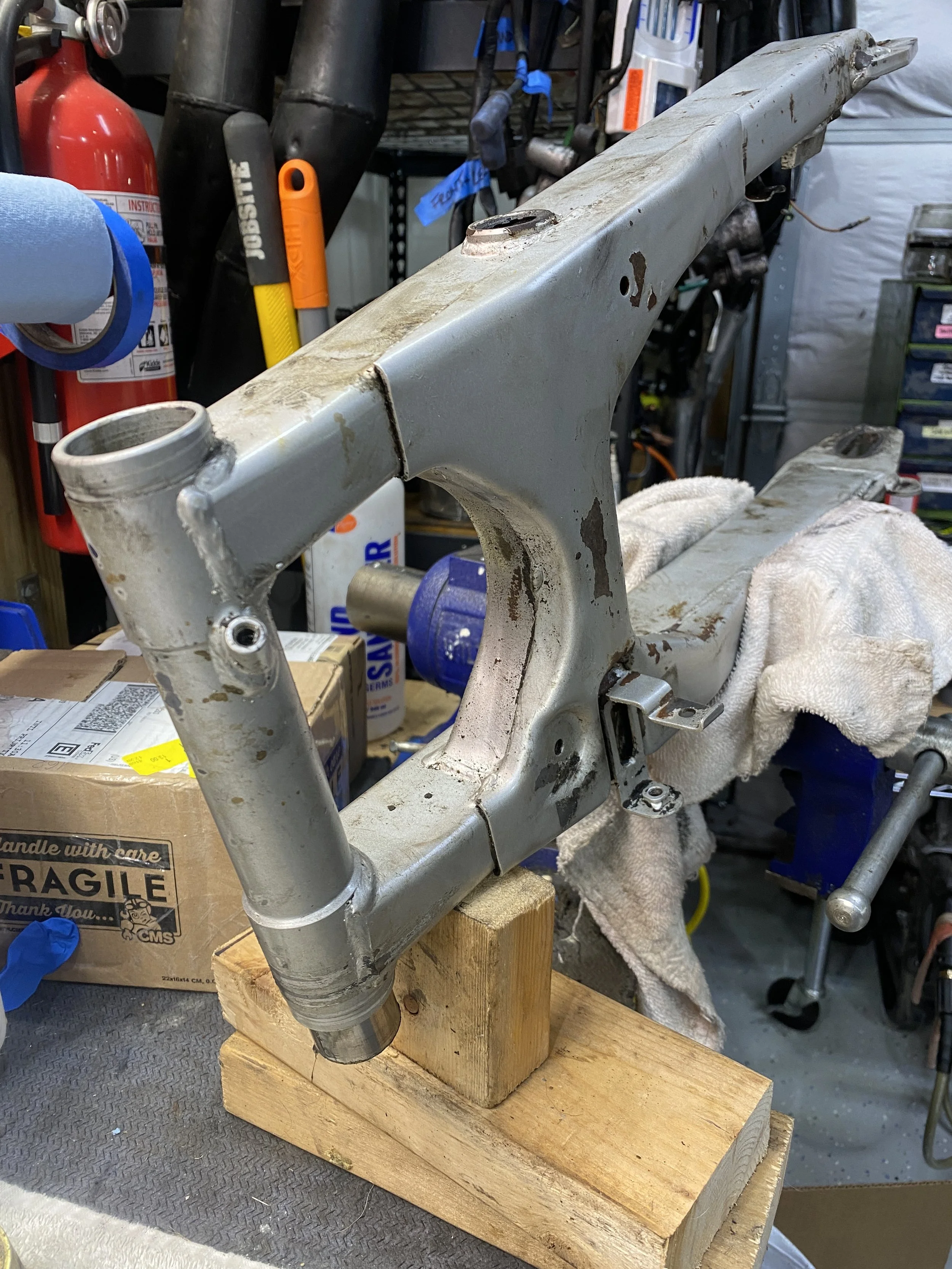

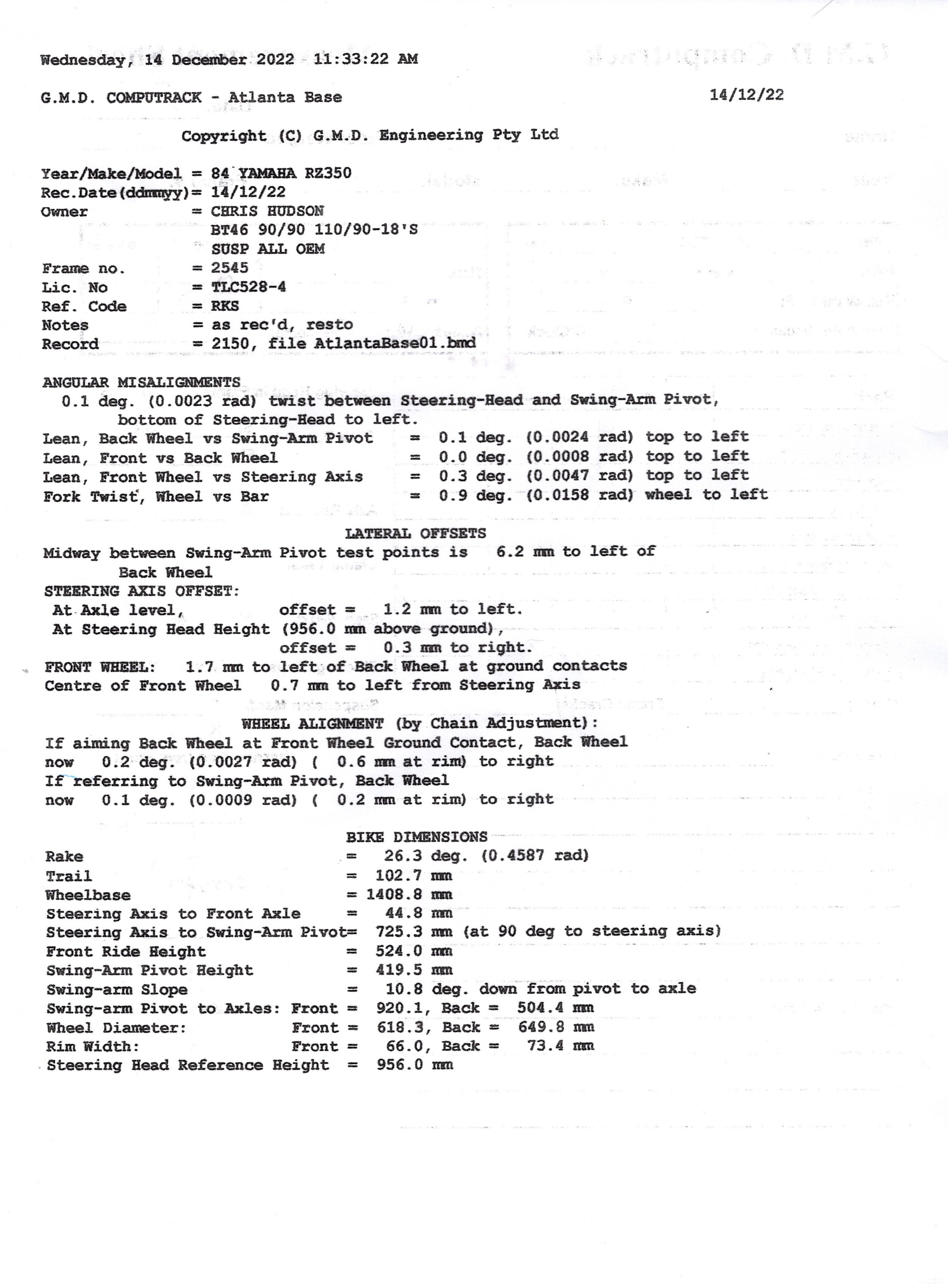

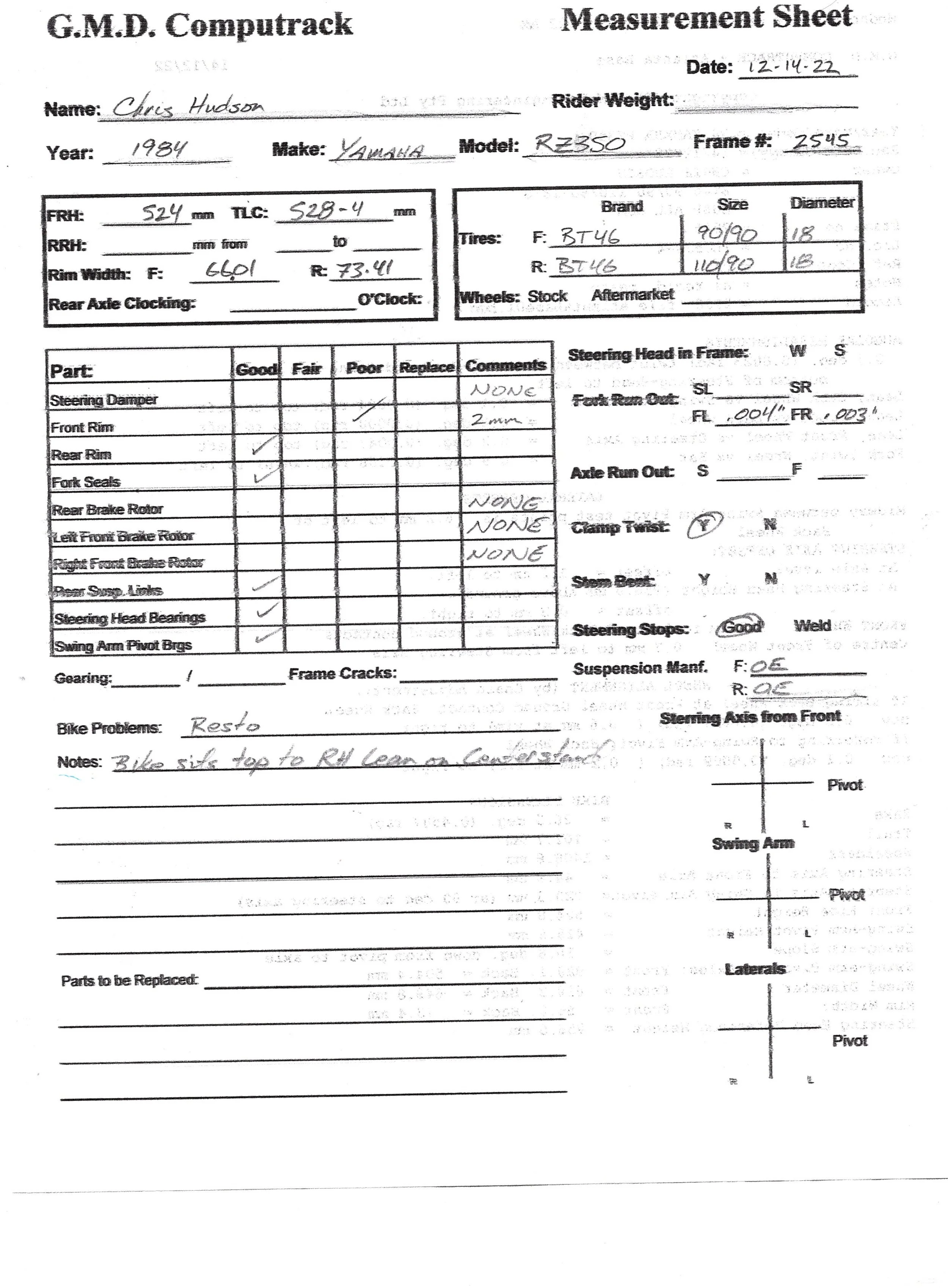

Frame

A little bit cart before the horse but · 4d · Anyone remember GMD Computrak? I do. I want the integrity of this BumbleBee resto to be rock solid and know that I'm building on a frame that is straight and true. In dismantling the bike there was some evidence of road rash but no real indication of how bad it was. Front end shunt? Forks could have been replaced. Something could have been tweaked. etc etc So I threw the frame, wheels, axles. spacers and bars into the back of my tiny Golf GTI and drove 3 hours to Fairmount, GA, just north of Atlanta to get the frame checked for trueness. After a couple of hours of laser measurement I was relieved to find it was fine- as any straightening would have probably involved some heat and not have done the powder coating any good. Ideal time to do this is really once the bike is stripped before you get it painted. All they need is a roller- but they also accept fully assembled bikes. The trip was well worth it as Kent Soignier (the owner) along with David his trusty assistant discovered that the triple clamps were out by a couple of degrees but he was able to fix the issue within an hour. Both Kent and David and even the Shop Cats were very welcoming, helpful in getting the bike in and out of the car and generous with their time in explaining the Computrak process and even gave me an impromtu demonstration of the String Theory as it pertains to wheel alignment using a very tricked out Ducati they had on a stand, some string and a couple of RD400 crankshaft weights-it finally put an end to the mystery for me of how to do it and....I think I'll be able take those two 10ft lengths of angle iron back to Home Depot. https://gmdatl.com/index.html

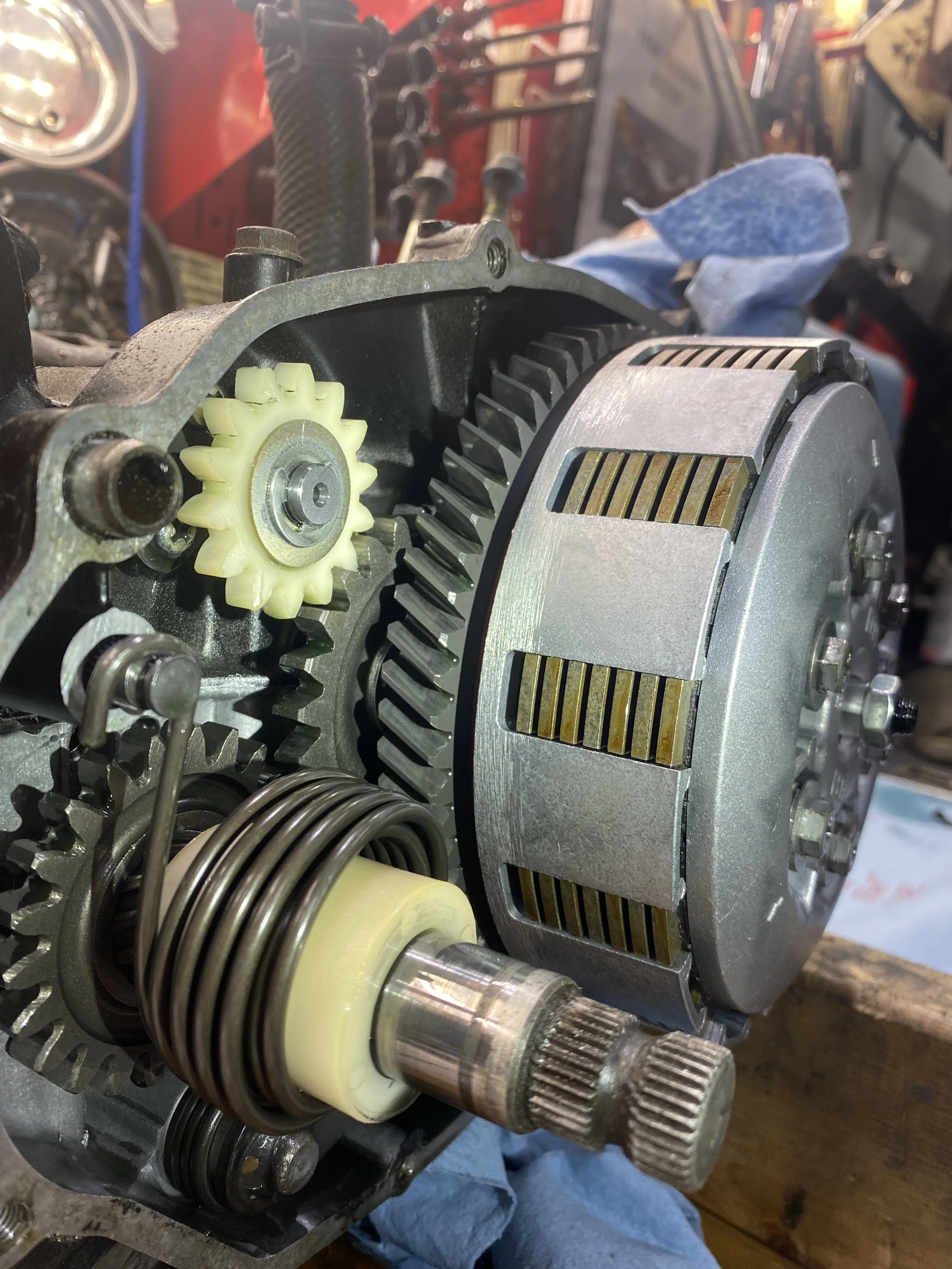

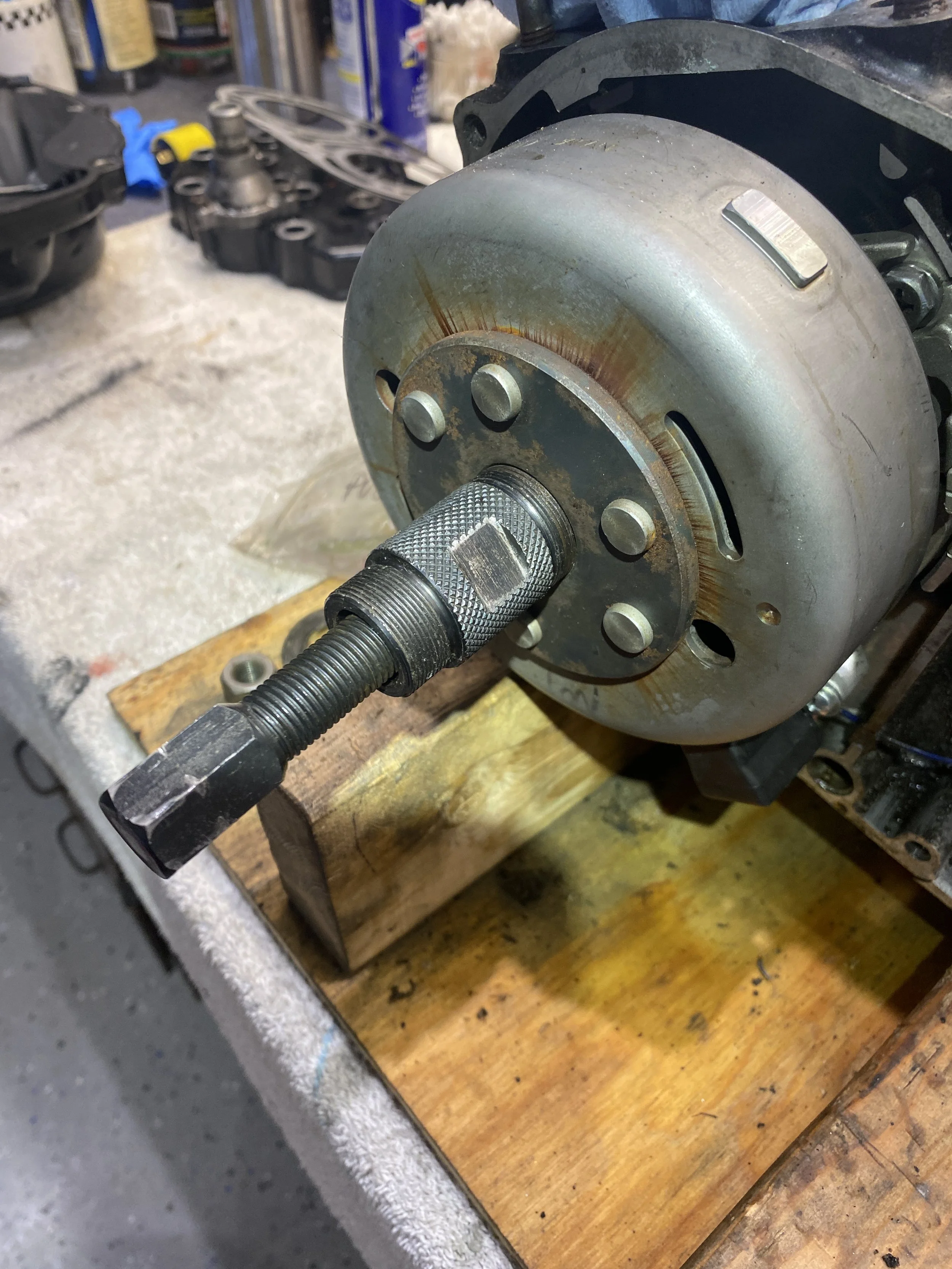

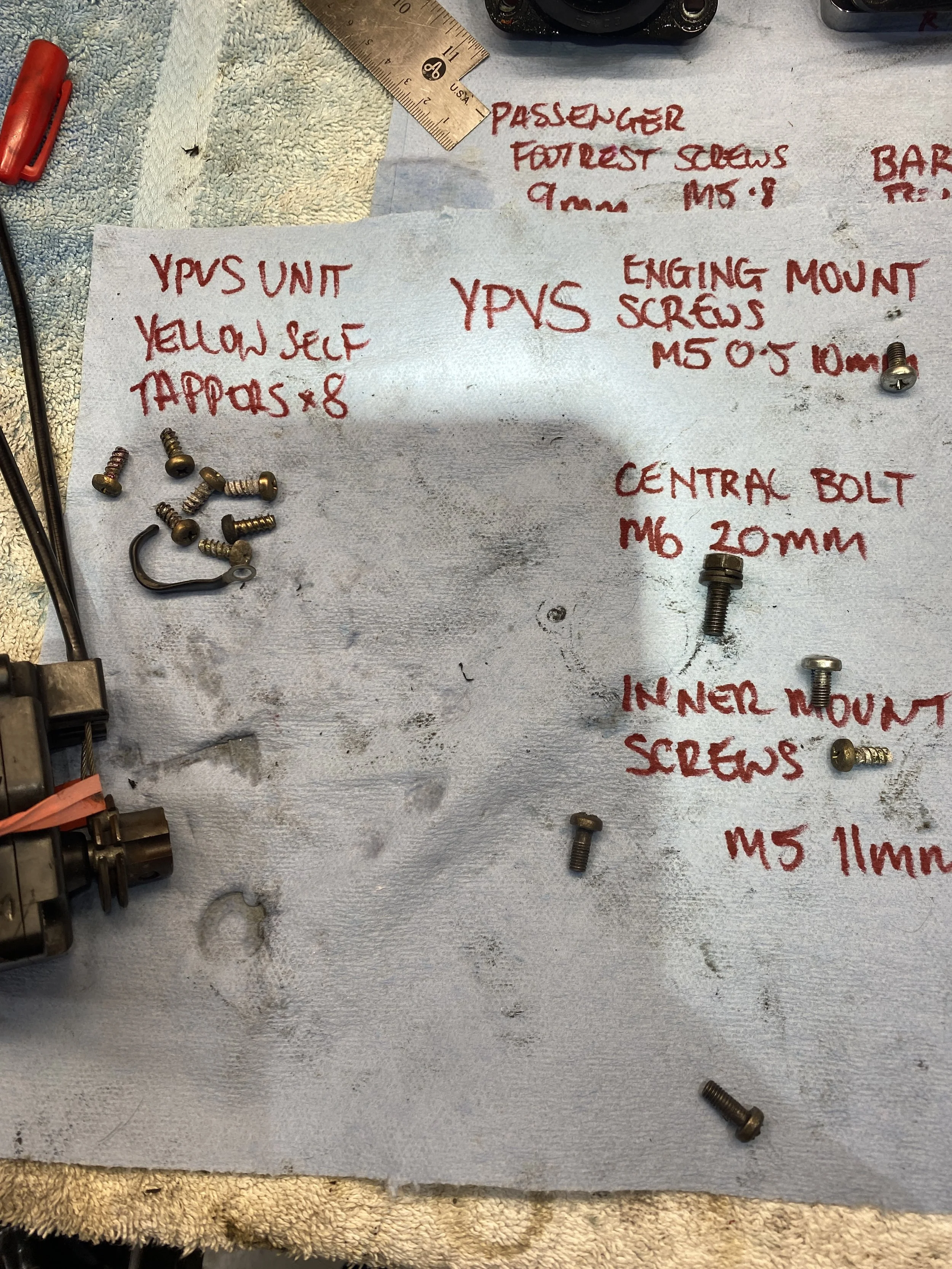

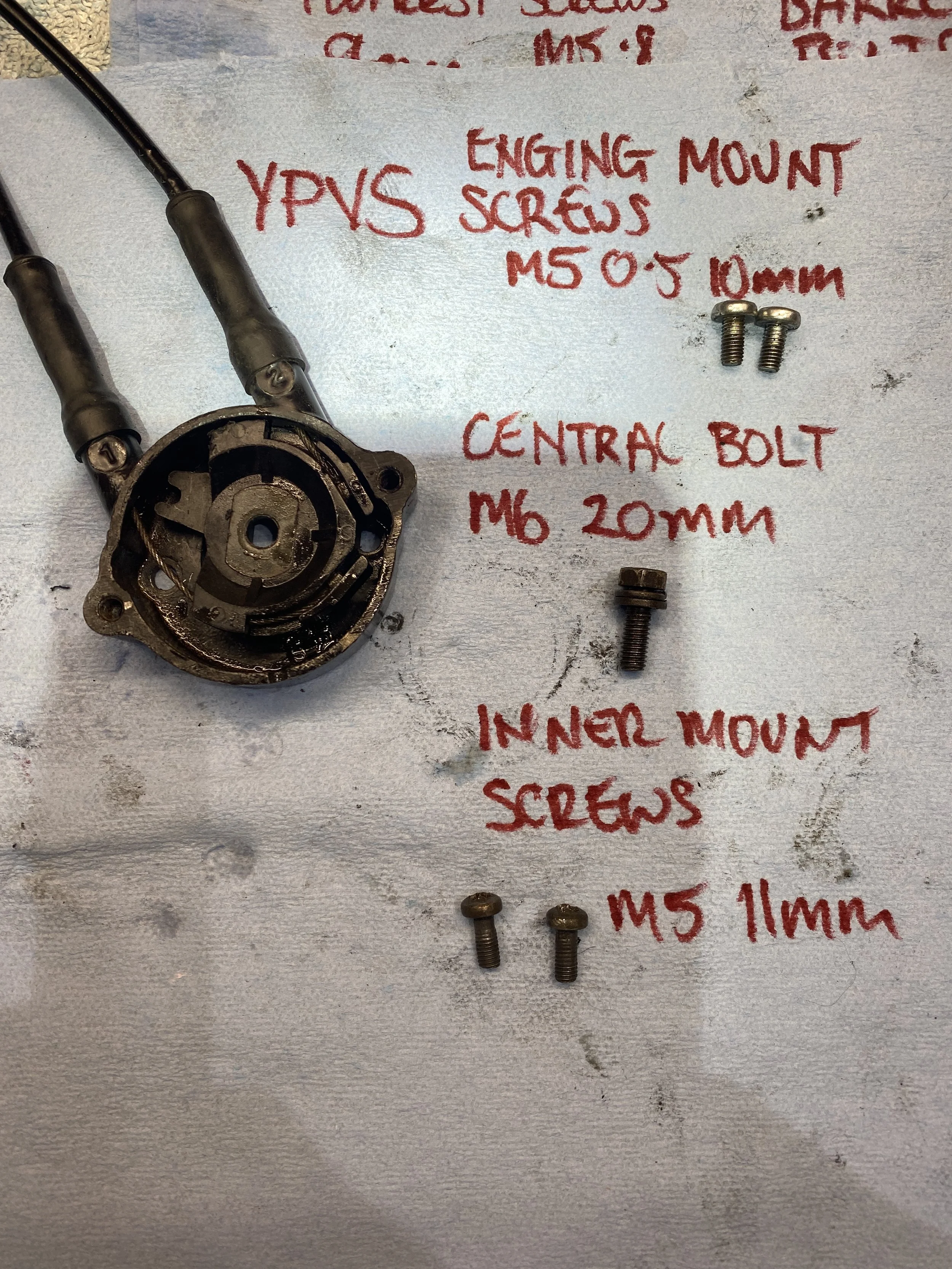

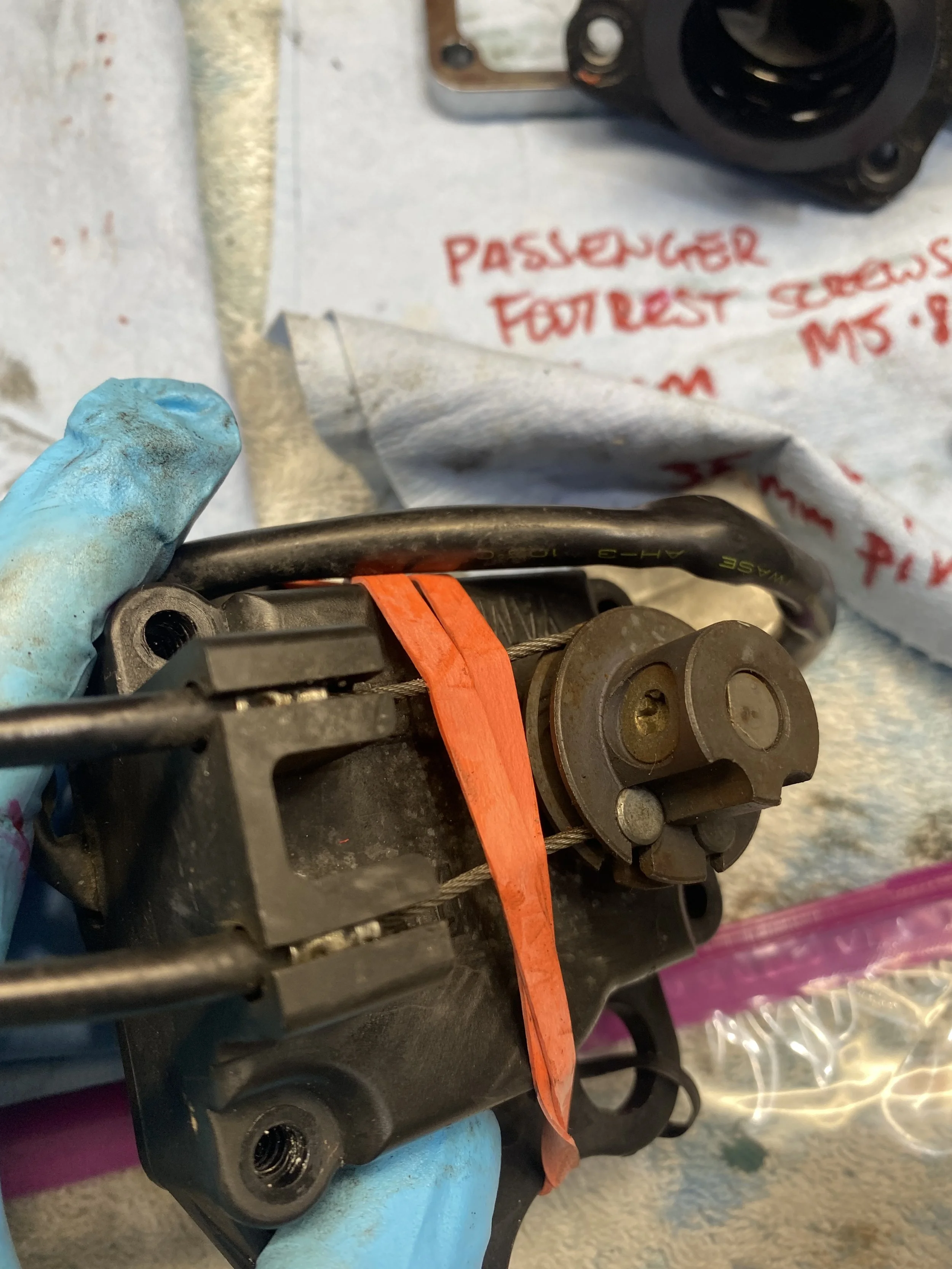

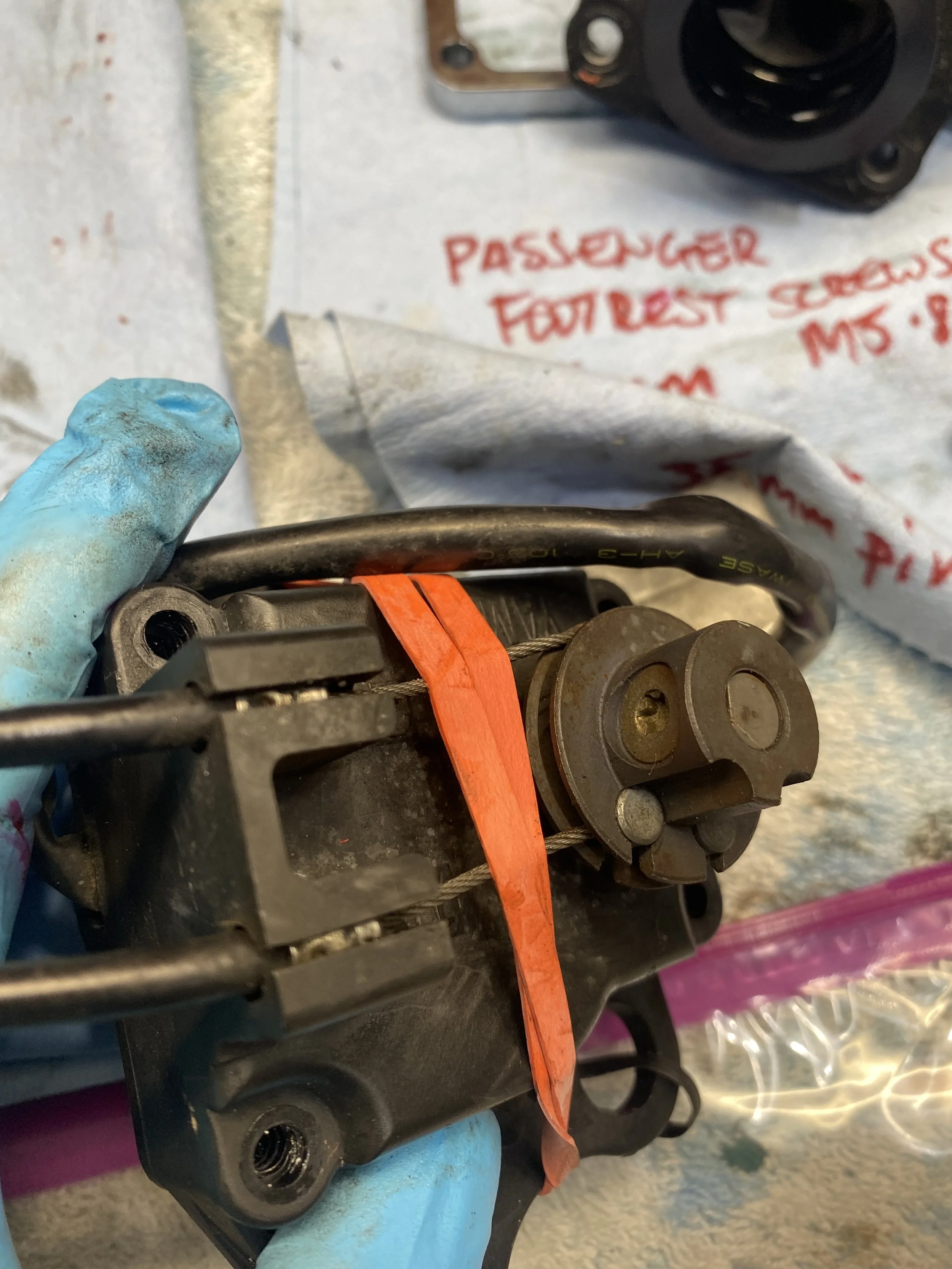

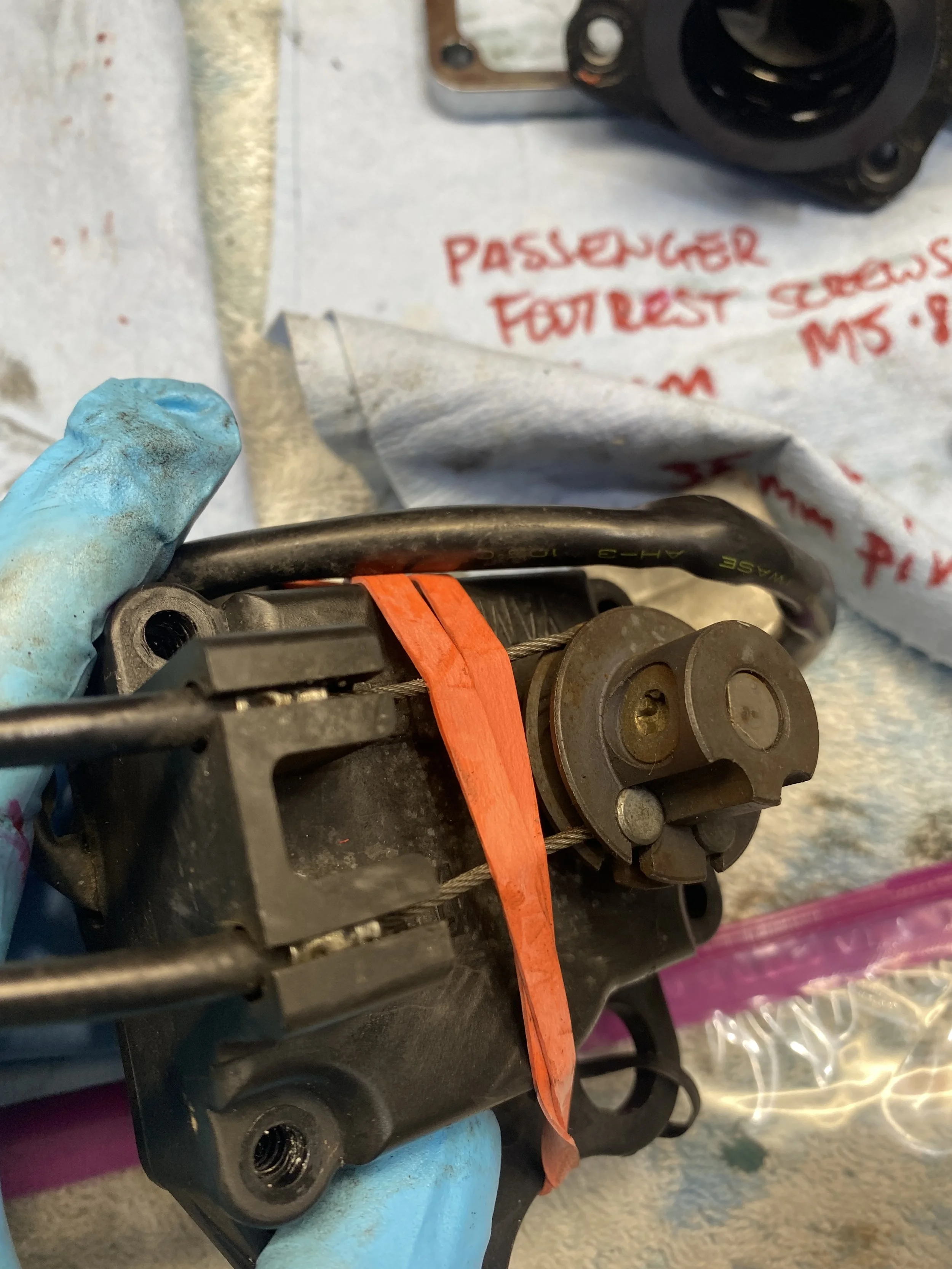

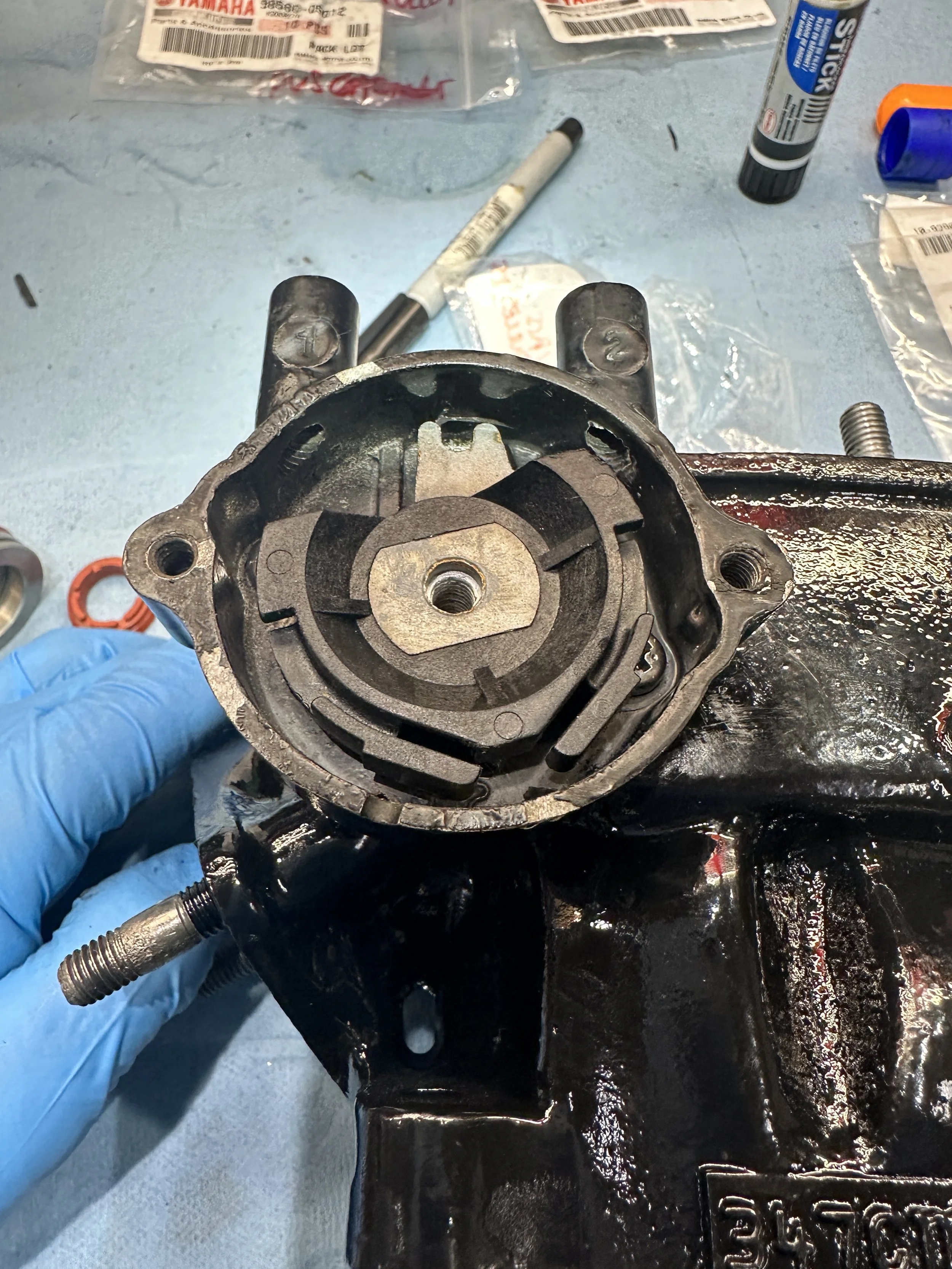

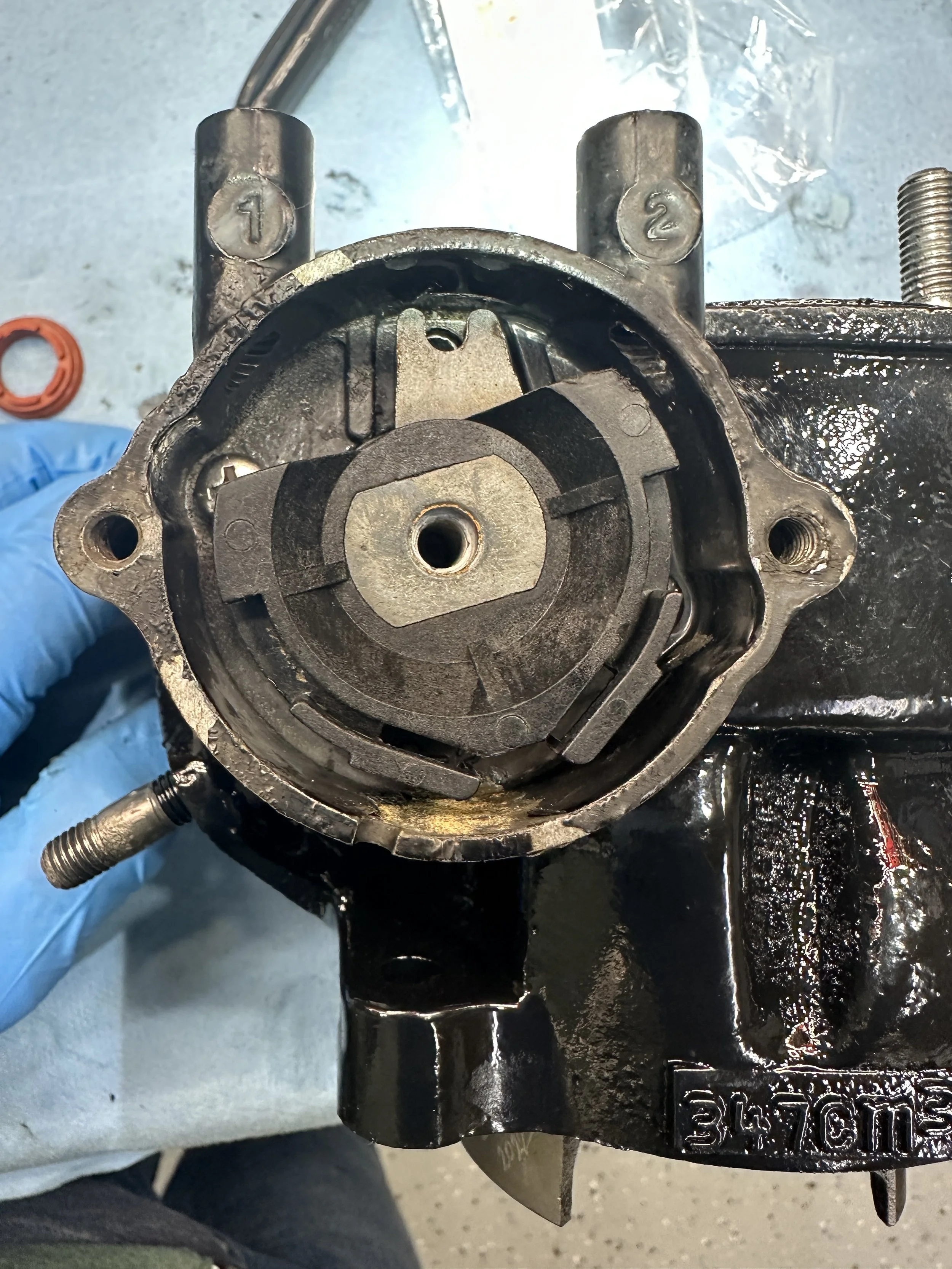

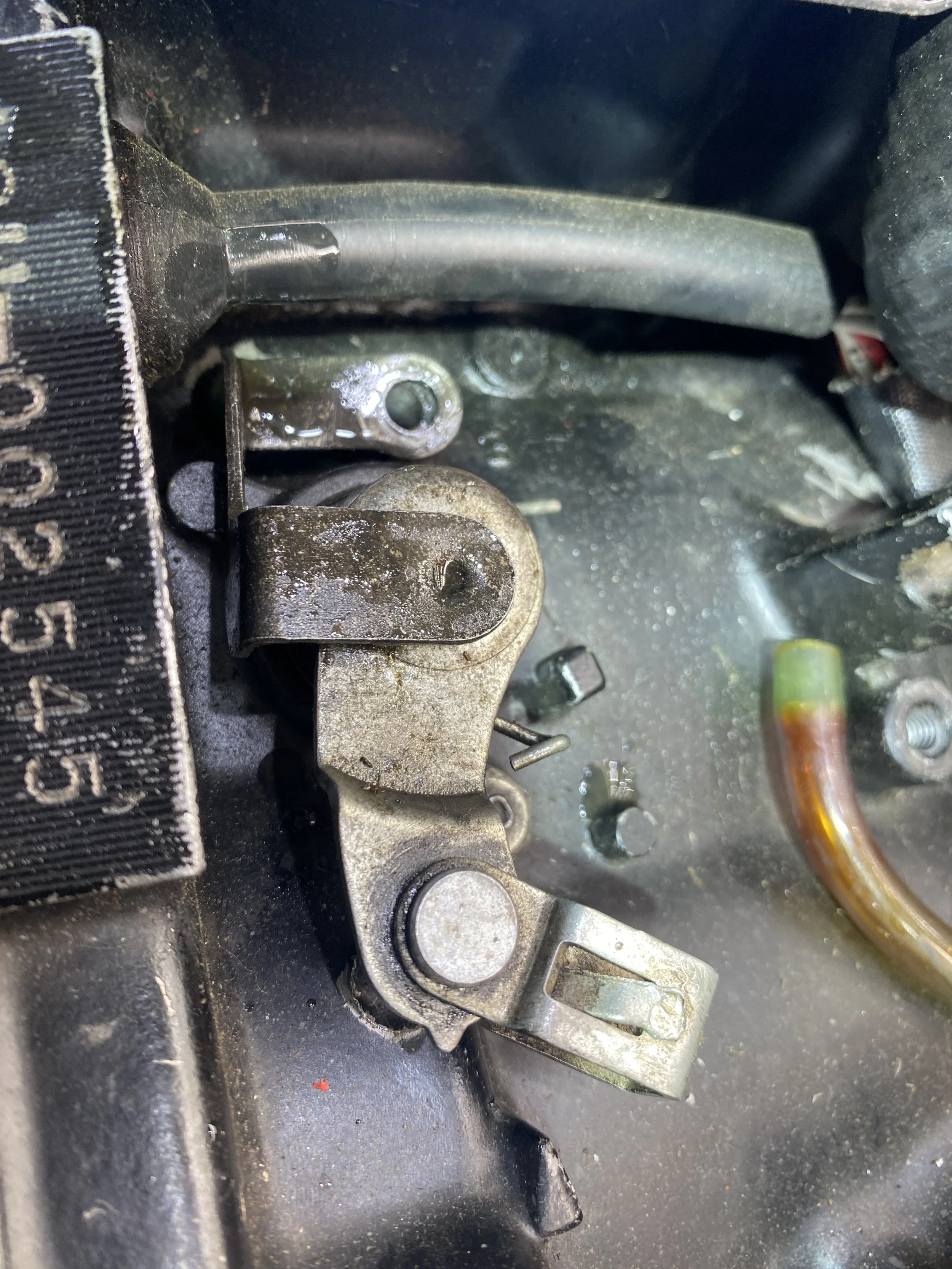

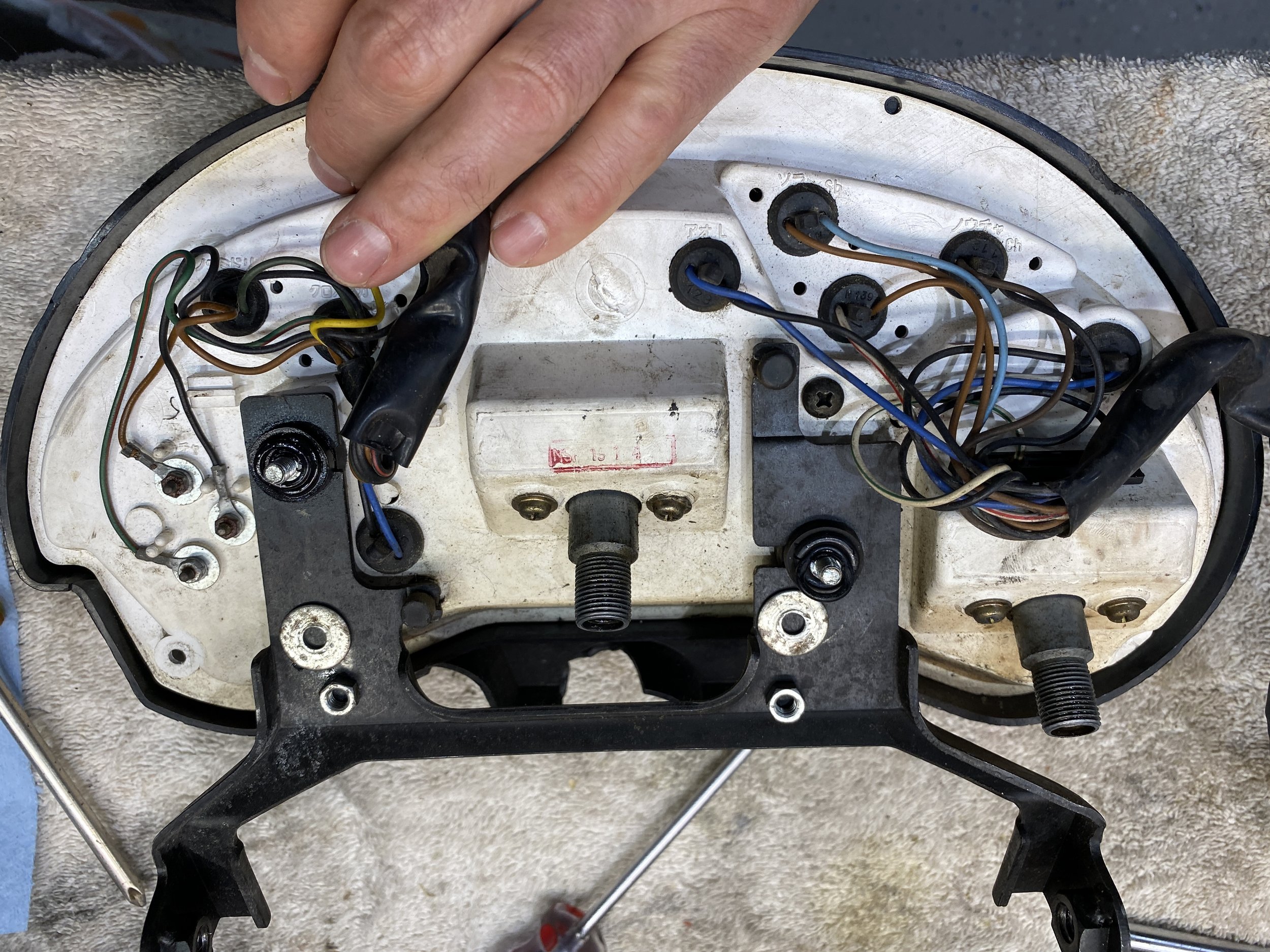

YPVS Unit

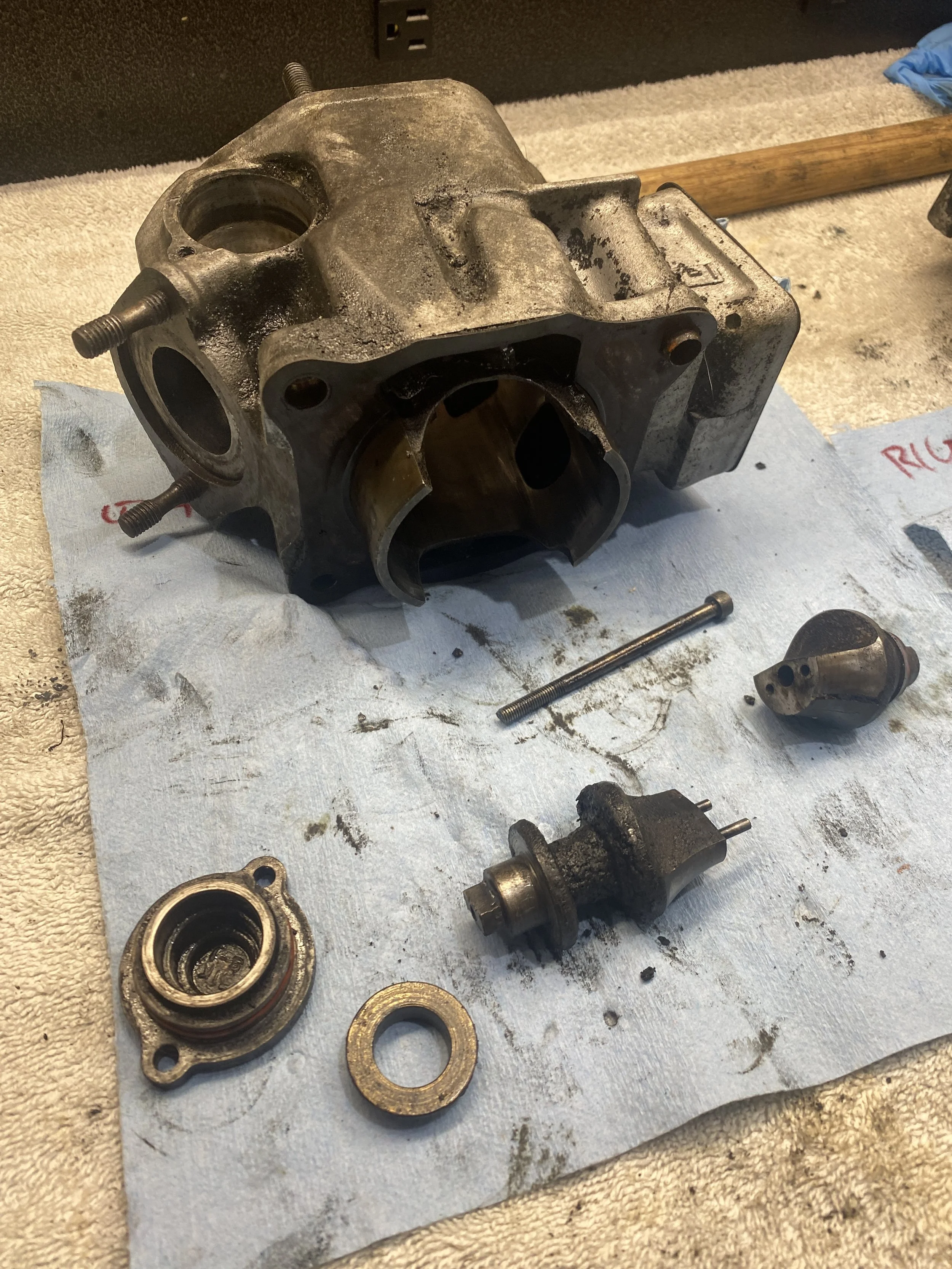

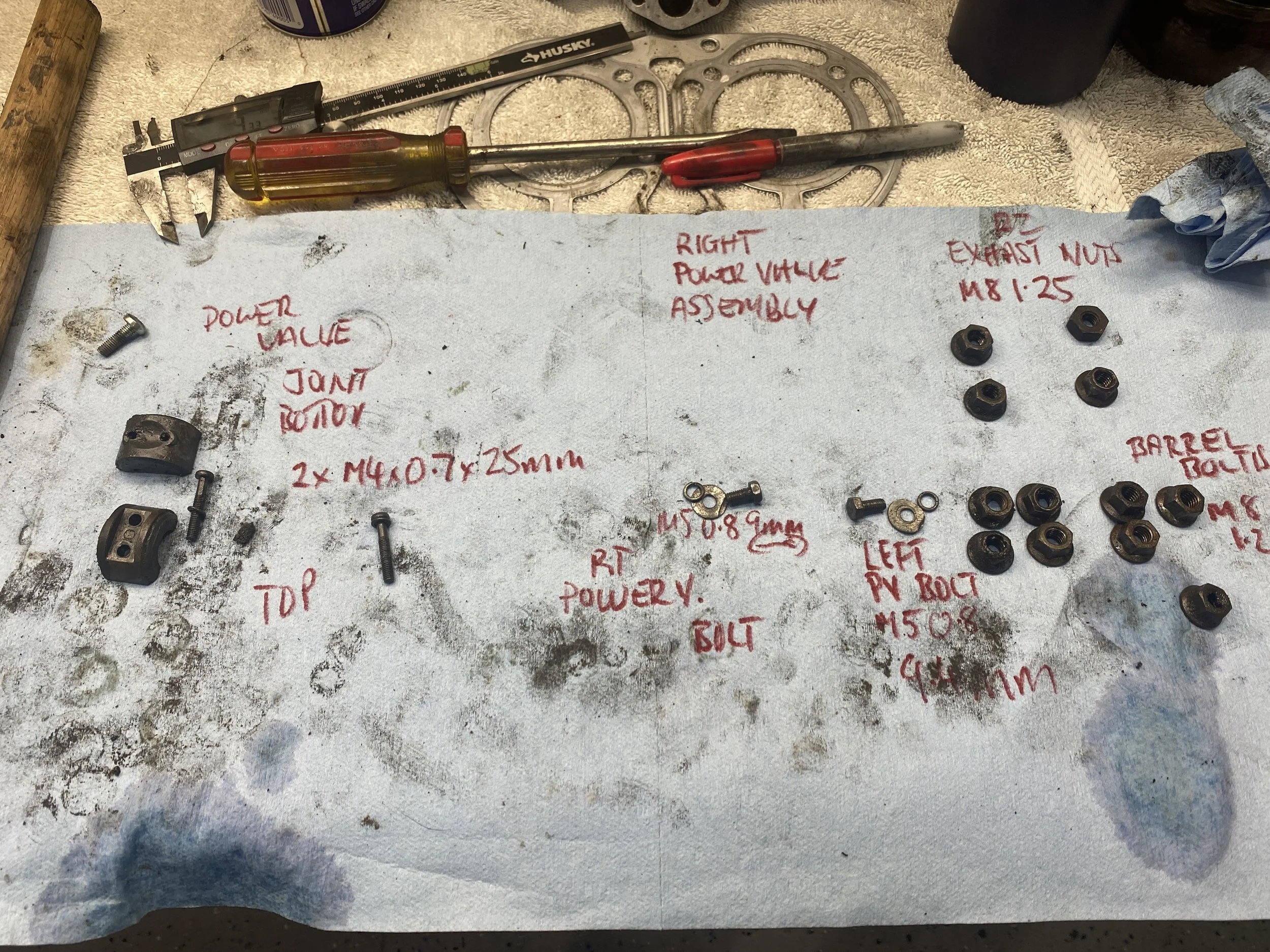

YPVS Valves

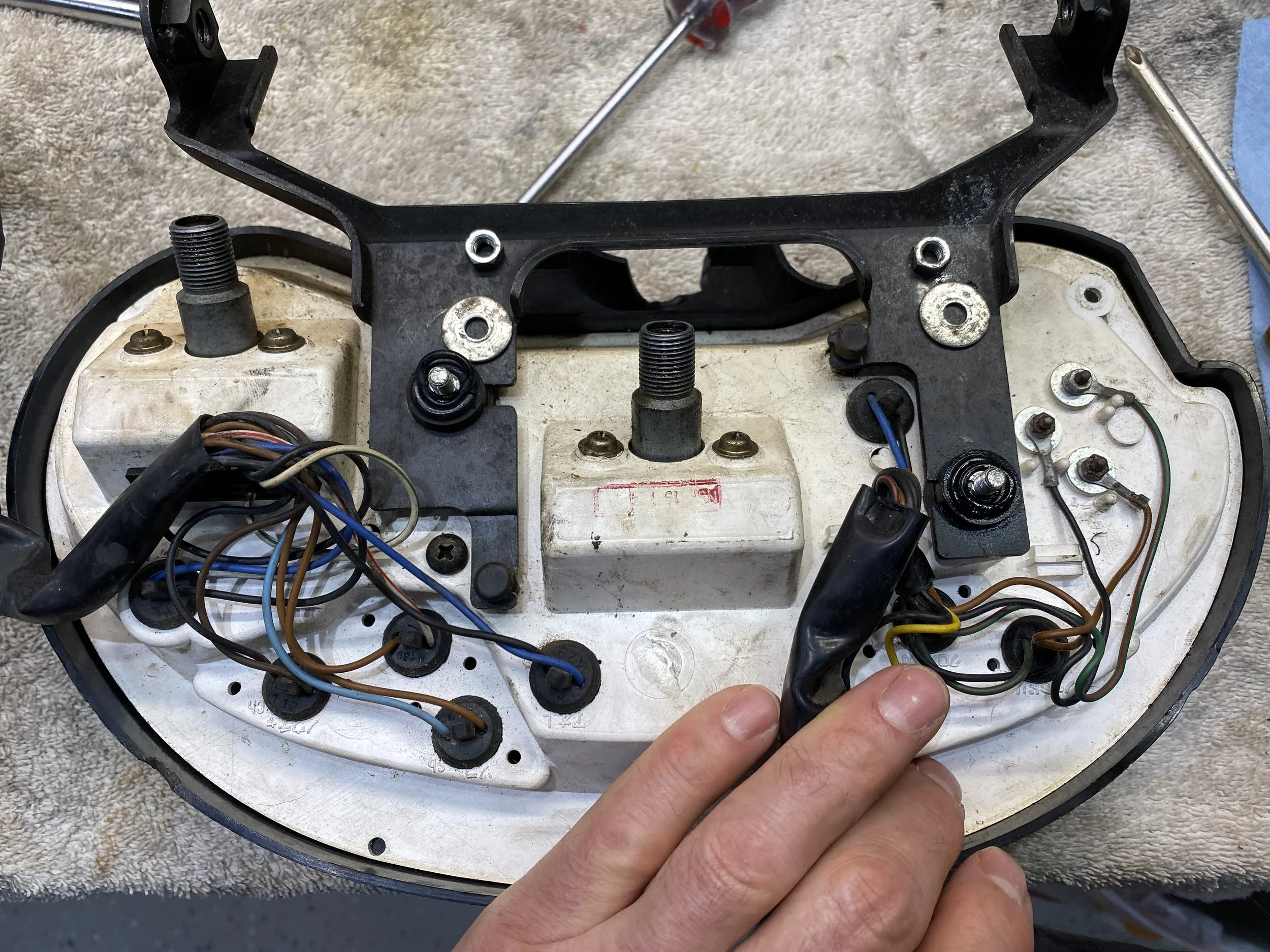

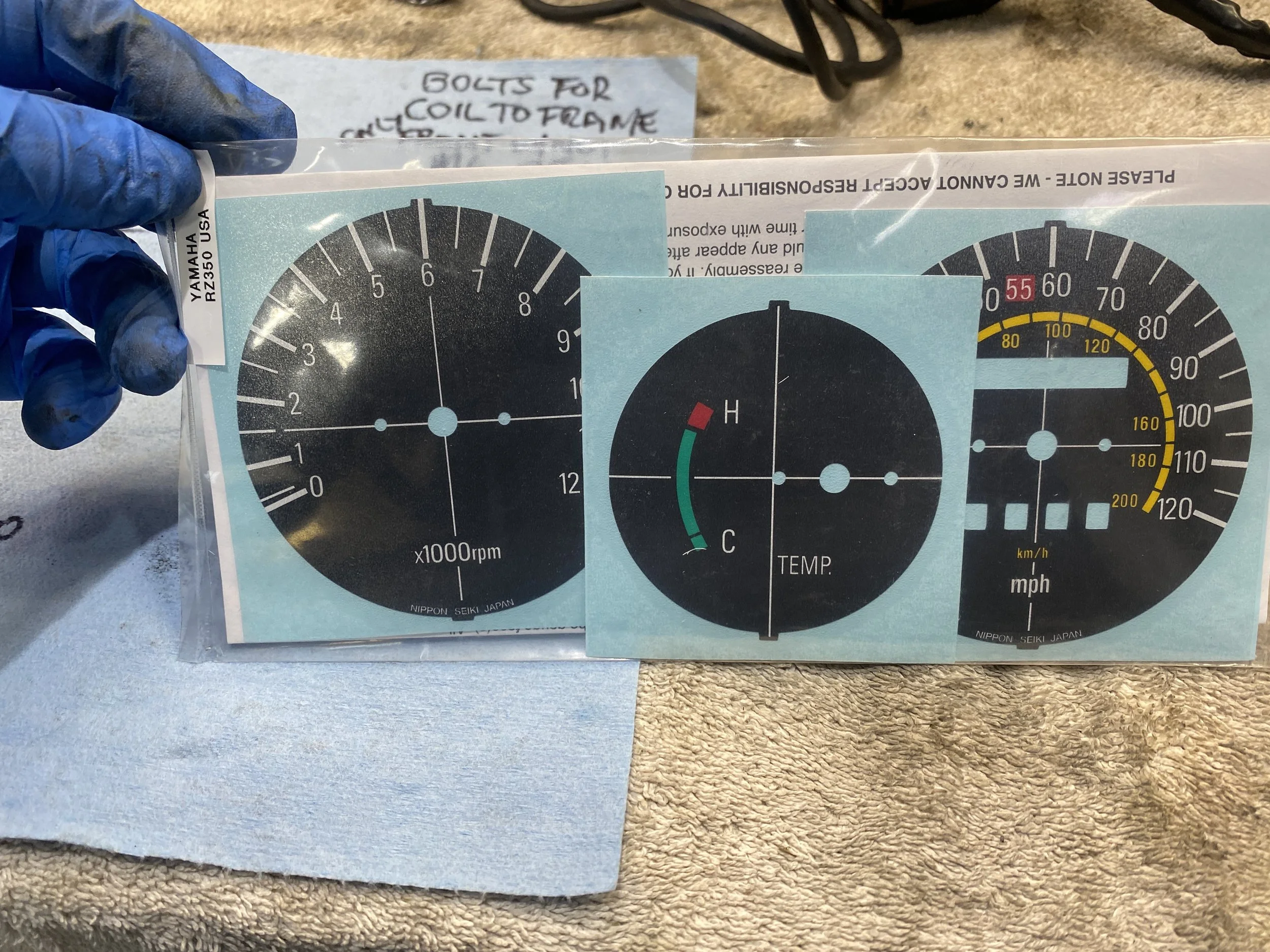

Meters

Got these from Diablo Cycle...https://www.diablocycle.com/ making decals is how they made their name

also sending off the next projects meters 1981 Blue and white LC350.

Petcock

Petcock Reassembly

Exceedingly happy that our Previous Owner included the notoriously ornery vacuum petcock in it's entirety. True I could have got a brand new unit from Yambits for £100, but I took the long route and had Ryan of motorresurrection blast all the alloy parts, Quality Plating replate the original fasteners in either silver or yellow and ordered a Yambits rebuild kit for £20. (https://yambits.co.uk/air_intake_parts_for_yamaha_rz350l.html?cat=air_intake?page=2)

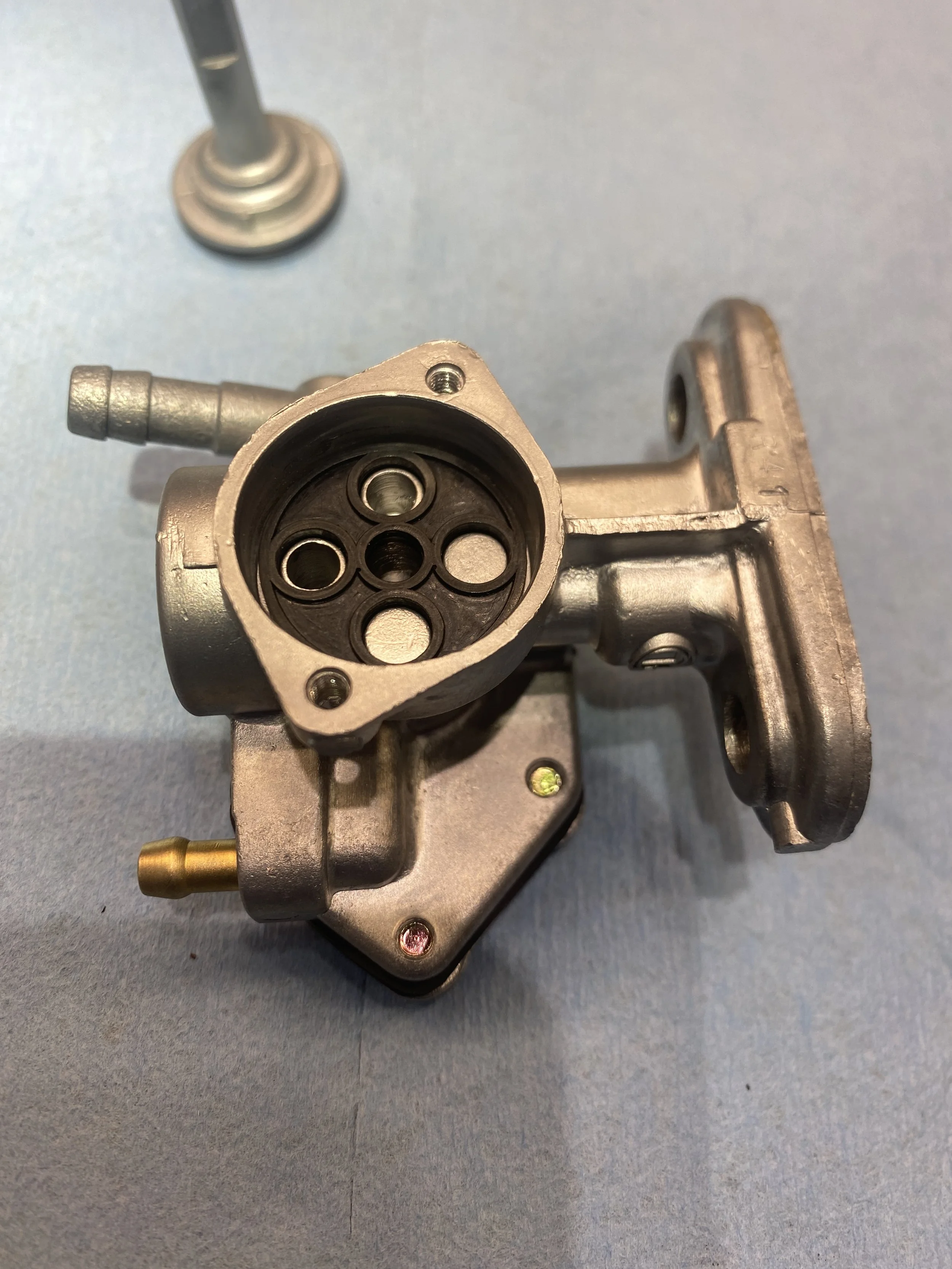

First things first, I learnt the hard way from the similar designed H2 petcocks- you must make sure this central orifice...

....is clean and smooth....allowing for...

an good seal between this o-ring and the walls of the cylinder...

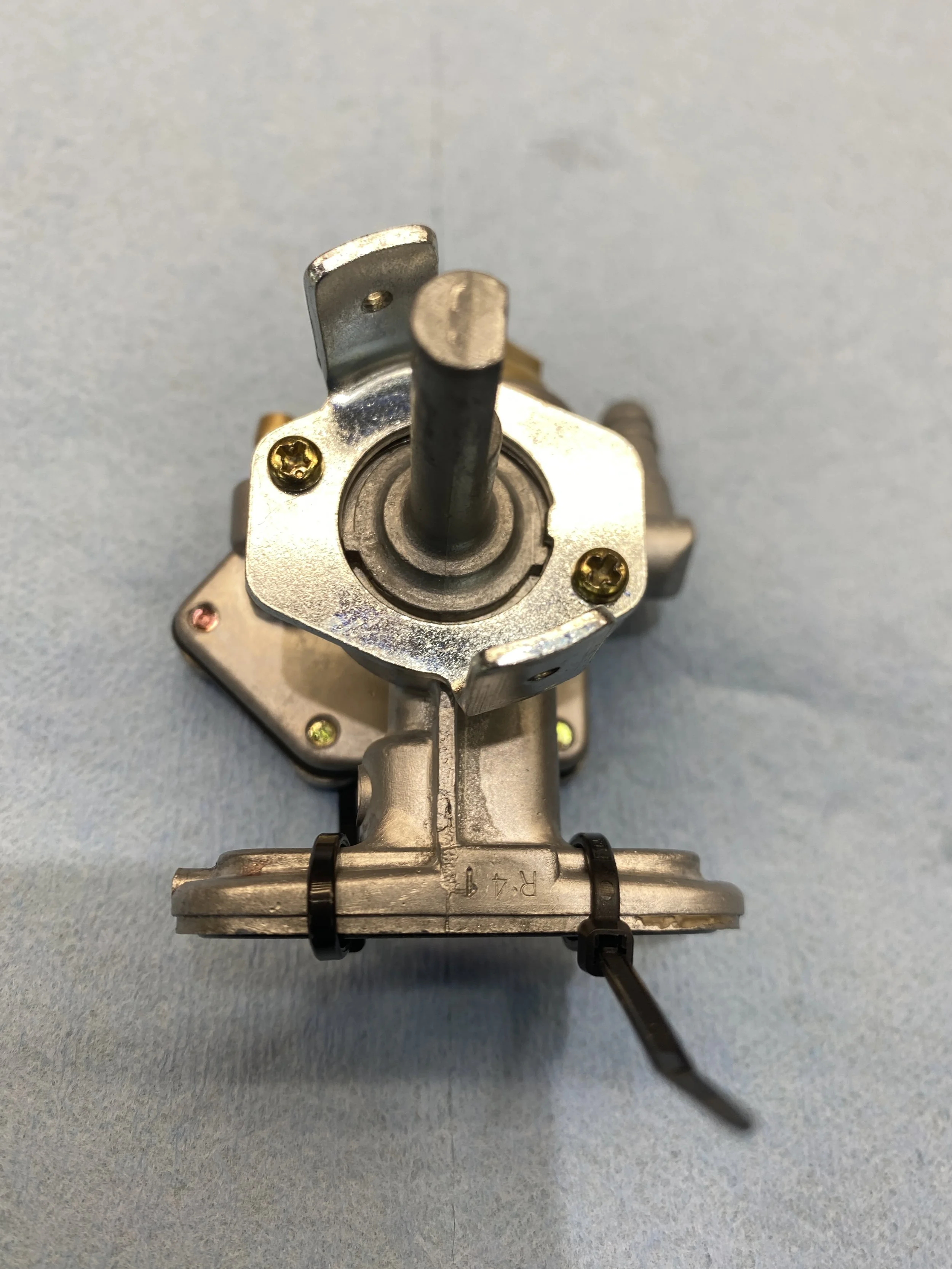

with the plastic divider in place small spring sits on top....and the top plate is then screwed in place.

gasket in place

all these rubber pieces these encounter and move against alloy and so are given a light smear of red rubber grease to help them slide...

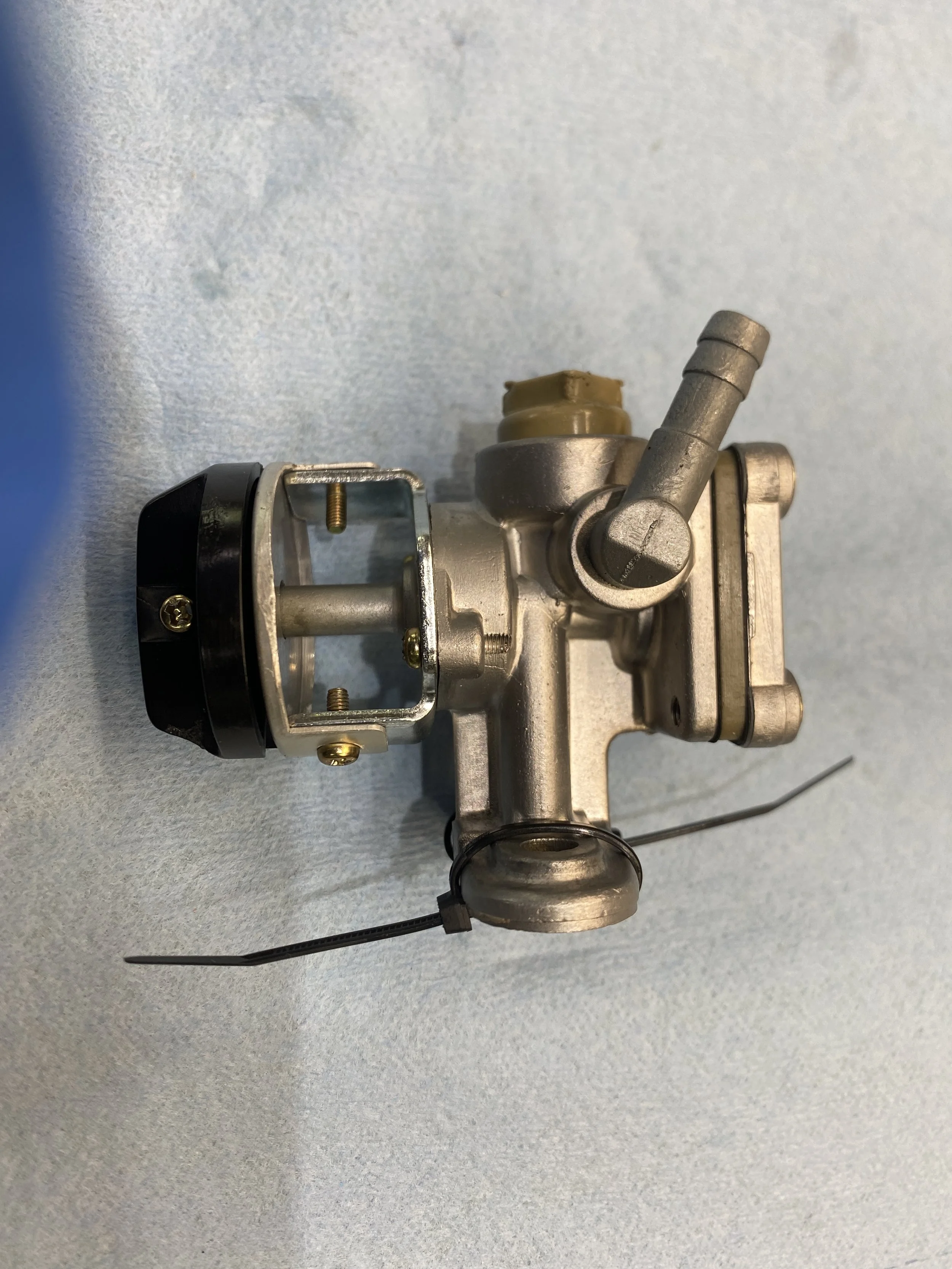

This spring washer goes on the outside of the fuel tap between the fuel tap and the plate holding it in place. Try putting it on the other side and you will get a Niagra-like flow of fuel coming out of there...

plate...

...and newly plated plate and original screws....

..an additional upper plate....

...indicating the position of the petcock handle....now in place.

Sediment float bowl also gets some new rubber....

...in the form of a lightly red rubber greased o-ring.

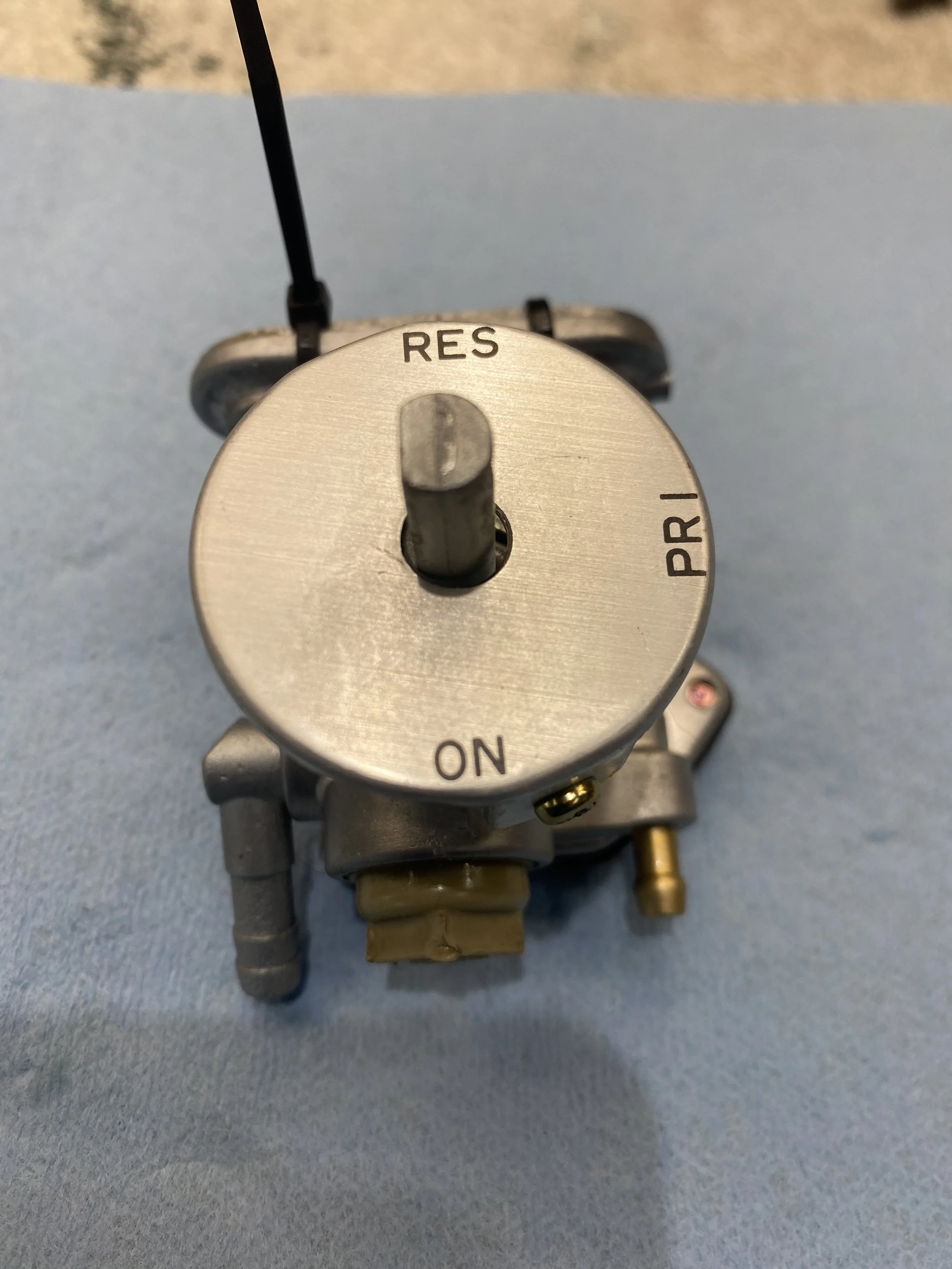

Finished article. I've lost a few of these handles in my time....so a bit of Loctite on the M4x0.7 screw should prevent history repeating itself.

Original OEM JIS crossheads, (signified by the dot on the face of the screws) replated yellow zinc...

Japanese Industry Standard (JIS) screwdrivers, tools a must.

Radiator

Sticker Repro

Tail Light

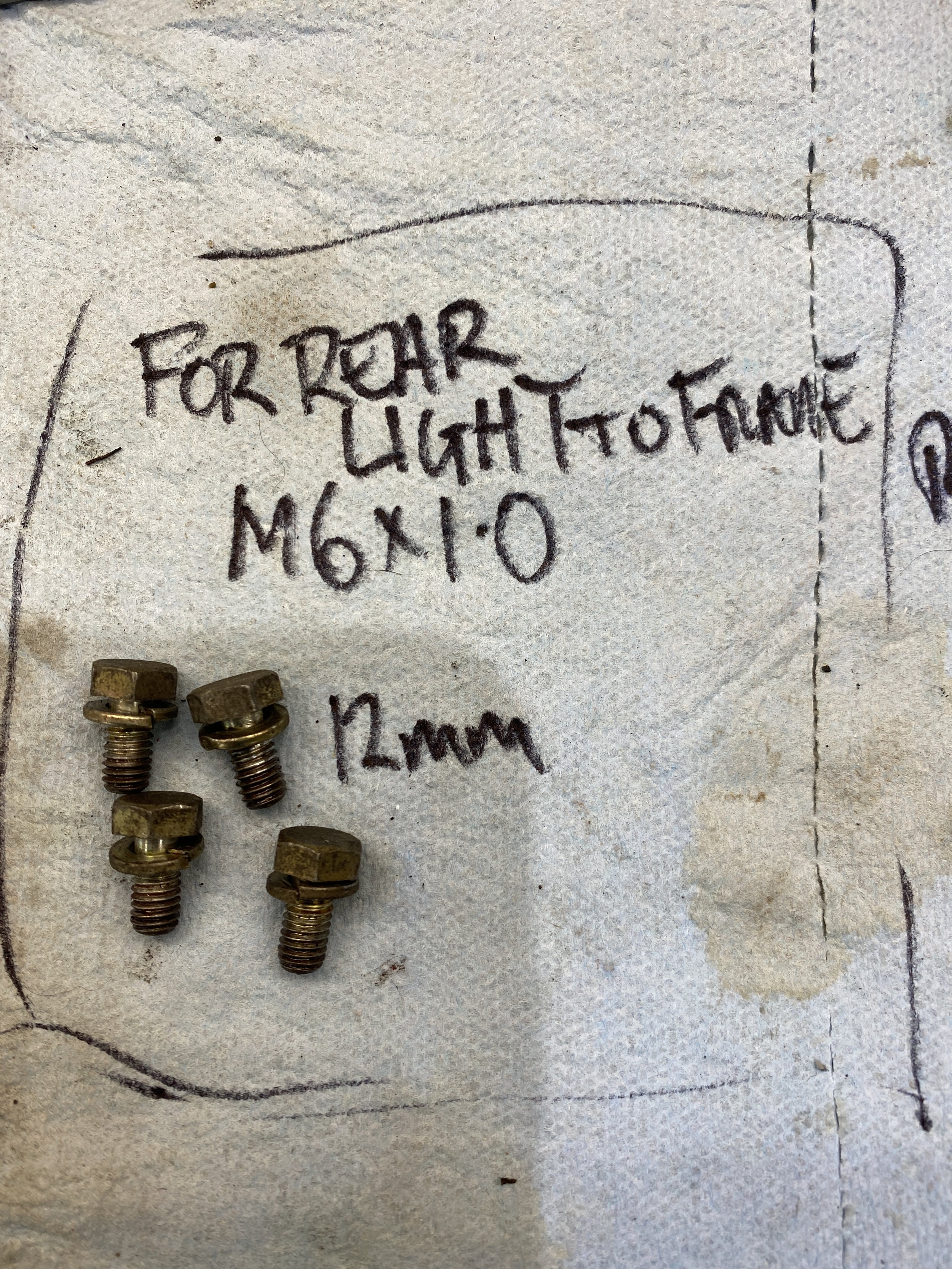

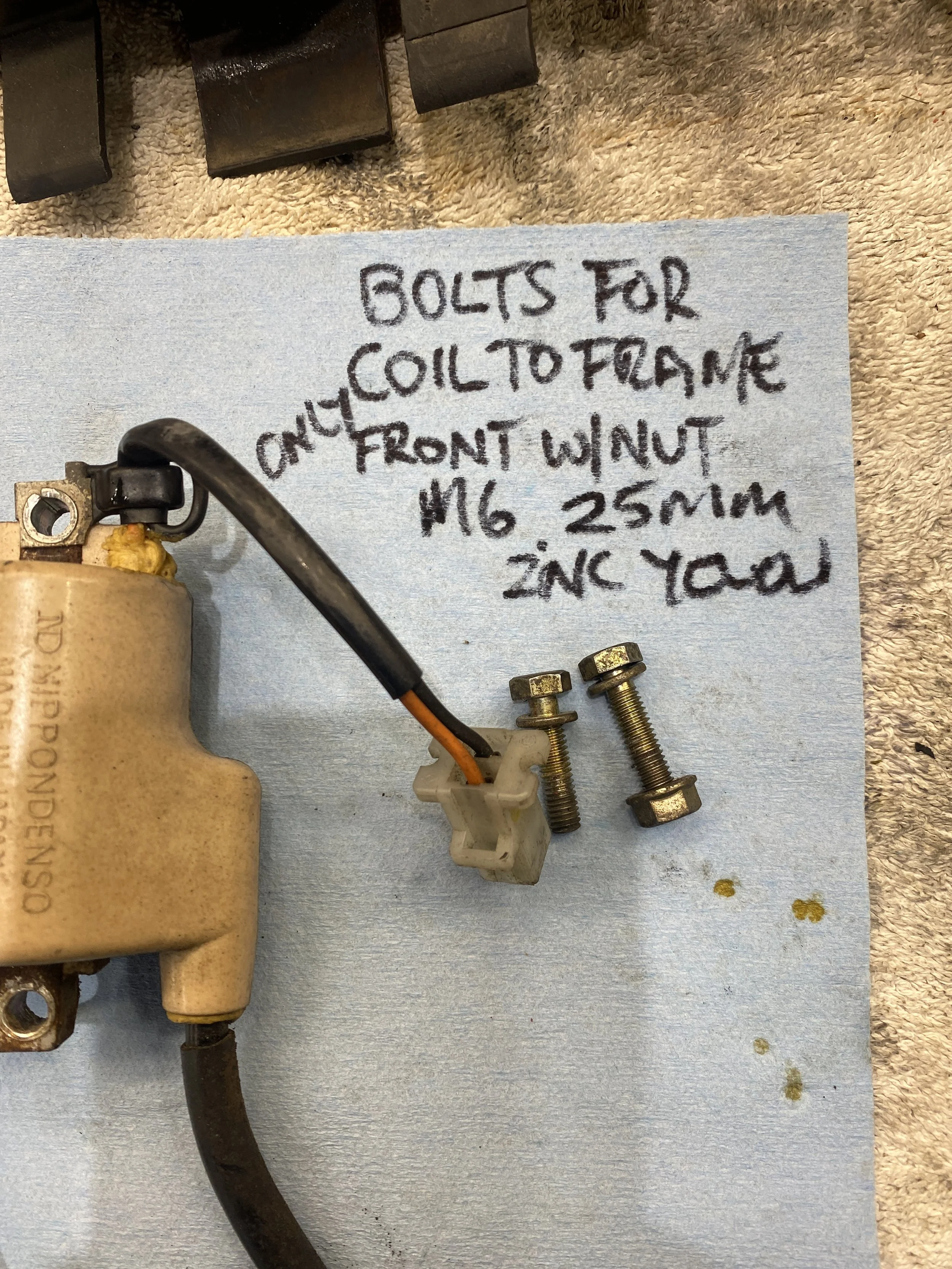

Fasteners

Silver Fasteners before plating...

....after plating

Yellow Zinc before plating....

...after plating.

Olive Drab....didn't get done....might have to go to UK

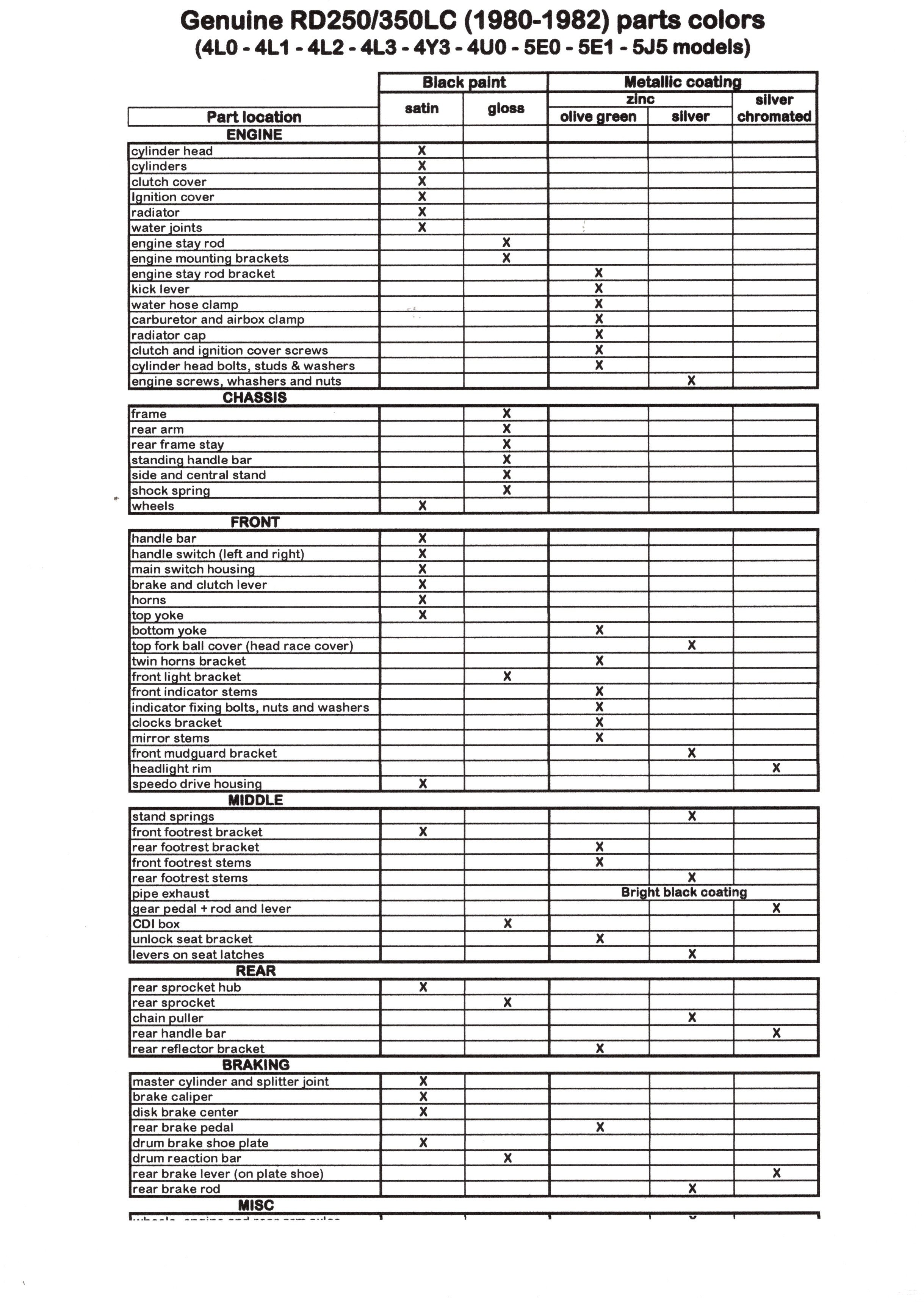

Some guidelines....I discovered later....not for the RZ you notice but for the RDLCI

This lot off to the chromers on Aug 24. Thankfully not much chrome on this bike. $300. And, damn, I realize I'm missing the mounting brackets for the pegs.

bracket powder coated, nuts and bolts plated

Chrome's home

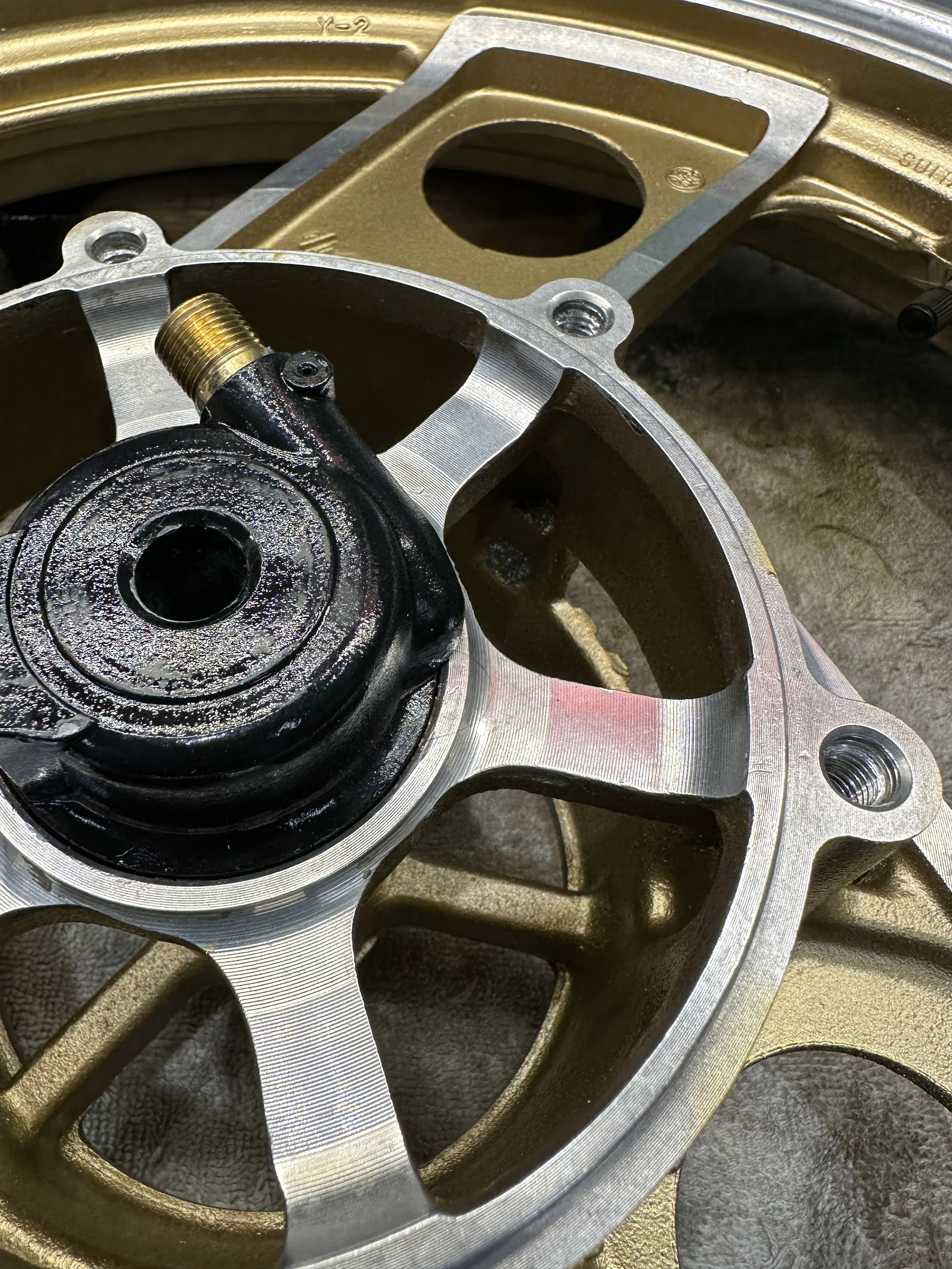

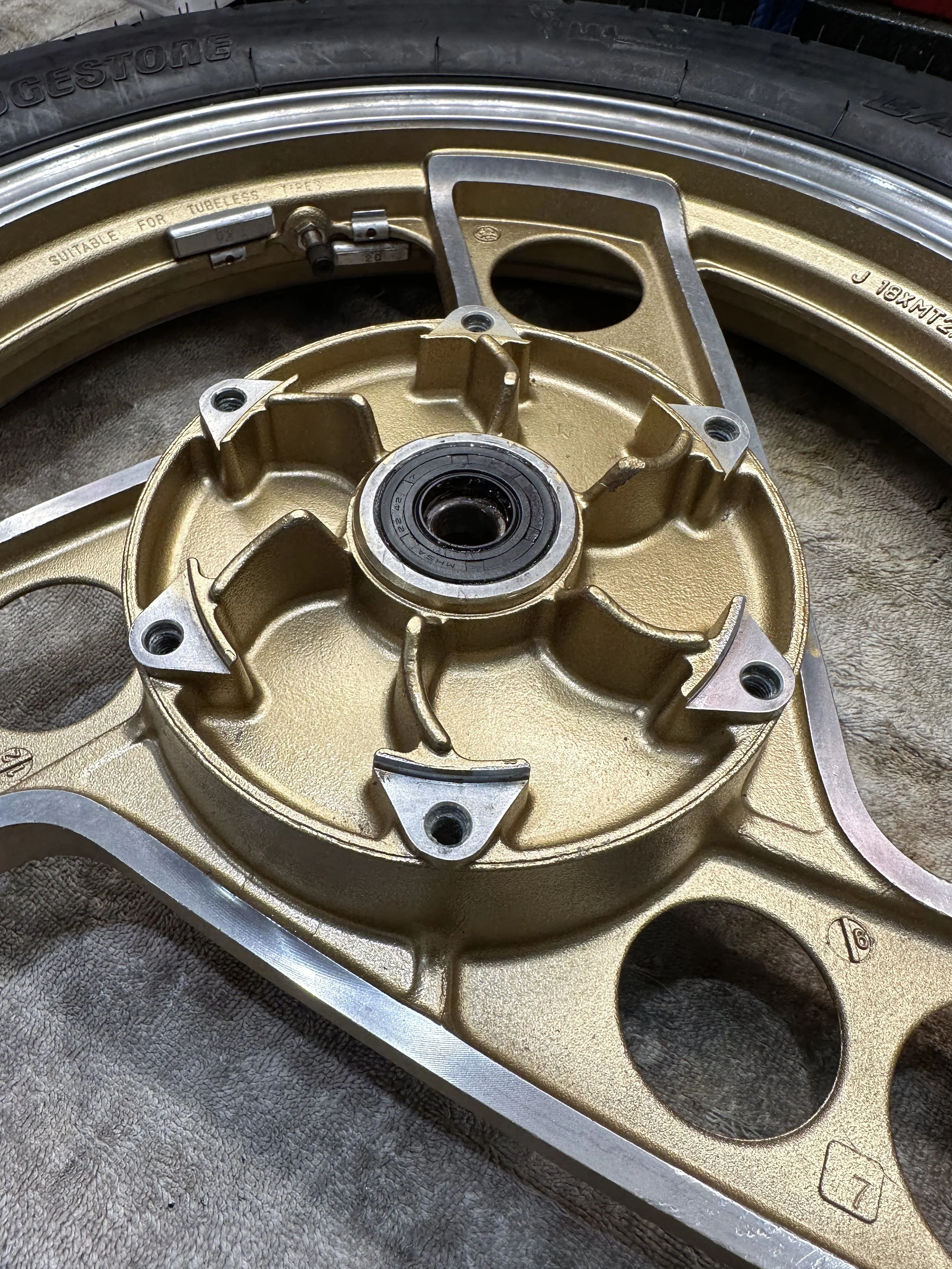

Wheels

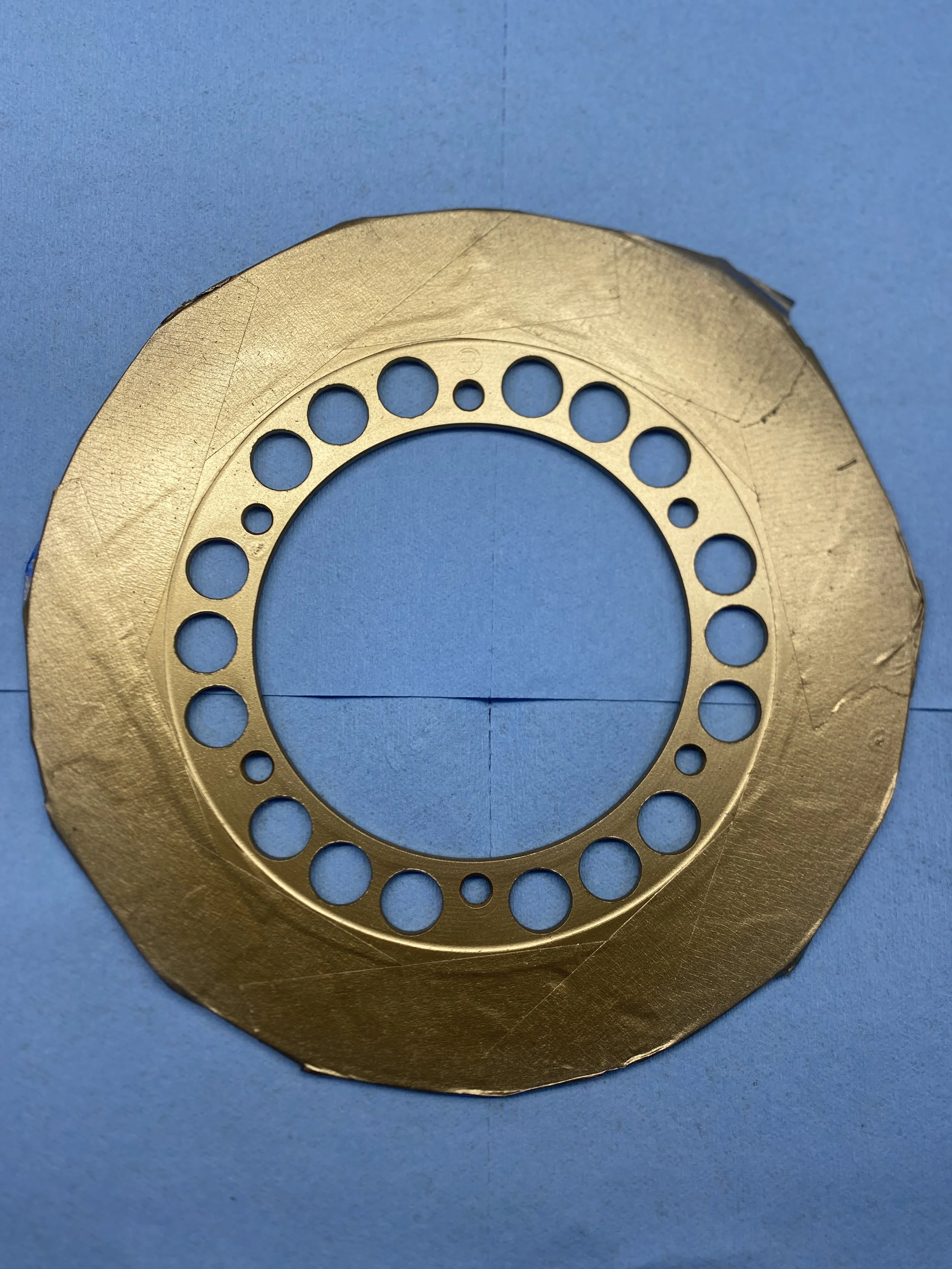

This was the paint used for the wheels (only.) Ended up using 2 cans of the primer and 4 of the Gold to more than adequatell cover two wheels and three disks. Available at most Autostores in the US or at Amazon.

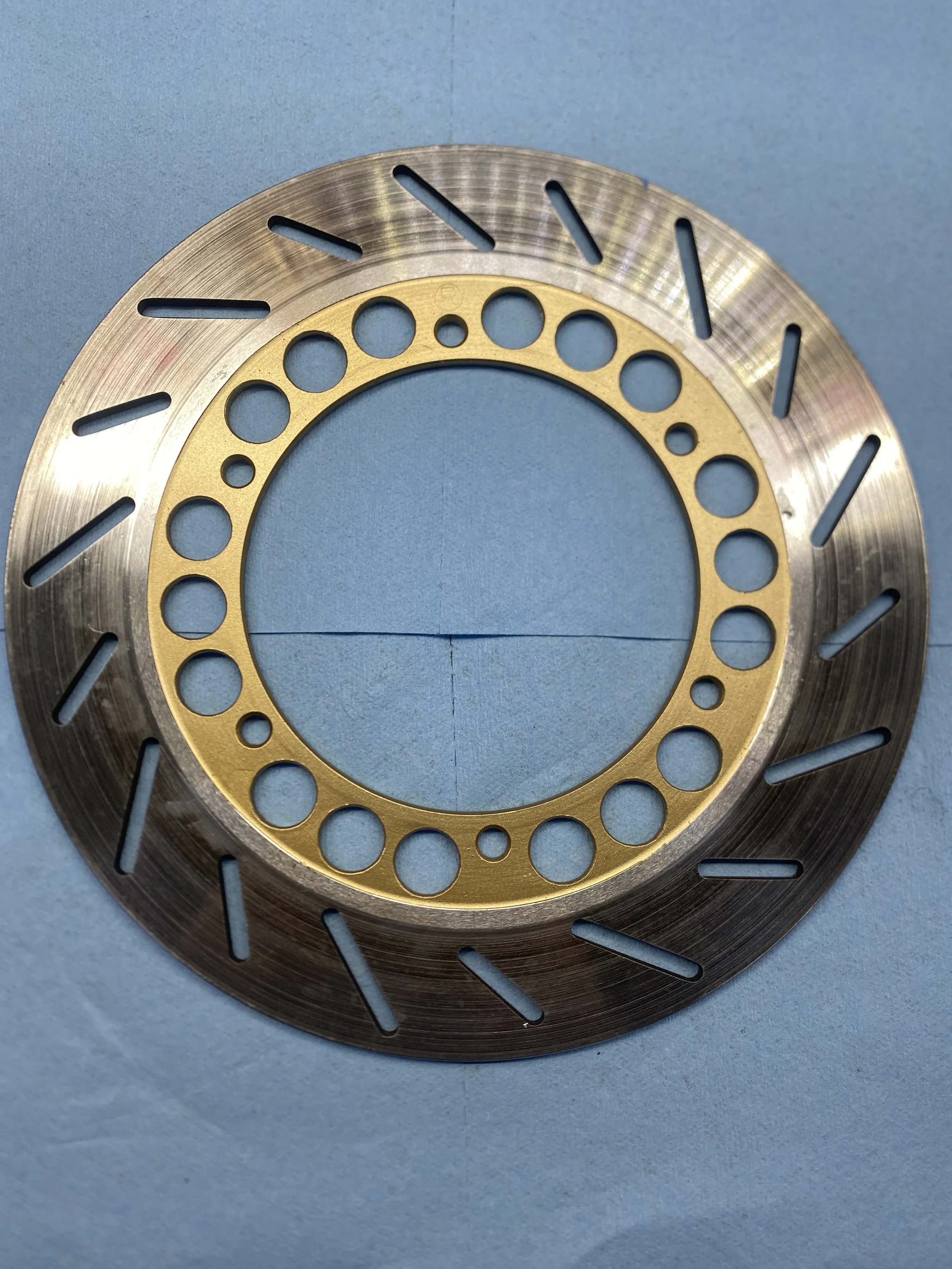

Nope. Lame. It was these marks that had me reconsider using Dupli-Color for the disk....and doing it all over again.

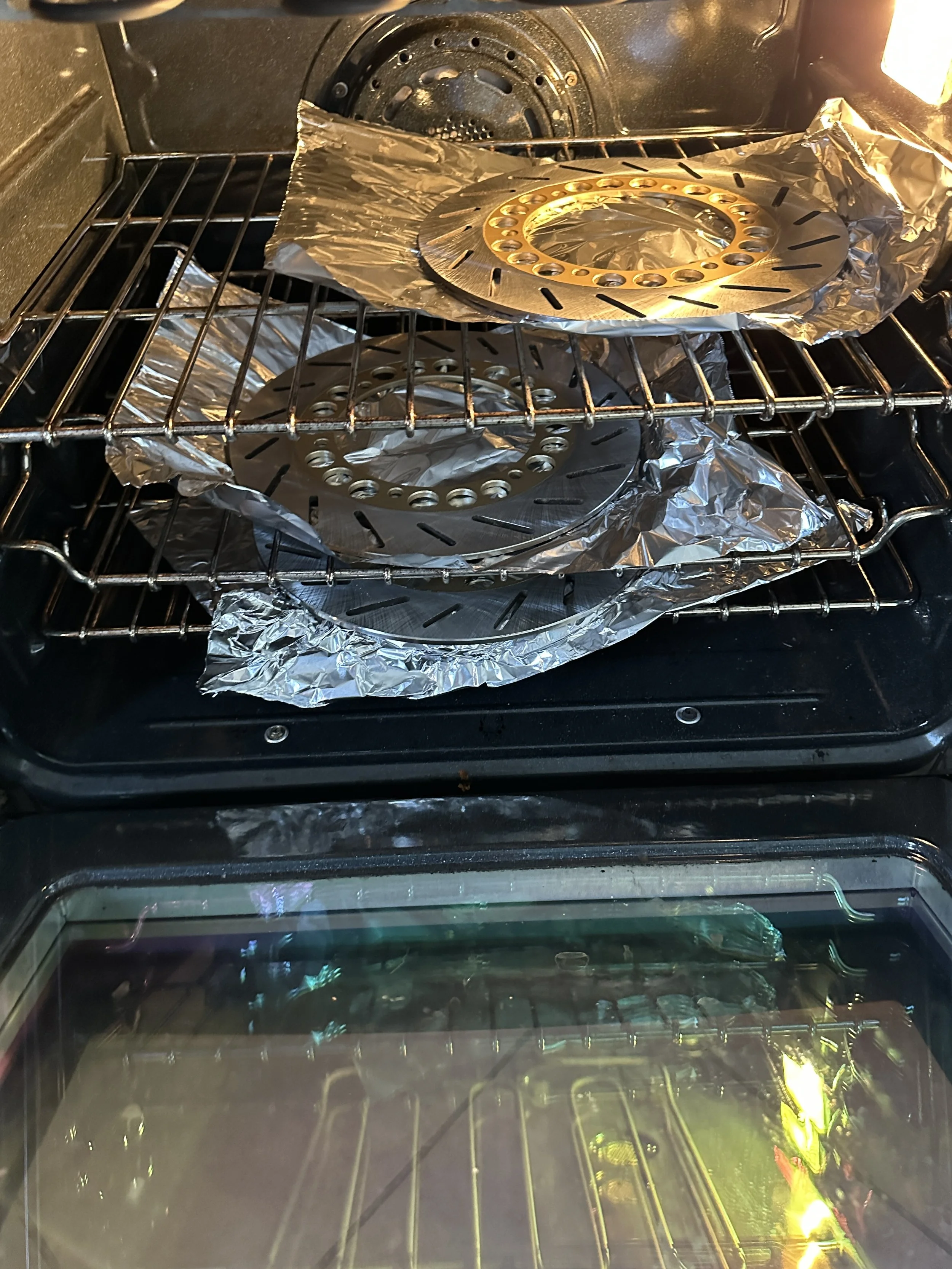

This time used the VHT caliper paint....

....which recommends baking at 200ºF for an hour....something which I don't think Dupli-Color was developed for.

cleaned the Loctite out of the threads...

...i think results speak for themselves.

....disk grinding by...https://truedisk.net/

brought to you by...VHT Caliper Paint.

Shakedown #1- Desperately Seeking Neutral

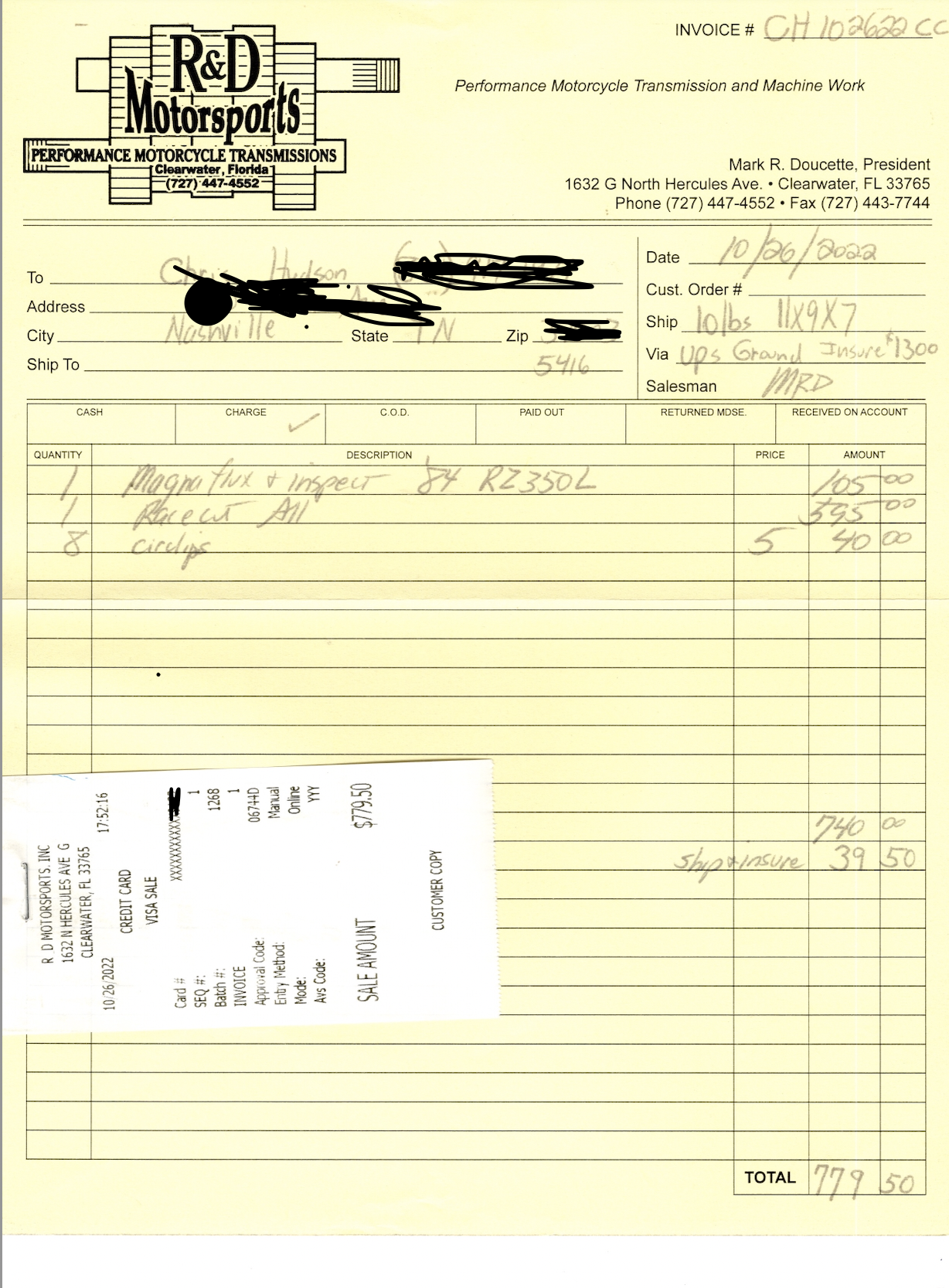

Despite the fact that Carey has the clocks to properly calibrate the temp control, I decided, being otherwise completely legal, there was no reason I could ride around the block a few times….and maybe farther…and it ran fine but I had a newar impossible time getting it into neutral even while rolling to a stop. Not having the patience to try one thing at a time I decided to try…..everything. And so I installed..

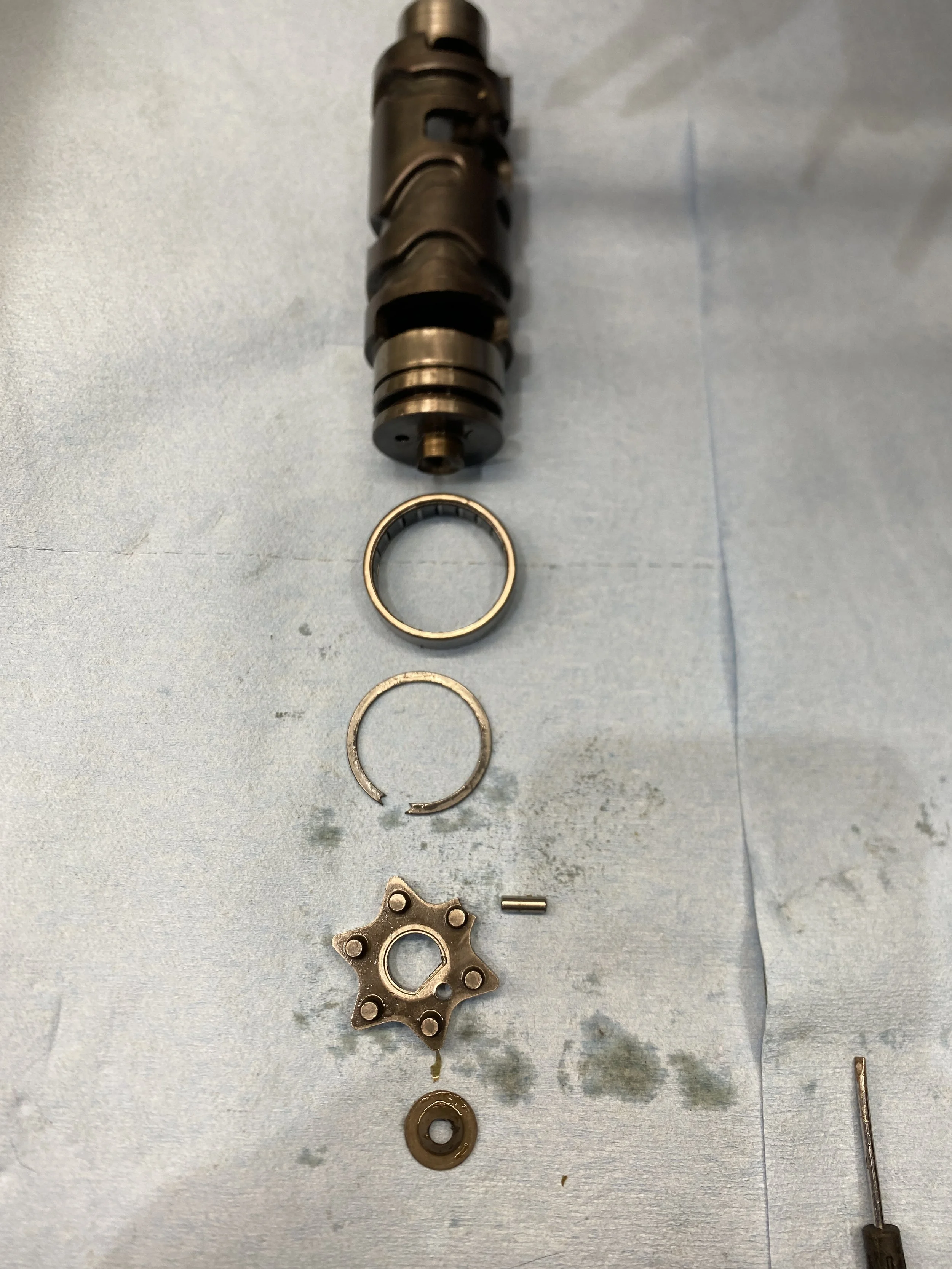

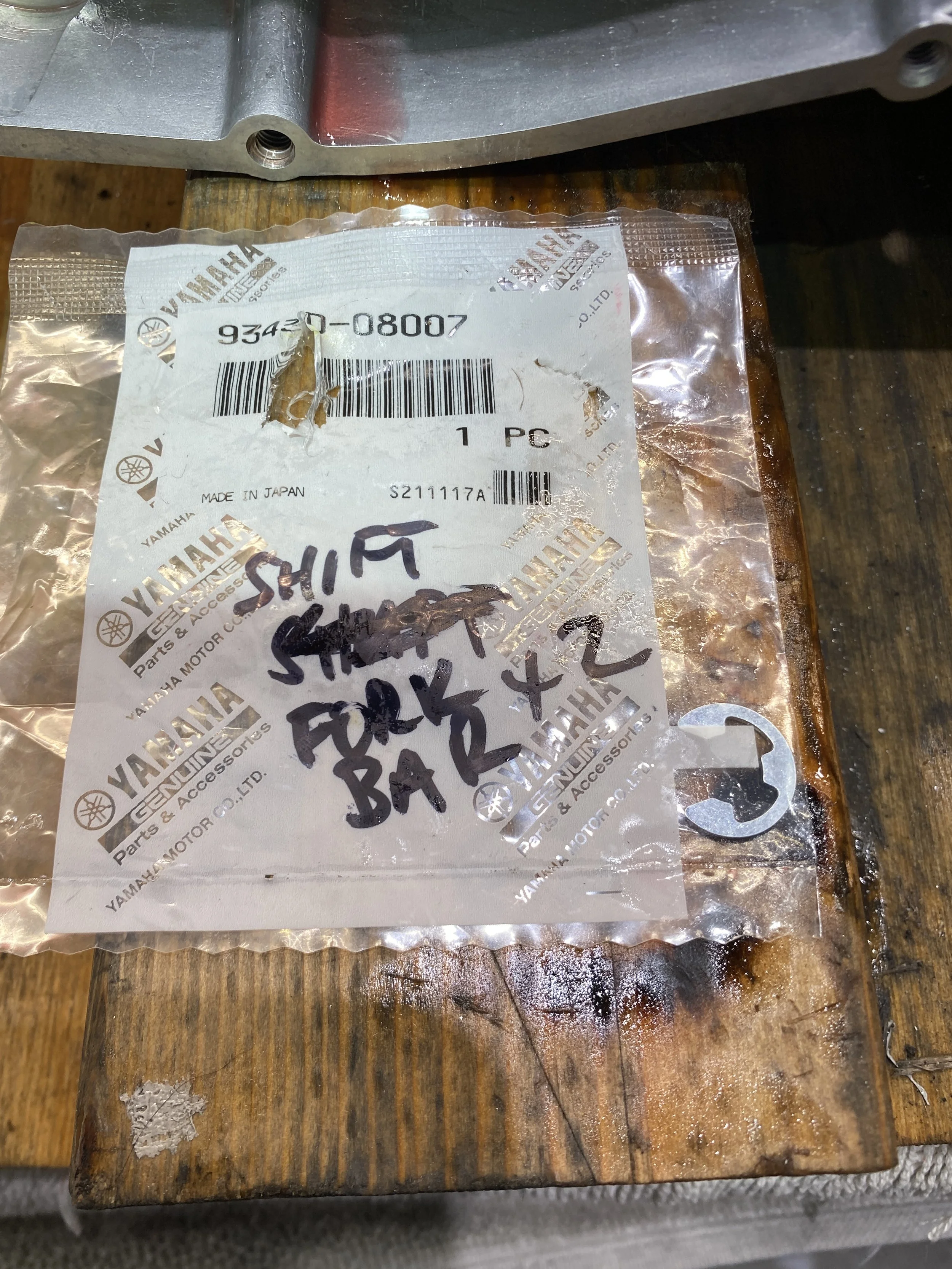

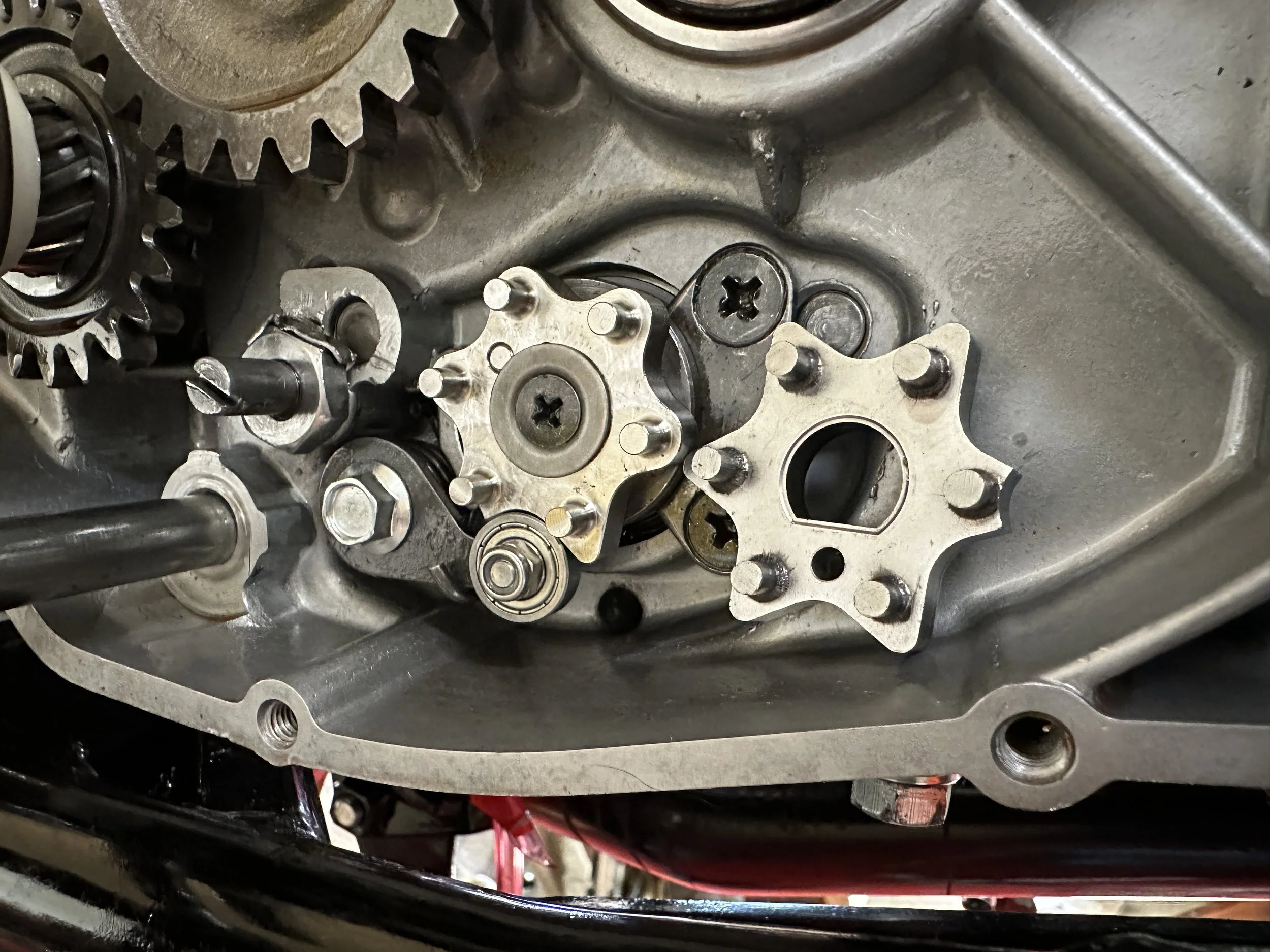

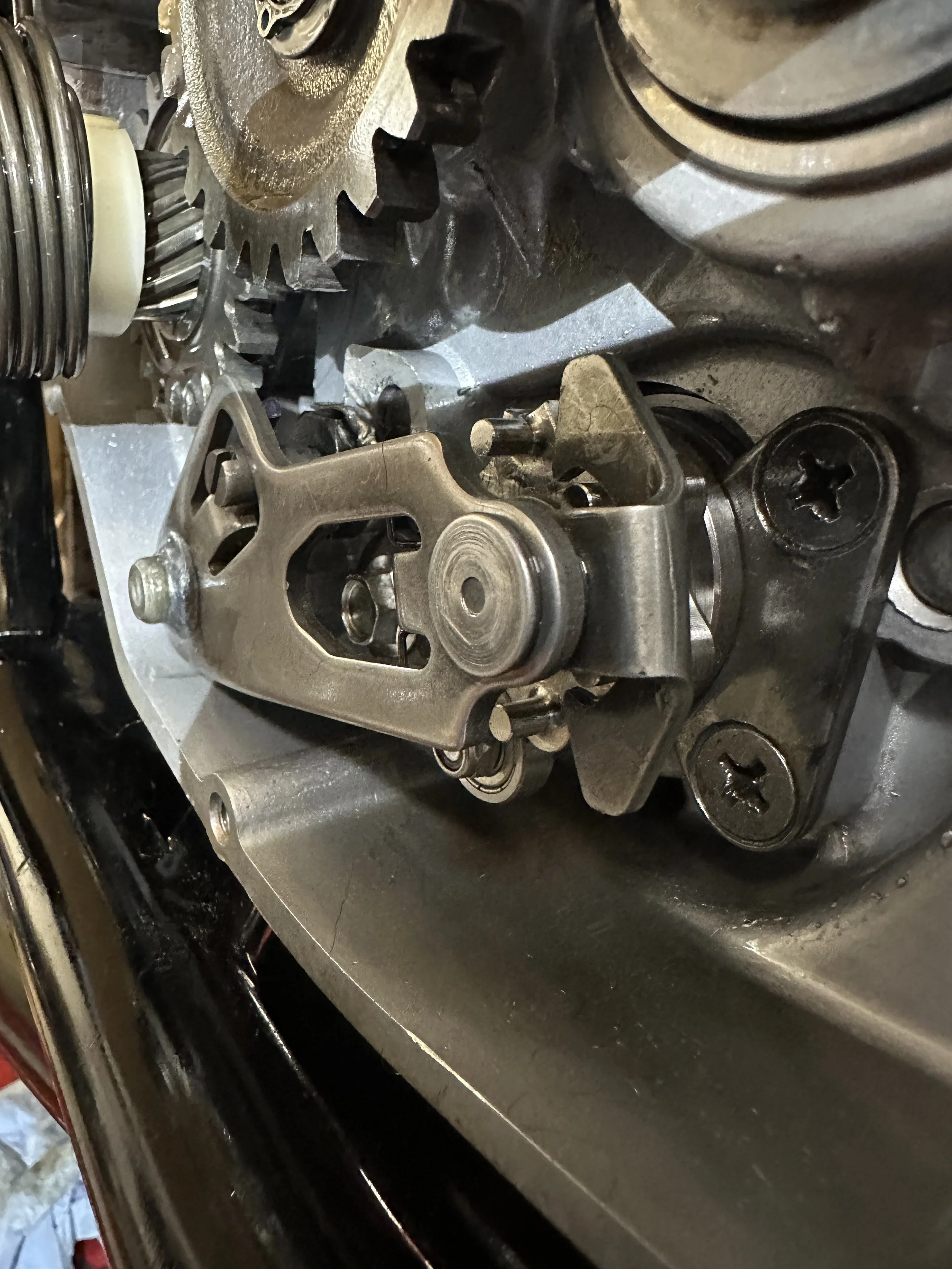

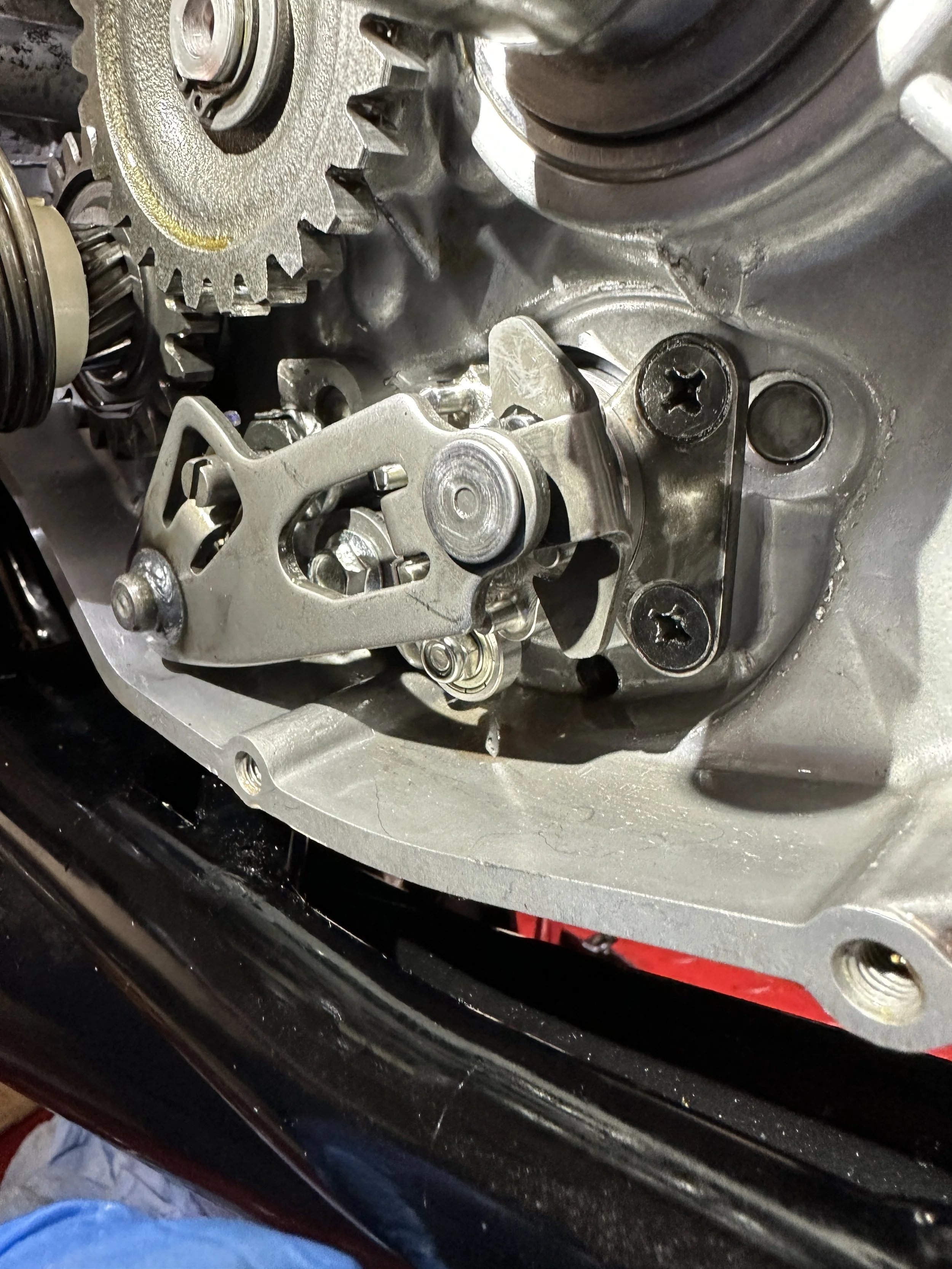

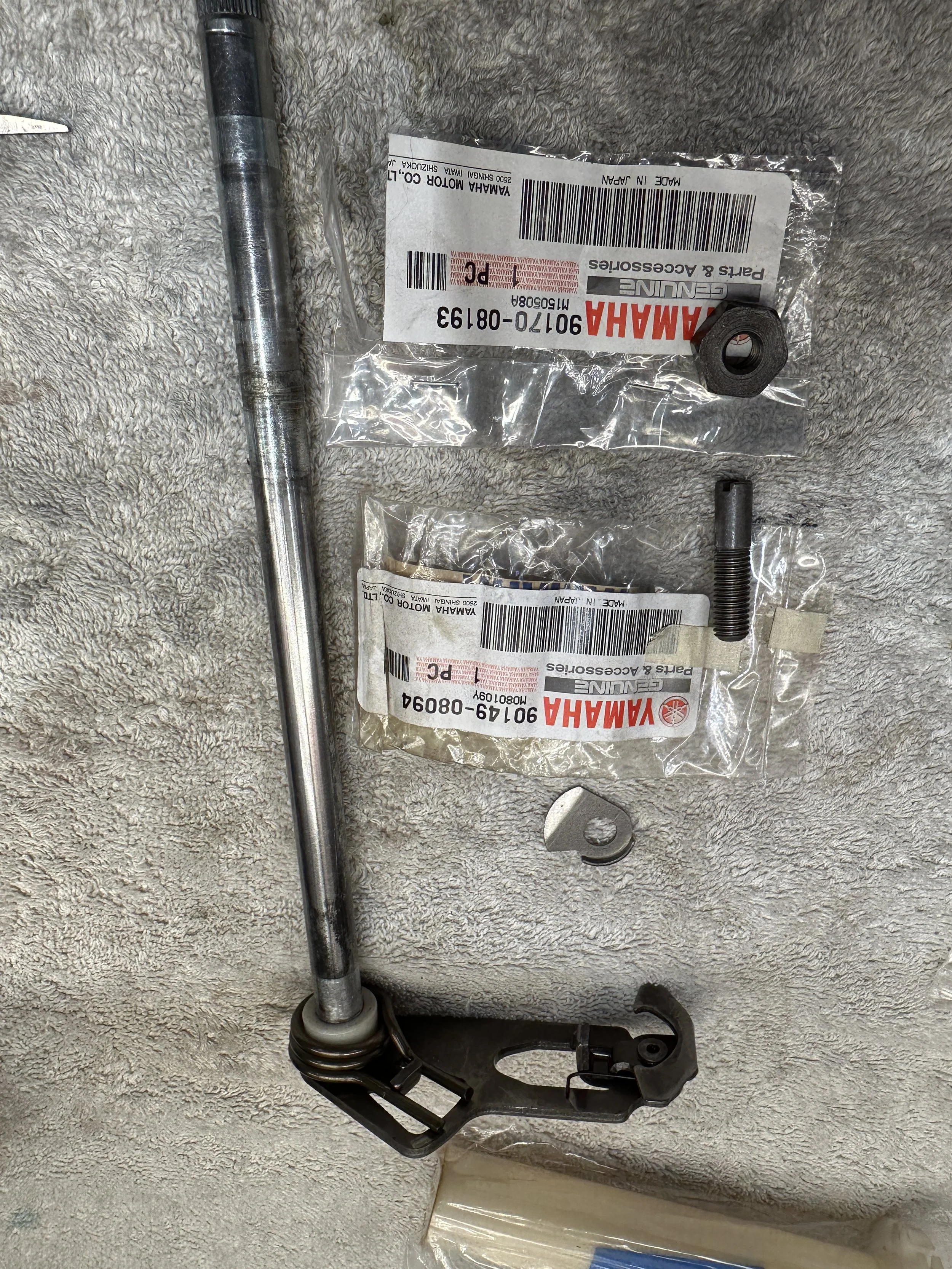

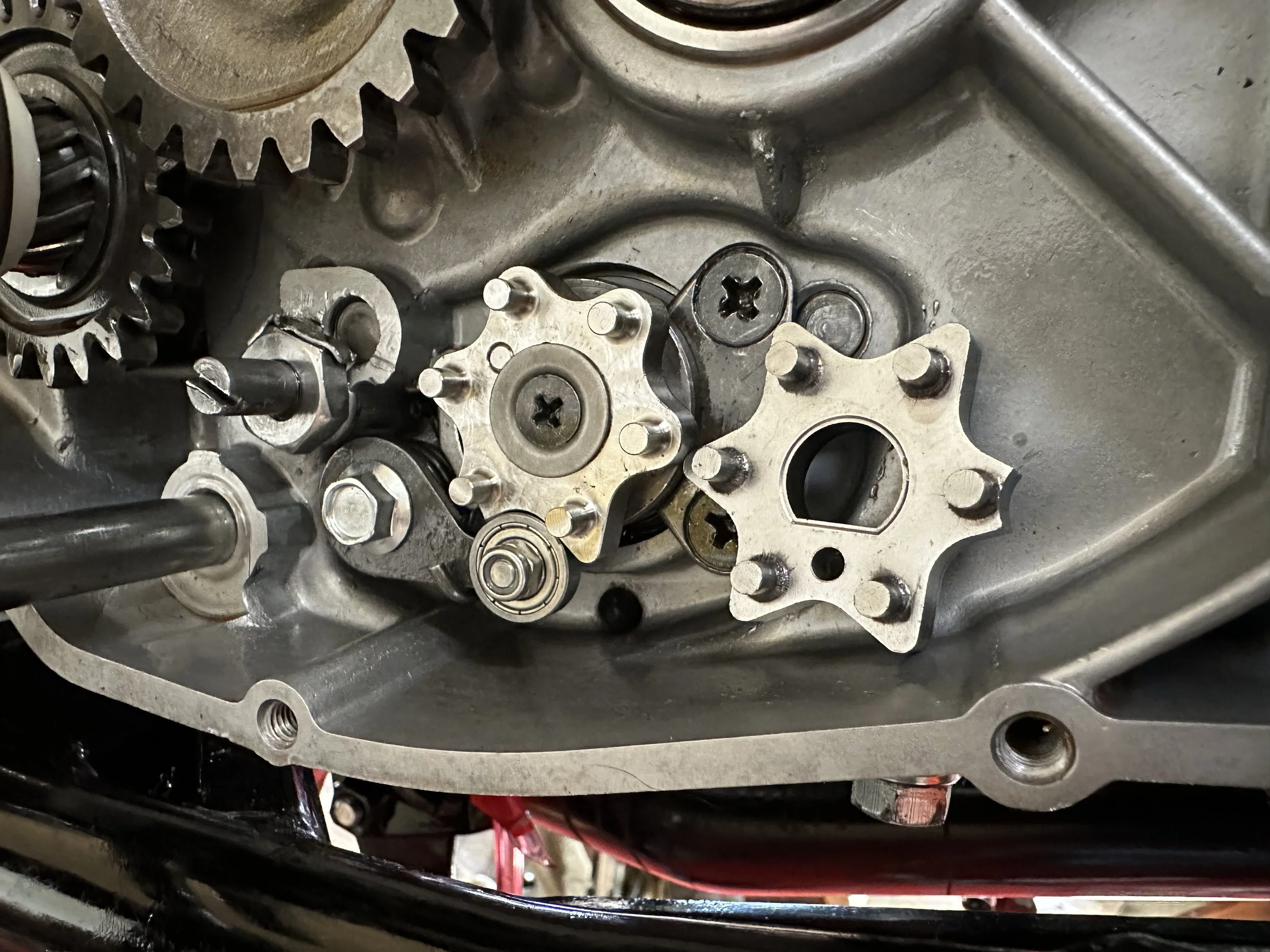

Modified Shifter star-from macdaddyracing.com

Modified Shifter arm-macdaddyracing.com

Shifter arm spring macdaddyracing.com $110 for all of the above

EBC Clutch plates-has a fraction more (wider) clutch material

3 OEM Springs to go with the heavier aftermarket springs

New Steel Plates-originals rusted $150 for both fibre & steel plates & springs

New OEM Yamaha clutch cable-original too long $150! (it’s a discontinued component)

Shift shaft torsion spring. $7

Shift cam adjusting bolt $7

Shift cam nut. $4

There's no question: the bike looks hot. The problem was finding neutral...even while rolling to a stop was almost impossible. Otherwise it shifted great. Reminder: it's a R&D Motorsports race cut transmission.

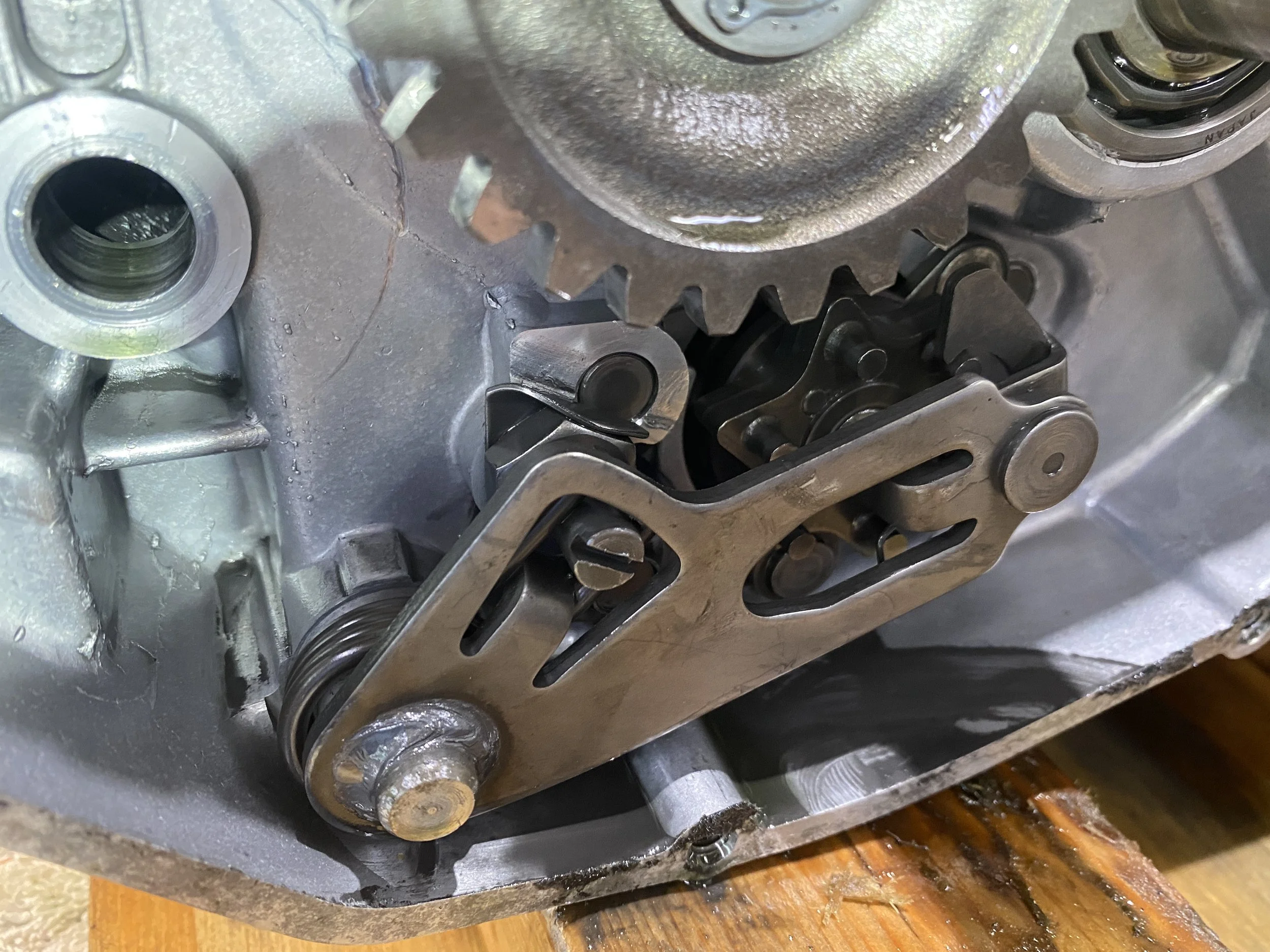

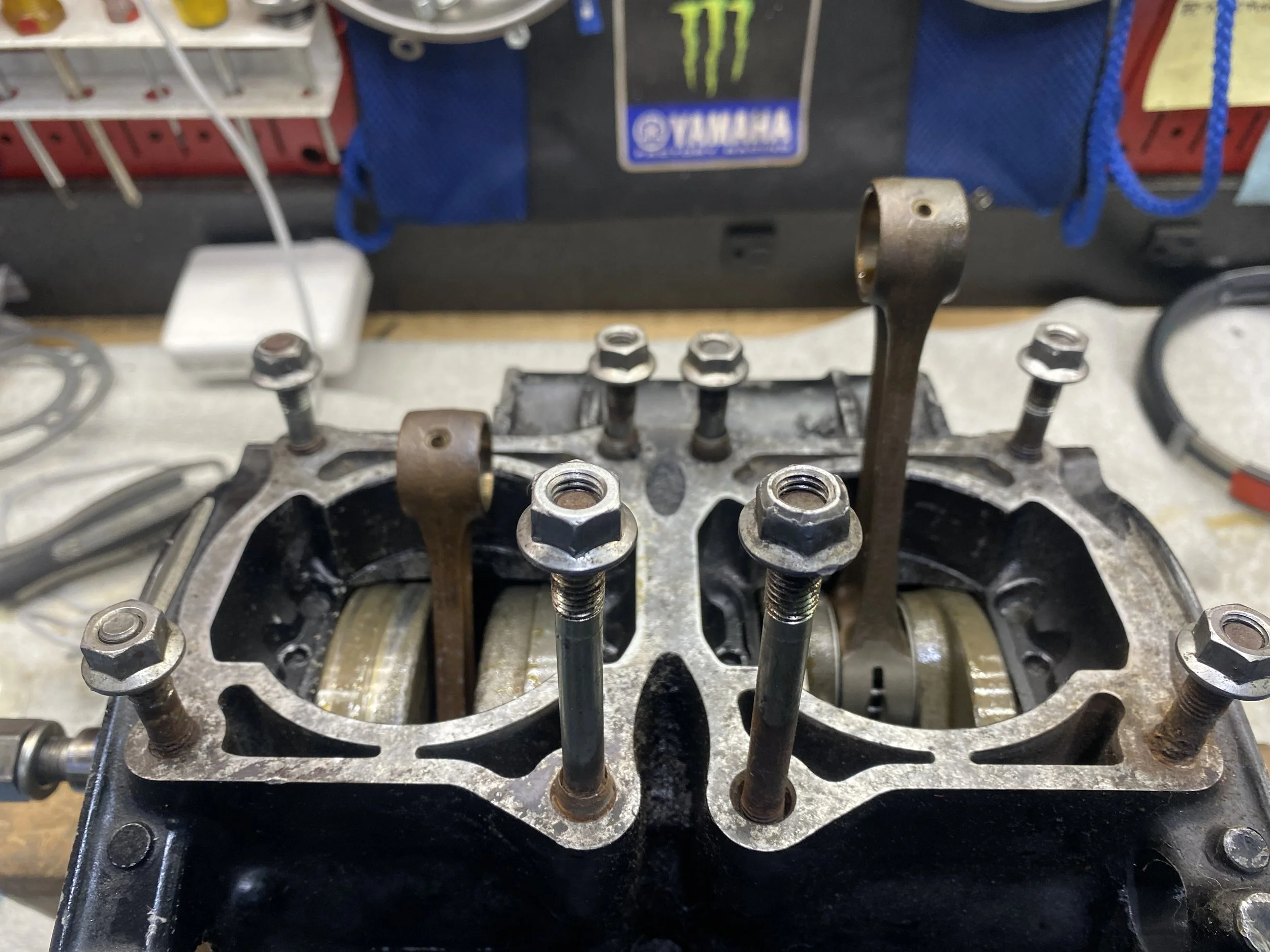

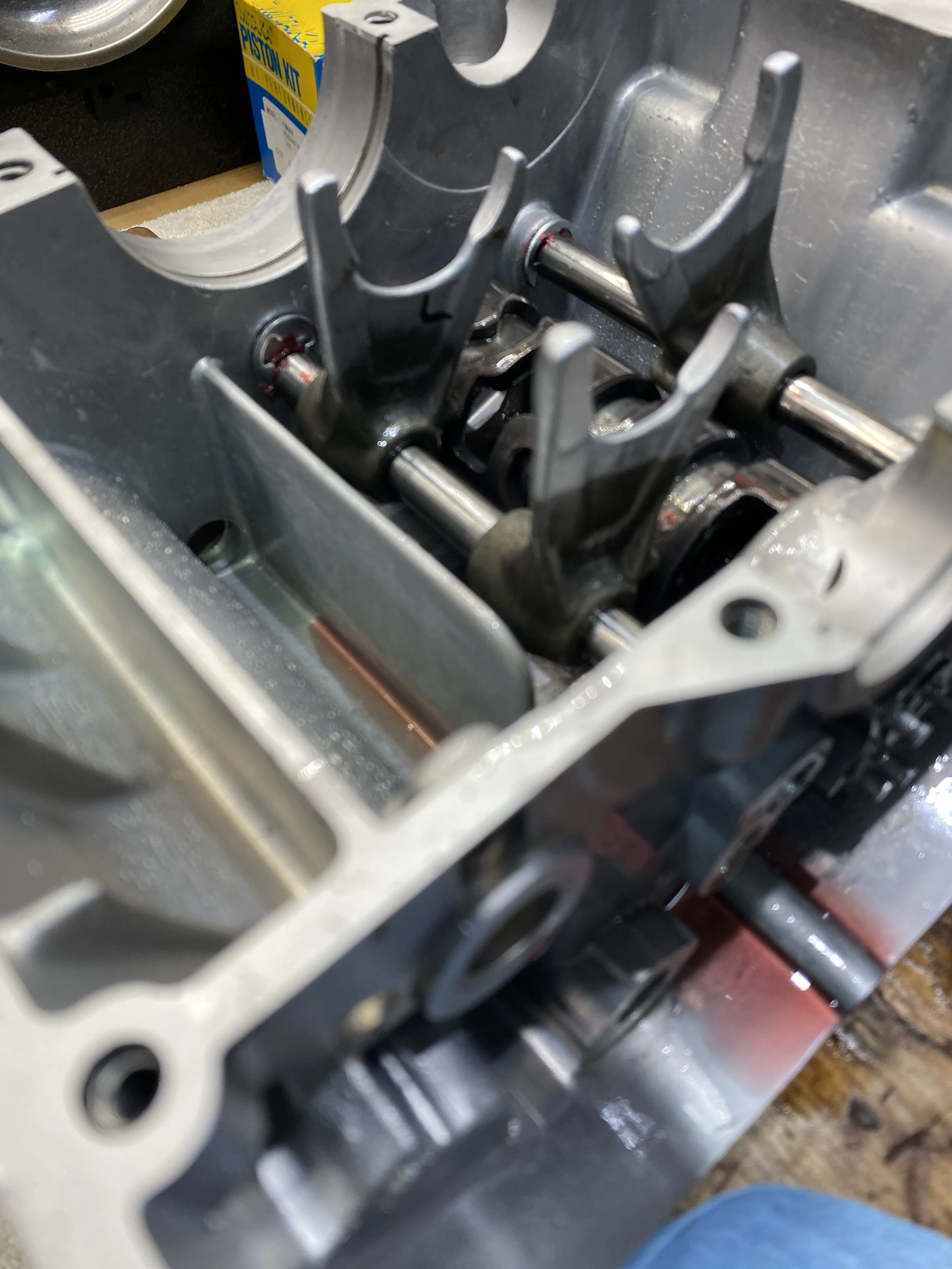

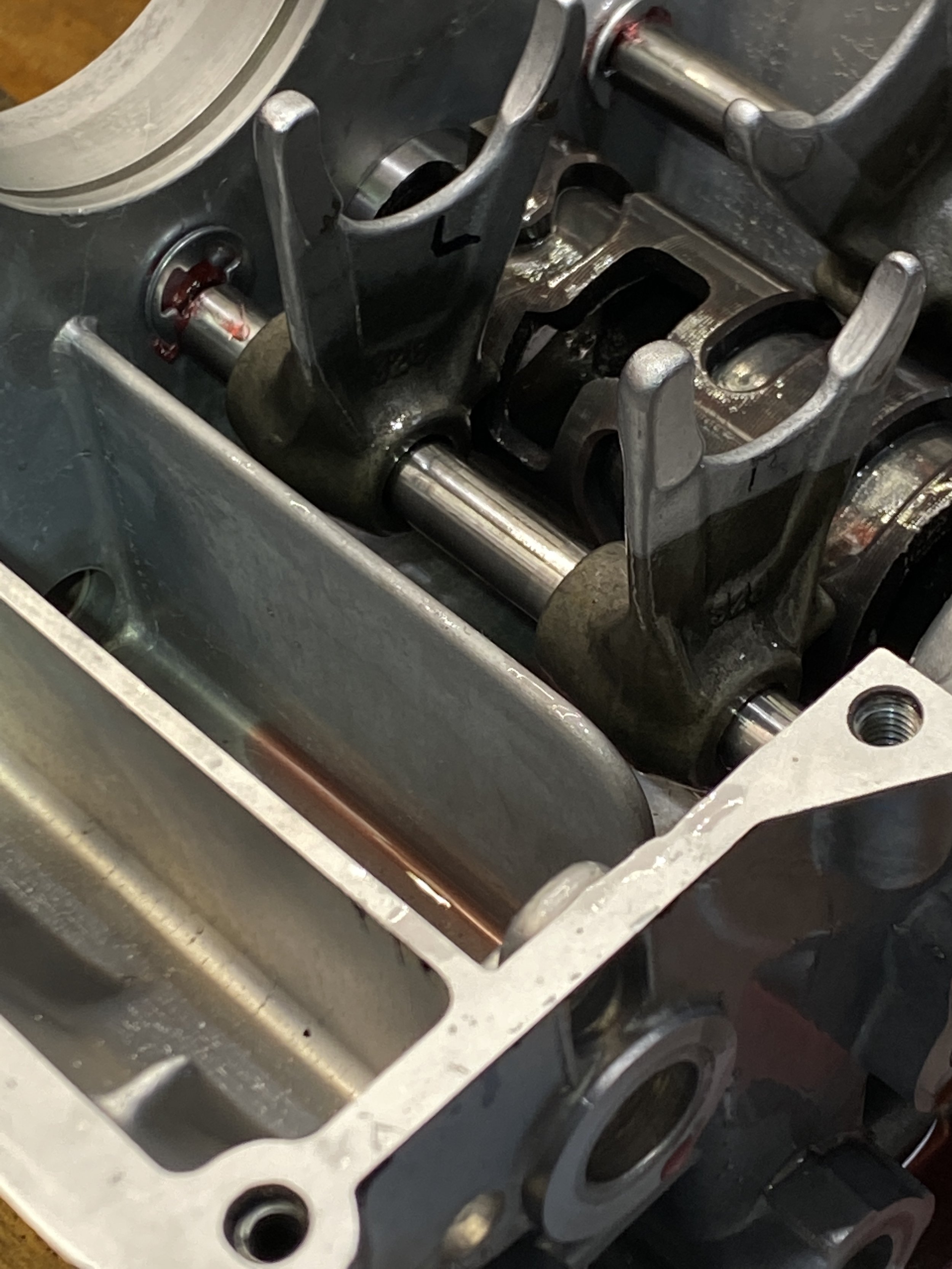

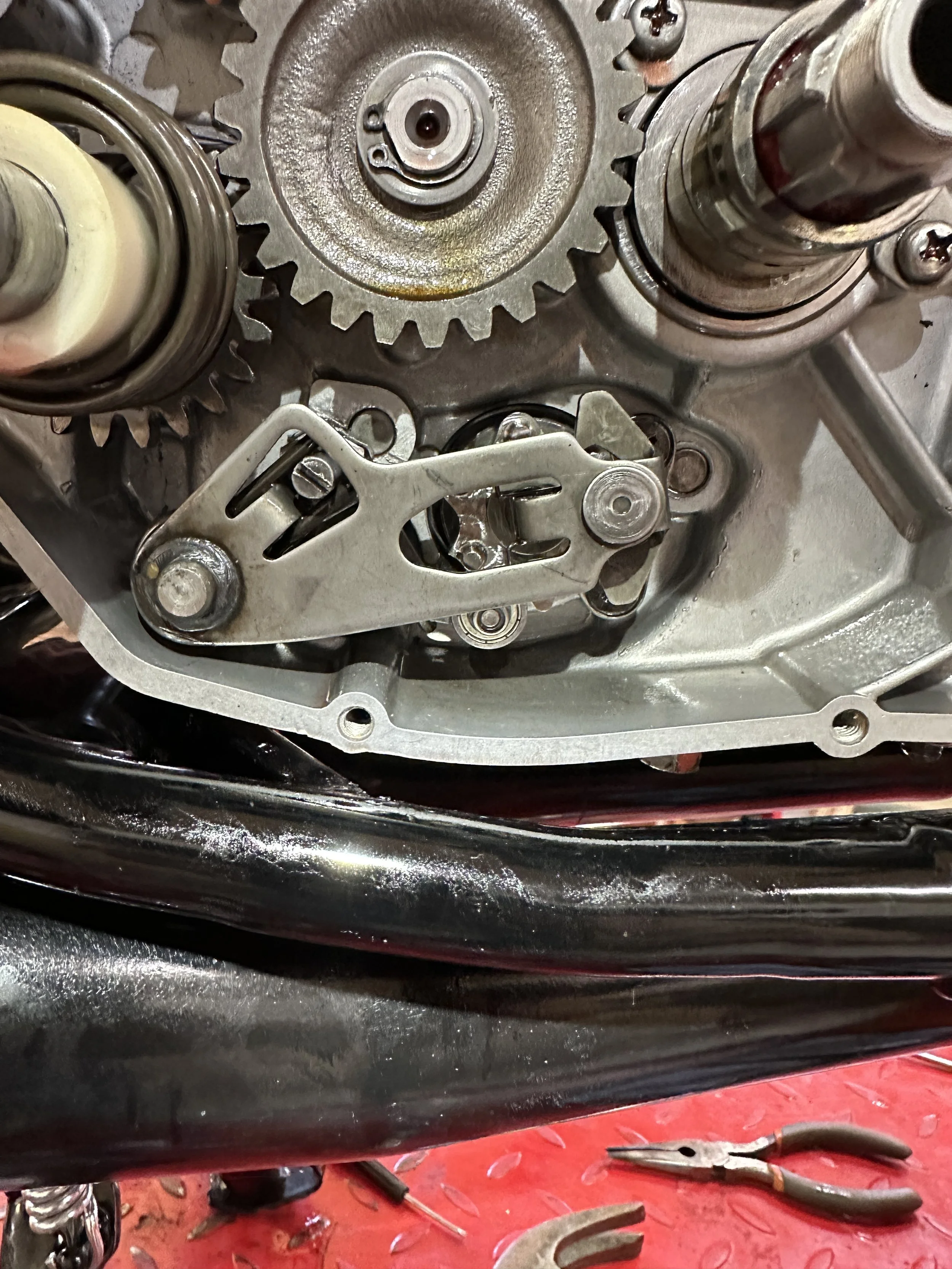

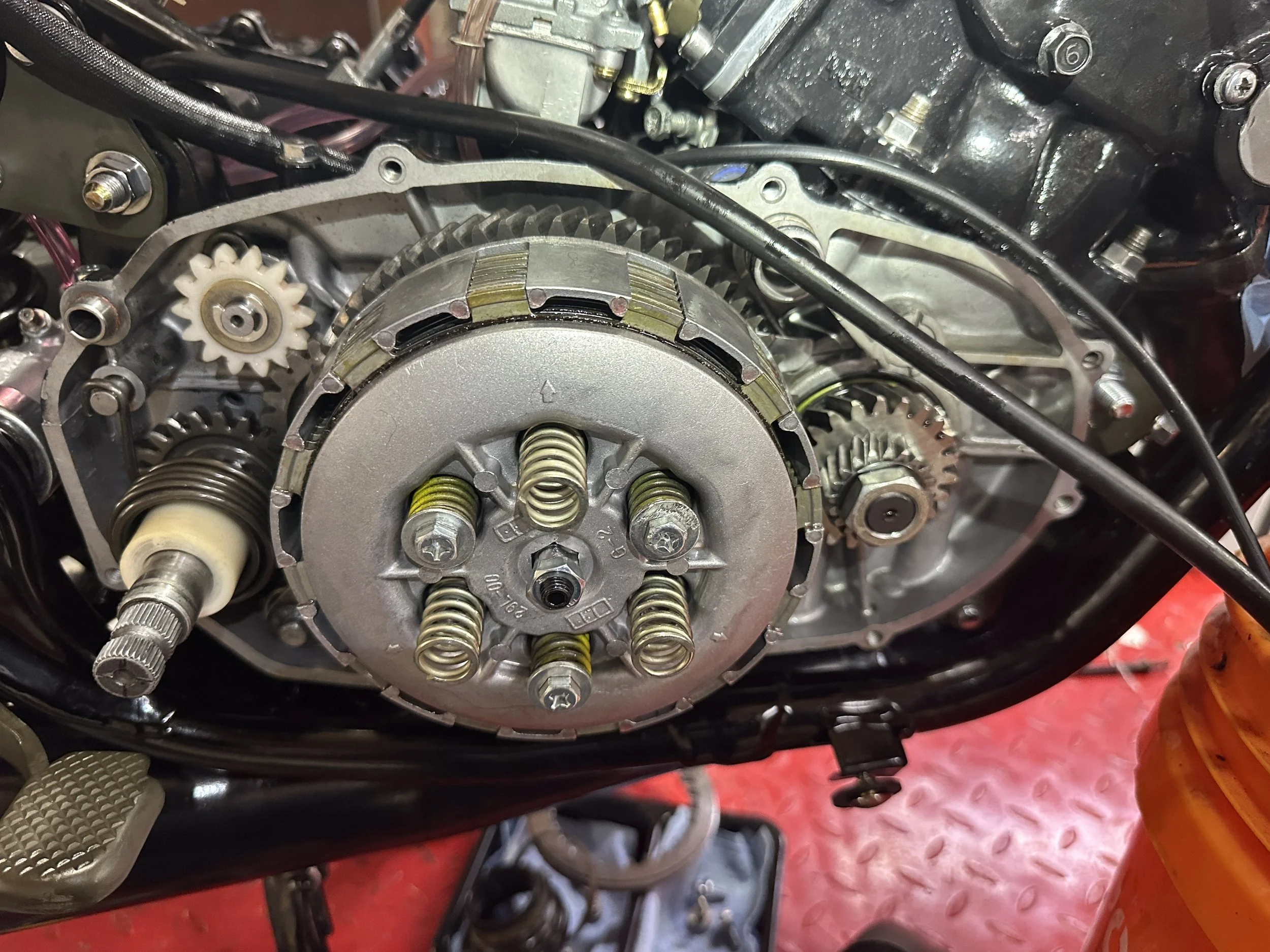

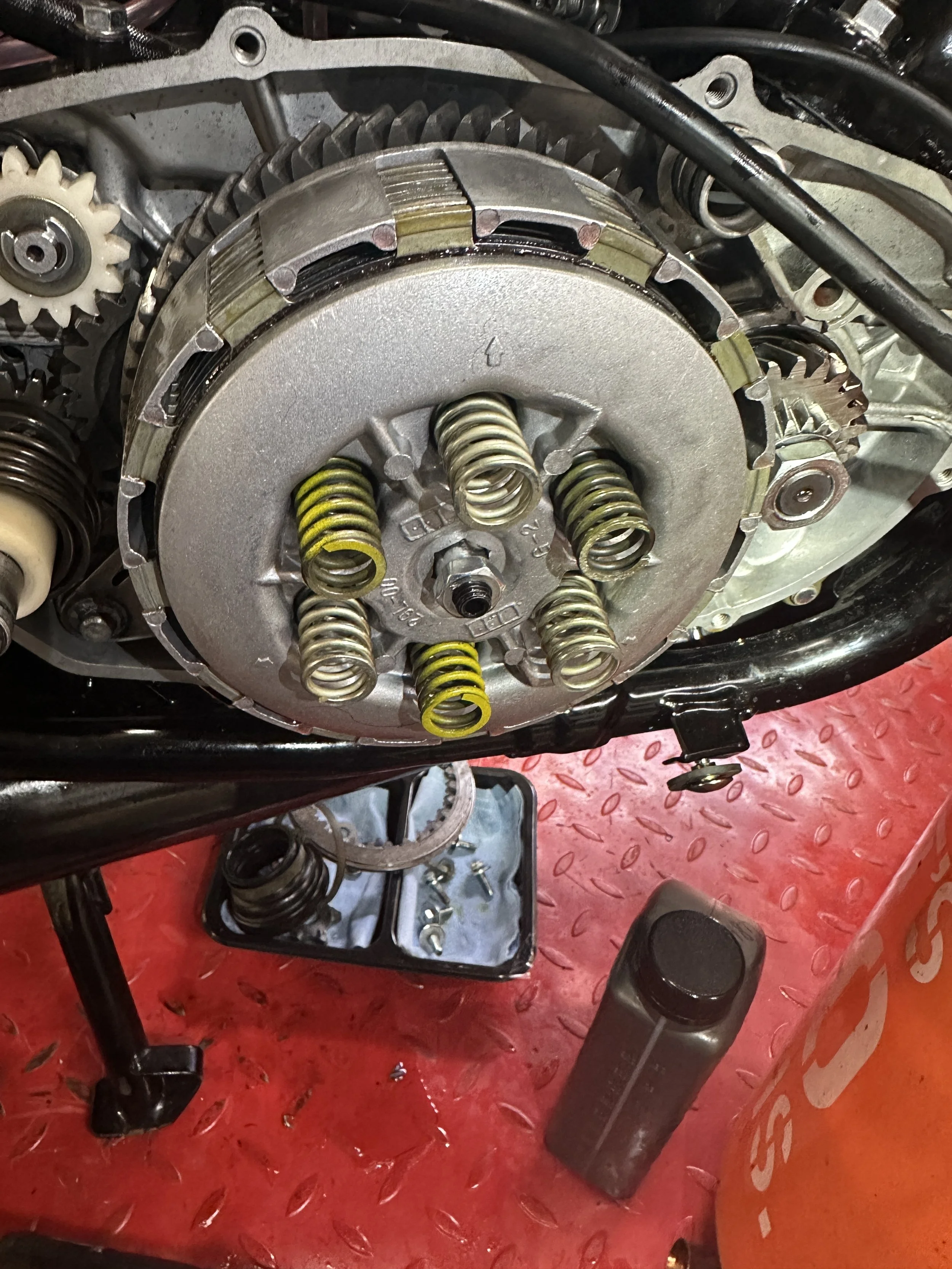

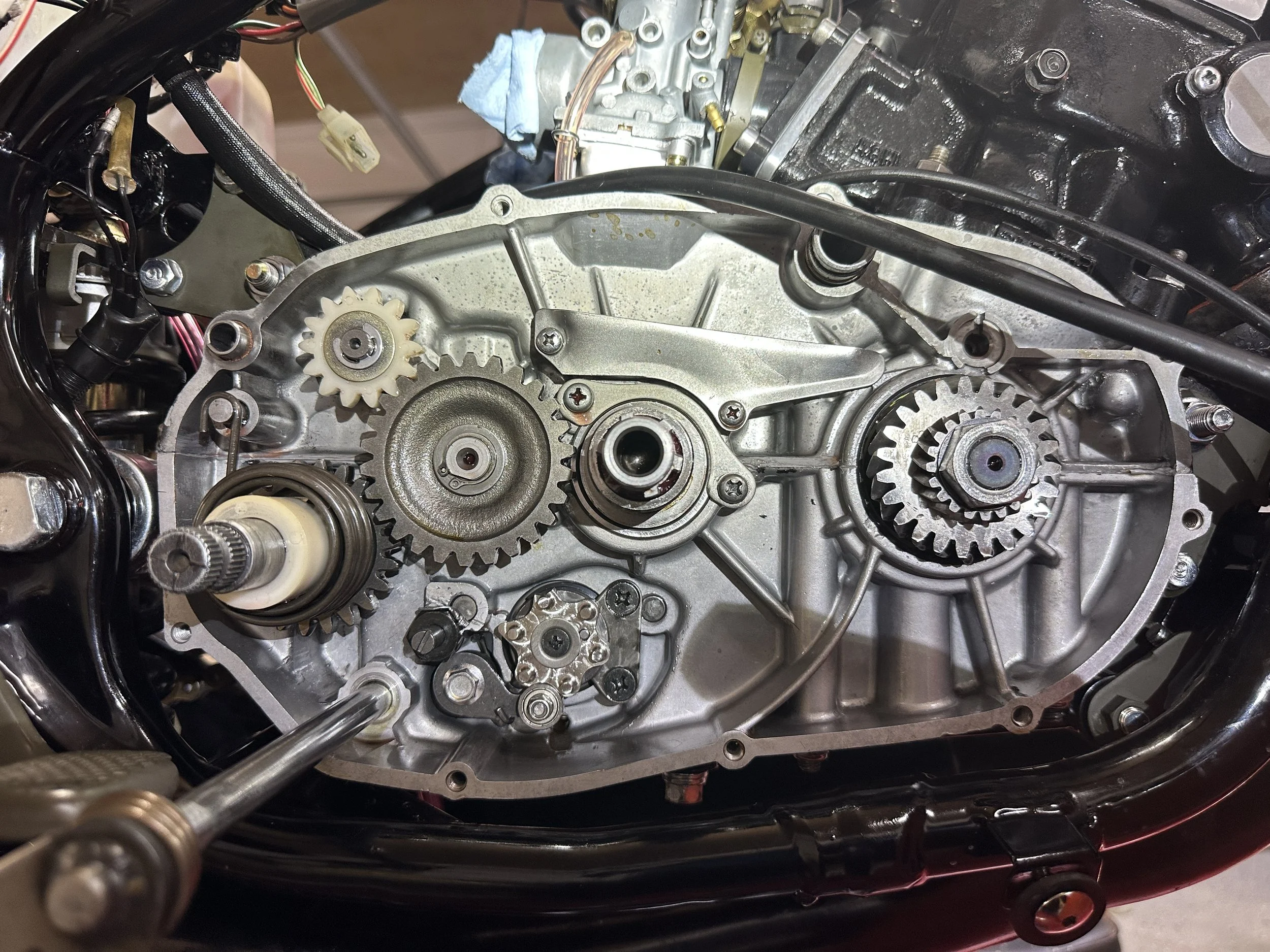

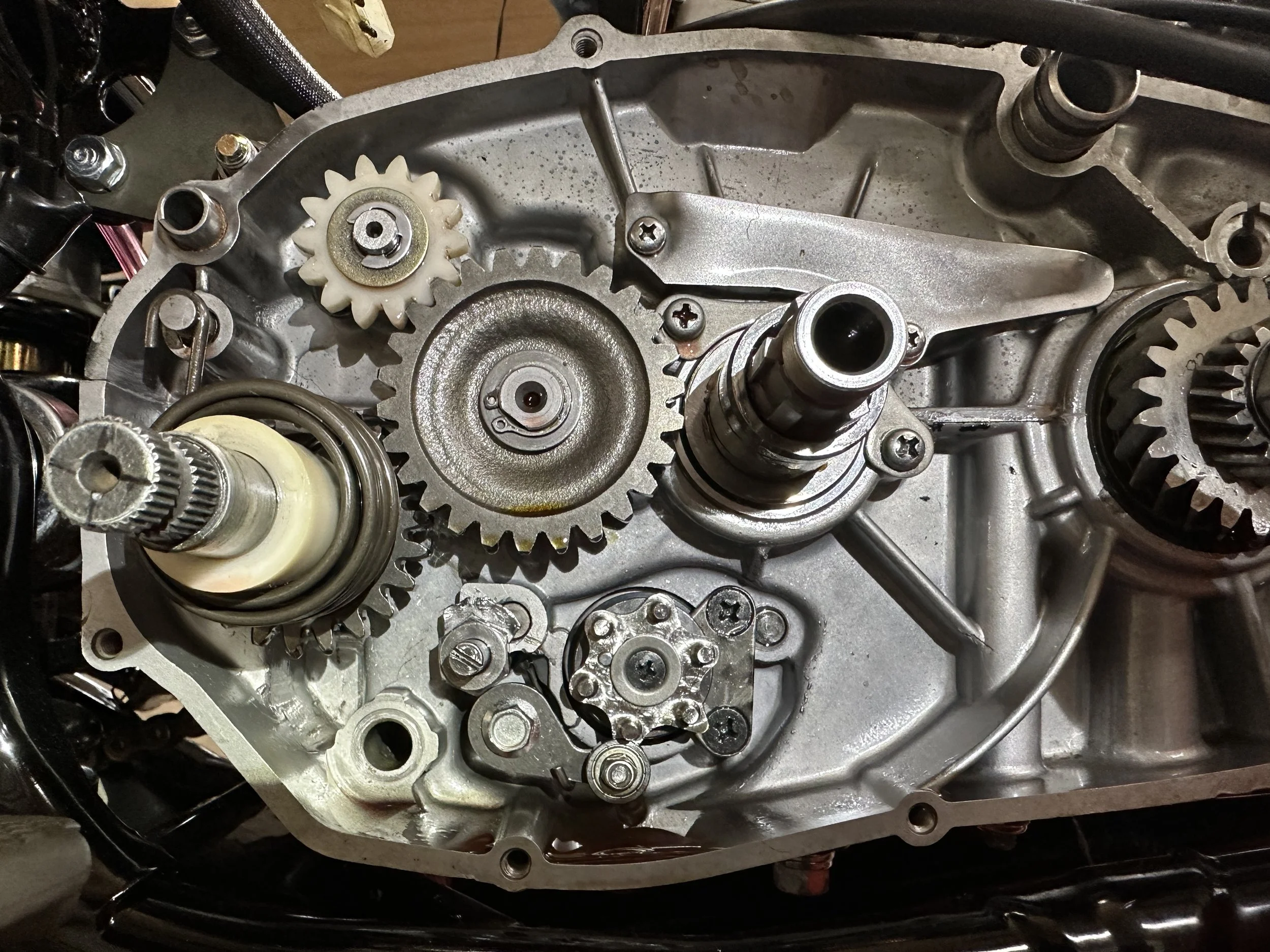

open heart surgery

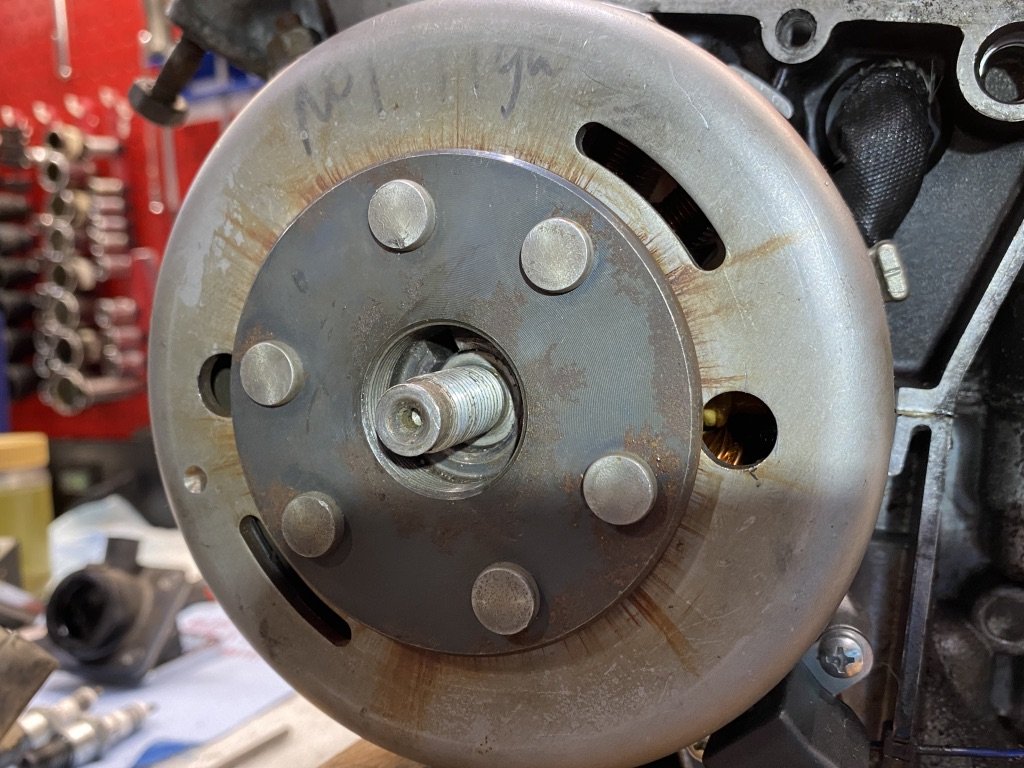

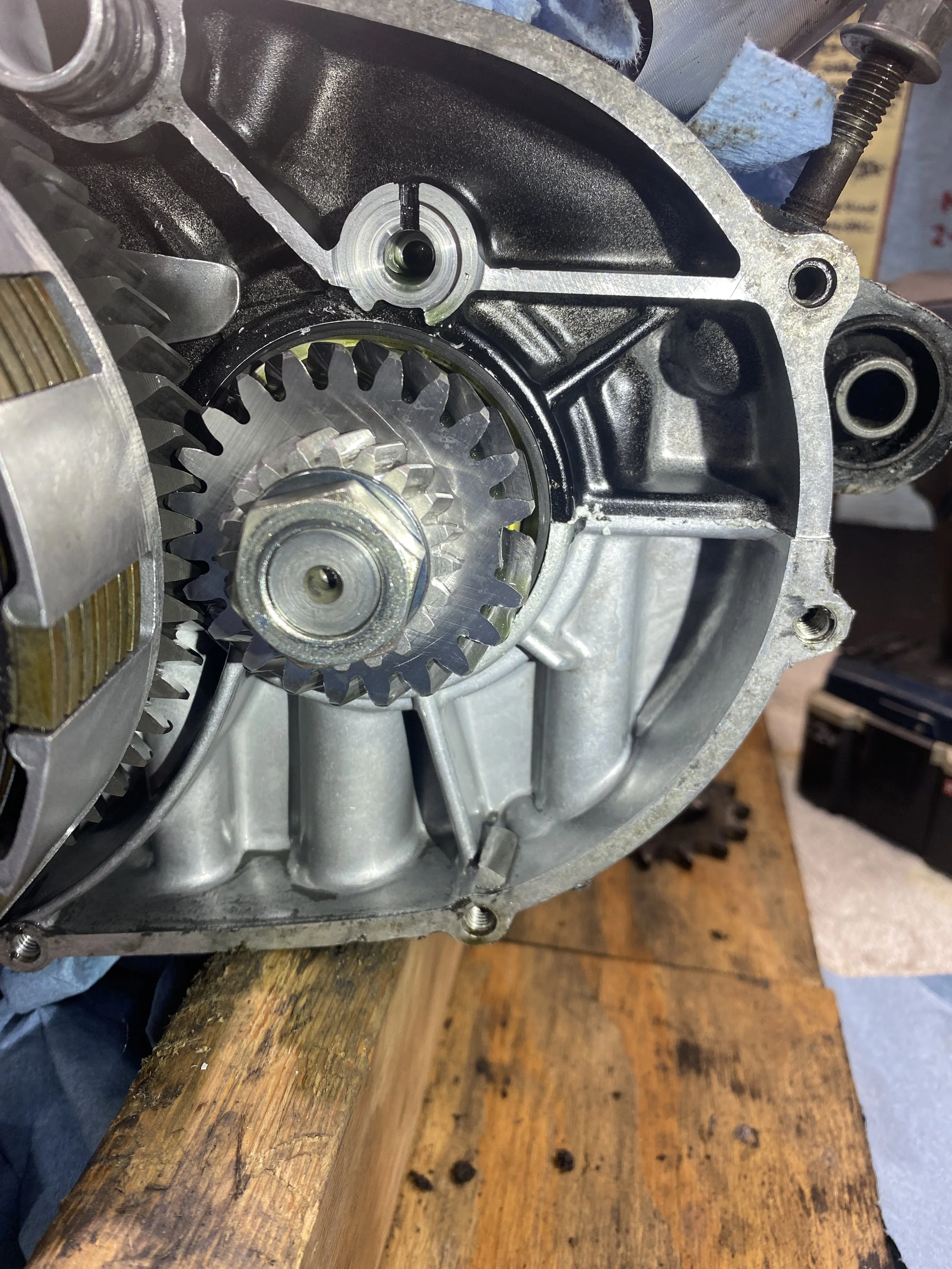

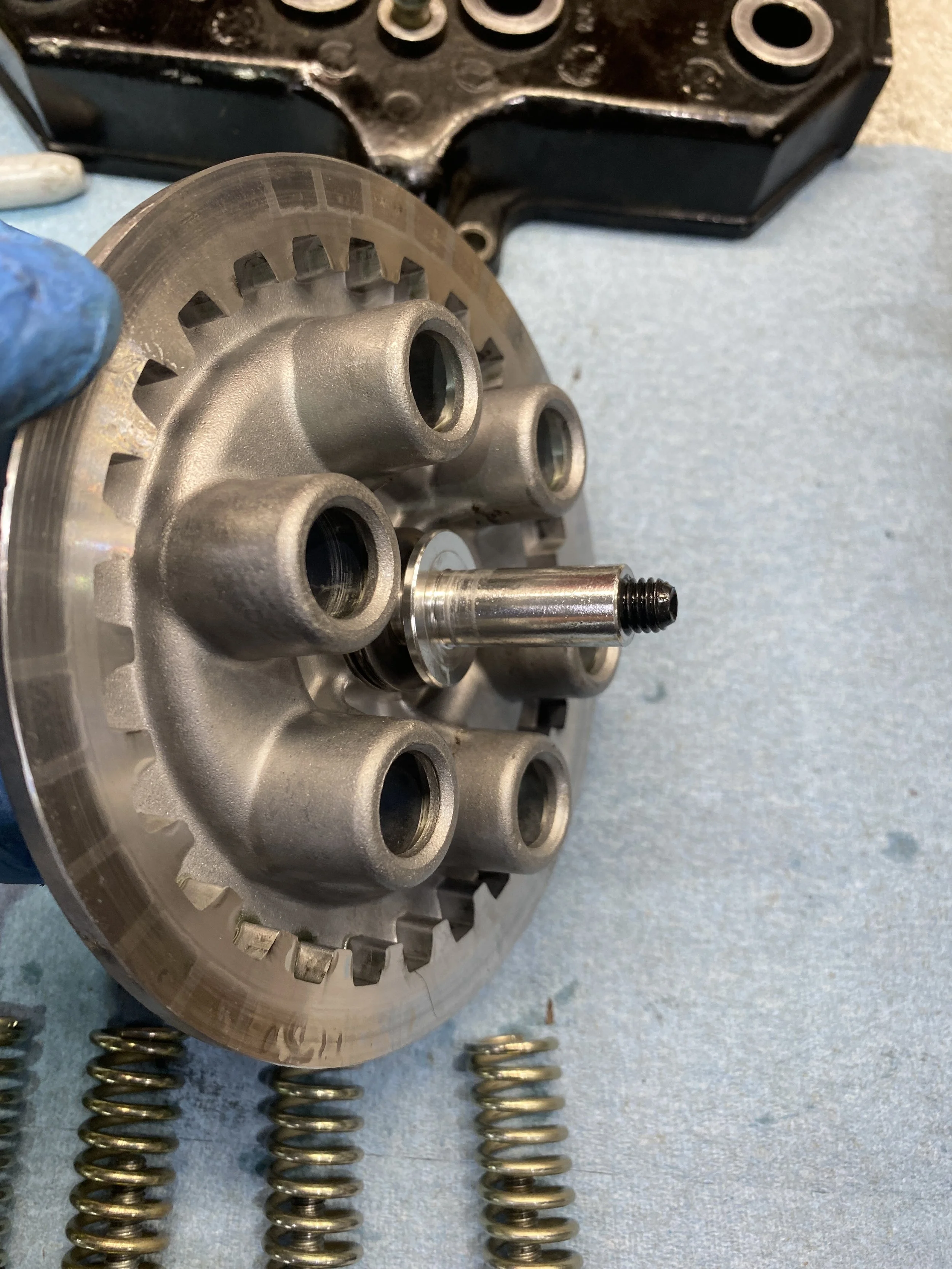

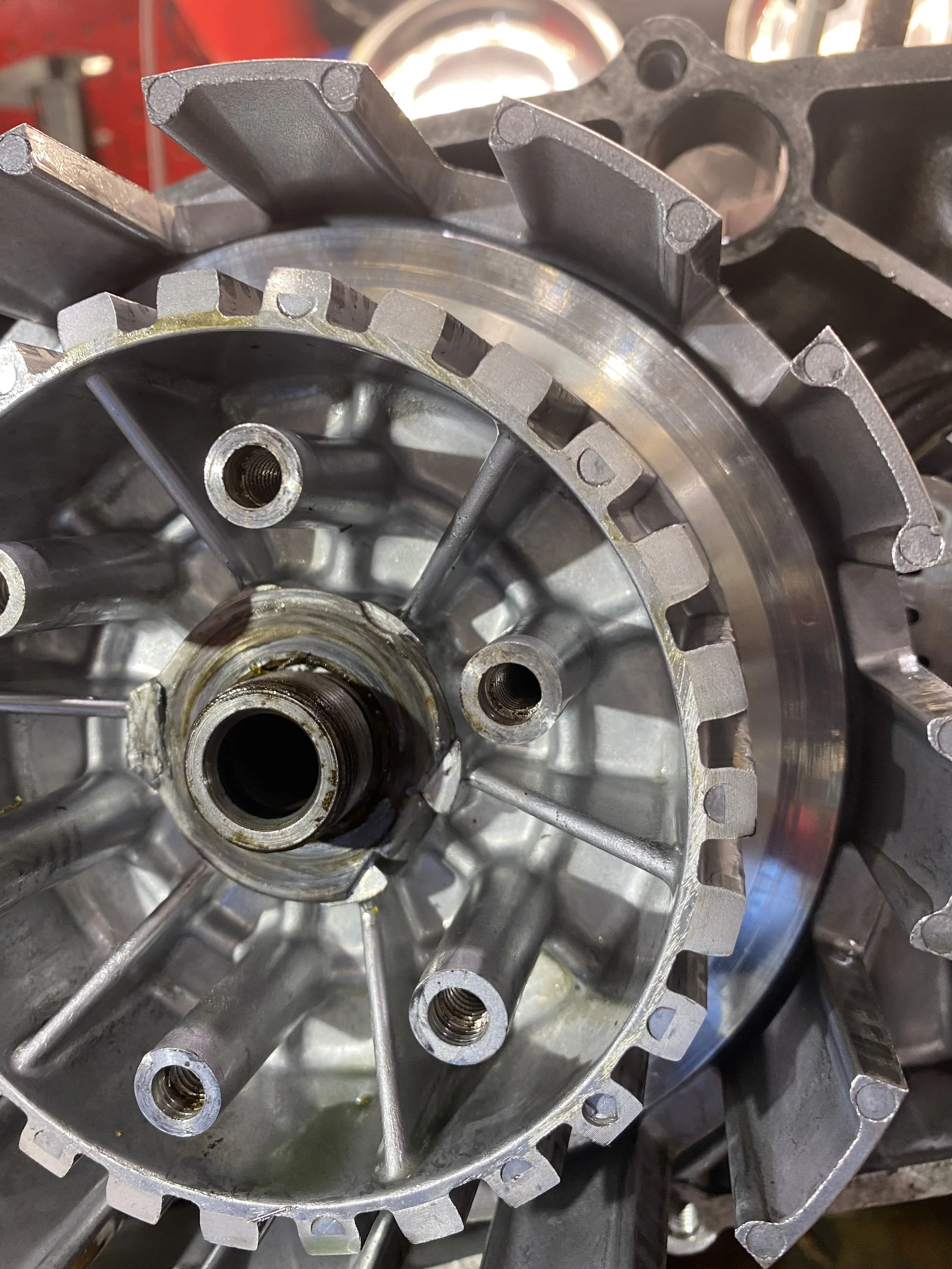

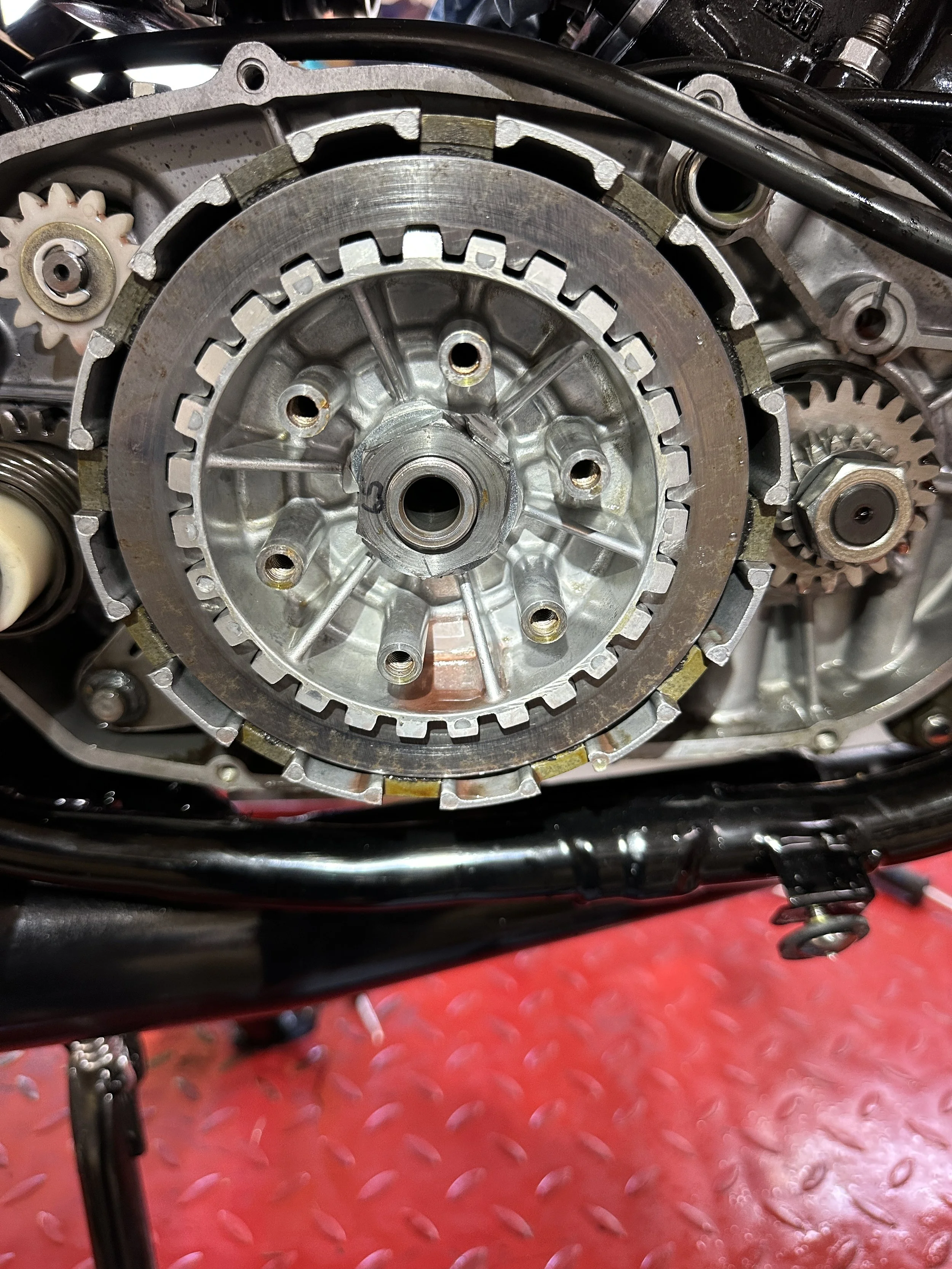

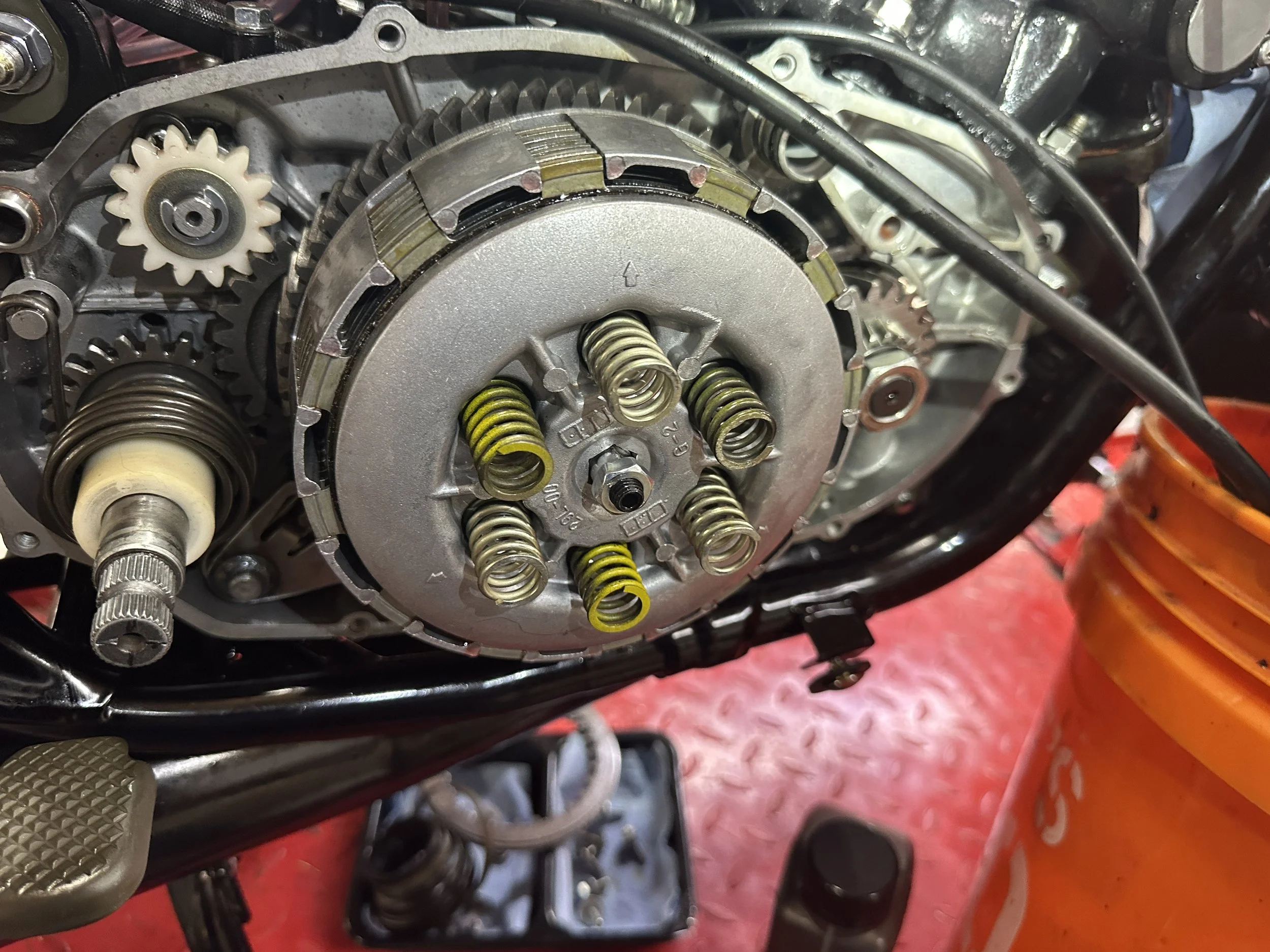

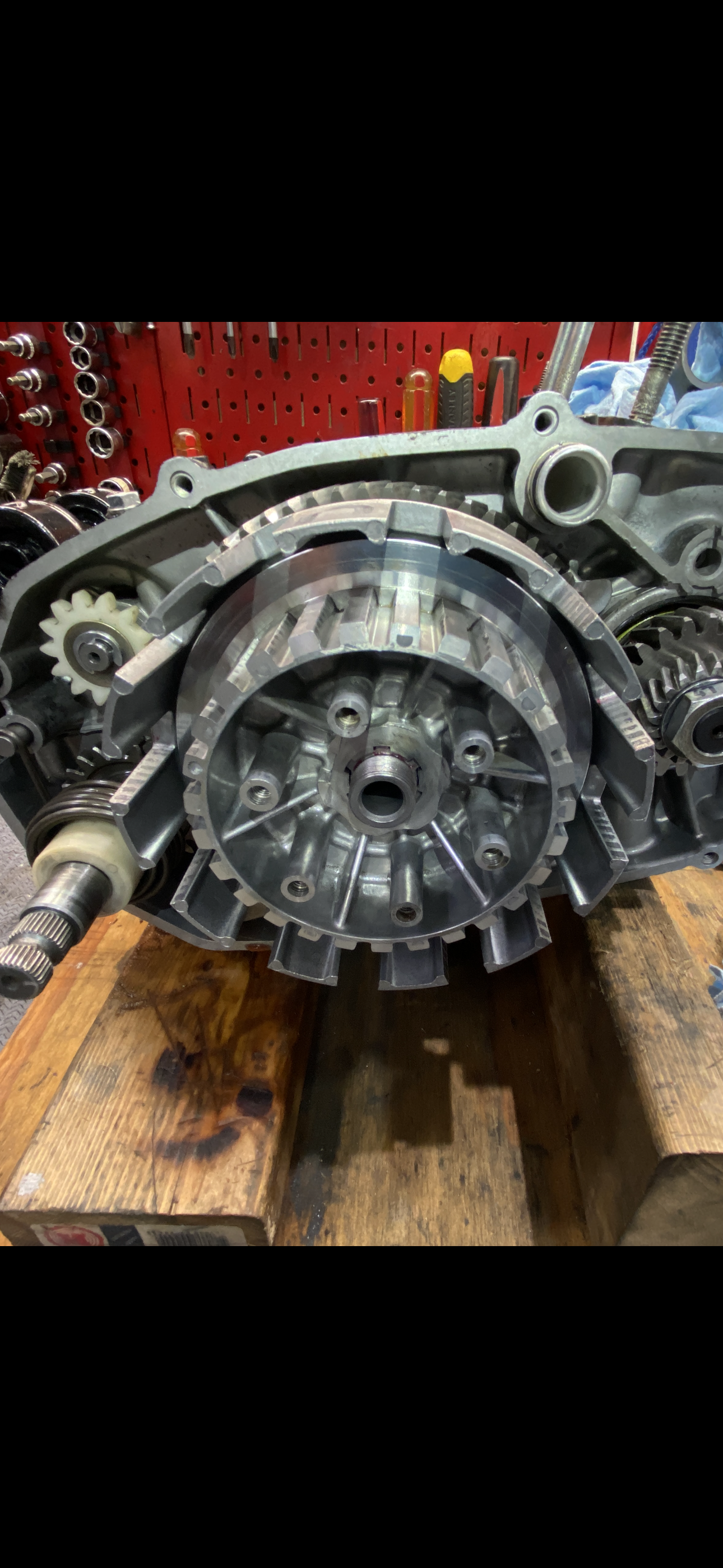

No issue with the clutch basket. OEM and smooth fingers.

Pressure plate also looks new. Even got a pancake bearing...

hate having to strip down this much after you think it's finished.

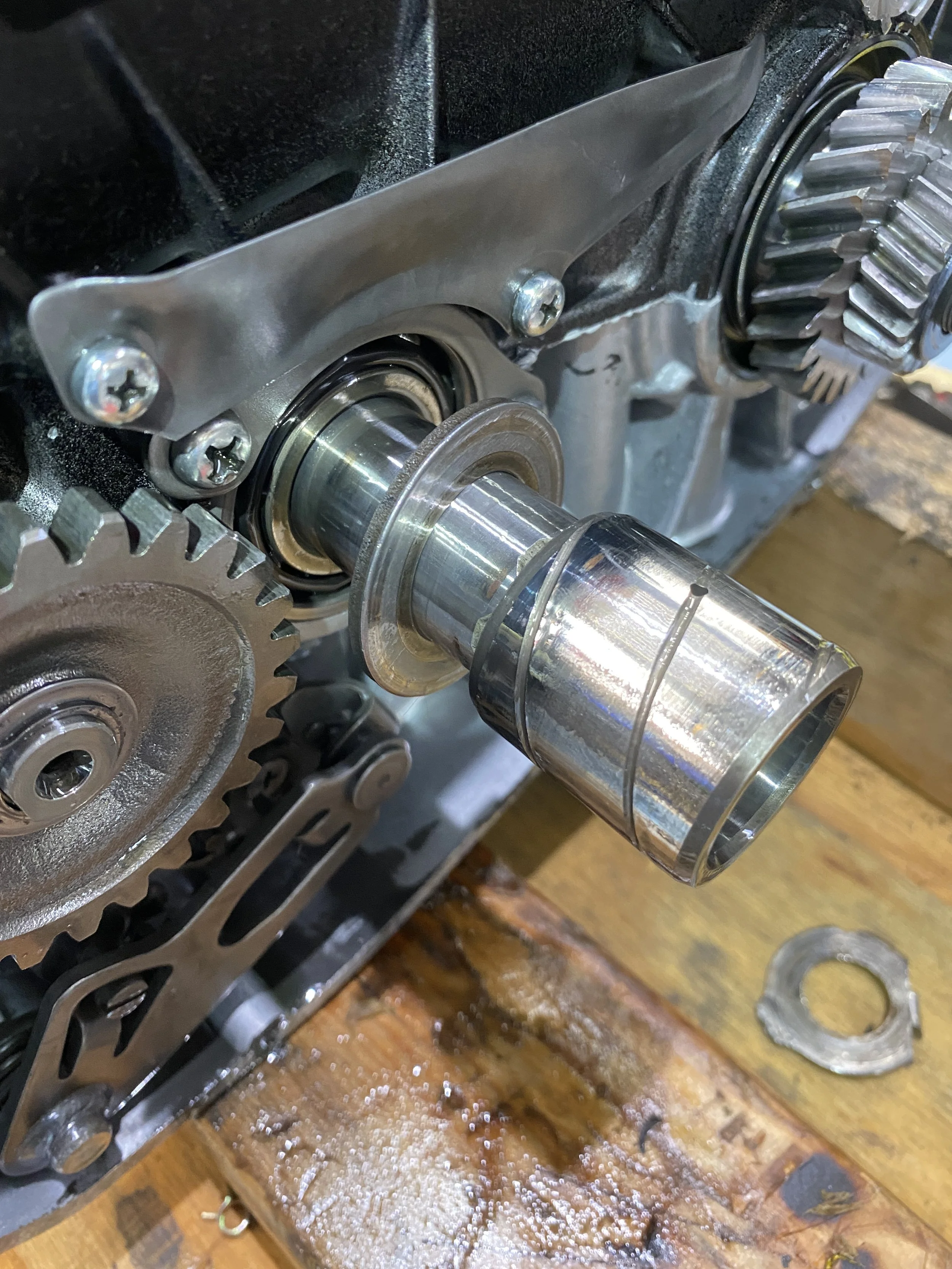

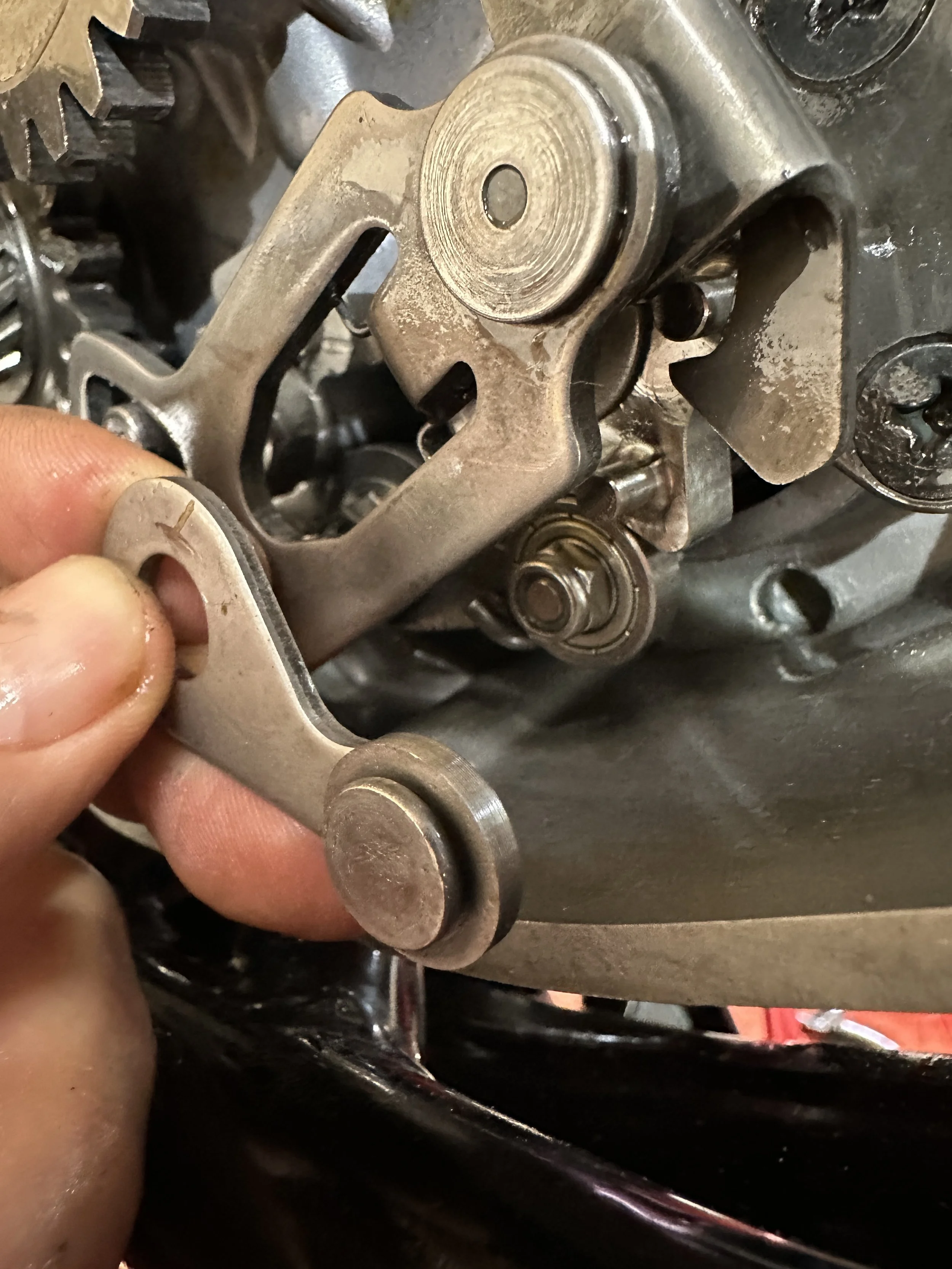

taking this guy out...

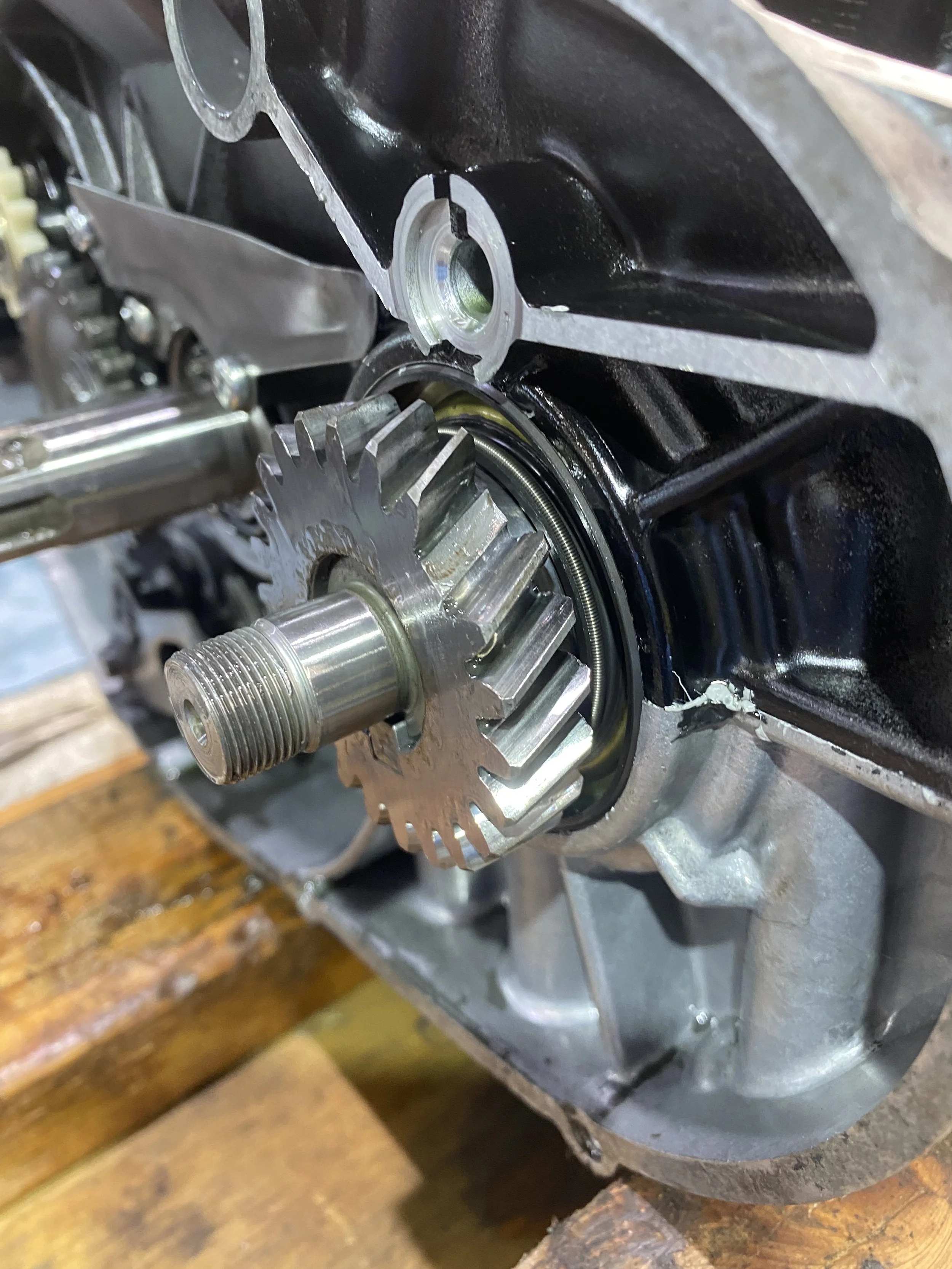

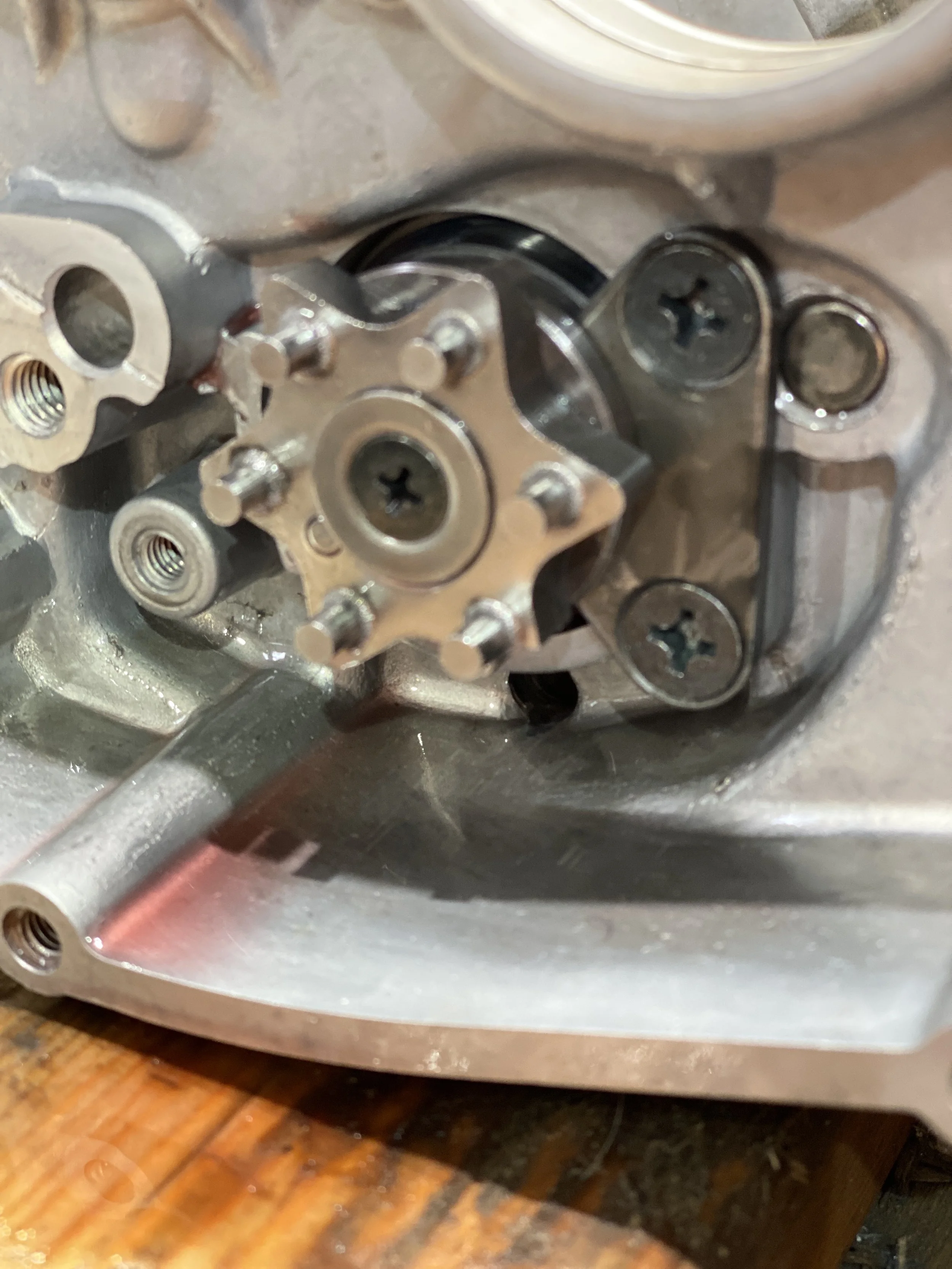

Modified star, with rounded points, installed. Easy enough to do yourself, but I never want to mess with an NLA OEM part. Maybe they are available...but still.

forgot to do a comparison shot before install...but the difference is the OEM I'm holding is simply a thin 'ring' whereas the modified arm is a wider bearing

Clutch plates also OEM but replaced with EBC which are much wider

These steels have some light corrosion. I didn't think it mattered- but got new ones just to eliminate that dynamic

UPDATE: Feb 4 2024- been running about on it long enough to declare that the elusive neutral syndrome is banished...I can slot it in neutral at any time...rolling or even stand still. Bike appears to be bedding in well and coming into it's own. I no longer think it's the lesser cousin to the Mars Bar. At this stage only a few things to sort: -front wheel feels unbalanced. I noticed there were no weights on it when I picked it up from tire fitment and thought it was just luck it didn't need any... now I'm thinking maybe not -temp gauge isn't registering. I borrowed the temp sender from the Bounty build, patched it in and put a bit of heat gun on it. The needle moved! Ordered a new sender from Norbo. -left carb is incontinent- but responds well to a hammer and socket extension. Although I def put in a new float valve and seat ordered another AND a set of floats- will see if that helps once I can face dealing with the carbs again. But in summary though: it's going well. A soon to be 100% great bike.

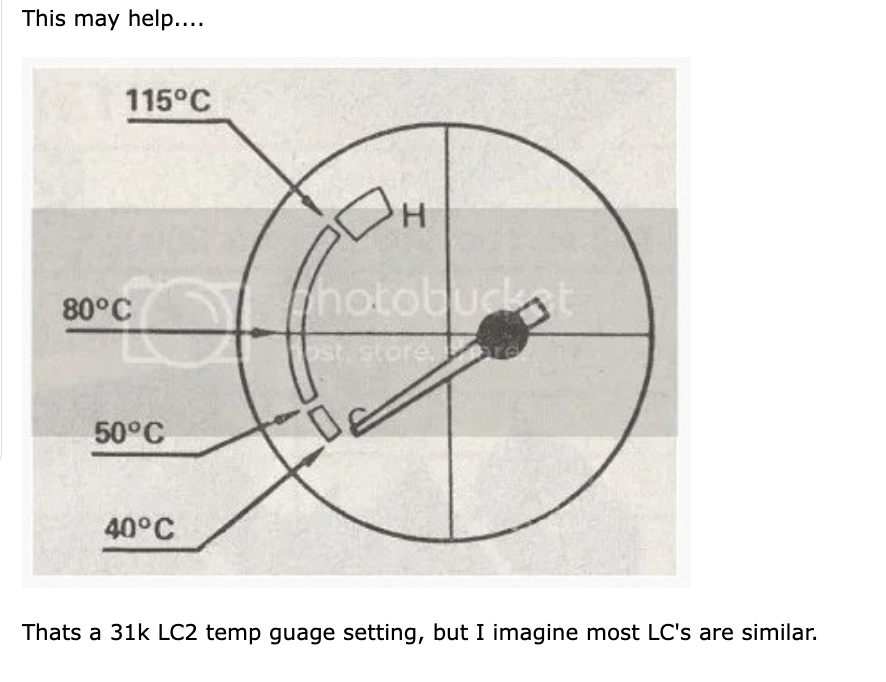

Bike is still looking fantastic. Neutral issue solved. Last thing to deal with is the indicated over-heating.

As you can see here, bumbling along the interstate keeping up with traffic and the needles very close to the red....

.....which according to this diagram, sourced from the RDLC Crazy Forum, means the bike is running well hot in the 115ºC range....

...but the bike isn't acting stressed...so I figure I need to get a second opinion in the form on an inline temp gauge from Norbo....

....I installed this morning AND replaced the original coolant with recommended-by-friends 'Engine Ice' went for a quick run and was horrified to see the needle buried in the high 170's...

...until I looked a little closer and realized the gauge was in Fahrenheit meaning the Celsius equivalent is about 82ºC which is right on the money.....so at least the problem is identified: the gauge reads wrong and needs to be recalibrated.

Gauge in it's new home...

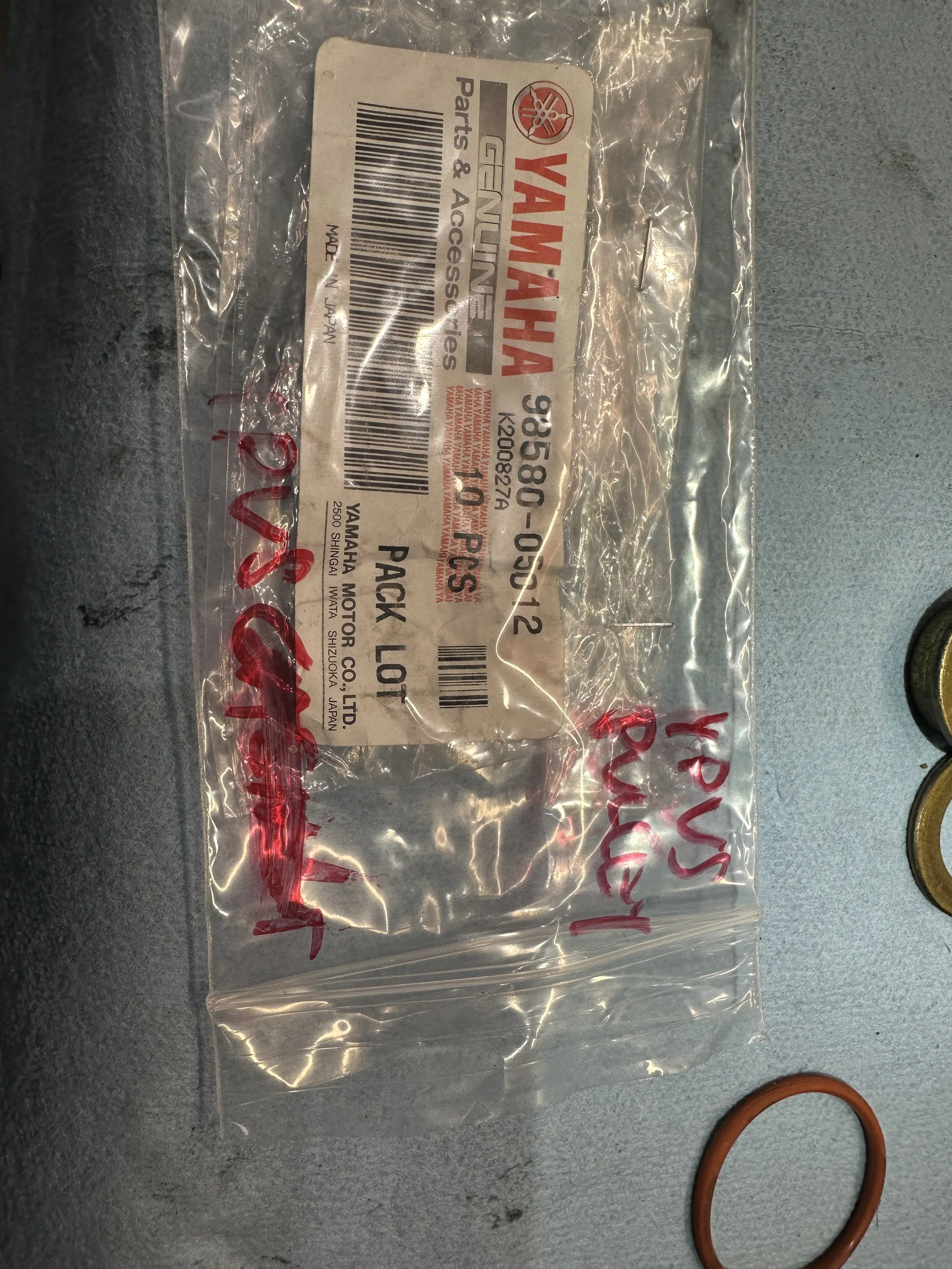

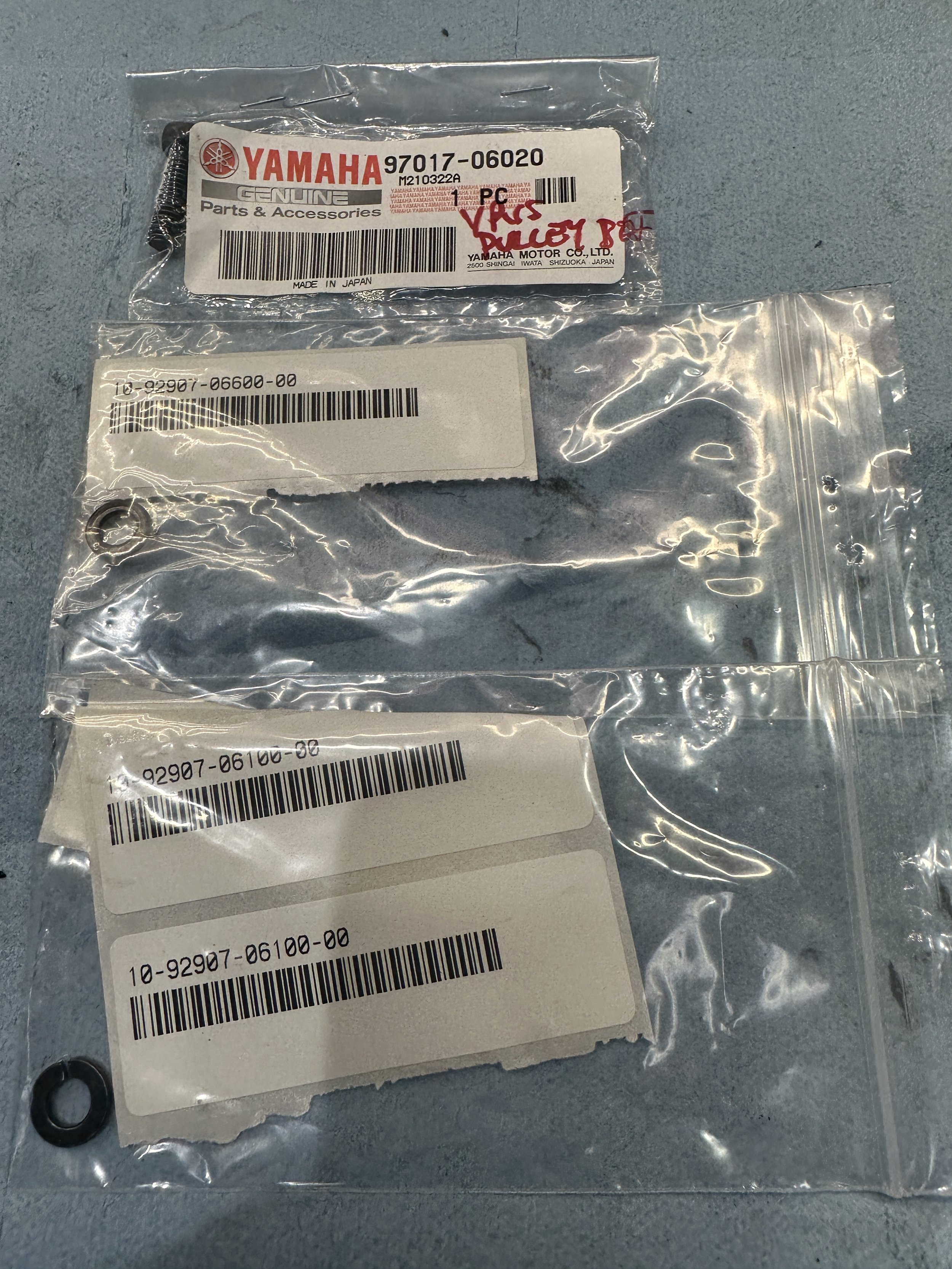

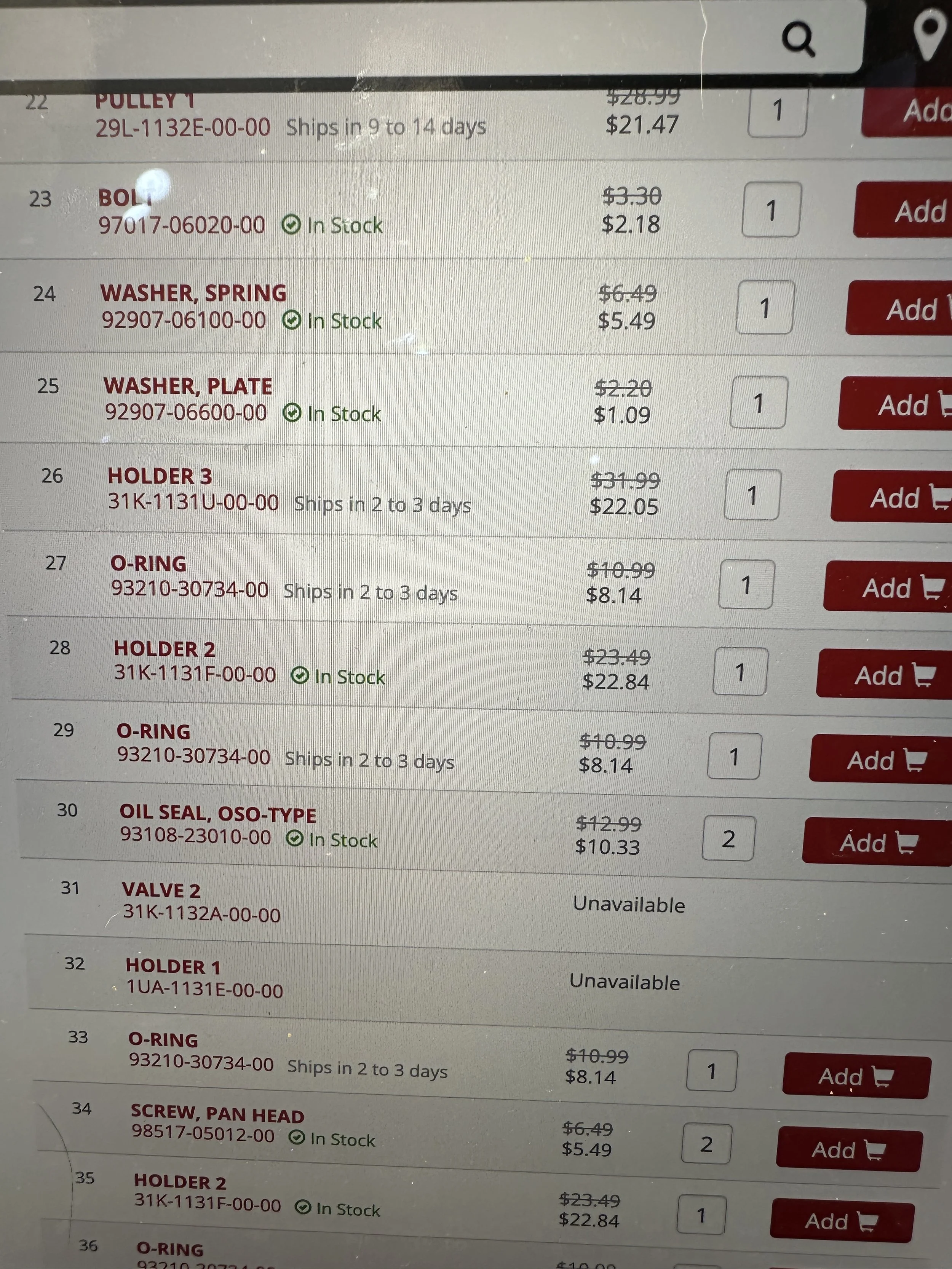

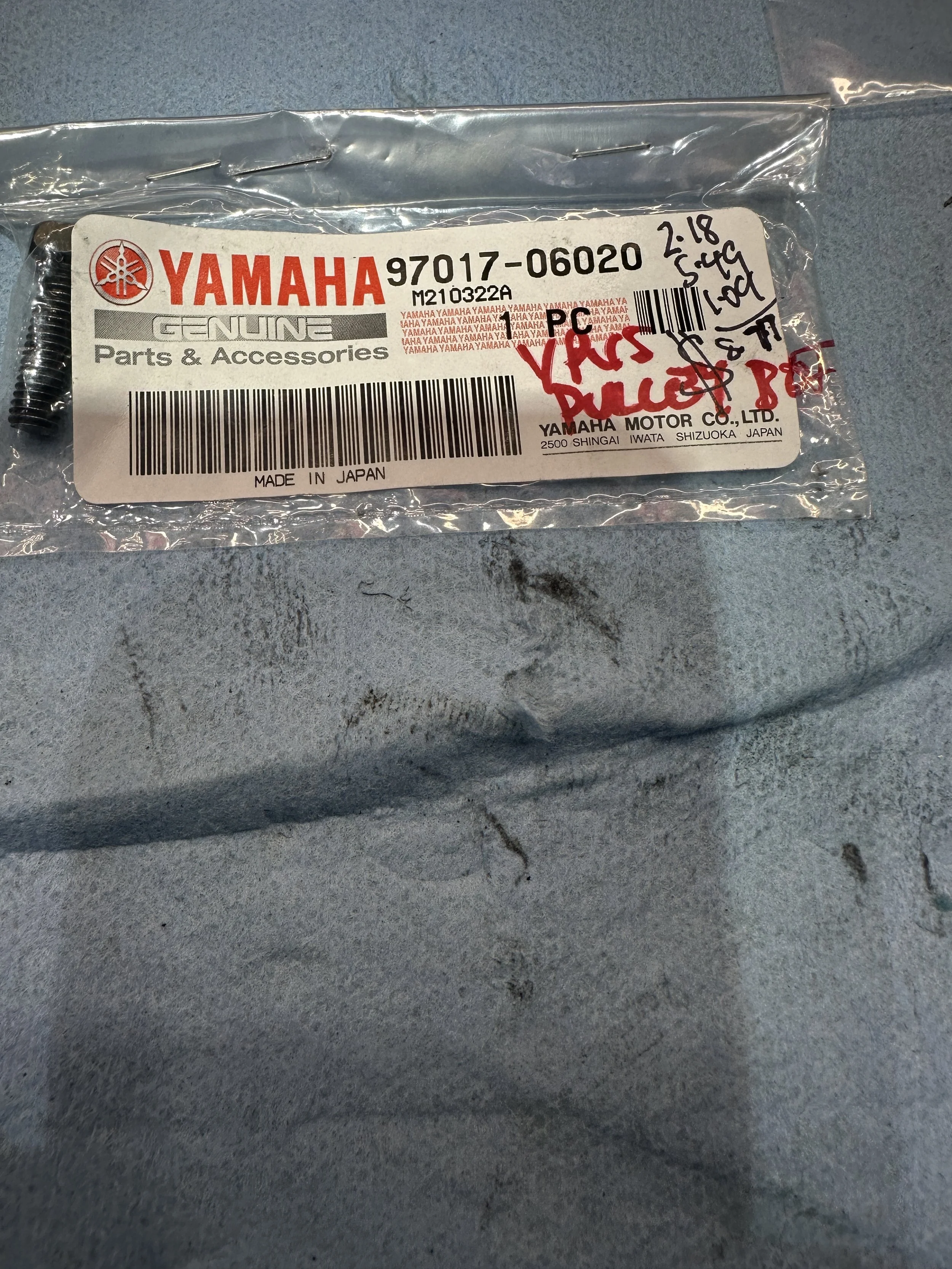

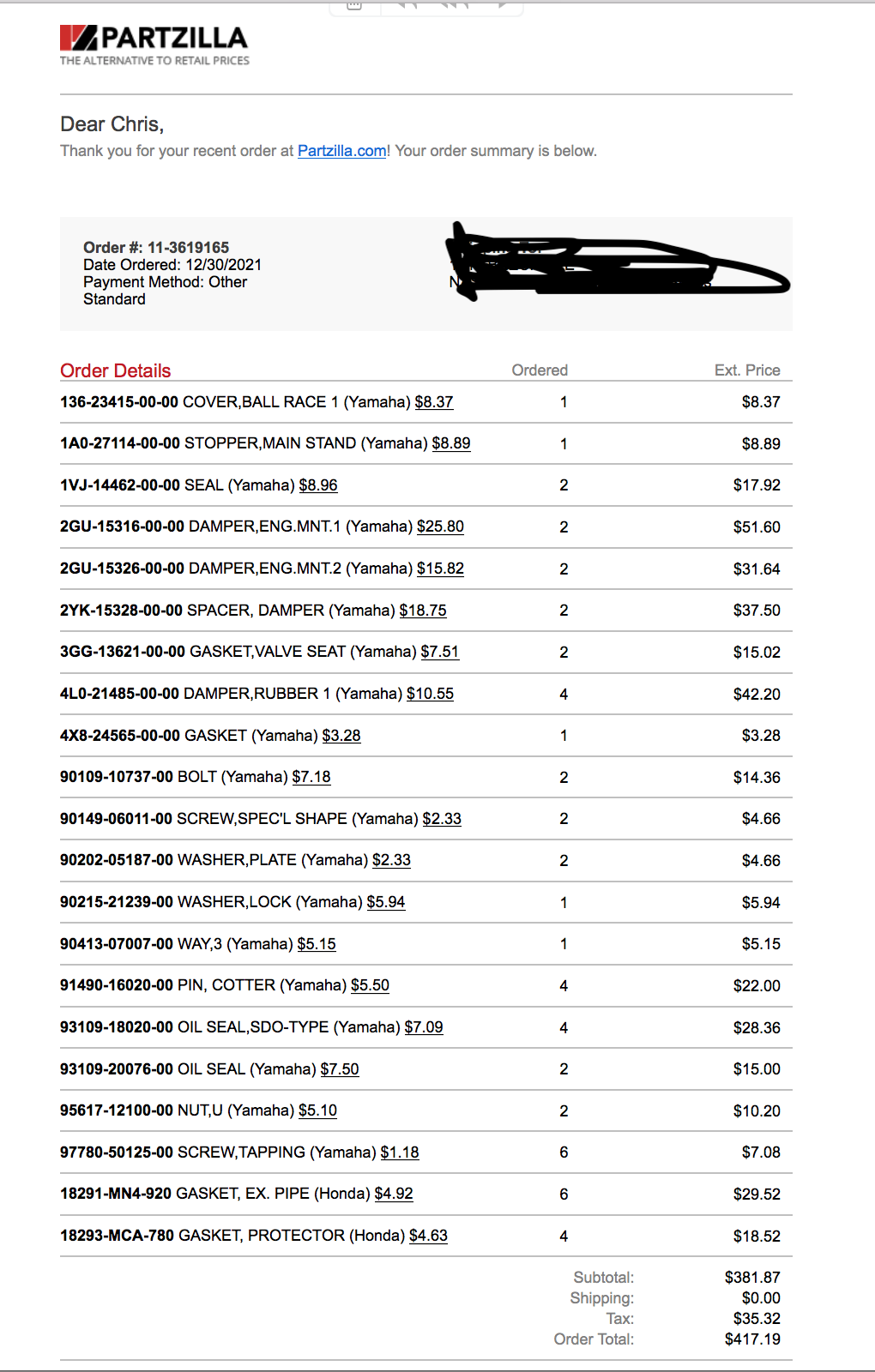

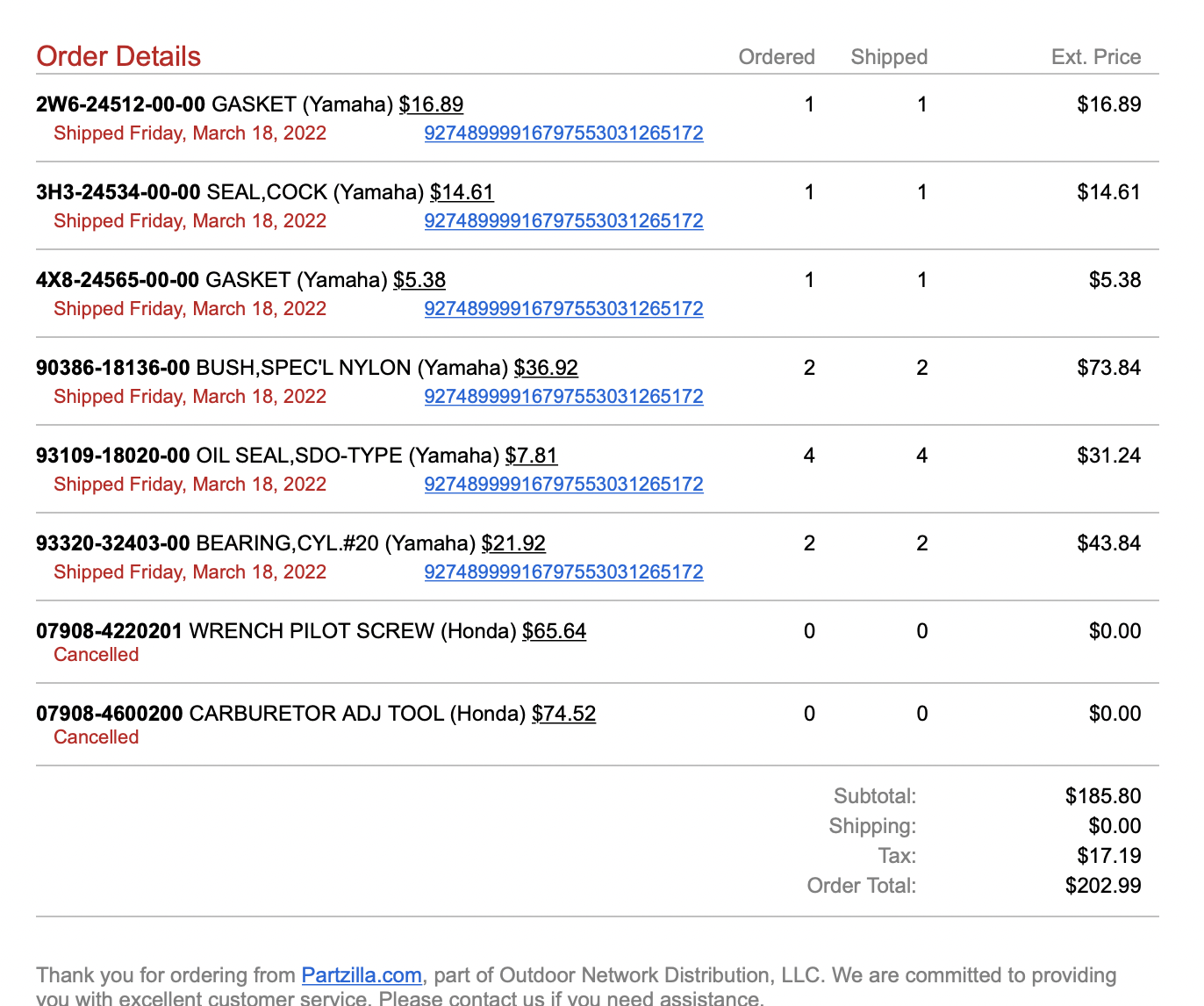

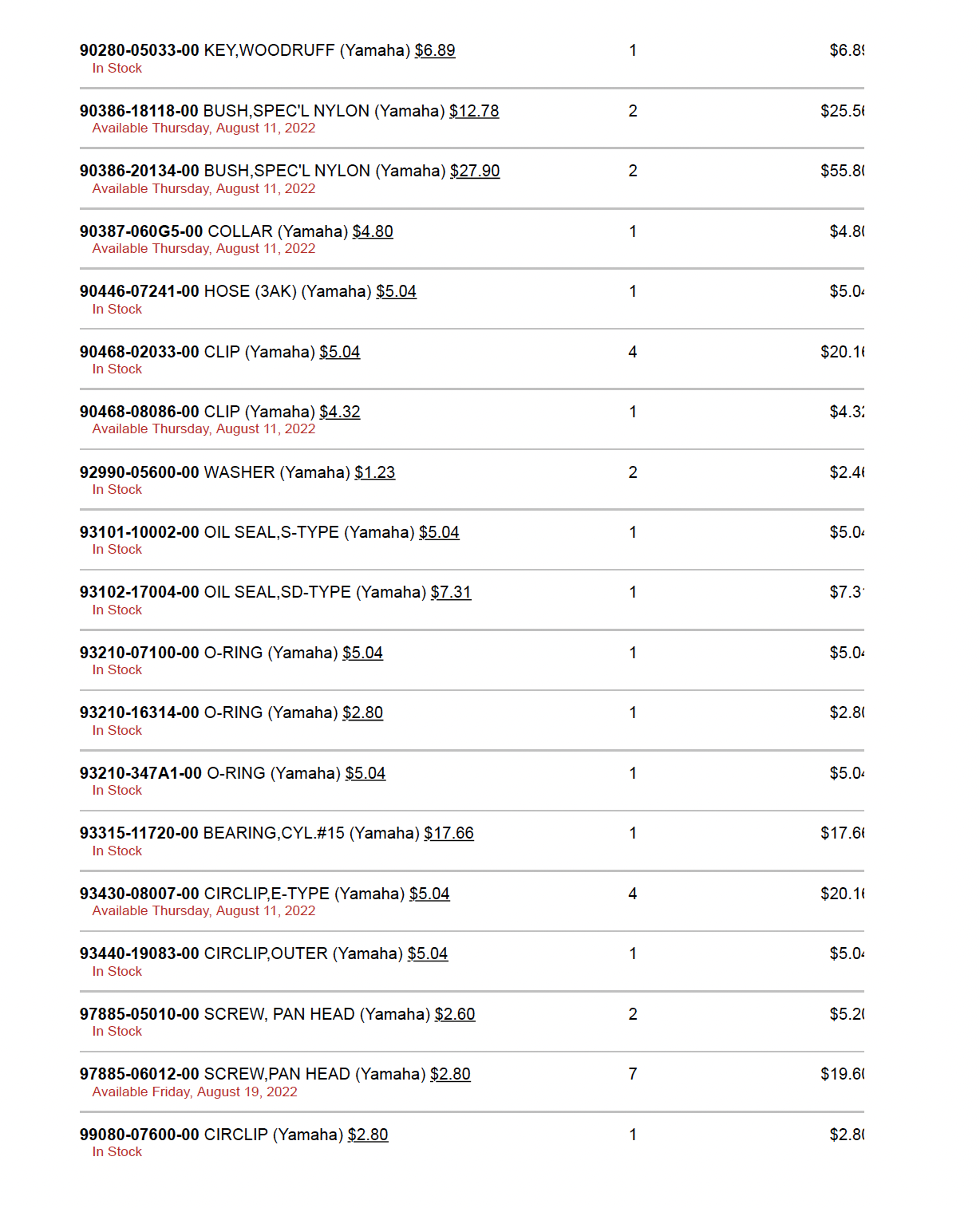

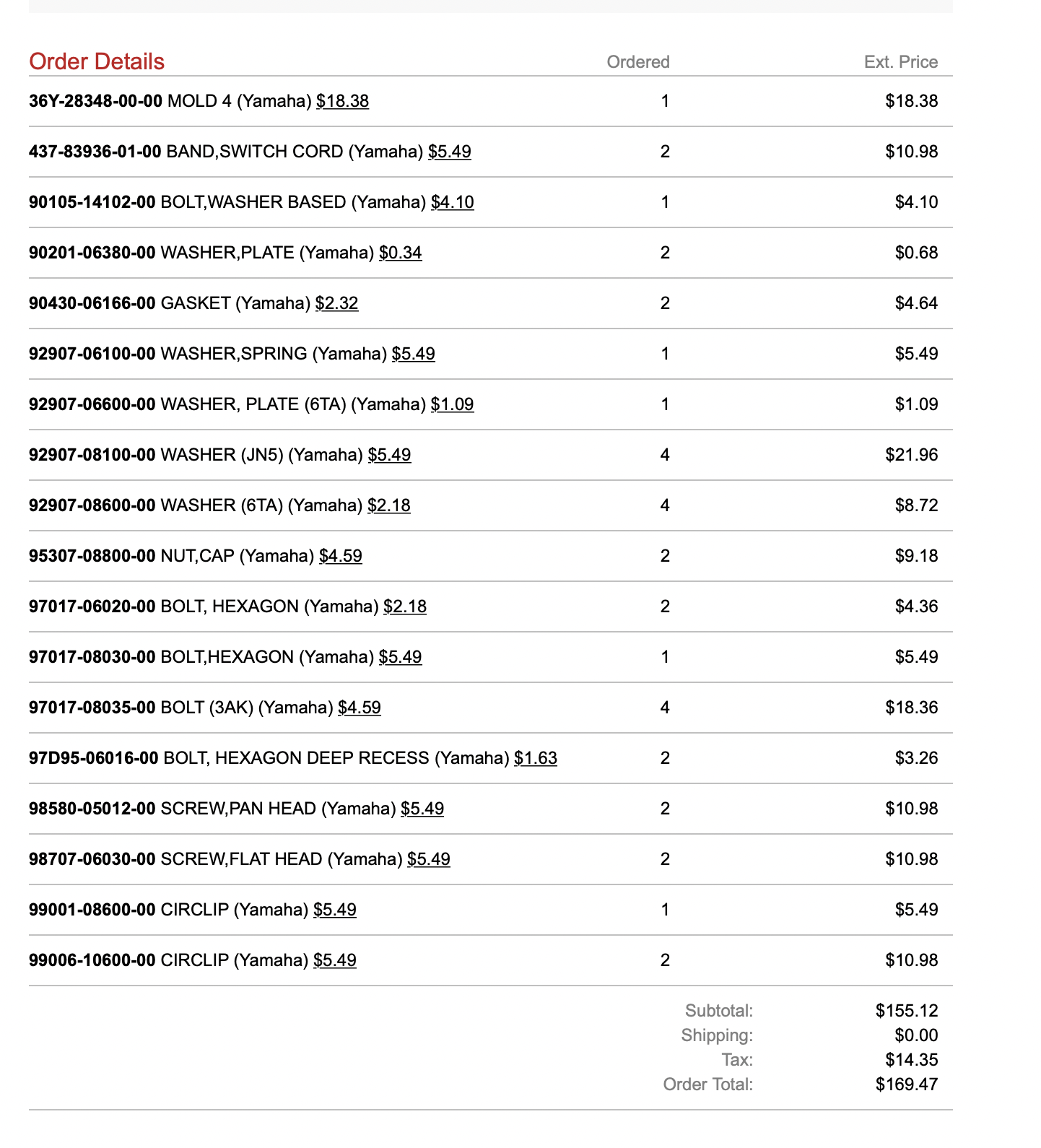

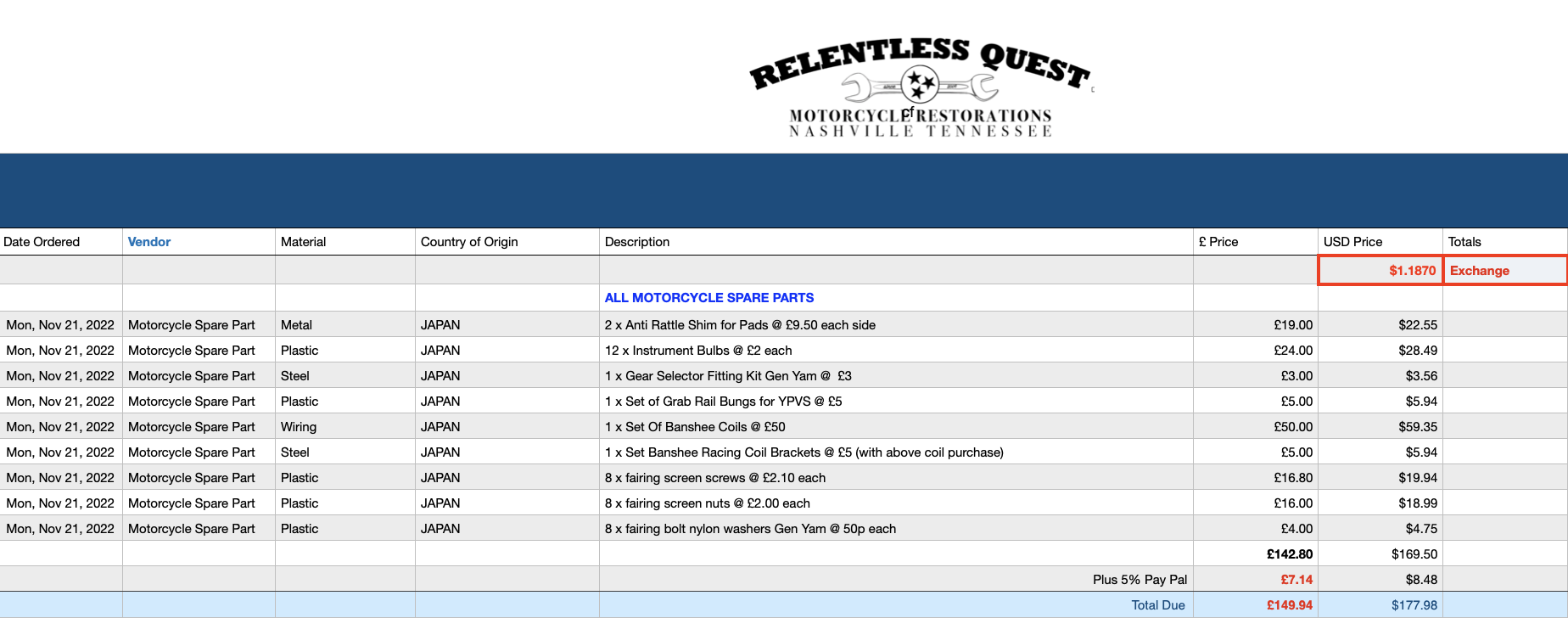

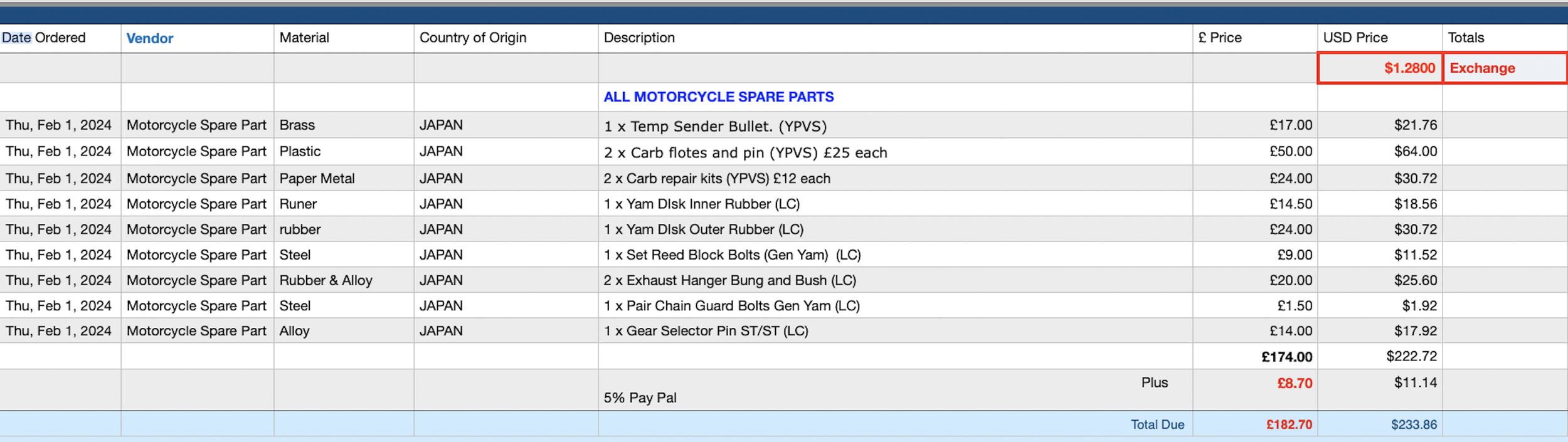

Parts Ordered Department

A lot of M10's to be used as thread protectors in the frame.....also going to be used on 6 of the H2 front brake calipers..

From Norbo...

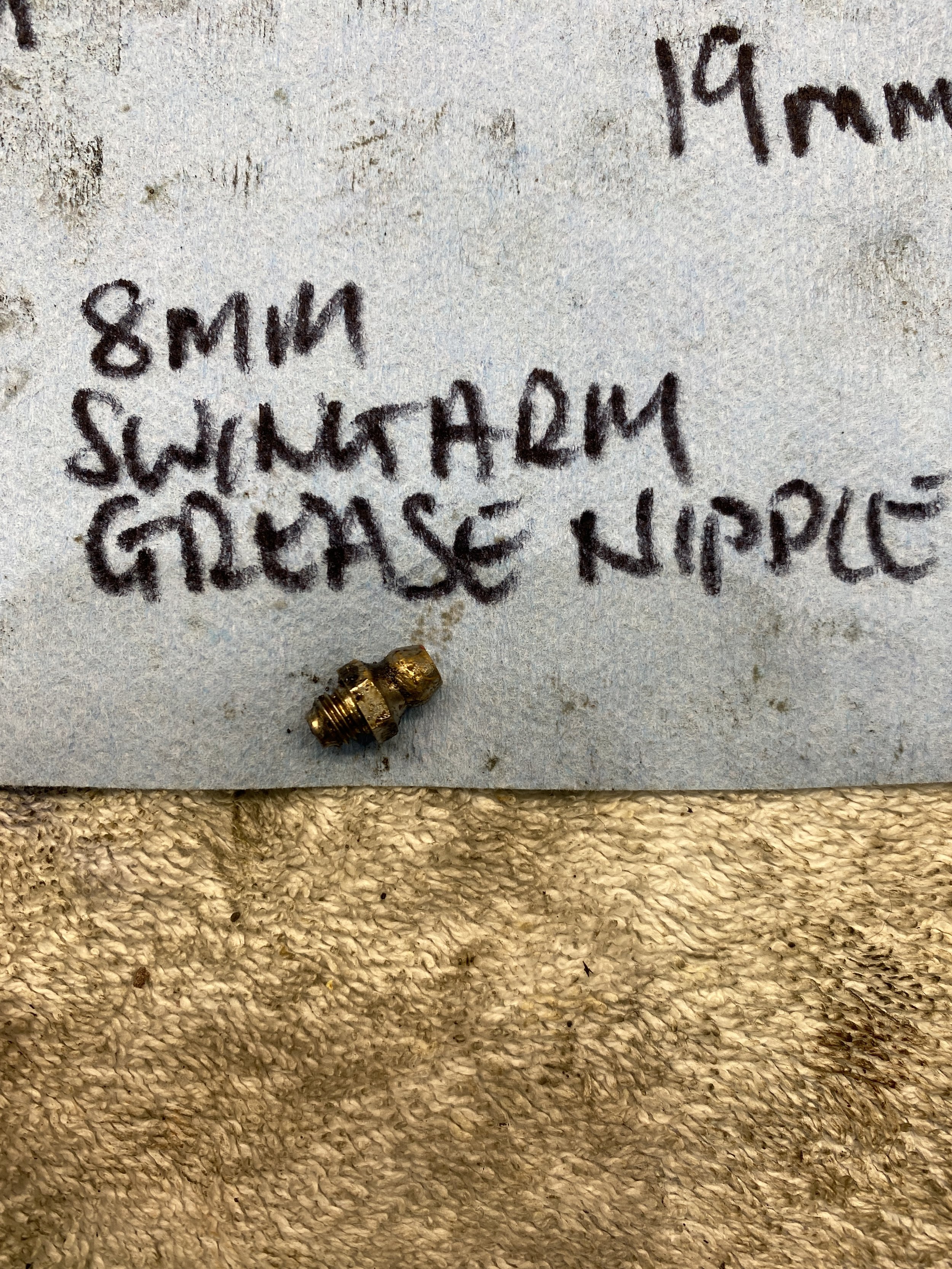

Swingarm bearings and shock bearings & seals and petcock seal.

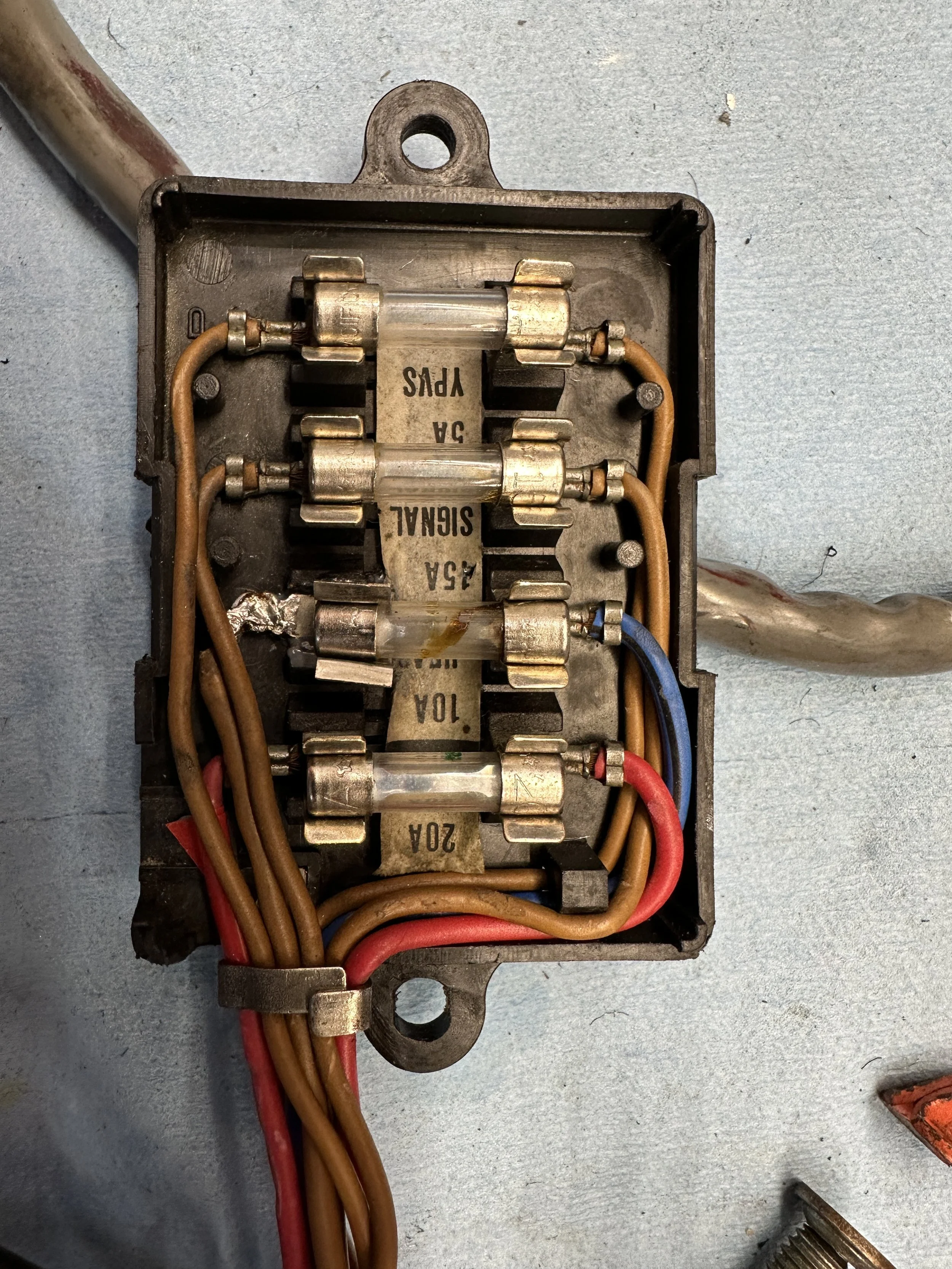

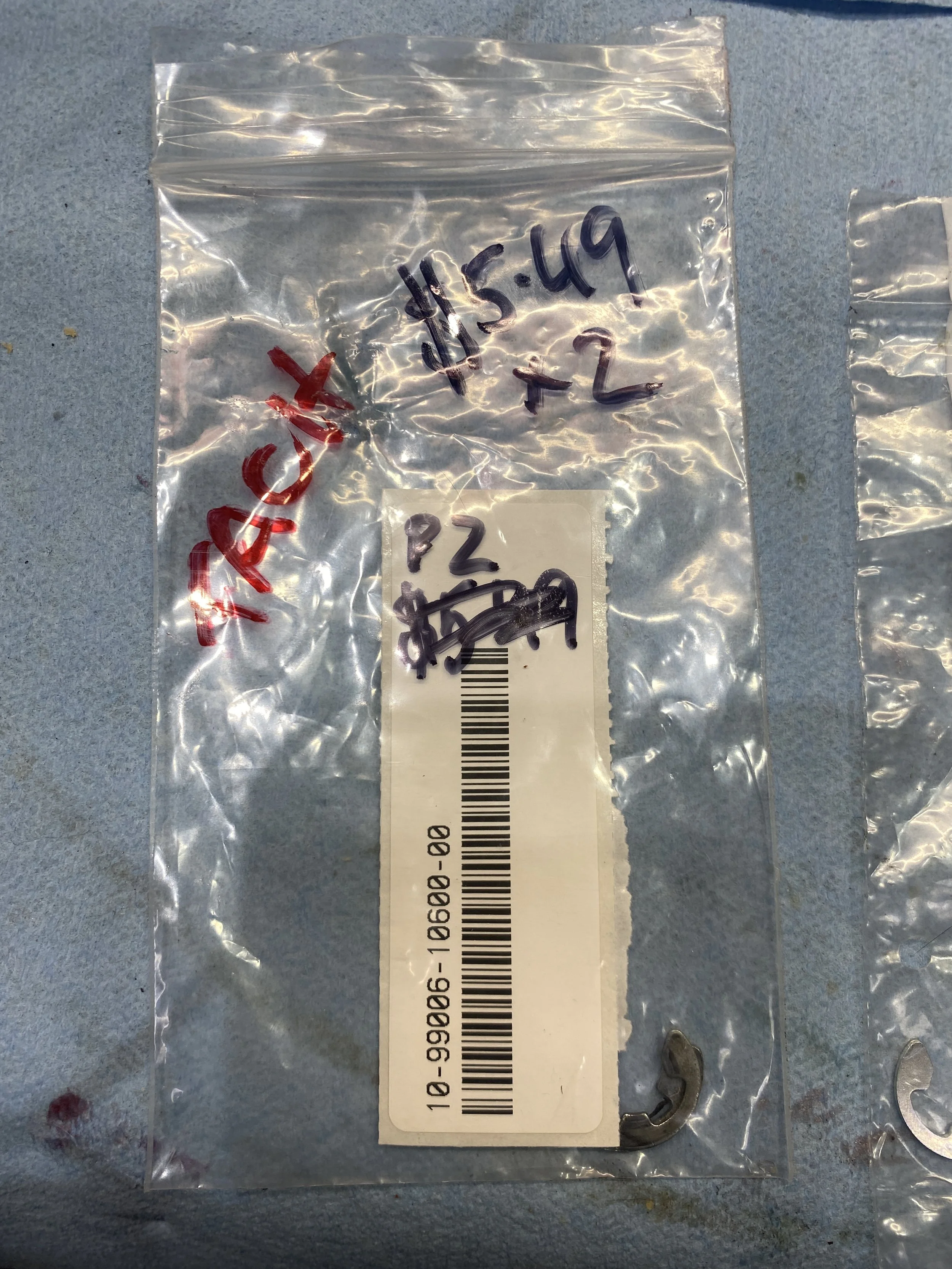

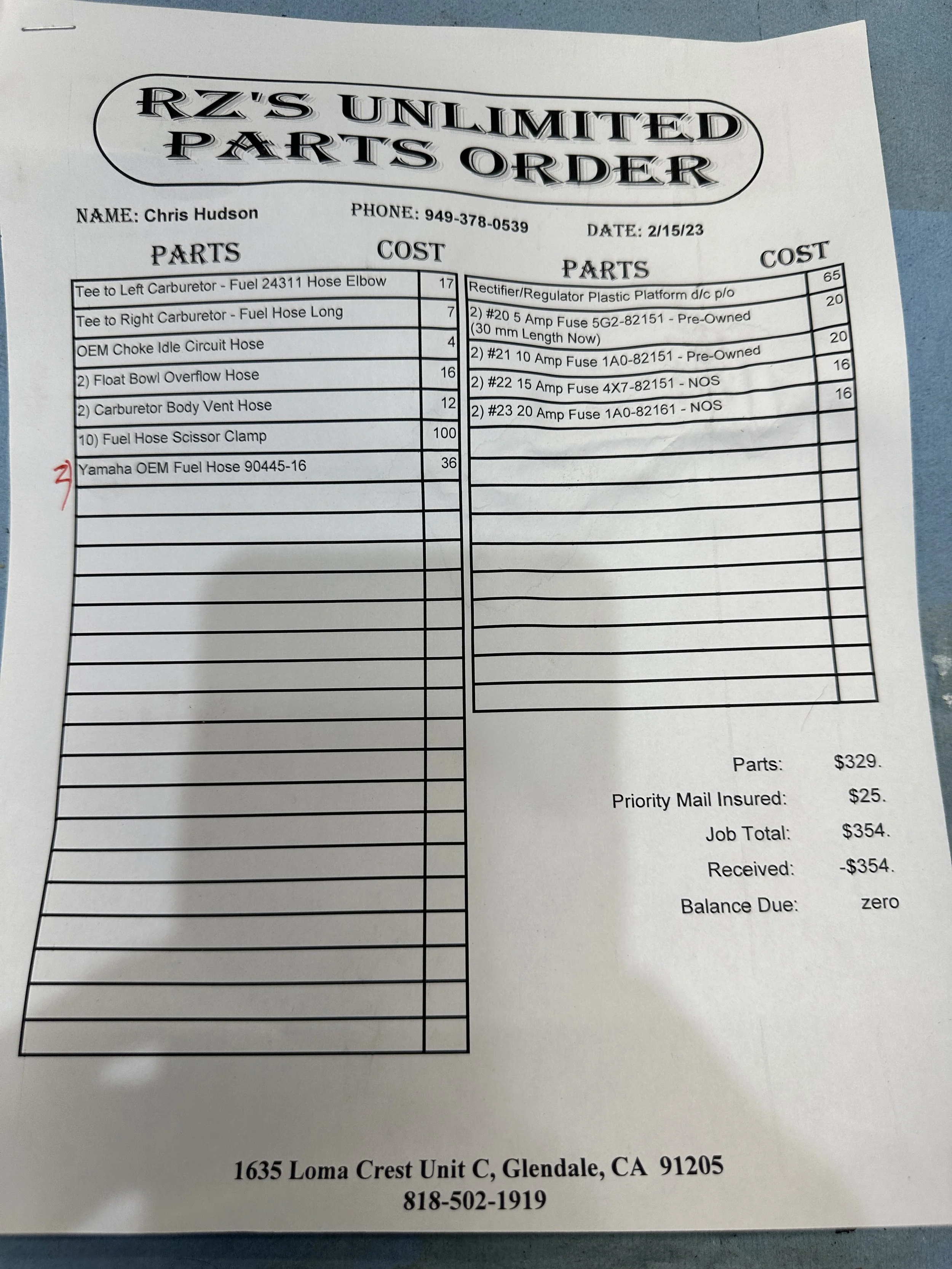

them fuses are hard to get. also pre-ordering fuel line for the next LC resto.